Промежуточный Вал Повторная Сборка. Corolla ZZE150

INSTALL DIRECT CLUTCH DRUM O-RING

INSTALL DIRECT CLUTCH PISTON O-RING

INSTALL DIRECT CLUTCH DRUM SUB-ASSEMBLY

INSTALL DIRECT CLUTCH PISTON SUB-ASSEMBLY

INSTALL DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY

INSTALL DIRECT CLUTCH DISC

INSTALL REVERSE CLUTCH DISC

INSPECT PACK CLEARANCE OF REVERSE CLUTCH

INSPECT PACK CLEARANCE OF DIRECT CLUTCH

Промежуточный Вал -- Повторная Сборка |

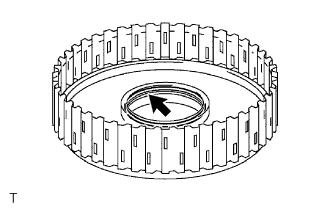

| 1. INSTALL DIRECT CLUTCH DRUM O-RING |

Coat a new O-ring with ATF and install it to the direct clutch drum.

- ПРИМЕЧАНИЕ:

- Do not damage the O-ring.

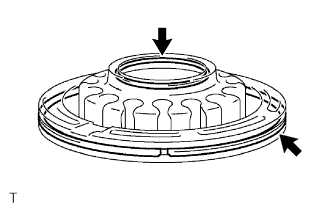

| 2. INSTALL DIRECT CLUTCH PISTON O-RING |

Coat 2 new O-rings with ATF and install them to the direct clutch piston.

- ПРИМЕЧАНИЕ:

- Do not damage the O-rings.

| 3. INSTALL DIRECT CLUTCH DRUM SUB-ASSEMBLY |

Coat the direct clutch drum with ATF.

Align a cutout on the intermediate shaft assembly with the matchmark on the direct clutch drum and install the direct clutch drum to the intermediate shaft assembly.

- ПРИМЕЧАНИЕ:

- Do not damage the O-ring or the lip of the clutch drum.

| 4. INSTALL DIRECT CLUTCH PISTON SUB-ASSEMBLY |

Coat the direct clutch piston with ATF and install it to the intermediate shaft.

- ПРИМЕЧАНИЕ:

- Do not damage the O-ring or the direct clutch piston.

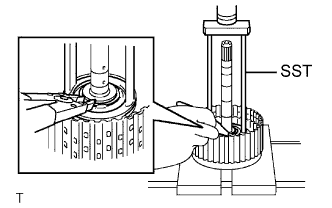

| 5. INSTALL DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY |

Install the direct clutch return spring onto the direct clutch piston.

Place SST on the piston return spring and compress the springs with a press.

- SST

- 09387-00020

Using snap ring pliers, install the snap ring to the direct clutch drum.

- ПРИМЕЧАНИЕ:

- Stop pressing the press when the spring seat is lowered to 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove to prevent the spring seat from deforming.

- Do not expand the snap ring excessively.

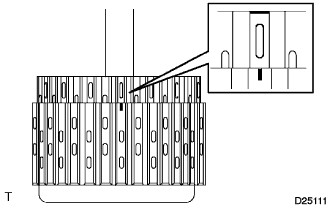

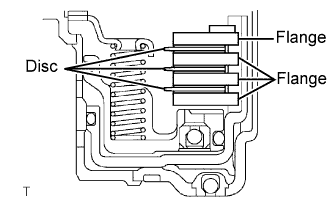

| 6. INSTALL DIRECT CLUTCH DISC |

Coat the 3 rear clutch flanges, 3 discs and direct clutch flange with ATF and install them to the intermediate shaft.

Install the snap ring to the intermediate shaft.

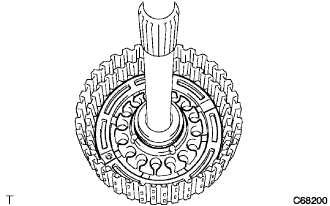

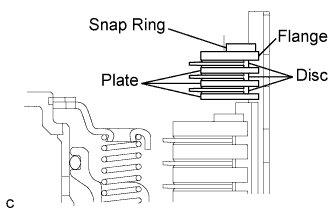

| 7. INSTALL REVERSE CLUTCH DISC |

Coat the 3 plates, 3 discs and flange with ATF, and install them to the intermediate shaft.

Install the snap ring to the intermediate shaft.

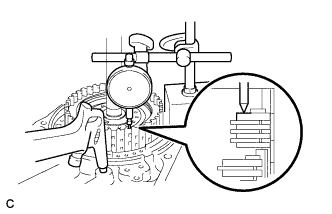

| 8. INSPECT PACK CLEARANCE OF REVERSE CLUTCH |

Install the intermediate shaft and thrust needle roller bearing to the transaxle rear cover.

Using a dial indicator, measure the reverse clutch pack clearance while applying and releasing compressed air (392 kPa, 4.0 kgf/cm2, 57 psi).

- Pack clearance:

- 0.62 to 1.16 mm (0.0244 to 0.0457 in.)

- ПРИМЕЧАНИЕ:

- If the clearance is not within the specified range, select a new clutch flange.

- УКАЗАНИЕ:

- There are 4 different flange thicknesses.

- Flange thickness:

No.

| Thickness mm (in.)

| No.

| Thickness mm (in.)

|

-

| 3.0 (0.118)

| 2

| 3.4 (0.134)

|

1

| 3.2 (0.126)

| 3

| 3.6 (0.142)

|

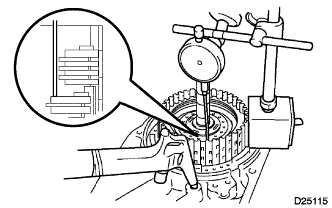

| 9. INSPECT PACK CLEARANCE OF DIRECT CLUTCH |

Install the intermediate shaft and thrust needle roller bearing to the transaxle rear cover.

Using a dial indicator and measuring terminal (SST), measure the forward clutch pack clearance while applying and releasing compressed air (392 kPa, 4.0 kgf/cm2, 57 psi).

- SST

- 09350-36010(09350-06110)

- УКАЗАНИЕ:

- The direct and reverse clutch will come out as the compressed air is applied.

- Therefore, while performing the check, press on the input shaft of the direct and reverse clutch using a press or the equivalent so that the pressure is not applied to the direct and reverse clutch.

- Pack clearance:

- 0.62 to 1.02 mm (0.0244 to 0.0402 in.)

- ПРИМЕЧАНИЕ:

- If the clearance is not within the specified range, select a new clutch flange.

- УКАЗАНИЕ:

- There are 4 different flange thicknesses.

- Flange thickness:

No.

| Thickness mm (in.)

| No.

| Thickness mm (in.)

|

-

| 3.0 (0.118)

| 2

| 3.4 (0.134)

|

1

| 3.2 (0.126)

| 3

| 3.6 (0.142)

|