Стартер (Изготовление Tmuk, Tmmt) -- Проверка |

| 1. INSPECT STARTER ASSEMBLY |

- ПРИМЕЧАНИЕ:

- The following tests must not be performed continuously for longer than 5 seconds to prevent the coil from burning out.

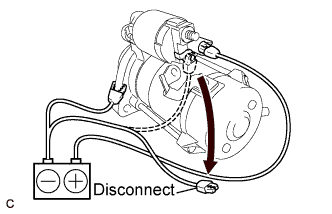

Perform a pull-in test.

Disconnect the field coil wire from terminal C.

Connect the battery to the magnetic switch as shown in the illustration. Check that the clutch pinion gear moves outward.

If the clutch pinion gear does not move outward, replace the starter magnetic switch assembly.

|

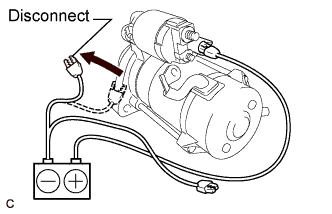

Perform a hold-in test.

Disconnect the negative (-) terminal lead from terminal C with the condition specified in the pull-in test above being maintained. Check that the pinion gear remains out.

If the clutch pinion gear moves inward, replace the starter magnetic switch assembly.

|

Inspect the clutch pinion gear return.

Disconnect the negative (-) lead from the starter body. Check that the clutch pinion gear moves inward.

If the clutch pinion gear does not move inward, replace the starter magnetic switch assembly.

|

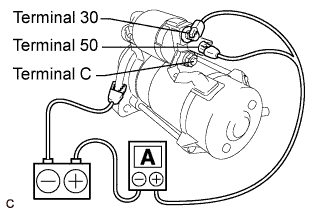

Perform a no-load performance test.

Connect the field coil wire to terminal C with the nut. Make sure that the lead is not grounded.

- Момент затяжки:

- 6.5 Н*м{66 кгс*см, 57 фунт-сила-дюймов}

Clamp the starter in a vise.

Connect the battery and an ammeter to the starter as shown in the illustration.

Check that the starter rotates smoothly and steadily while the pinion gear is moving out. Then measure the current.

- Standard current:

- 190 A or less at 11.5 V

|

| 2. INSPECT STARTER ARMATURE ASSEMBLY |

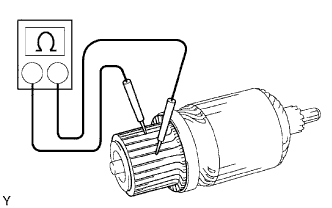

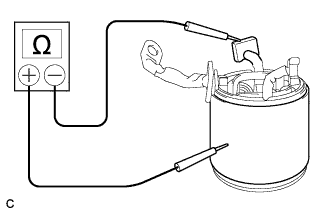

Inspect the resistance of the commutator.

If there is no continuity between any segments, replace the armature.Measure the resistance between the segments of the commutator.

- Standard resistance:

- Below 1 Ω

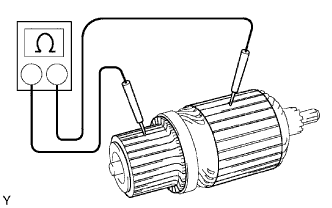

Measure the resistance between the commutator and armature coil core.

- Standard resistance:

- 10 kΩ or higher

Check the surface of the commutator for dirt or burns.

If the surface is dirty or burnt, smooth it with 400-grit sandpaper or lathe it.

Using vernier calipers, measure the commutator diameter.

- Standard diameter:

- 35.0 mm (1.378 in.)

- Minimum diameter:

- 34.0 mm (1.339 in.)

|

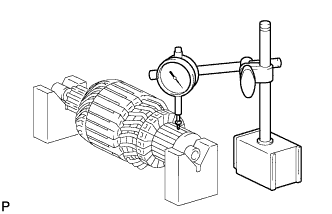

Using a dial indicator, measure the commutator's runout.

- Maximum commutator's runout:

- 0.05 mm (0.0020 in.)

|

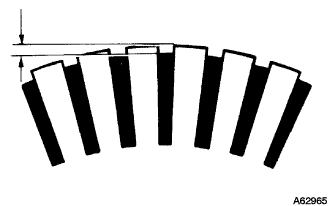

Check that the undercut depth is clean and free of foreign materials. Smooth out the edge.

- Standard undercut depth:

- 0.7 mm (0.028 in.)

- Minimum undercut depth:

- 0.2 mm (0.008 in.)

|

| 3. INSPECT STARTER YOKE ASSEMBLY |

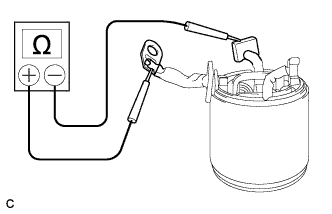

Inspect the resistance of the field coil.

Measure the resistance between the lead wire and field coil brush lead.

- Standard resistance:

- Below 1 Ω

Measure the resistance between the field coil end and field frame.

- Standard resistance:

- 10 kΩ or higher

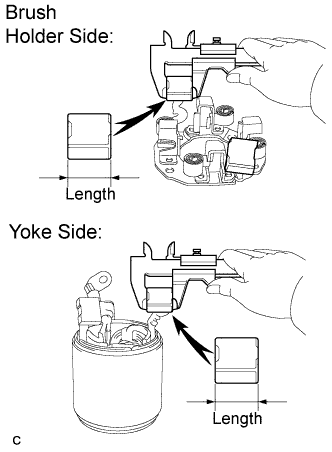

| 4. INSPECT BRUSH |

Using vernier calipers, measure the brush length.

- Standard length:

- 15 mm (0.591 in.)

- Minimum length:

- 10.0 mm (0.394 in.)

|

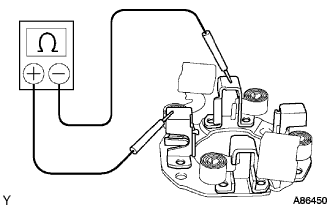

| 5. INSPECT STARTER BRUSH HOLDER ASSEMBLY |

Inspect the insulation.

Measure the resistance between the positive (+) and negative (-) brush holders.

- Standard resistance:

- 10 kΩ or higher

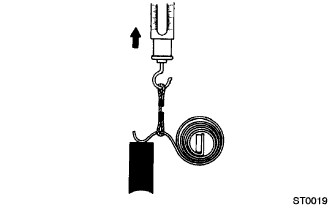

Inspect the load of the brush spring.

Take the pull scale reading immediately after the brush spring separates from the brush.

- Standard spring installed load:

- 22 to 28 N (2 to 3 kgf, 4.8 to 6.2 lbf)

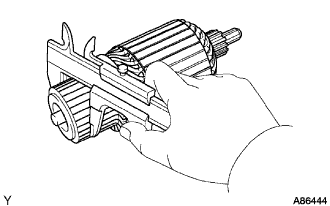

| 6. INSPECT STARTER CENTER BEARING CLUTCH SUB-ASSEMBLY |

Check the gear teeth of the planetary gear and starter center bearing clutch for wear or damage.

If any planetary gear is damaged, replace the planetary gear assembly.

If any gear of the starter center bearing clutch is damaged, replace the starter center bearing clutch sub-assembly.

Check the movement of the clutch pinion gear.

Rotate the clutch pinion gear clockwise, and check that it turns freely.

Try to rotate the clutch pinion gear counterclockwise, and check that it locks.

If the clutch pinion gear cannot be turned clockwise smoothly, or does not lock in the counterclockwise direction, replace the starter center bearing clutch sub-assembly.

|

| 7. INSPECT STARTER MAGNETIC SWITCH ASSEMBLY |

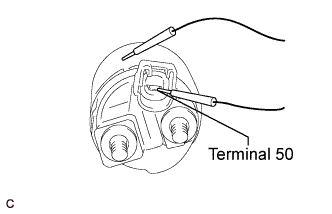

Inspect the resistance of the pull-in coil.

Measure the resistance between terminals 50 and C.

- Standard resistance:

- Below 1 Ω

Inspect the resistance of the hold-in coil.

Measure the resistance between terminal 50 and the switch body.

- Standard resistance:

- Below 2 Ω