Выходной Вал Проверка. Corolla ZZE150

INSPECT OUTPUT SHAFT

INSPECT 2ND GEAR

INSPECT 1ST GEAR

INSPECT 1ST GEAR THRUST WASHER

INSPECT NO. 2 SYNCHRONIZER RING SET (FOR 2ND GEAR)

INSPECT NO. 1 SYNCHRONIZER RING SET (FOR 1ST GEAR)

INSPECT REVERSE GEAR

INSPECT NO. 1 TRANSMISSION CLUTCH HUB

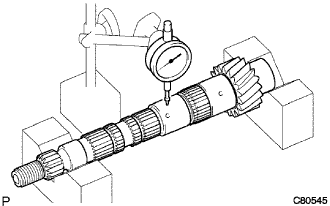

Using a dial gauge and 2 V-blocks, check the output shaft runout.

- Maximum runout:

- 0.015 mm (0.0006 in.)

If the runout exceeds the maximum, replace the output shaft.

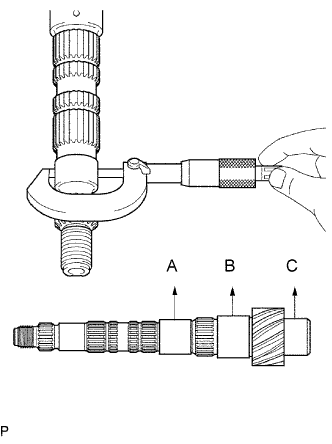

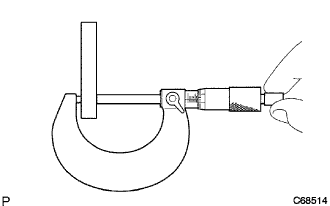

Using a micrometer, measure the outer diameter of the output shaft journal surface at the locations indicated.

- Standard outer diameter:

- Part A:

- 31.985 to 32.000 mm (1.2592 to 1.2598 in.)

- Part B:

- 37.985 to 38.000 mm (1.4955 to 1.4961 in.)

- Part C:

- 32.985 to 33.000 mm (1.2986 to 1.2992 in.)

If the outer diameters are less than the minimums, replace the output shaft.

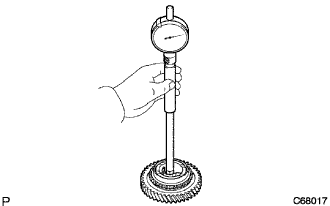

Using a cylinder gauge, measure the inside diameter of the 2nd gear.

- Standard inside diameter:

- 38.015 to 38.031 mm (1.4967 to 1.4972 in.)

- Maximum inside diameter:

- 38.031 mm (1.4972 in.)

If the inside diameter exceeds the maximum, replace the 1st gear.

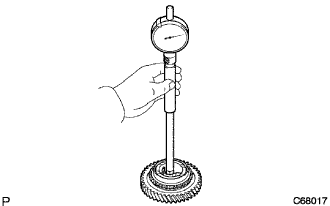

Using a cylinder gauge, measure the inside diameter of the 1st gear.

- Standard inside diameter:

- 44.015 to 44.031 mm (1.7328 to 1.7335 in.)

- Maximum inside diameter:

- 44.031 mm (1.7335 in.)

If the inside diameter exceeds the maximum, replace the 1st gear.

| 4. INSPECT 1ST GEAR THRUST WASHER |

Using a micrometer, measure the 1st gear thrust washer.

- Standard thickness:

- 5.975 to 6.025 mm (0.2352 to 0.2372 in.)

- Minimum thickness:

- 5.975 mm (0.2352 in.)

If the thickness is less than the minimum, replace the 1st gear thrust washer.

| 5. INSPECT NO. 2 SYNCHRONIZER RING SET (FOR 2ND GEAR) |

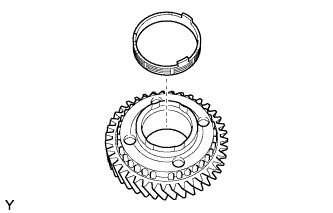

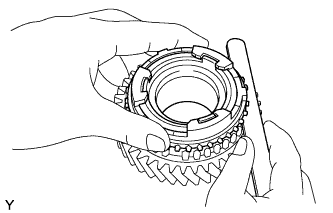

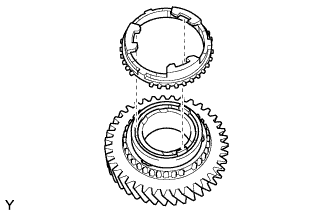

Coat the 2nd gear cone and No. 2 synchronizer ring set (inner ring, middle ring, and outer ring) with gear oil.

Install the inner ring onto the 2nd gear.

Install the middle ring onto the 2nd gear.

Install the outer ring onto the 2nd gear.

Check for wear and damage.

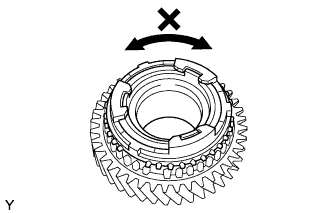

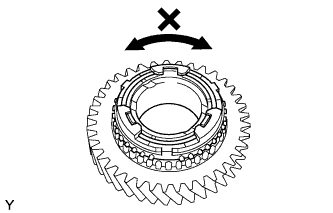

Turn the synchronizer ring set in one direction while pushing it against the 2nd gear cone.

Check that the ring locks.

If the synchronizer ring set does not lock, replace the synchronizer ring set.

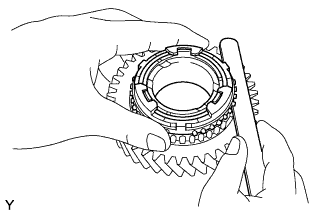

Using a feeler gauge, measure the clearance between the synchronizer ring back and the gear spline end.

- Standard clearance:

- TMC made:

- 0.60 to 1.40 mm (0.0236 to 0.0551 in.)

- TMUK, TMMT made:

- 0.64 to 1.36 mm (0.0252 to 0.0535 in.)

- Minimum clearance:

- TMC made:

- 0.60 mm (0.0236 in.)

- TMUK, TMMT made:

- 0.64 mm (0.0252 in.)

If the clearance is less than the minimum, replace the synchronizer ring set.

| 6. INSPECT NO. 1 SYNCHRONIZER RING SET (FOR 1ST GEAR) |

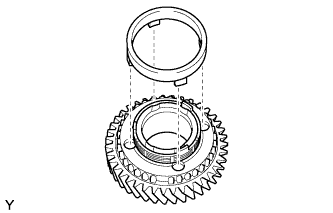

Coat the 1st gear cone and No. 1 synchronizer ring set (inner ring, middle ring, and outer ring) with gear oil.

Install the inner ring onto the 1st gear.

Install the middle ring onto the 1st gear.

Install the outer ring onto the 1st gear.

Check for wear and damage.

Turn the synchronizer ring set in one direction while pushing it against the 1st gear cone.

Check that the ring locks.

If the synchronizer ring does not lock, replace the synchronizer ring set.

Using a feeler gauge, measure the clearance between the synchronizer ring back and the gear spline end.

- Standard clearance:

- TMC made:

- 0.60 to 1.40 mm (0.0236 to 0.0551 in.)

- TMUK, TMMT made:

- 0.64 to 1.36 mm (0.0252 to 0.0535 in.)

- Minimum clearance:

- TMC made:

- 0.60 mm (0.0236 in.)

- TMUK, TMMT made:

- 0.64 mm (0.0252 in.)

If the clearance is less than the minimum, replace the synchronizer ring set.

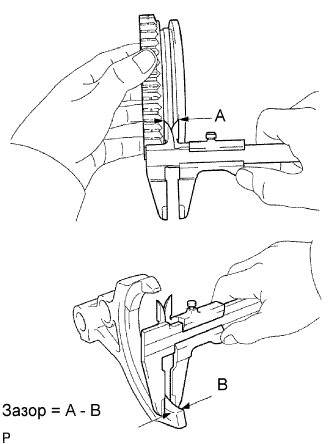

Using vernier calipers, measure the width of the reverse gear groove (A) and the thickness of the claw part on the reverse shift fork (B), and calculate the clearance.

- Standard clearance (A - B):

- 0.15 to 0.35 mm (0.0059 to 0.0138 in.)

If the clearance is outside the specifications, replace the reverse gear and reverse shift fork.

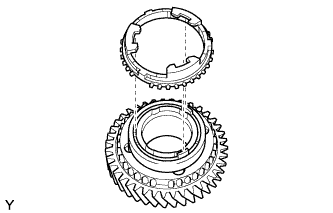

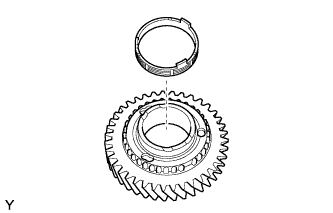

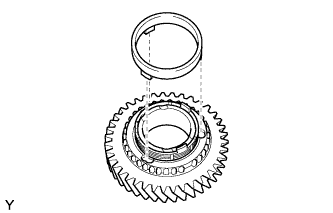

| 8. INSPECT NO. 1 TRANSMISSION CLUTCH HUB |

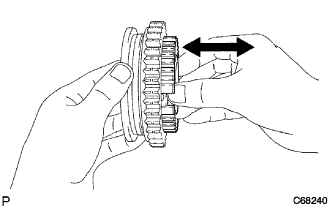

Check that the No. 1 transmission clutch hub and reverse gear slide smoothly.

Check that the edges of the reverse gear spline gear are not worn down.