INSPECTION PROCEDURE

CHECK OUTPUT DTC (RELATED TO ENGINE)

READ VALUE OF INJECTOR ASSEMBLY (INJECTION VOLUME AND INJECTION FEED BACK VAL #1 TO #4)

PERFORM ENGINE RPM ACCELERATION

CHECK AIR INTAKE SYSTEM AND EXHAUST SYSTEM

CHECK EGR VALVE ASSEMBLY

CHECK TURBOCHARGING PRESSURE

PERFORM ACTIVE TEST BY FUEL PRESSURE SENSOR AND INJECTOR ASSEMBLY

CHECK CYLINDER COMPRESSION PRESSURE

CHECK WIRE HARNESS (INJECTOR - EDU)

PERFORM ACTIVE TEST BY INTELLIGENT TESTER (CONTROL THE CYLINDER FUEL CUT)

READ VALUE USING INTELLIGENT TESTER (ENGINE COOLANT TEMPERATURE)

READ VALUE OF MANIFOLD ABSOLUTE PRESSURE SENSOR

READ VALUE USING INTELLIGENT TESTER (ENGINE SPEED)

READ VALUE USING INTELLIGENT TESTER (ACCEL POSITION 1 AND 2)

READ VALUE USING INTELLIGENT TESTER (INTAKE AIR TEMPERATURE)

READ VALUE USING INTELLIGENT TESTER (FUEL PRESSURE)

INSPECT ENGINE COOLANT TEMPERATURE SENSOR

CHECK WIRE HARNESS (MANIFOLD ABSOLUTE PRESSURE SENSOR - ECM)

INSPECT CRANKSHAFT POSITION SENSOR

CHECK WIRE HARNESS (ACCELERATOR PEDAL POSITION SENSOR - ECM)

INSPECT INTAKE AIR TEMPERATURE SENSOR

INSPECT COMMON RAIL ASSEMBLY (FUEL PRESSURE SENSOR)

CHECK WIRE HARNESS (FUEL PRESSURE SENSOR - ECM)

REPLACE ECM

ECD SYSTEM - Black Smoke Emitted |

INSPECTION PROCEDURE

- ПРИМЕЧАНИЕ:

- After replacing the ECM, the new ECM needs registration (see page RAV4_ACA30 RM000000TJ400AX.html) and initialization (see page RAV4_ACA30 RM000000TIN009X.html).

- After replacing a supply pump, the ECM needs initialization (see page RAV4_ACA30 RM000000TIN009X.html).

- After replacing a injector, the ECM needs registration (see page RAV4_ACA30 RM000000TJ400AX.html).

- УКАЗАНИЕ:

- Specified values in the following troubleshooting flowchart are for reference only. Variations in the Data List values may occur depending on the measuring conditions or the vehicle's age. Do not assume the vehicle to be normal when the Data List outputs standard values. There may be concealed factors of the malfunction.

| 1.CHECK OUTPUT DTC (RELATED TO ENGINE) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

- Result:

Display (DTC Output)

| Proceed to

|

No output

| A

|

DTCs related to the engine

| B

|

| | REPAIR OR REPLACE ENGINE CONTROL SYSTEM ACCORDING TO DTC OUTPUT |

|

|

| 2.READ VALUE OF INJECTOR ASSEMBLY (INJECTION VOLUME AND INJECTION FEED BACK VAL #1 TO #4) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List.

Select the following menu items in order and read the values.

- Injection Volume

- Injection Feedback Val #1, #2, #3, and #4

- Standard value:

Item

| Engine Speed*

| Reference Value

|

Injection Volume

| Idling (No engine load)

| 4.5 to 9.0 mm3

|

Injection Feedback Val #1

| Idling (No engine load)

| -3.5 to 3.5 mm3

|

Injection Feedback Val #2

| Idling (No engine load)

| -3.5 to 3.5 mm3

|

Injection Feedback Val #3

| Idling (No engine load)

| -3.5 to 3.5 mm3

|

Injection Feedback Val #4

| Idling (No engine load)

| -3.5 to 3.5 mm3

|

- УКАЗАНИЕ:

- *: If no idling conditions are specified, the shift lever should be in the neutral position, and the A/C switch and all accessory switches should be OFF.

| 3.PERFORM ENGINE RPM ACCELERATION |

- УКАЗАНИЕ:

- If the exhaust gas contains excessive black smoke, perform the following operations:

Accelerate the engine speed to the maximum rpm with no load 20 times.

Check the volume of black smoke in the exhaust gas.

- Result:

Result

| Proceed to

|

Black smoke is not present

| OK

|

Black smoke remains in the exhaust gas

| NG

|

- УКАЗАНИЕ:

- Soot deposits in the exhaust system may cause excessive black smoke.

| 4.CHECK AIR INTAKE SYSTEM AND EXHAUST SYSTEM |

Inspect the engine condition (see page RAV4_ACA30 RM000001877005X_02_0002.html).

| | CHECK AND REPLACE LOCATIONS WHERE MALFUNCTIONS EXIST |

|

|

| 5.CHECK EGR VALVE ASSEMBLY |

Check the EGR valve assembly (see page RAV4_ACA30 RM0000015C4002X.html).

| | REPLACE ELECTRIC EGR CONTROL VALVE ASSEMBLY |

|

|

| 6.CHECK TURBOCHARGING PRESSURE |

Check the turbocharger pressure (see page RAV4_ACA30 RM0000022TO000X.html).

- Standard pressure:

- 58.5 to 78.9 kPa (0.60 to 0.80 kgf/cm2, 8.5 to 11.4 psi)

| | REPLACE TURBOCHARGER SUB-ASSEMBLY |

|

|

| 7.PERFORM ACTIVE TEST BY FUEL PRESSURE SENSOR AND INJECTOR ASSEMBLY |

Connect the intelligent tester to the DLC3.

Start the engine and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List.

Select the following menu items in order and read the values.

- Fuel Pressure

- Injection Volume

- Main Injection

- Pilot 2 Injection

- Injection Feedback Val #1, #2, #3, and #4

- Reference:

Item

| Engine Speed*

| Reference Value

|

Fuel Pressure

| Idling

| 35 to 40 MPa

|

Fuel Pressure

| 2,000 rpm (no engine load)

| 65 to 78 MPa

|

Fuel Pressure

| 3,000 rpm (no engine load)

| 78 to 88 MPa

|

Injection Volume

| Idling

| 4.5 to 9.0 mm3

|

Injection Volume

| 2,000 rpm (no engine load)

| 5.0 to 9.5 mm3

|

Injection Volume

| 3,000 rpm (no engine load)

| 6.6 to 11.1 mm3

|

Main Injection

| Idling

| 460 to 610 μs

|

Pilot 2 Injection

| Idling

| 410 to 510 μs

|

Injection Feedback Val #1

| Idling

| -3.5 to 3.5 mm3

|

Injection Feedback Val #2

| Idling

| -3.5 to 3.5 mm3

|

Injection Feedback Val #3

| Idling

| -3.5 to 3.5 mm3

|

Injection Feedback Val #4

| Idling

| -3.5 to 3.5 mm3

|

- УКАЗАНИЕ:

- If no idling conditions are specified, the shift lever should be in the neutral position, and the A/C switch and all accessory switches should be OFF.

- Result:

Result

| Proceed to

|

Within reference value

| A

|

One of Injection Feedback Val #1 to #4 is not within reference value

| B

|

Other result

| C

|

| | REPLACE INJECTOR ASSEMBLY |

|

|

| |

|

| 8.CHECK CYLINDER COMPRESSION PRESSURE |

Check the cylinder compression pressure (see page RAV4_ACA30 RM000000RPP005X_01_0008.html).

- Standard pressure:

- 2,700 kPa (27.5 kgf/cm2, 392 psi)

- Minimum pressure:

- 2,200 kPa (22.4 kgf/cm2, 319 psi)

- Difference between each cylinder:

- 500 kPa (5.1 kgf/cm2, 73 psi)

| | CHECK ENGINE TO DETERMINE CAUSE OF LOW COMPRESSION |

|

|

| 9.CHECK WIRE HARNESS (INJECTOR - EDU) |

Disconnect the B36, B37, B38, and B39 injector connectors.

Disconnect the B64 EDU connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

B36-1 - B64-4 (INJ1)

| Below 1 Ω

|

B37-1 - B64-2 (INJ2)

| Below 1 Ω

|

B38-1 - B64-1 (INJ3)

| Below 1 Ω

|

B39-1 - B64-3 (INJ4)

| Below 1 Ω

|

B36-2 - B64-5 (COM1)

| Below 1 Ω

|

B37-2 - B64-6 (COM2)

| Below 1 Ω

|

B38-2 - B64-6 (COM2)

| Below 1 Ω

|

B39-2 - B64-5 (COM1)

| Below 1 Ω

|

B36-1 or B64-4 (INJ1) - Body ground

| 10 kΩ or higher

|

B37-1 or B64-2 (INJ2) - Body ground

| 10 kΩ or higher

|

B38-1 or B64-1 (INJ3) - Body ground

| 10 kΩ or higher

|

B39-1 or B64-3 (INJ4) - Body ground

| 10 kΩ or higher

|

B36-2 or B64-5 (COM1) - Body ground

| 10 kΩ or higher

|

B37-2 or B64-6 (COM2) - Body ground

| 10 kΩ or higher

|

B38-2 or B64-6 (COM2) - Body ground

| 10 kΩ or higher

|

B39-2 or B64-5 (COM1) - Body ground

| 10 kΩ or higher

|

Reconnect the injector connectors.

Reconnect the EDU connector.

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| 10.PERFORM ACTIVE TEST BY INTELLIGENT TESTER (CONTROL THE CYLINDER FUEL CUT) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Cylinder #1, #2, #3, and #4 Fuel Cut.

Check the engine idling condition while the fuel injection of each cylinder is cut using the tester.

- Result:

Engine Idling Condition

| Proceed to

|

Becomes unstable

| A

|

Does not change

| B

|

- УКАЗАНИЕ:

- Replace the injector mounted on the cylinder that causes no significant idle speed change.

| | REPLACE INJECTOR ASSEMBLY |

|

|

| 11.READ VALUE USING INTELLIGENT TESTER (ENGINE COOLANT TEMPERATURE) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Coolant Temp.

Read the value.

- Standard value:

- Between 75 and 95°C (167 and 203°F) with warm engine.

| 12.READ VALUE OF MANIFOLD ABSOLUTE PRESSURE SENSOR |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / MAP and Atmosphere Pressure.

Read the value.

- Standard value:

Condition

| MAP Value

|

No pressure applied

| Same as atmospheric pressure

|

Vacuum applied

| Becomes vacuum

|

Pressure applied

| Becomes pressurized

|

| 13.READ VALUE USING INTELLIGENT TESTER (ENGINE SPEED) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Engine Speed.

Read the value.

- Standard value:

- Between 750 to 1,000 rpm with warm engine (A/C switch OFF).

| 14.READ VALUE USING INTELLIGENT TESTER (ACCEL POSITION 1 AND 2) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Coolant Temp.

Read the value.

- Standard voltage:

Accelerator Pedal

| Accelerator Pedal Condition

| Specified Condition

|

Accel Position 1

| Released

| 0.6 to 1.0 V

|

Accel Position 1

| Depressed

| 3.4 to 3.8 V

|

Accel Position 2

| Released

| 1.4 to 1.8 V

|

Accel Position 2

| Depressed

| 4.2 to 4.6 V

|

- УКАЗАНИЕ:

- In the chart above, "Idling" means that the engine should be idled under the following conditions:

- Idle the engine, turn the A/C switch OFF and move the shift lever to N.

- After the engine is warmed up, the engine should have no load.

| 15.READ VALUE USING INTELLIGENT TESTER (INTAKE AIR TEMPERATURE) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Inlet Air.

Read the value.

- OK:

- Same as air temperature near to intake manifold.

- УКАЗАНИЕ:

- In the chart above, "Idling" means that the engine should be idled under the following conditions:

- Idle the engine, turn the A/C switch OFF and move the shift lever to N.

- After the engine is warmed up, the engine should have no load.

| 16.READ VALUE USING INTELLIGENT TESTER (FUEL PRESSURE) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Coolant Temp.

Read the value.

- Standard value:

- 35 to 45 MPa engine idling.

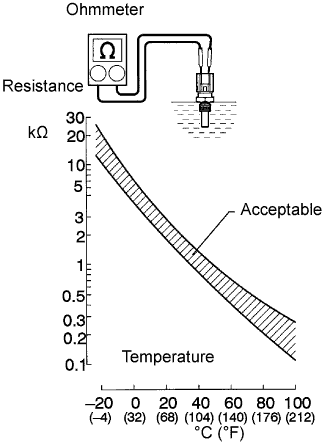

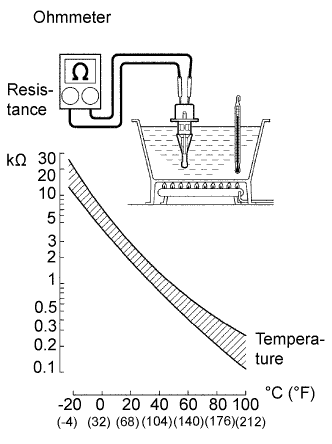

| 17.INSPECT ENGINE COOLANT TEMPERATURE SENSOR |

Disconnect the engine coolant temperature sensor.

Measure the resistance of the sensor.

- Standard resistance:

Connection

| Specified Condition

|

20°C (68°F)

| 2.32 to 2.59 kΩ

|

80°C (176°F)

| 0.310 to 0.326 kΩ

|

- ПРИМЕЧАНИЕ:

- When checking the ECT sensor in water, keep the terminals dry. After the check, wipe the sensor dry.

- УКАЗАНИЕ:

- Alternative procedure: Connect an ohmmeter to the installed ECT sensor and read the resistance. Use an infrared thermometer to measure the engine temperature in the immediate vicinity of the sensor. Compare these values against the resistance/ temperature graph. Change the engine temperature (warm up or cool down) and repeat the test.

Reconnect the engine coolant temperature sensor.

| | REPLACE ENGINE COOLANT TEMPERATURE SENSOR |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

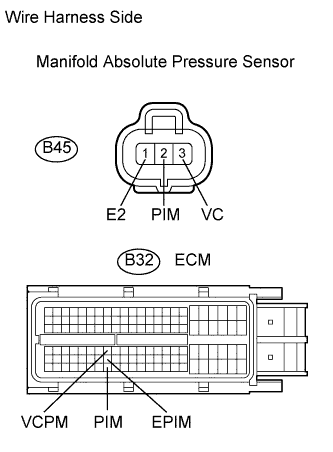

| 18.CHECK WIRE HARNESS (MANIFOLD ABSOLUTE PRESSURE SENSOR - ECM) |

Disconnect the B45 manifold absolute pressure sensor connector.

Disconnect the B32 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

B45-2 (PIM) - B32-117 (PIM)

| Below 1 Ω

|

B45-3 (VC) - B32-71 (VCPM)

| Below 1 Ω

|

B45-1 (E) - B32-94 (EPIM)

| Below 1 Ω

|

B45-2 (PIM) or B32-117 (PIM) - Body ground

| 10 kΩ or higher

|

B45-3 (VC) or B32-71 (VCPM) - Body ground

| 10 kΩ or higher

|

B45-1 (E) or B32-94 (EPIM) - Body ground

| 10 kΩ or higher

|

Reconnect the manifold absolute pressure sensor connector.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE MANIFOLD ABSOLUTE PRESSURE SENSOR |

|

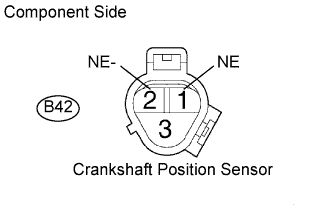

| 19.INSPECT CRANKSHAFT POSITION SENSOR |

Disconnect the B42 crankshaft position sensor connector.

Measure the resistance of the sensor.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

B42-1 (NE) - B42-2 (NE-)

| Cold

| 835 to 1,400 Ω

|

B42-1 (NE) - B42-2 (NE-)

| Hot

| 1,060 to 1,645 Ω

|

- УКАЗАНИЕ:

- In the table above, the terms "Cold" and "Hot" refer to the temperature of the coils in the sensor. "Cold" means approximately -10 to 50°C (14 to 122°F). "Hot" means approximately 50 to 100°C (122 to 212°F).

Reconnect the crankshaft position sensor connector.

| | REPLACE CRANKSHAFT POSITION SENSOR |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

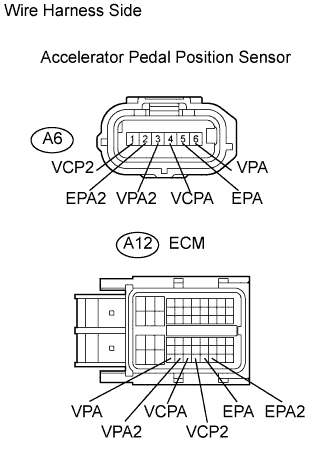

| 20.CHECK WIRE HARNESS (ACCELERATOR PEDAL POSITION SENSOR - ECM) |

Disconnect the A6 sensor connector.

Disconnect the A12 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

A6-1 (VCP2) - A12-56 (VCP2)

| Below 1 Ω

|

A6-2 (EPA2) - A12-58 (EPA2)

| Below 1 Ω

|

A6-3 (VPA2) - A12-54 (VPA2)

| Below 1 Ω

|

A6-4 (VCPA) - A12-55 (VCPA)

| Below 1 Ω

|

A6-5 (EPA) - A12-57 (EPA)

| Below 1 Ω

|

A6-6 (VPA) - A12-53 (VPA)

| Below 1 Ω

|

A6-1 (VCP2) or A12-56 (VCP2) - Body ground

| 10 kΩ or higher

|

A6-2 (EPA2) or A12-58 (EPA2) - Body ground

| 10 kΩ or higher

|

A6-3 (VPA2) or A12-54 (VPA2) - Body ground

| 10 kΩ or higher

|

A6-4 (VCPA) or A12-55 (VCPA) - Body ground

| 10 kΩ or higher

|

A6-5 (EPA) or A12-57 (EPA) - Body ground

| 10 kΩ or higher

|

A6-6 (VPA) or A12-53 (VPA) - Body ground

| 10 kΩ or higher

|

Reconnect the sensor connector.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE ACCELERATOR PEDAL ROD ASSEMBLY (ACCELERATOR PEDAL POSITION SENSOR) |

|

| 21.INSPECT INTAKE AIR TEMPERATURE SENSOR |

Remove the intake air temperature sensor.

Measure the resistance of the sensor.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - 2

| 20°C (68°F)

| 2.21 to 2.69 kΩ

|

- ПРИМЕЧАНИЕ:

- When checking the sensor in water, keep the terminals dry. After the check, wipe the sensor dry.

Reconnect the intake air temperature sensor.

| | REPLACE INTAKE AIR TEMPERATURE SENSOR |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

| 22.INSPECT COMMON RAIL ASSEMBLY (FUEL PRESSURE SENSOR) |

Disconnect the B60 fuel pressure sensor connector.

Measure the resistance of each terminal of the fuel pressure sensor.

- Standard resistance:

Tester Connection

| Specified Condition

|

B60-2 (PR) - B60-1 (E2)

| 16.4 kΩ or less

|

B60-2 (PR) - B60-3 (VC)

| 3 kΩ or less

|

Reconnect the fuel pressure sensor connector.

| | REPLACE COMMON RAIL ASSEMBLY |

|

|

| 23.CHECK WIRE HARNESS (FUEL PRESSURE SENSOR - ECM) |

Disconnect the B60 fuel pressure sensor connector.

Disconnect the B32 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

B60-2 (PR) - B32-67 (PCR1)

| Below 1 Ω

|

B60-3 (VC) - B32-69 (VCM)

| Below 1 Ω

|

B60-1 (E2) - B32-91 (E2M)

| Below 1 Ω

|

B60-2 (PR) or B32-67 (PCR1) - Body ground

| 10 kΩ or higher

|

B60-3 (VC) or B32-69 (VCM) - Body ground

| 10 kΩ or higher

|

B60-1 (E2) or B32-91 (E2M) - Body ground

| 10 kΩ or higher

|

Reconnect the fuel pressure sensor connector.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

Replace the ECM.

- ПРИМЕЧАНИЕ:

- After replacing the ECM, the new ECM needs registration (see page RAV4_ACA30 RM000000TJ400AX.html) and initialization (see page RAV4_ACA30 RM000000TIN009X.html).

Check the volume of black smoke in the exhaust gas.

- OK:

- Black smoke is not present.

| | REPLACE SUPPLY PUMP ASSEMBLY |

|

|