Топливная Форсунка -- Проверка |

| 1. INSPECT FUEL INJECTOR ASSEMBLY |

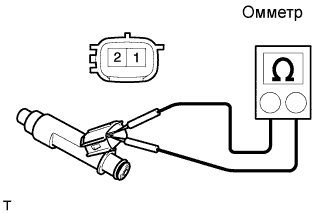

Check the resistance.

Using an ohmmeter, measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection Condition Specified Condition 1 - 2 20°C (68°F) 11.6 to 12.4 Ω

|

Check the operation.

- ПРЕДОСТЕРЕЖЕНИЕ:

- Perform the inspection in a well-ventilated area.

- Do not perform the inspection near any naked flames.

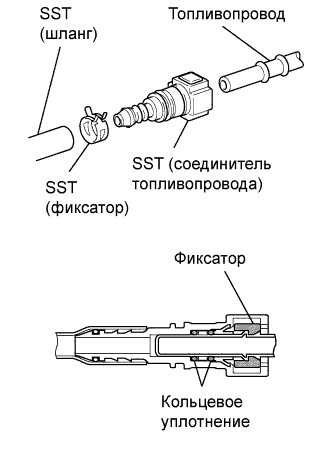

Connect SST (fuel tube connector) to SST (hose), then connect them to the fuel pipe (vehicle side).

- SST

- 09268-31012(90467-13001,95336-08070,09268-41500)

Install the O-ring onto the fuel injector assembly.

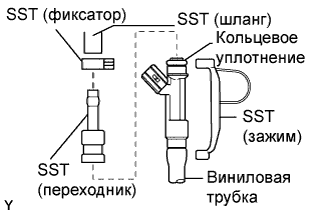

Connect SST (adapter and hose) to the injector assembly, and hold the injector assembly and union with SST (clamp).

- SST

- 09268-31012(09268-41110,90467-13001,95336-08070,09268-41310)

Set the injector assembly in a graduated cylinder.

- ПРЕДОСТЕРЕЖЕНИЕ:

- Install a suitable vinyl tube onto the injector assembly to prevent gasoline from splashing.

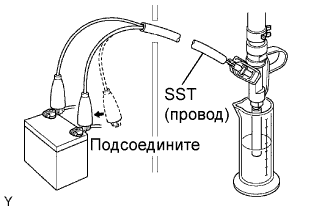

Operate the fuel pump (See page Нажмите здесь ).

Connect SST (wire) to the injector assembly and the battery for 15 seconds, and measure the injection volume with the graduated cylinder. Test each injector 2 or 3 times.

- SST

- 09842-30080

- Injection volume:

Tester Connection Condition Specified Condition Positive terminal - Ground terminal 15 seconds (2 or 3 times) 60 to 73 cm3 (3.7 to 4.5 cu in.)

- Difference between each injector:

- 13 cm3 (0.8 cu in.) or less

- ПРИМЕЧАНИЕ:

- Always do the switching at the battery side.

Check the leakage.

In the condition above, disconnect the test probes of SST (wire) from the battery and check the fuel leakage from the injector.

- Fuel drop:

- 1 drop or less every 12 minutes

|