Двигатель -- Проверка Без Снятия С Автомобиля |

| 1. INSPECT ENGINE COOLANT |

Remove the radiator cap sub-assembly.

- ПРЕДОСТЕРЕЖЕНИЕ:

- To avoid the danger of being burned, do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot.

- Thermal expansion will cause hot engine coolant and steam to blow out from the radiator assembly.

Check for excessive deposits of rust or scale around the radiator cap sub-assembly and radiator filler hole. The engine coolant should be free of oil.

If excessively dirty, replace the engine coolant.

Reinstall the radiator cap sub-assembly.

| 2. INSPECT ENGINE OIL |

Check the oil for deterioration, entry of water, discoloring or thinning.

If the quality is visibly poor, replace the oil.

| 3. INSPECT BATTERY |

- ПРИМЕЧАНИЕ:

- If the battery is weak or if the engine is difficult to start, perform the following procedure.

Check the battery for damage and deformation. If severe damage, deformation or leakage is found, replace the battery.

Check the electrolyte quantity of each cell.

For maintenance-free batteries:

- If the electrolyte quantity is below the lower line, replace the battery.

- If the electrolyte quantity is above the lower line, check the battery voltage when cranking the engine. If the voltage is less than 9.6 V, recharge or replace the battery.

- УКАЗАНИЕ:

- Before checking the battery voltage, turn off all the electrical systems (headlights, blower motor, rear defogger, etc.).

- If the electrolyte quantity is below the lower line, replace the battery.

For non-maintenance-free batteries:

- If the electrolyte quantity is below the lower line, add distilled water to each cell. Then, recharge the battery and check the electrolyte's specific gravity.

- Standard specific gravity:

- 1.25 to 1.29 at 20°C (68°F)

- If the electrolyte quantity is above the lower line, check the battery voltage when cranking the engine. If the voltage is less than 9.6 V, recharge or replace the battery.

- УКАЗАНИЕ:

- Before checking the battery voltage, turn off all the electrical systems (headlights, blower motor, rear defogger, etc.).

- If the electrolyte quantity is below the lower line, add distilled water to each cell. Then, recharge the battery and check the electrolyte's specific gravity.

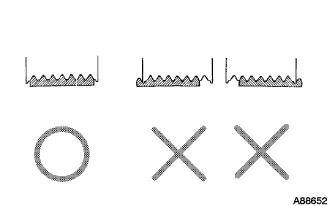

| 4. INSPECT AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

Remove the air cleaner cap.

Remove the air filter element.

Visually check that the air filter is not excessively damaged or oily. If necessary, replace the air filter.

| 5. INSPECT SPARK PLUG |

- ПРИМЕЧАНИЕ:

- Do not use a wire brush for cleaning.

- Do not attempt to adjust the electrode gap of a used spark plug.

Check the electrode.

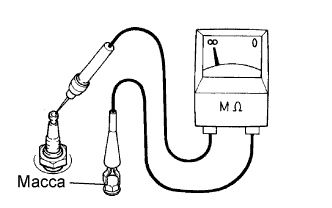

Using a megohmmeter, measure the insulation resistance.

- Standard resistance:

- 10 MΩ or more

- УКАЗАНИЕ:

- If the result is not as specified, clean the spark plug with a spark plug cleaner and measure the resistance again.

- If a megohmmeter is not available, perform the following simple inspection instead.

|

Alternative inspection method:

Quickly accelerate the engine to 4000 rpm 5 times.

Remove the spark plug.

Visually check the spark plug.

If the electrode is dry, the spark plug is functioning properly. If the electrode is damp, proceed to the next step.

Check the spark plug for any damage to its thread and insulator.

If there is any damage, replace the spark plug.- Recommended spark plug:

Manufacturer Product DENSO SC20HR11

Reference:

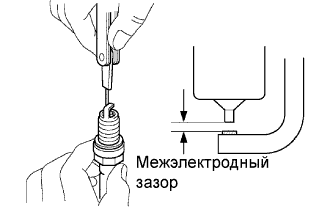

Check the spark plug electrode gap.

- Maximum electrode gap for used spark plug:

- 1.3 mm (0.051 in.)

- Electrode gap for new spark plug:

- 1.0 to 1.1 mm (0.039 to 0.043 in.)

Clean the spark plug.

If the electrode has traces of wet carbon, clean the electrode with a spark plug cleaner and then dry it.- Air pressure:

- 588 kPa (6 kgf/cm2, 85 psi)

- Duration:

- 20 seconds or less

- УКАЗАНИЕ:

- Only use the spark plug cleaner when the electrode is free of oil. If the electrode has traces of oil, use gasoline to clean off the oil before using the spark plug cleaner.

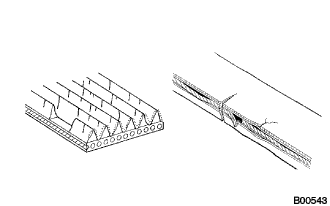

| 6. INSPECT V-RIBBED BELT |

Visually check the belt for excessive wear, frayed cords etc. If any defects are found, replace the belt.

- УКАЗАНИЕ:

- If any defects are found, replace the belt.

- Cracks on the rib side of a belt are considered acceptable. If the belt has pieces missing from the ribs, it should be replaced.

|

After installing the drive belt, check that it fits properly in the ribbed grooves. Check with your hand to confirm that the belt has not slipped out of the grooves on the bottom of the crank pulley.

- УКАЗАНИЕ:

- A "new belt" is a belt which has been used for less than 5 minutes on a running engine.

- A "used belt" is a belt which has been used on a running engine for 5 minutes or more.

- After installing a new belt, run the engine for approximately 5 minutes and then recheck the tension.

|

Check the V belt deflection and tension.

- Deflection:

Item Specified Condition New belt 7.5 to 8.6 mm (0.30 to 0.34 in.) Used belt 8.0 to 10.0 mm (0.32 to 0.39 in.)

- Tension:

Item Specified Condition New belt

(w/ A/C)688 to 940 N (70 to 96 kg, 155 to 211 lb) New belt

(w/o A/C)688 to 884 N (70 to 90 kg, 155 to 199 lb) Used belt 402 to 598 N (41 to 61 kg, 90 to 134 lb)

- УКАЗАНИЕ:

- Check the V belt deflection at the specified point.

- Check the drive belt deflection at the specified point.

- When installing a new belt, adjust its tension to the specified value.

- When inspecting a belt which has been used for over 5 minutes, apply the used belt specifications.

- When reinstalling a belt which has been used for over 5 minutes, adjust its deflection and tension to the intermediate values of each used belt specification.

- V-ribbed belt tension and deflection should be checked after 2 revolutions of engine cranking.

- When using a belt tension gauge, confirm its accuracy by using a master gauge first.

|

| 7. INSPECT VALVE AND ADJUSTER NOISE |

Rev up the engine several times. Check that the engine does not emit unusual noises. If unusual noises occur, warm up the engine and idle it for over 30 minutes. Then perform the inspection above again. If any defects or problems are found during the inspection above, perform a lash adjuster inspection.

| 8. INSPECT IGNITION TIMING |

When using an intelligent tester:

Warm up and stop the engine.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG).

Select the following menu items:

Powertrain / Engine and ECT / Active Test / TC (TE1) / ON.- УКАЗАНИЕ:

- Refer to the intelligent tester operator's manual for further details.

Inspect the ignition timing during idling.

- Ignition timing:

- 8 to 12 degrees BTDC

- ПРИМЕЧАНИЕ:

- Turn all the electrical systems and the A/C off.

- Inspect the ignition timing with the cooling fan off.

- When checking the ignition timing, shift the transmission to the neutral position.

Select the following menu items: TC (TE1) / OFF.

Turn the ignition switch off.

Disconnect the intelligent tester from the DLC3.

When not using an intelligent tester:

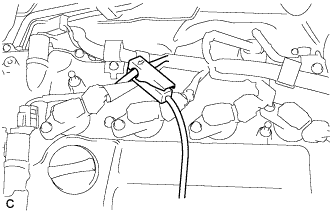

Remove the No. 2 cylinder head cover (See page Нажмите здесь).

Pull out the wire harness (brown) shown in the illustration.

- ПРИМЕЧАНИЕ:

- After checking, wrap the wire harness with tape.

Warm up and stop the engine.

Connect the clip of the timing light to the wire harness.

- ПРИМЕЧАНИЕ:

- Use a timing light that detects the first signal.

Turn the ignition switch on (IG).

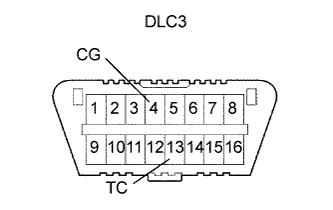

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

- ПРИМЕЧАНИЕ:

- Examine the terminal numbers before connecting them. Connecting the wrong terminals can damage the engine.

Inspect the ignition timing during idling.

- Ignition timing:

- 8 to 12 degrees BTDC

- ПРИМЕЧАНИЕ:

- Turn all the electrical systems and the A/C off.

- Inspect the ignition timing with the cooling fan off.

- When checking the ignition timing, shift the transmission to the neutral position.

Disconnect terminals 13 (TC) and 4 (CG) of the DLC3.

Turn the ignition switch off.

Remove the timing light.

Install the No. 2 cylinder head cover (See page Нажмите здесь).

| 9. INSPECT ENGINE IDLE SPEED |

Warm up and stop the engine.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG).

Select the following menu items: Powertrain / Engine and ECT / Data List / Engine Speed.

- УКАЗАНИЕ:

- Refer to the intelligent tester operator's manual for further details.

Inspect the engine idling speed.

- Idling speed:

- 600 to 700 rpm

- ПРИМЕЧАНИЕ:

- Turn all the electrical systems and the A/C off.

- Inspect the idling speed with the cooling fan off.

- When checking the idling speed, shift the transmission to either the neutral position or the parking position.

Turn the ignition switch off.

Disconnect the intelligent tester from the DLC3.

| 10. INSPECT COMPRESSION |

Warm up and stop the engine.

Remove the No. 2 cylinder head cover (See page Нажмите здесь).

Remove the 4 ignition coils.

Remove the 4 spark plugs (See page Нажмите здесь).

Disconnect the 4 fuel injector connectors.

Inspect the cylinder compression pressure.

Insert a compression gauge into the spark plug hole.

Fully open the throttle.

While cranking the engine, measure the compression pressure.

- Compression:

- 1373 kPa (14.0 kgf/cm2, 199 psi)

- Minimum pressure:

- 1079 kPa (11.0 kgf/cm2, 157 psi)

- Difference between each cylinder:

- 98 kPa (1.0 kgf/cm2, 14 psi) or less

- ПРИМЕЧАНИЕ:

- Use a fully-charged battery so the engine speed can be increased to 250 rpm or more.

- Inspect the other cylinders in the same way.

- Measure the compression in as short a time as possible.

If the cylinder compression is low, pour a small amount of engine oil into the cylinder through the spark plug hole, then inspect it again.

- УКАЗАНИЕ:

- If adding oil increases the compression, the piston rings and/or cylinder bore may be worn or damaged.

- If the pressure stays low, the valve may be stuck or seated improperly, or there may be leakage from the gasket.

|

Connect the 4 fuel injector connectors.

Install the 4 spark plugs (See page Нажмите здесь).

Install the 4 ignition coils.

- Момент затяжки:

- 10 Н*м{102 кгс*см, 7 фунт-сила-футов}

Install the No. 2 cylinder head cover (See page Нажмите здесь).

| 11. INSPECT CO/HC |

Start the engine.

Run the engine at 2500 rpm for approximately 180 seconds.

Insert the CO/HC meter testing probe at least 40 cm (1.3 ft.) into the tailpipe while idling.

Check the CO/HC concentration during idling and when the engine is running at 2500 rpm.

- УКАЗАНИЕ:

- When doing the 2 mode (with the engine idling/ running at 2500 rpm) test, the measuring procedures are determined by applicable local regulations.

- If the CO/HC concentration does not comply with the regulations, troubleshoot in the order given below.

Check the heated oxygen sensor operation (See page Нажмите здесь).

See the table below for possible causes, then inspect the applicable parts and repair them if necessary.

CO HC Problems Possible Causes Normal High Rough idling - Faulty ignition:

- Incorrect timing

- Fouled, shorted or improperly gapped plugs

- Incorrect valve clearance

- Leakage from intake and exhaust valves

- Leakage from cylinders

Low High Rough idling (Fluctuating HC reading) - Vacuum leaks:

- PCV hoses

- Intake manifold

- Throttle body

- Brake booster line

- Lean mixture causing misfire

High High Rough idling (Black smoke from exhaust) - Restricted air cleaner filter element

- Plugged PCV valve

- Faulty EFI systems:

- Faulty pressure regulator

- Faulty engine coolant temperature sensor

- Faulty mass air flow meter

- Faulty ECM

- Faulty injectors

- Throttle body

- Faulty ignition: