Блок Двигателя Разборка. Corolla Auris

Двигатель. COROLLA, AURIS. ZZE150 ZRE151,152 NDE150

REMOVE OIL FILLER CAP SUB-ASSEMBLY

REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

REMOVE NO. 2 OIL PAN SUB-ASSEMBLY

REMOVE OIL FILTER CAP ASSEMBLY

REMOVE OIL FILTER ELEMENT

REMOVE OIL FILTER BRACKET

REMOVE OIL STRAINER SUB-ASSEMBLY

REMOVE CRANKSHAFT PULLEY

REMOVE WATER PUMP ASSEMBLY

REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

REMOVE CHAIN TENSIONER SLIPPER

REMOVE NO. 1 CHAIN VIBRATION DAMPER

REMOVE CAMSHAFT TIMING SPROCKET

REMOVE NO. 1 CAMSHAFT

REMOVE VALVE ROCKER ARM

REMOVE VALVE LASH ADJUSTER ASSEMBLY

REMOVE CYLINDER HEAD SUB-ASSEMBLY

REMOVE ENGINE BALANCER ASSEMBLY

CLEAN CYLINDER BLOCK SUB-ASSEMBLY

Блок Двигателя -- Разборка |

| 1. REMOVE OIL FILLER CAP SUB-ASSEMBLY |

| 2. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY |

| 3. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY |

Remove the drain plug and gasket.

Remove the 18 bolts and 2 nuts.

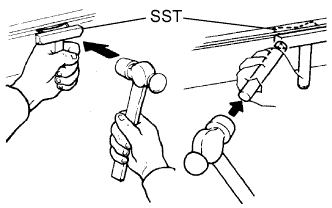

Insert the blade of SST between the oil pan and crankshaft bearing cap, cut through the applied sealer, and remove the oil pan.

- SST

- 09032-00100

- ПРИМЕЧАНИЕ:

- Do not use SST for the timing chain cover side.

- Be careful not to damage the contact surfaces of the oil pan.

| 4. REMOVE OIL FILTER CAP ASSEMBLY |

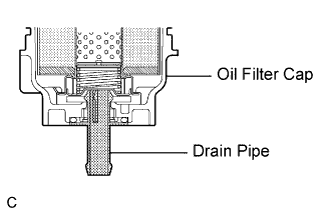

Remove the oil filter drain plug and O-ring, then insert the drain pipe into the oil filter cap and drain the engine oil into a container.

- УКАЗАНИЕ:

- The drain pipe is supplied with the oil filter element.

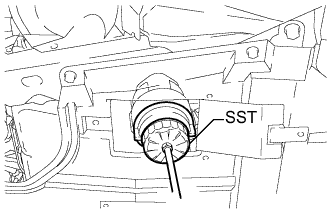

Using SST, remove the oil filter cap.

- SST

- 09228-06501

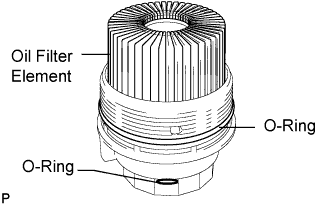

| 5. REMOVE OIL FILTER ELEMENT |

Remove the oil filter element and 2 O-rings from the oil filter cap.

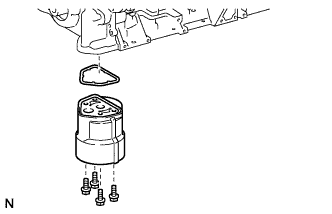

| 6. REMOVE OIL FILTER BRACKET |

Remove the 4 bolts, oil filter bracket, and gasket.

| 7. REMOVE OIL STRAINER SUB-ASSEMBLY |

Remove the 3 bolts, oil strainer, and O-ring.

| 8. REMOVE CRANKSHAFT PULLEY |

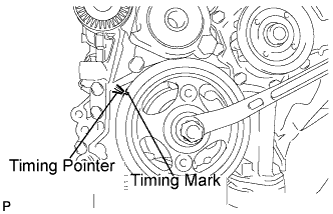

Set the No. 1 piston to TDC/compression.

Turn the crankshaft pulley clockwise to align the timing pointer of the timing chain cover and timing mark on the pulley.

Make sure that the timing mark is at the top of the camshaft timing sprocket.

If not, turn the crankshaft 1 revolution (360°) and align the mark as described above.

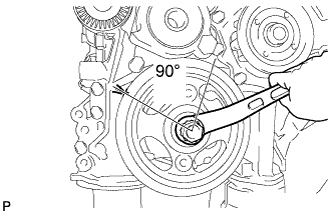

Turn the crankshaft by approximately 90° in the engine revolution direction at the point where the No. 1 piston is set to TDC/compression so that the lifted valve and piston do not contact each other when removing the camshaft.

Using SST, remove the pulley bolt.

- SST

- 09213-58013

09330-00021

Insert the service bolt.

- Recommended service bolt:

Item

| Specified Condition

|

Thread diameter

| 22 mm (0.87 in.)

|

Thread pitch

| 1.5 mm (0.059 in.)

|

Bolt length

| Approx. 30 to 38 mm (1.18 to 1.50 in.)

|

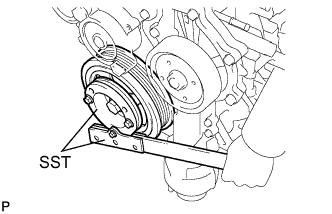

Using SST, remove the crankshaft pulley.

- SST

- 09950-50013(09951-05010,09952-05010,09953-05020,09954-05021)

| 9. REMOVE WATER PUMP ASSEMBLY |

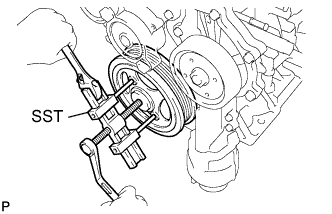

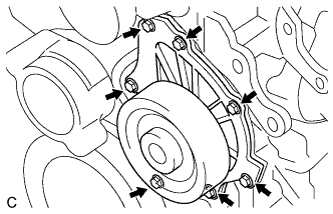

Remove the 7 bolts, water pump and gasket.

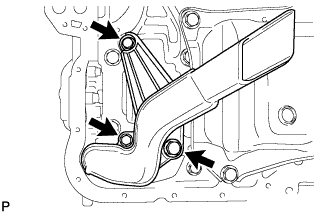

| 10. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY |

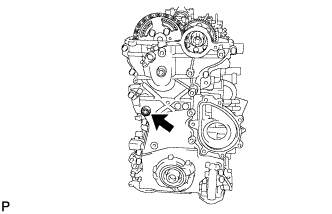

Using a 10 mm socket hexagon wrench, remove the timing chain cover tight plug and gasket.

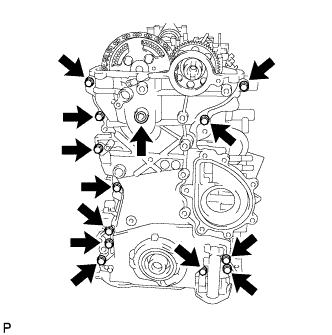

Remove the 13 bolts and seal washer as shown in the illustration.

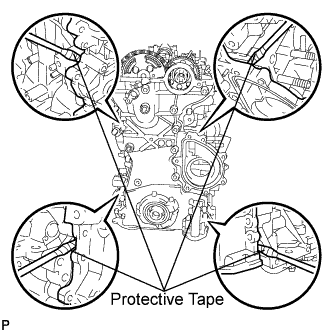

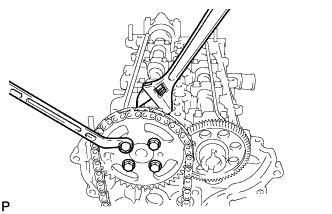

Remove the timing chain cover by prying between the timing chain cover and cylinder head or cylinder block with a screwdriver.

- УКАЗАНИЕ:

- Tape the screwdriver tip before use.

- ПРИМЕЧАНИЕ:

- Do not damage the contact surfaces of the cylinder head, cylinder block, and timing chain cover.

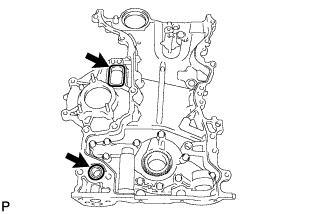

Remove the gasket and O-ring.

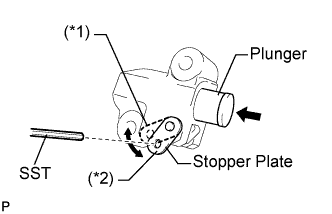

| 11. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY |

Move the stopper plate upward to release the lock, and push the plunger deep into the tensioner (*1).

Move the stopper plate downward to set the lock, and insert SST into the stopper plate hole (*2).

- SST

- 09240-00020(09242-00250)

Remove the 2 bolts and the No. 1 chain tensioner.

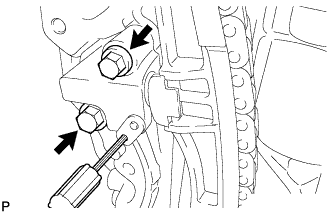

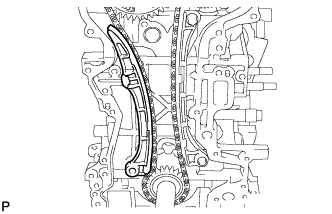

| 12. REMOVE CHAIN TENSIONER SLIPPER |

Remove the chain tensioner slipper.

| 13. REMOVE NO. 1 CHAIN VIBRATION DAMPER |

Remove the 2 bolts and vibration damper.

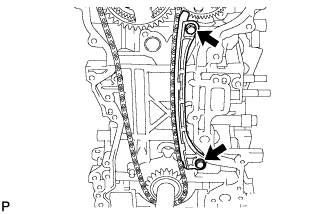

| 14. REMOVE CAMSHAFT TIMING SPROCKET |

Remove the 4 bolts on the sprocket while holding the hexagonal portion of the No. 2 camshaft.

Remove the camshaft timing sprocket, oil pump drive gear, crankshaft timing sprocket and chain.

| 15. REMOVE NO. 1 CAMSHAFT |

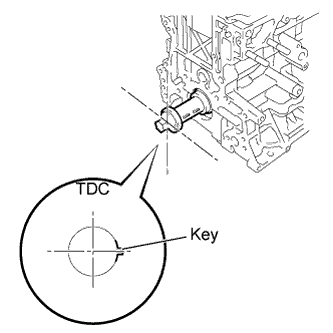

Check that the following conditions are met:

The No. 1 piston is set to approximately 90° BTDC/compression.

The key is set to the position shown in the illustration.

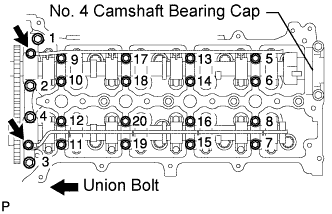

Remove the 2 union bolts.

- ПРИМЕЧАНИЕ:

- Be careful not to deform the camshaft oil delivery pipe LH when loosening the union bolts.

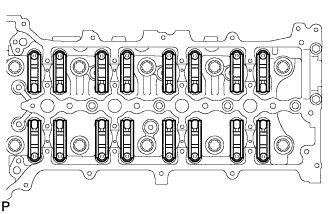

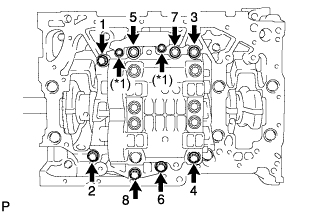

Using several steps, loosen and remove the 20 camshaft bearing cap bolts uniformly in the sequence shown in the illustration.

- ПРИМЕЧАНИЕ:

- Be careful not to deform the oil delivery pipe LH when loosening the bearing cap bolts.

Remove the 8 No. 3 camshaft bearing caps, No. 1 camshaft bearing cap and 2 camshaft oil delivery pipes.

- УКАЗАНИЕ:

- Do not remove the No. 4 bearing cap.

Remove the No. 1 camshaft and No. 2 camshaft.

Remove the No. 2 camshaft bearing cap.

| 16. REMOVE VALVE ROCKER ARM |

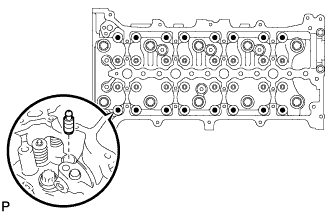

Remove the 16 valve rocker arms.

| 17. REMOVE VALVE LASH ADJUSTER ASSEMBLY |

Remove the 16 valve lash adjusters from the cylinder head.

- УКАЗАНИЕ:

- Arrange the removed parts in the correct order.

| 18. REMOVE CYLINDER HEAD SUB-ASSEMBLY |

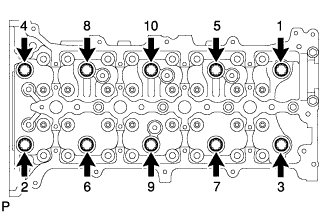

Uniformly loosen the 10 bolts in the sequence shown in the illustration. Remove the 10 cylinder head bolts and plate washers.

- ПРИМЕЧАНИЕ:

- Head warpage or cracking could result from removing the bolts in the incorrect order.

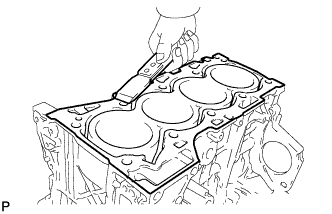

Remove the cylinder head and gasket.

| 19. REMOVE ENGINE BALANCER ASSEMBLY |

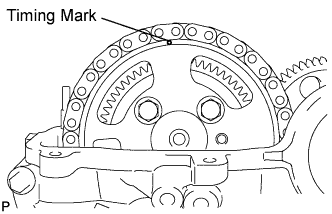

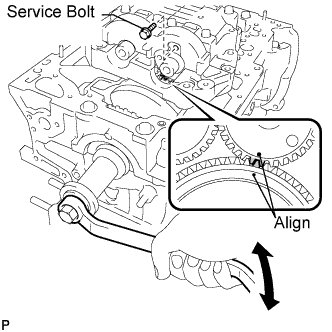

Align the drive and driven gear's timing marks (1 dot mark each) by turning the crankshaft with a wrench.

Install the service bolt.

- Recommended service bolt:

Item

| Specified Condition

|

Thread diameter

| 6 mm (0.24 in.)

|

Thread pitch

| 1 mm (0.04 in.)

|

Bolt length

| 16 to 18 mm (0.63 to 0.71 in.)

|

- Момент затяжки:

- 1.5 Н*м{15 кгс*см, 13 фунт-сила-дюймов}

- УКАЗАНИЕ:

- When removing the balancer, make certain that the torsional spring force of the sub gear has been eliminated by installation of the service bolt.

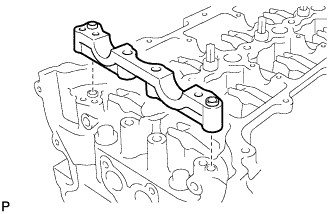

Remove the 2 bolts and oil baffle plate (*1).

Uniformly loosen the 8 bolts in several steps, in the sequence shown in the illustration.

Remove the engine balancer.

| 20. CLEAN CYLINDER BLOCK SUB-ASSEMBLY |

Using a gasket scraper, remove all the gasket material from the top surface of the cylinder block.

Using a soft brush and solvent, thoroughly clean the cylinder block.