READ VALUE USING INTELLIGENT TESTER

INSPECT CLUTCH STROKE SENSOR (MAIN)

INSPECT CLUTCH STROKE SENSOR (SUB)

CHECK HARNESS AND CONNECTOR (CLUTCH STROKE SENSOR - TCM)

DTC P0806 Clutch Position Sensor Circuit (Range / Performance) |

DTC P0807 Clutch Position Sensor (Low) |

DTC P0808 Clutch Position Sensor (High) |

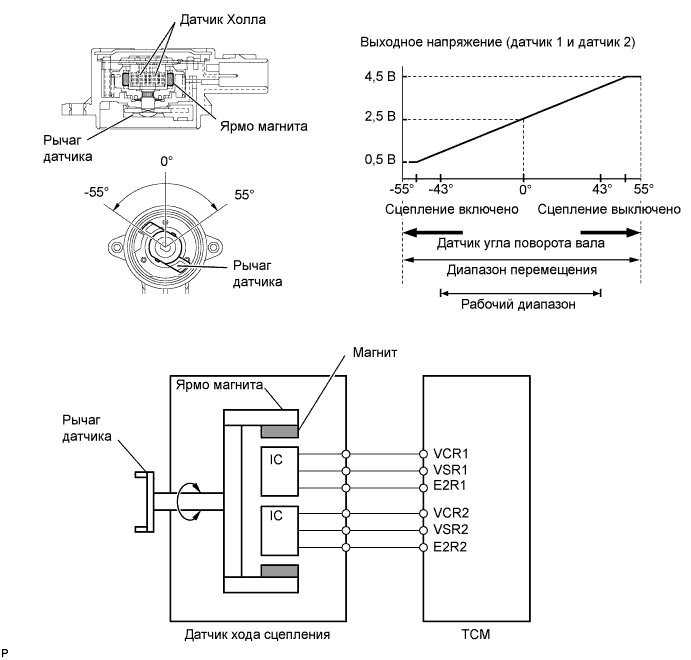

DESCRIPTION

The clutch stroke sensor is mounted on the clutch actuator, and detects the pull rod position of the clutch actuator. The sensor consists of a sensor arm, a magnetic yoke and 2 Hall-ICs. This sensor is a non-contact type, and uses Hall-effect elements (Hall-ICs: main and sub), in order to yield accurate signals.When the clutch actuator is operating, the magnetic yoke that is coaxially positioned on the sensor arm is rotated and the magnet position changes. The hall-ICs convert the magnet position change into the voltage signals and send them to the TCM. The TCM judges the clutch condition (whether the clutch is engaged, disengaged, or partially engaged) based on the signal from the clutch stroke sensor.

The main and sub circuits in the clutch stroke sensor have the same output characteristics.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0806 | Deviation between sensor signal 1 (main) and sensor signal 2 (sub) is 2.0 mm (0.078 in.) or more for 1.0 second or more (1-trip detection logic) |

|

| P0807 | Clutch stroke sensor (main) signal voltage is 0.2 V or less for 0.5 seconds or more (1-trip detection logic) |

|

| P0807 | Clutch stroke sensor (sub) signal voltage is 0.2 V or less for 0.5 seconds or more (1-trip detection logic) |

|

| P0808 | Clutch stroke sensor (main) signal voltage is 4.8 V or more for 0.5 seconds or more (1-trip detection logic) |

|

| P0808 | Clutch stroke sensor (sub) signal voltage is 4.8 V or more for 0.5 seconds or more (1-trip detection logic) |

|

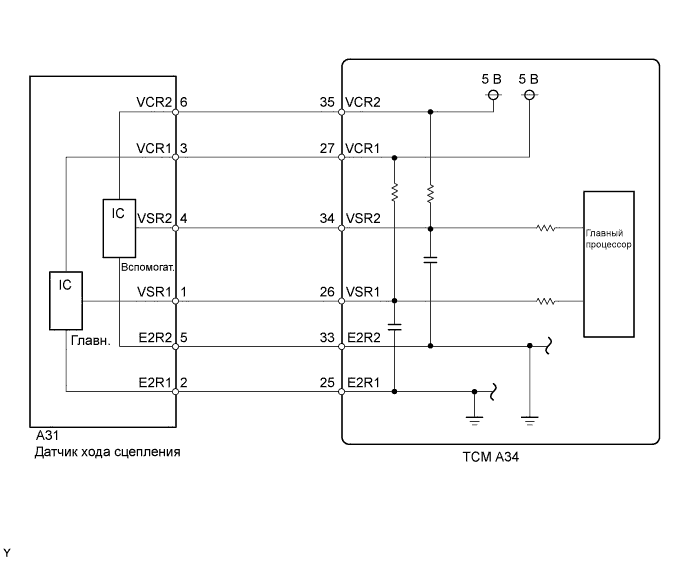

WIRING DIAGRAM

INSPECTION PROCEDURE

- ПРИМЕЧАНИЕ:

- In clutch stroke sensor replacement, perform the initialization and learning of the multi-mode manual transaxle system after installing the sensor (See page Нажмите здесь).

- If the sensor is installed without the initialization and learning, it may cause driving performance degradation or system component breakage.

- УКАЗАНИЕ:

- When only DTC P0806 is set, replace the clutch stroke sensor.

| 1.READ OUTPUT DTC |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / DTC.

Read DTCs.

- Result:

Result Proceed to P0806, P0807 and/or P0808 A Only P0806 B

|

| ||||

| A | |

| 2.READ VALUE USING INTELLIGENT TESTER |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / Data List / Clutch Position (Current).

Items

[Abbreviation]Measurement Items: Display Normal Conditions Diagnostic Notes Clutch Position (Current)

[Clutch Pos-Cur]Current clutch position:

Min.: 0 mm, Max.: 127.998 mm23.75 mm (0.94 in.) to 42.47 mm (1.67 in.) Current clutch position displayed - OK:

- The value on the tester is within the normal range.

- Result:

Result Proceed to NG A OK B

|

| ||||

| A | |

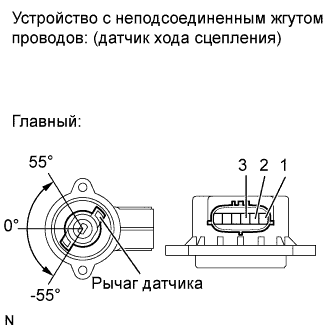

| 3.INSPECT CLUTCH STROKE SENSOR (MAIN) |

Remove the clutch stroke sensor.

|

Measure the voltage between the terminals of the clutch stroke sensor connector (main).

Prepare 3 dry cell batteries (1.5 V) and 2 leads for connecting the batteries and the sensor.

Connect the batteries in series.

Connect the positive battery terminal to sensor terminal 3, and the negative battery terminal to sensor terminal 2.

Check the voltage between terminals 1 and 2.

- Standard voltage (combined dry cell battery voltage of 4.5 V):

Sensor Angle Terminal (1-2) Output Voltage 55° Approximately 4.05 V 0° Approximately 2.25 V -55° Approximately 0.45 V

- Reference voltage (combined dry cell battery voltage of 5.0 +- 0.3 V):

Sensor Angle Terminal (1-2) Output Voltage 55° Approximately 4.5 V 0° Approximately 2.5 V -55° Approximately 0.5 V

- ПРИМЕЧАНИЕ:

- Do not apply more than 6 V

- Do not use a sensor which has been dropped.

Reinstall the clutch stroke sensor (See page Нажмите здесь).

Perform initialization and learning (See page Нажмите здесь).

|

| ||||

| OK | |

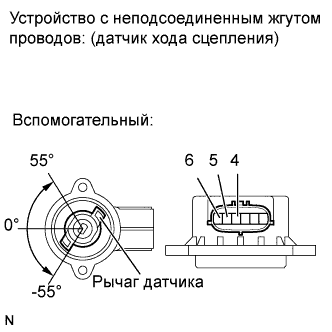

| 4.INSPECT CLUTCH STROKE SENSOR (SUB) |

Remove the clutch stroke sensor.

|

Measure the voltage between the terminals of the clutch stroke sensor connector (sub).

Prepare 3 dry cell batteries (1.5 V) and 2 leads for connecting the batteries and the sensor.

Connect the batteries in series.

Connect the positive battery terminal to sensor terminal 6, and the negative battery terminal to sensor terminal 5.

Check the voltage between terminals 4 and 5.

- Standard voltage (combined dry cell battery voltage of 4.5 V):

Sensor Angle Terminal (4-5) Output Voltage 55° Approximately 4.05 V 0° Approximately 2.25 V -55° Approximately 0.45 V

- Reference voltage (combined dry cell battery voltage of 5.0 +- 0.3 V):

Sensor Angle Terminal (4-5) Output Voltage 55° Approximately 4.5 V 0° Approximately 2.5 V -55° Approximately 0.5 V

- ПРИМЕЧАНИЕ:

- Do not apply more than 6 V

- Do not use a sensor which has been dropped.

Reinstall the clutch stroke sensor (See page Нажмите здесь).

Perform initialization and learning (See page Нажмите здесь).

|

| ||||

| OK | |

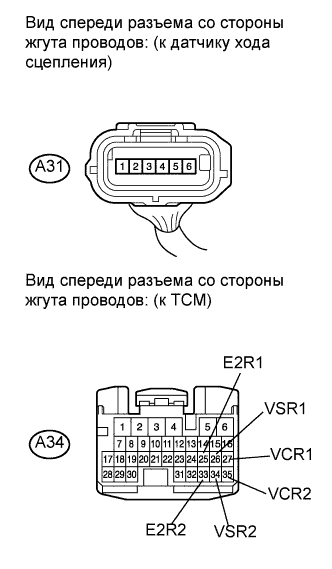

| 5.CHECK HARNESS AND CONNECTOR (CLUTCH STROKE SENSOR - TCM) |

Disconnect the clutch stroke sensor connector.

|

Disconnect the TCM connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection Condition Specified Condition A34-35 (VCR2) - A31-6 Always Below 1 Ω A34-34 (VSR2) - A31-4 ↑ Below 1 Ω A34-33 (E2R2) - A31-5 ↑ Below 1 Ω A34-27 (VCR1) - A31-3 ↑ Below 1 Ω A34-26 (VSR1) - A31-1 ↑ Below 1 Ω A34-25 (E2R1) - A31-2 ↑ Below 1 Ω A34-35 (VCR2) - Body ground ↑ 10 kΩ or higher A34-34 (VSR2) - Body ground ↑ 10 kΩ or higher A34-33 (E2R2) - Body ground ↑ 10 kΩ or higher A34-27 (VCR1) - Body ground ↑ 10 kΩ or higher A34-26 (VSR1) - Body ground ↑ 10 kΩ or higher A34-25 (E2R1) - Body ground ↑ 10 kΩ or higher

Reconnect the clutch stroke sensor connector.

Reconnect the TCM connector.

|

| ||||

| OK | ||

| ||