Блок Двигателя -- Проверка |

| 1. INSPECT CHAIN SUB-ASSEMBLY |

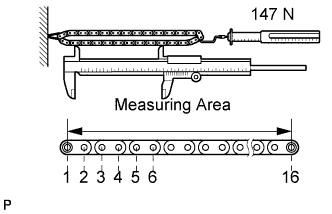

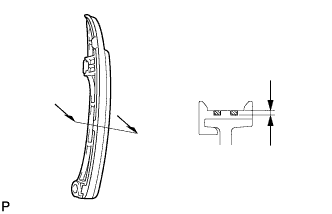

Using a spring scale, pull the chain with a force of 147 N (15 kgf, 33 lbf) as shown in the illustration.

|

Using vernier calipers, measure the length of 16 pins.

- Maximum chain elongation:

- 144.3 mm (5.681 in.)

- ПРИМЕЧАНИЕ:

- Perform the measurement at 3 random places.

| 2. INSPECT NO. 1 CHAIN TENSIONER ASSEMBLY |

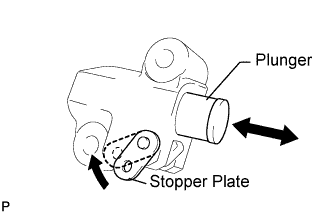

Move the stopper plate upward to release the lock. Push the plunger and check that it moves smoothly.

|

| 3. INSPECT CAMSHAFT TIMING SPROCKET |

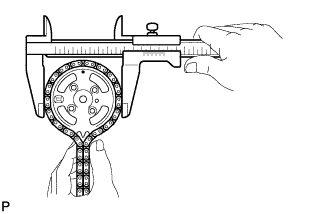

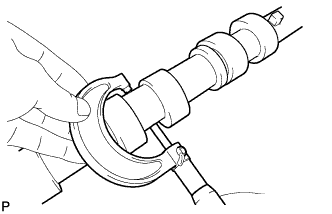

Place the chain around the sprocket.

|

Using vernier calipers, measure the sprocket diameter with the chain.

- Minimum sprocket diameter with chain:

- 132.6 mm (5.220 in.)

- УКАЗАНИЕ:

- The vernier calipers must contact the chain rollers for the measurement.

- If the diameter is less than the minimum, replace the chain and sprocket.

| 4. INSPECT CRANKSHAFT TIMING SPROCKET |

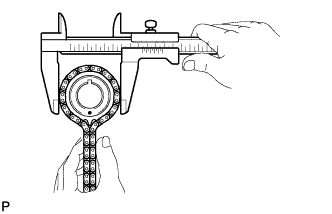

Place the chain around the sprocket.

|

Using vernier calipers, measure the sprocket diameter with the chain.

- Minimum sprocket diameter with chain:

- 69.1 mm (2.720 in.)

- УКАЗАНИЕ:

- The vernier calipers must contact the chain rollers for the measurement.

| 5. INSPECT CHAIN TENSIONER SLIPPER |

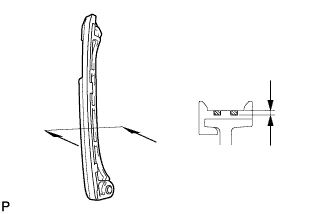

Using vernier calipers, measure the tensioner slipper wear.

- Maximum wear:

- 1.0 mm (0.039 in.)

|

| 6. INSPECT NO. 1 CHAIN VIBRATION DAMPER |

Using vernier calipers, measure the vibration damper wear.

- Maximum wear:

- 1.0 mm (0.039 in.)

|

| 7. INSPECT VALVE LASH ADJUSTER ASSEMBLY |

- ПРИМЕЧАНИЕ:

- Keep the lash adjuster free from dirt and foreign objects.

- Use only clean engine oil.

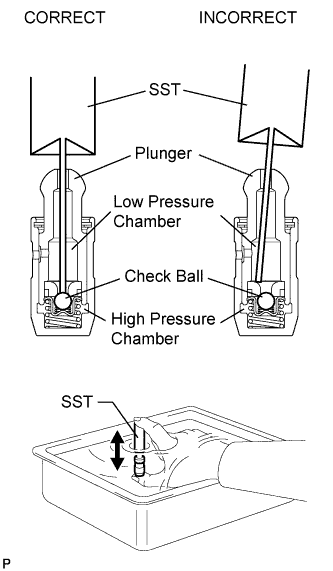

Place the lash adjuster into a container full of new engine oil.

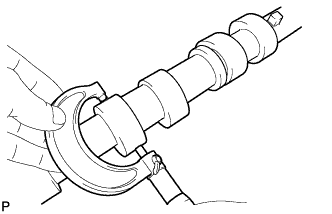

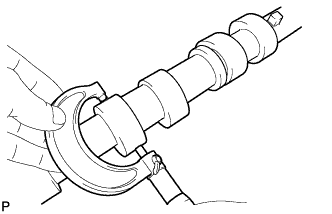

Insert the SST's tip into the lash adjuster's plunger and use the tip to press down on the check ball inside the plunger.

- SST

- 09276-75010

|

Squeeze SST and the lash adjuster together to move the plunger up and down 5 to 6 times.

Check the movement of the plunger and bleed air.

- OK:

- Plunger moves up and down.

- ПРИМЕЧАНИЕ:

- When bleeding high-pressure air from the compression chamber, make sure that the tip of SST is actually pressing the check ball as shown in the illustration. If the check ball is not pressed, air will not bleed.

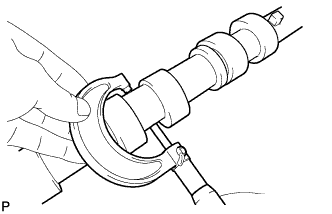

After bleeding the air, remove SST. Then try to quickly and firmly press the plunger with your fingers.

- OK:

- Plunger can be pressed 3 times.

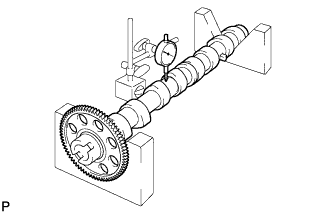

| 8. INSPECT NO. 1 CAMSHAFT |

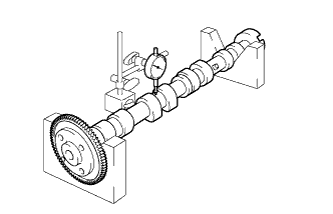

Check the camshaft for runout.

Place the camshaft on V-blocks.

Using a dial indicator, measure the circle runout at the center journal.

- Maximum circle runout:

- 0.03 mm (0.0012 in.)

|

Using a micrometer, measure the cam lobe height.

- Standard cam lobe height:

- 37.559 to 37.759 mm (1.4787 to 1.4866 in.)

- Minimum cam lobe height:

- 37.559 mm (1.4787 in.)

|

Using a micrometer, measure the journal diameter.

- Standard journal diameter:

- 26.969 to 26.985 mm (1.0617 to 1.0624 in.)

|

| 9. INSPECT NO. 2 CAMSHAFT |

Check the camshaft for runout.

Place the camshaft on V-blocks.

Using a dial indicator, measure the circle runout at the center journal.

- Maximum circle runout:

- 0.03 mm (0.0012 in.)

|

Using a micrometer, measure the cam lobe height.

- Standard cam lobe height:

- 38.270 to 38.470 mm (1.5067 to 1.5146 in.)

- Minimum cam lobe height:

- 38.270 mm (1.5067 in.)

|

Using a micrometer, measure the journal diameter.

- Standard journal diameter:

- 26.969 to 26.985 mm (1.0617 to 1.0624 in.)

|