Форсунка Добавления Отработавшего Топлива -- Установка |

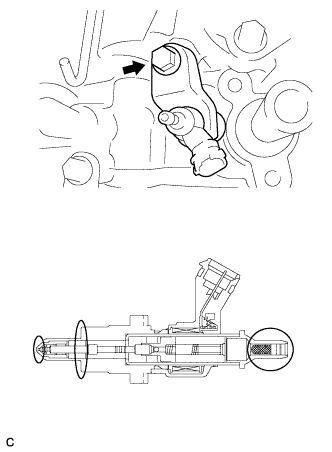

| 1. INSTALL EXHAUST FUEL ADDITION INJECTOR ASSEMBLY |

Install a new gasket, exhaust fuel addition injector and nozzle holder clamp with the washer and bolt.

- Момент затяжки:

- 29 Н*м{296 кгс*см, 21 фунт-сила-футов}

- ПРИМЕЧАНИЕ:

- Do not use an injector which has been dropped.

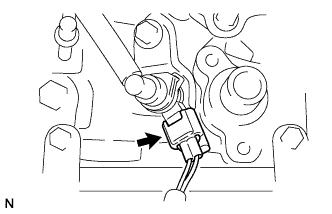

- Do not damage the areas indicated in the illustration.

- Do not allow the areas indicated in the illustration to be contaminated.

- УКАЗАНИЕ:

- Install the nozzle holder clamp while holding it.

|

| 2. INSTALL FUEL TUBE SUB-ASSEMBLY |

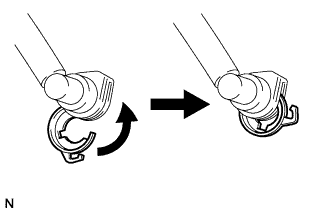

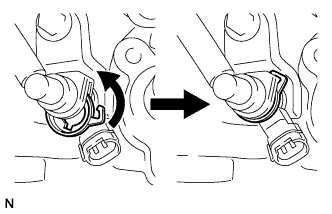

Turn the retainer in the direction indicated by the arrow until the retainer stops.

|

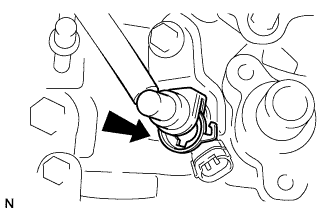

Install the fuel tube sub-assembly and a new gasket with the union bolt.

- Момент затяжки:

- 23 Н*м{235 кгс*см, 17 фунт-сила-футов}

|

Insert the fuel tube connector into the injector.

|

Turn the retainer in the direction indicated by the arrow until it makes a "click" sound.

- ПРИМЕЧАНИЕ:

- If the fuel tube connector is not inserted to the correct position of the injector, the retainer cannot be turned further in the direction of the arrow.

|

Connect the exhaust fuel addition injector connector.

|

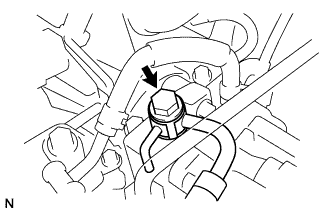

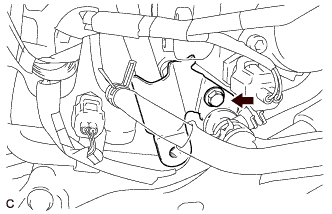

| 3. INSTALL FUEL HOSE PROTECTOR |

Install the fuel hose protector with the bolt.

- Момент затяжки:

- 21 Н*м{210 кгс*см, 15 фунт-сила-футов}

|

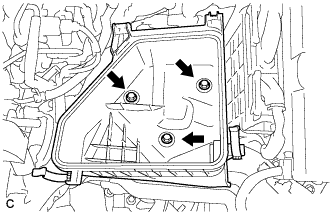

| 4. INSTALL AIR CLEANER CASE |

Install the 3 bolts and air cleaner case.

- Момент затяжки:

- 7.0 Н*м{71 кгс*см, 62 фунт-сила-дюймов}

|

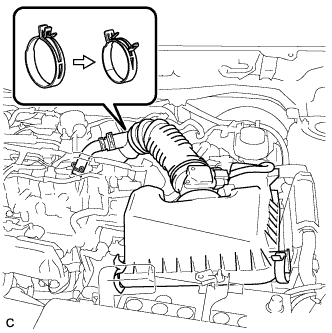

| 5. INSTALL AIR CLEANER CAP SUB-ASSEMBLY |

Install the air cleaner filter element.

Install the air cleaner cap sub-assembly, and connect the 2 clamps and band.

|

Connect the No. 2 ventilation hose.

Connect the mass air flow meter connector.

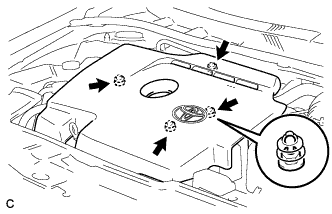

| 6. INSTALL NO. 1 ENGINE COVER |

Attach the 4 clips to install the engine cover.

|

| 7. INSPECT FOR FUEL LEAK |

PERFORM ACTIVE TEST

Connect the intelligent tester to the DLC3.

Turn the ignition switch to the ON position.

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine / Active Test.

Perform the Active Test.

Tester Display Test Part Control Range Diagnostic Notes Test the Fuel Leak Pressurizing common rail internal fuel pressure, and checking for fuel leaks. Stop/Start - Fuel pressure inside common rail is pressurized to specified value and engine speed is increased to 2000 rpm when ON is selected.

- Above conditions are maintained while test is ON.

- Fuel pressure inside common rail is pressurized to specified value and engine speed is increased to 2000 rpm when ON is selected.