CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0919)

PERFORM ACTIVE TEST USING INTELLIGENT TESTER

INSPECT TRANSAXLE ASSEMBLY (GEAR SHIFT MECHANICAL SYSTEM)

DTC P0919 Gear Shift Position Control Error |

DESCRIPTION

In the multi-mode manual transaxle system, the transaxle gear is shifted up and down by the TCM using a shift and select actuator. The shift and select actuator assembly consists of two motors (shift motor and select motor), stroke sensors (shift stroke sensor and select stroke sensor) and gears to move the shift and select lever shaft. The shift motor moves the shift and select lever shaft in the shift direction according to the signal from the TCM.This DTC is set in accordance with the stroke speed of the shift and select actuator or the difference between the target shift position and the actual shift position. Therefore, if malfunctions occur in the shift stroke sensor or the shift motor circuit, the DTCs relating to the sensor or motor circuit open/short (DTC P0915, P0916, P0917 and/or P0920) are set before this DTC is set.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0919 | The TCM detects the following conditions simultaneously: (1-trip detection logic)

|

|

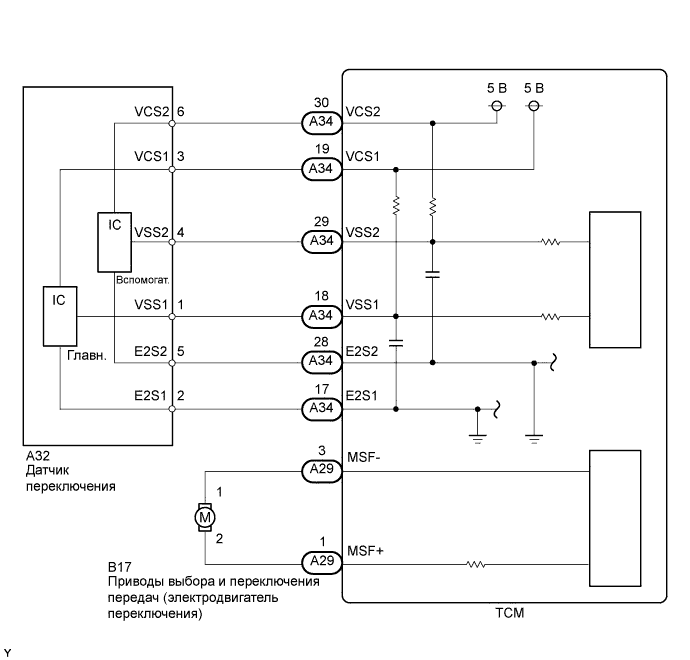

WIRING DIAGRAM

INSPECTION PROCEDURE

- ПРИМЕЧАНИЕ:

- In shift stroke sensor or shift and select actuator assembly replacement, perform the [Initialization and Learning] procedure (See page Нажмите здесь) and [Synchronization Position Calibration] procedure (See page Нажмите здесь) after installing the sensor or actuator assembly. If the sensor or actuator is installed without performing [Initialization and Learning] and [Synchronization Position Calibration], it may cause driving performance degradation or system component breakage.

- УКАЗАНИЕ:

- If the symptom still occurs even after checking the following parts for dirt, wear, and defects and replacing the defective parts, replace the TCM.

- Synchronizer Rings

- Shift Forks

- Hub Sleeves

| 1.CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0919) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / DTC.

Read DTCs.

- Result:

Result Proceed to P0919 A P0919 and other DTCs B

|

| ||||

| A | |

| 2.INSPECT TCM |

Check the shift and select actuator motor terminal output using an oscilloscope.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Clear the DTC after saving the recorded freeze frame data.

Turn the ignition switch off within 2 seconds of clearing the DTC.

Connect the oscilloscope probes to the TCM terminals.

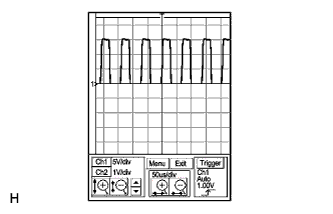

Check the waveform when the ignition switch is turned on (IG), and the shift lever position is changed from the N position to any other position.

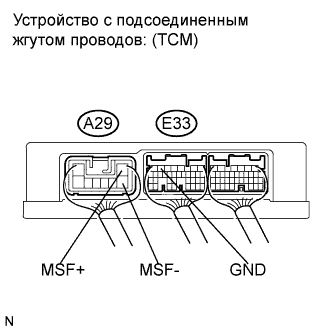

Oscilloscope settings Items Contents Terminals A29-3 (MSF-) - E33-6 (GND)

A29-1 (MSF+) - E33-6 (GND)Gauge set 5 V/DIV., 50 μs/DIV. Condition Ignition switch on (IG) - Standard:

- Correct waveform shown in the illustration.

- УКАЗАНИЕ:

- The waveform is displayed for several seconds until the DTC is set.

|

|

| ||||

| OK | |

| 3.INSPECT TCM |

Remove the shift stroke sensor from the shift and select actuator assembly.

|

Connect the shift stroke sensor connector.

Turn the ignition switch on (IG).

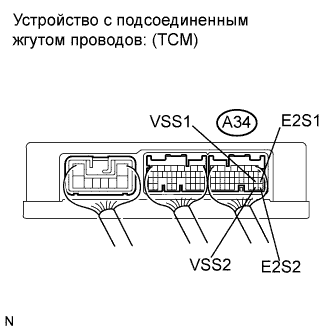

Check the voltage change between the terminals of the TCM connector when moving the sensor arm of the shift stroke sensor.

- Standard voltage:

Tester Connection Switch Condition Specified Condition A34-18 (VSS1) - A34-17 (E2S1) Ignition switch on (IG) Voltage changes in accordance with sensor arm position A34-29 (VSS2) - A34-28 (E2S2) ↑ Voltage changes in accordance with sensor arm position

Reinstall the shift stroke sensor (See page Нажмите здесь).

Perform [Initialization and Learning] (See page Нажмите здесь) and [Synchronization Position Calibration] (See page Нажмите здесь).

- Result:

Result Proceed to NG A OK B

|

| ||||

| A | |

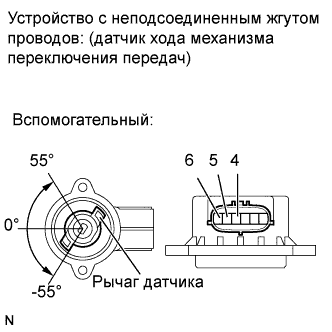

| 4.INSPECT SHIFT STROKE SENSOR |

Remove the shift stroke sensor.

|

Measure the voltage between the terminals of the shift stroke sensor connector (main).

Prepare 3 dry cell batteries (1.5 V) and 2 leads for connecting the batteries and the sensor.

Connect the batteries in series.

Connect the positive battery terminal to sensor terminal 3, and the negative battery terminal to sensor terminal 2.

Check the voltage between terminals 1 and 2.

- Standard voltage (combined dry cell battery voltage of 4.5 V):

Sensor Angle Terminal (1-2) Output Voltage 55° Approximately 4.05 V 0° Approximately 2.25 V -55° Approximately 0.45 V

- Reference voltage (combined dry cell battery voltage of 5.0 +- 0.3 V):

Sensor Angle Terminal (1-2) Output Voltage 55° Approximately 4.5 V 0° Approximately 2.5 V -55° Approximately 0.5 V

Measure the voltage between the terminals of the shift stroke sensor connector (sub).

Connect the positive battery terminal to sensor terminal 6, and the negative battery terminal to sensor terminal 5.

Check the voltage between terminals 4 and 5.

- Standard voltage (combined dry cell battery voltage of 4.5 V):

Sensor Angle Terminal (4-5) Output Voltage 55° Approximately 4.05 V 0° Approximately 2.25 V -55° Approximately 0.45 V

- Reference voltage (combined dry cell battery voltage of 5.0 +- 0.3 V):

Sensor Angle Terminal (4-5) Output Voltage 55° Approximately 4.5 V 0° Approximately 2.5 V -55° Approximately 0.5 V

- ПРИМЕЧАНИЕ:

- Do not apply more than 6 V

- Do not use a sensor which has been dropped.

|

Reinstall the shift stroke sensor (See page Нажмите здесь).

Perform [Initialization and Learning] (See page Нажмите здесь) and [Synchronization Position Calibration] (See page Нажмите здесь).

|

| ||||

| OK | ||

| ||

| 5.PERFORM ACTIVE TEST USING INTELLIGENT TESTER |

Remove the shift and select actuator.

Connect the connectors to the shift and select actuator.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Clear the DTC after saving the recorded freeze frame data

Turn the ignition switch off within 2 seconds of clearing the DTC.

Turn the ignition switch on (IG).

Select the following menu items: Powertrain / Multi-Mode M/T / Active Test / Target Gear Position Control.

Perform the Active Test.

- OK:

- Shift and select actuator moves smoothly in accordance with the tester operation.

Reinstall the shift and select actuator.

Perform [Initialization and Learning] (See page Нажмите здесь) and [Synchronization Position Calibration] (See page Нажмите здесь).

|

| ||||

| OK | |

| 6.INSPECT TRANSAXLE ASSEMBLY (GEAR SHIFT MECHANICAL SYSTEM) |

Remove the transaxle assembly (See page Нажмите здесь).

Check for dirt, wear and defects in the gear shift mechanical system (synchronizer rings, shift forks, hub sleeves, etc.).

- OK:

- No defective parts in the transaxle assembly.

|

| ||||

| OK | ||

| ||