Двигатель -- Проверка Без Снятия С Автомобиля |

| 1. INSPECT ENGINE COOLANT QUALITY |

Remove the radiator cap sub-assembly.

- ПРЕДОСТЕРЕЖЕНИЕ:

- To avoid the danger of being burned, do not remove the radiator cap sub-assembly while the engine and radiator assembly are still hot.

- Thermal expansion will cause hot engine coolant and steam to blow out from the radiator assembly.

Check for excessive deposits of rust or scale around the radiator cap sub-assembly and radiator filler hole. The engine coolant should be free of oil.

If excessively dirty, replace the engine coolant.

Reinstall the radiator cap sub-assembly.

| 2. INSPECT ENGINE OIL |

Check the engine oil level.

Warm up the engine. Then stop the engine, and wait 5 minutes.

Check that the engine oil level is between the 2 marks on the oil level gauge. If low, check for leaks and top off oil to the upper mark.

- ПРИМЕЧАНИЕ:

- Do not fill to above the upper mark.

| 3. INSPECT BATTERY |

- ПРИМЕЧАНИЕ:

- If the battery is weak or if the engine is difficult to start, perform the following procedures.

Check the battery for damage and deformation. If severe damage, deformation or leakage is found, replace the battery.

Check the electrolyte quantity of each cell.

For maintenance-free batteries:

- If the electrolyte quantity is below the lower line, replace the battery.

- If the electrolyte quantity is above the lower line, check the battery voltage when cranking the engine. If the voltage is less than 9.6 V, recharge or replace the battery.

- УКАЗАНИЕ:

- Before checking the battery voltage, turn off all the electrical systems (headlights, blower motor, rear defogger, etc.).

- If the electrolyte quantity is below the lower line, replace the battery.

For non-maintenance-free batteries:

- If the electrolyte quantity is below the lower line, add distilled water to each cell. Then, recharge the battery and check the electrolyte's specific gravity.

- Standard specific gravity:

- 1.25 to 1.29 at 20°C (68°F)

- If the electrolyte quantity is above the lower line, check the battery voltage when cranking the engine. If the voltage is less than 9.6 V, recharge or replace the battery.

- УКАЗАНИЕ:

- Before checking the battery voltage, turn off all the electrical systems (headlights, blower motor, rear defogger, etc.).

- If the electrolyte quantity is below the lower line, add distilled water to each cell. Then, recharge the battery and check the electrolyte's specific gravity.

| 4. INSPECT AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

Remove the air cleaner filter element sub-assembly.

Visually check that there is no dirt, blockage, or damage to the air cleaner filter element.

- УКАЗАНИЕ:

- If there is any dirt or blockage in the air cleaner filter element, clean it with compressed air.

- If any dirt or blockage remains even after cleaning the air cleaner filter element with compressed air, replace it.

| 5. CHECK ENGINE IDLING SPEED AND MAXIMUM SPEED |

- ПРИМЕЧАНИЕ:

- Turn all the electrical systems and the A/C OFF.

- Inspect the ignition timing with the cooling fan OFF.

Warm up and stop the engine.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG).

Select the following menu items:

Powertrain / Engine and ECT / Data List / Engine SPD.- УКАЗАНИЕ:

- Refer to the intelligent tester operator's manual for further information regarding the selection of Data List.

Inspect the engine idling speed.

- Idling speed:

- 720 to 820 rpm

Fully depress the accelerator pedal.

Check the maximum speed.

- Maximum speed:

- 5100 to 5250 rpm

Turn the ignition switch off.

Disconnect the intelligent tester from the DLC3.

When not using the intelligent tester:

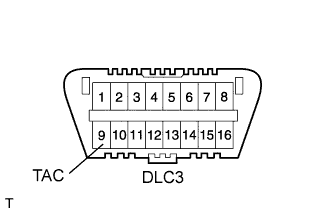

Install SST to terminal 9 (TAC) of DLC3, then connect a tachometer.

- SST

- 09843-18040

- ПРИМЕЧАНИЕ:

- Examine the terminal numbers before connecting them. Connecting the wrong terminals can damage the engine.

Turn the ignition switch on (IG).

Inspect the engine idling speed.

- Idle speed:

- 720 to 820 rpm

Fully depress the accelerator pedal.

Check the maximum speed.

- Maximum speed:

- 5100 to 5250 rpm

Turn the ignition switch off.

Disconnect the tachometer.

Remove SST from terminal 9.

|

| 6. INSPECT COMPRESSION |

|

Warm up and stop the engine.

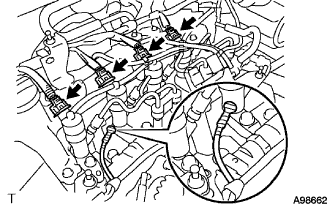

Remove the 4 glow plugs (See page Нажмите здесь).

- ПРИМЕЧАНИЕ:

- In order to avoid shorting the circuit of the wire harness connected to the glow plug No. 1 connector, wind vinyl tape around the wire harness terminal portion.

Disconnect all the connectors from the 4 injectors.

Connect the negative battery terminal.

Crank the engine to remove foreign objects before measuring the compression.

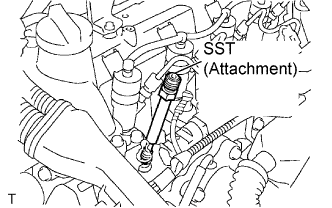

Install the attachment into the glow plug hole.

- SST

- 09992-00025(09992-00121)

- Момент затяжки:

- 13 Н*м{133 кгс*см, 10 фунт-сила-футов}

|

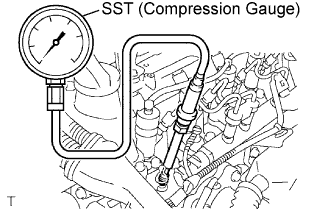

Connect a compression gauge to the attachment.

- SST

- 09992-00025(09992-00211,09992-00121)

|

While cranking the engine, measure the compression pressure.

- Compression pressure:

- 2700 kPa (27.5 kgf/cm2, 391 psi)

- Minimum pressure:

- 2200 kPa (22.5 kgf/cm2, 320 psi)

- Difference between each cylinder:

- 500 kPa (5.0 kgf/cm2, 71 psi) or less

- ПРИМЕЧАНИЕ:

- Use a fully-charged battery so that the engine speed can be increased to 250 rpm or more.

- Inspect the other cylinders in the same way.

- Measure the compression pressure in as short a time as possible.

- УКАЗАНИЕ:

- If adding oil increases the compression, the piston rings and/or cylinder bore may be worn or damaged.

- If the pressure stays low, a valve may be stuck or seated improperly, or there may be leakage from the gasket.

Remove the compression gauge and attachment.

Disconnect the cable from the negative battery terminal.

Connect all the connectors to the 4 injectors.

Install the 4 glow plugs.

| 7. INSPECT DIESEL EXHAUST |