Головка Блока Цилиндров -- Проверка |

| 1. INSPECT CYLINDER HEAD SUB-ASSEMBLY |

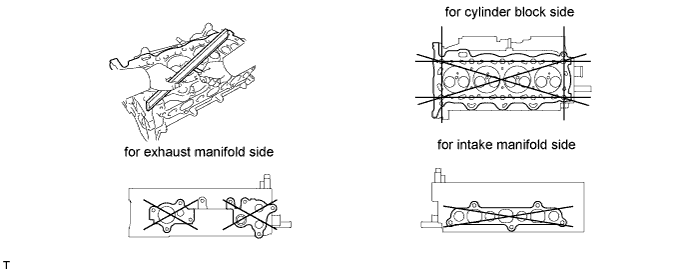

Inspect the flatness.

Using a precision straight edge and feeler gauge, measure the warpage on the cylinder block side and the intake and exhaust manifold sides.

- Maximum warpage:

- 0.08 mm (0.0032 in.) for cylinder block side

0.20 mm (0.0079 in.) for intake manifold side

0.20 mm (0.0079 in.) for exhaust manifold side

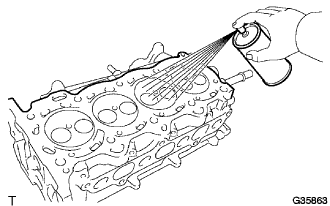

Inspect for cracks.

Using a dye penetrate, check the combustion chambers, intake ports, exhaust ports and contact surface of the cylinder block for cracks.

If cracked, replace the cylinder head sub-assembly.

|

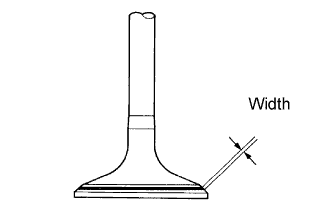

| 2. INSPECT VALVE SEAT |

Apply a light coat of prussian blue to each valve face.

|

Gently push the valve seat with the valve installed onto the cylinder head.

- ПРИМЕЧАНИЕ:

- Do not rotate the valve.

Remove the valve from the cylinder head.

If blue appears 360° around the face, the valve is concentric. If not, replace the valve.

If blue appears 360° around the valve seat, the guide and face are concentric. If not, resurface the seat.

Check that the seat contact is in the middle of the valve face with the following width.

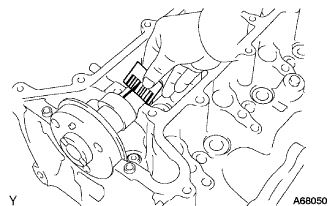

| 3. INSPECT CAMSHAFT OIL CLEARANCE |

Clean the camshaft and camshaft bearing cap.

|

Set the camshaft to the cylinder head sub-assembly.

Lay a strip of Plastigage across the camshaft journal.

- ПРИМЕЧАНИЕ:

- Do not turn the camshaft when measuring.

Install the bearing cap.

Remove the bearing cap.

Measure the Plastigage at its widest point.

- Standard oil clearance:

- 0.037 to 0.073 mm (0.0015 to 0.0029 in.)

- Maximum oil clearance:

- 0.10 mm (0.0039 in.)

- ПРИМЕЧАНИЕ:

- Completely remove the plastigage.

|

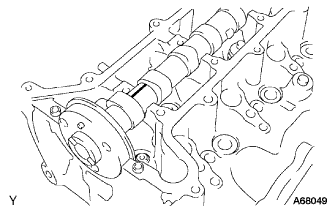

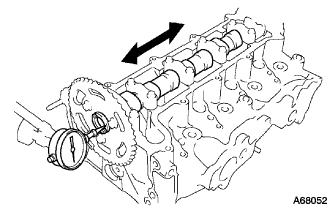

| 4. INSPECT CAMSHAFT THRUST CLEARANCE |

Set the camshaft to the cylinder head sub-assembly, then install the camshaft bearing cap.

Install the camshaft timing sprocket onto the camshaft.

Using a dial indicator, measure the thrust clearance of the camshaft while moving the camshaft back and forth.

- Standard thrust clearance:

- 0.040 to 0.090 mm (0.0016 to 0.0035 in.)

- Maximum thrust clearance:

- 0.25 mm (0.0098 in.)

|

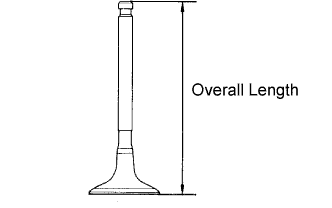

| 5. INSPECT INTAKE VALVE |

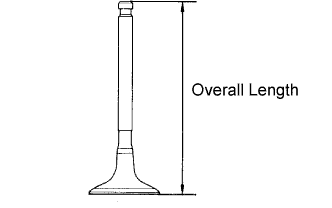

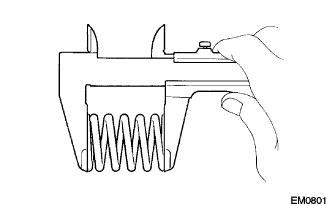

Using vernier calipers, measure the overall length of the intake valve.

- Standard overall length:

- 99.69 to 100.29 mm (3.9248 to 3.9484 in.)

- Minimum overall length:

- 99.19 mm (3.9051 in.)

|

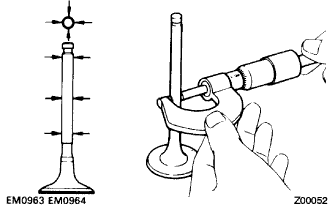

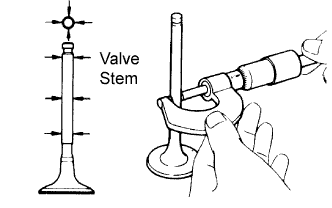

Using a micrometer, measure the diameter of the valve stem.

- Valve stem diameter:

- 5.970 to 5.985 mm (0.2350 to 0.2356 in.)

|

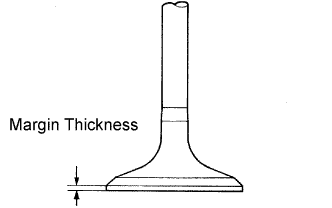

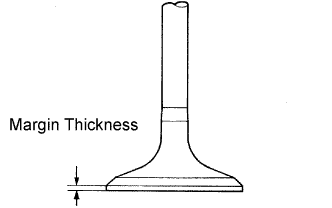

Using vernier calipers, measure the thickness of the valve head margin.

- Standard margin thickness:

- 1.2 mm (0.047 in.)

- Minimum margin thickness:

- 0.6 mm (0.024 in.)

|

| 6. INSPECT EXHAUST VALVE |

Using vernier calipers, measure the overall length of the exhaust valve.

- Standard overall length:

- 99.39 to 99.99 mm (3.9130 to 3.9366 in.)

- Minimum overall length:

- 98.89 mm (3.8933 in.)

|

Using a micrometer, measure the diameter of the valve stem.

- Valve stem diameter:

- 5.965 to 5.980 mm (0.2348 to 0.2354 in.)

|

Using vernier calipers, measure the thickness of the valve head margin.

- Standard margin thickness:

- 1.5 mm (0.059 in.)

- Minimum margin thickness:

- 0.7 mm (0.028 in.)

|

| 7. INSPECT OUTER COMPRESSION SPRING |

Using vernier calipers, measure the free length of the outer compression spring.

- Free length:

- 42.07 mm (1.6563 in.)

|

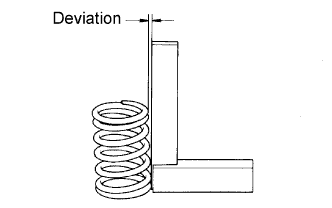

Using steel squares, measure the deviation of the outer compression spring.

- Maximum deviation:

- 1.5 mm (0.059 in.)

|

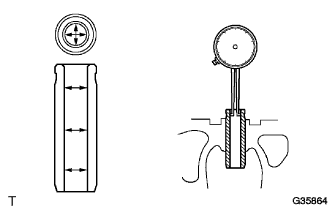

| 8. INSPECT VALVE GUIDE BUSH OIL CLEARANCE |

Using a caliper gauge, measure the internal diameter of the valve guide bushing.

- Bushing inside diameter:

- 6.010 to 6.030 mm (0.2366 to 0.2374 in.)

|

Subtract the valve stem diameter measurement from the internal diameter measurement of the valve guide bushing.

- Standard oil clearance:

- 0.025 to 0.060 mm (0.0010 to 0.0024 in.) for intake

0.003 to 0.065 mm (0.0001 to 0.0026 in.) for exhaust

- Maximum oil clearance:

- 0.08 mm (0.0031 in.) for intake

0.10 mm (0.0039 in.) for exhaust

| 9. INSPECT CYLINDER HEAD SET BOLT |

Using vernier calipers, measure the minimum outer diameter of the compressed thread at the measuring point.

- Standard outer diameter:

- 11.7 to 12.0 mm (0.461 to 0.472 in.)

- Minimum outer diameter:

- 11.5 mm (0.453 in.)

|