Блок Механической Трансмиссии В Блоке С Главной Передачей Повторная Сборка. Corolla ZZE150

INSTALL SHIFT FORK SHAFT BEARING

INSTALL OUTPUT SHAFT COVER

INSTALL NO. 2 OUTPUT SHAFT FRONT BEARING OUTER RACE

INSTALL OUTPUT SHAFT COVER

INSTALL OUTPUT SHAFT FRONT BEARING

INSTALL TRANSAXLE CASE OIL SEAL

INSTALL INPUT SHAFT FRONT BEARING

INSTALL INPUT SHAFT REAR BEARING SHAFT SNAP RING

INSTALL OUTPUT SHAFT REAR BEARING SHAFT SNAP RING

INSTALL SHIFT AND SELECT LEVER SHAFT NEEDLE ROLLER BEARING

INSTALL SHIFT FORK SHAFT BEARING

INSTALL FRONT DIFFERENTIAL CASE FRONT BEARING OUTER RACE

INSTALL FRONT DIFFERENTIAL CASE REAR SHIM

INSTALL FRONT DIFFERENTIAL CASE REAR BEARING OUTER RACE

ADJUST DIFFERENTIAL SIDE BEARING PRELOAD

INSTALL NO. 2 OUTPUT SHAFT REAR BEARING OUTER RACE

ADJUST NO. 2 OUTPUT SHAFT REAR BEARING PRELOAD

INSTALL TRANSMISSION MAGNET

INSTALL FRONT DIFFERENTIAL CASE ASSEMBLY

INSTALL TRANSMISSION OIL SEPARATOR

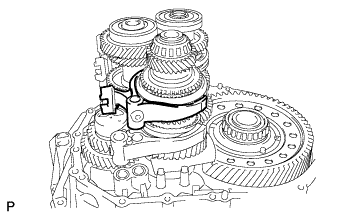

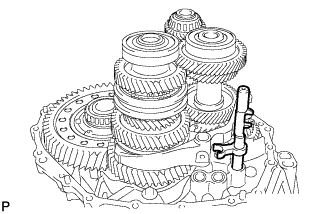

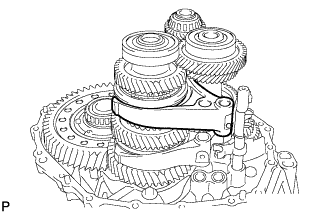

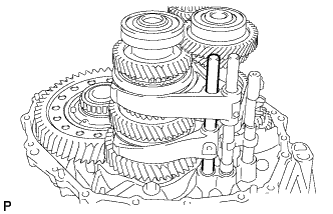

INSTALL INPUT SHAFT, NO. 1 OUTPUT SHAFT AND NO. 2 OUTPUT SHAFT

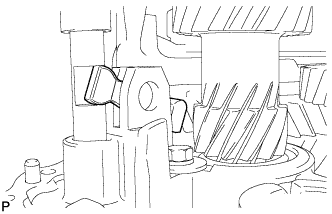

INSTALL REVERSE IDLER GEAR

INSTALL REVERSE SHIFT FORK

INSTALL NO. 3 GEAR SHIFT FORK

INSTALL 5TH AND 6TH SHIFT FORK SHAFT

INSTALL REVERSE SHIFT FORK SHAFT

INSTALL SHIFT ARM

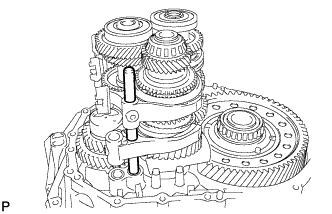

INSTALL NO. 1 GEAR SHIFT FORK

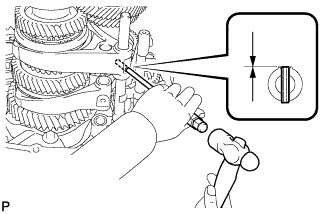

INSTALL NO. 5 GEAR SHIFT FORK SHAFT

INSTALL NO. 2 GEAR SHIFT FORK

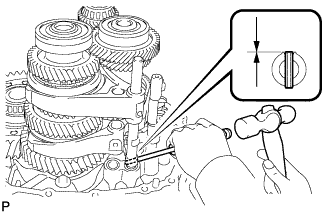

INSTALL 3RD AND 4TH SHIFT FORK SHAFT

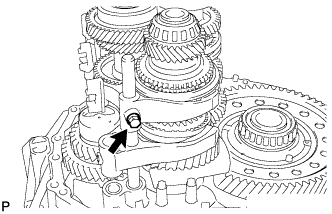

INSTALL 1ST AND 2ND SHIFT FORK SHAFT

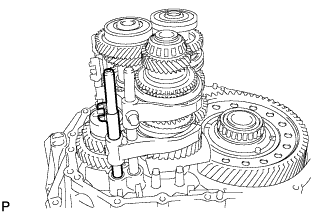

INSTALL TRANSMISSION OIL SEPARATOR

INSTALL NO. 1 OIL RECEIVER PIPE

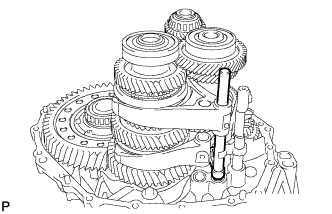

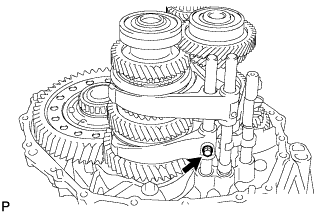

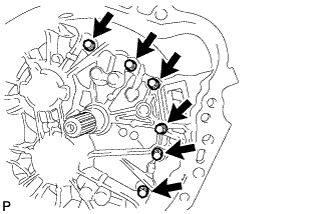

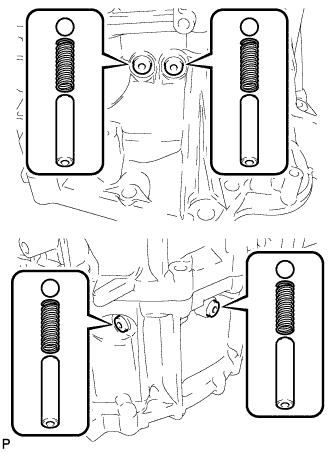

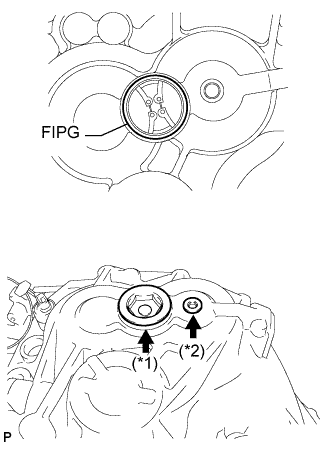

INSTALL MANUAL TRANSMISSION CASE

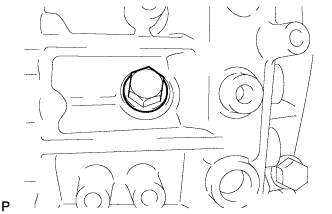

INSTALL REVERSE IDLER GEAR SHAFT BOLT

INSTALL SHIFT DETENT BALL

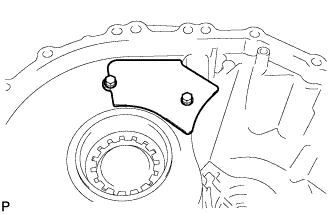

INSTALL MANUAL TRANSMISSION CASE PLUG

INSTALL MANUAL TRANSMISSION FILLER PLUG

INSTALL DRAIN PLUG

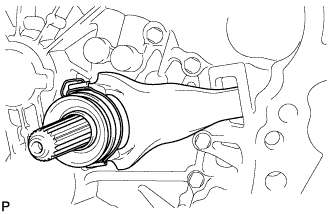

INSTALL TRANSMISSION CASE OIL SEAL

INSTALL TRANSAXLE CASE OIL SEAL

INSTALL CONTROL SHAFT COVER

INSTALL SHIFT GATE PIN

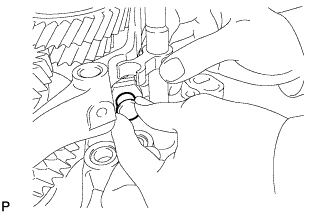

INSTALL NO. 2 LOCK BALL ASSEMBLY

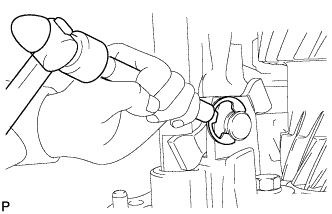

INSTALL NO. 1 LOCK BALL ASSEMBLY

INSTALL BACK-UP LIGHT SWITCH ASSEMBLY

INSTALL SELECTING BELL CRANK ASSEMBLY

INSTALL CONTROL CABLE BRACKET

INSTALL CLUTCH RELEASE FORK BOOT

INSTALL RELEASE FORK SUPPORT

INSTALL CLUTCH RELEASE BEARING ASSEMBLY

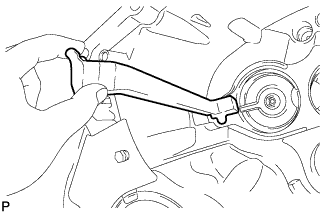

INSTALL CLUTCH RELEASE FORK SUB-ASSEMBLY

Блок Механической Трансмиссии В Блоке С Главной Передачей -- Повторная Сборка |

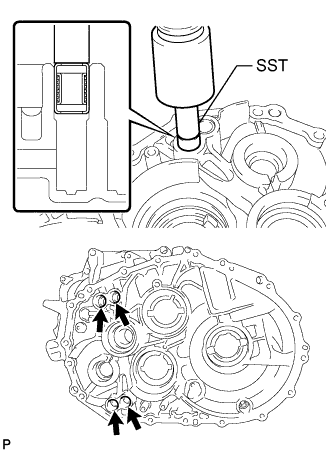

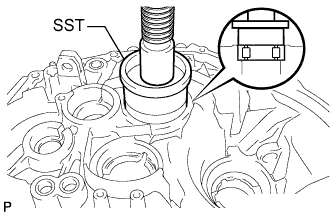

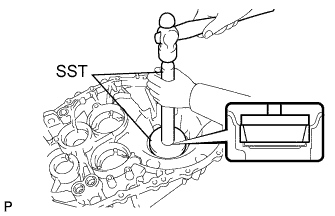

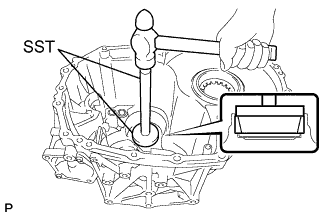

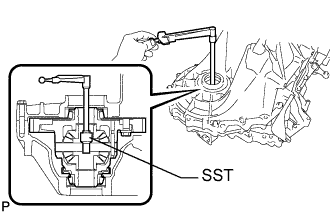

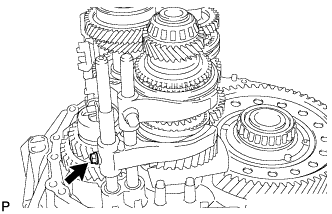

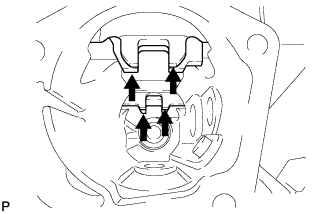

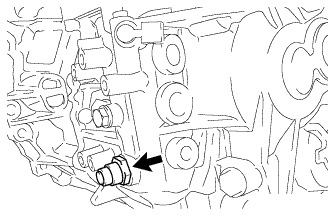

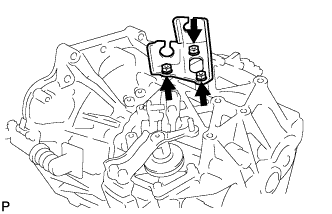

| 1. INSTALL SHIFT FORK SHAFT BEARING |

Using SST and a press, press in 4 new shift fork shaft bearings to the front transaxle case.

- SST

- 09820-00031

- Clearance:

- 0 to 0.5 mm (0.000 to 0.0197 in.)

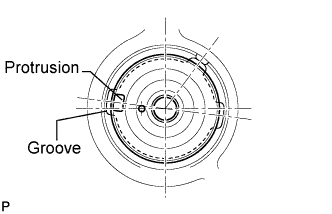

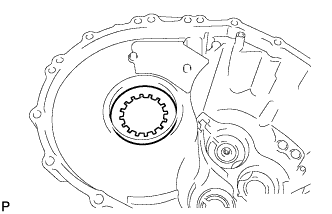

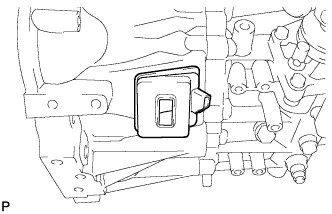

| 2. INSTALL OUTPUT SHAFT COVER |

Align the protrusion on the output shaft cover with the groove in the transaxle case, as shown in the illustration, and install the cover to the transaxle case.

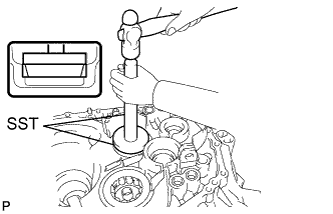

| 3. INSTALL NO. 2 OUTPUT SHAFT FRONT BEARING OUTER RACE |

Using SST and a hammer, install the No. 2 output shaft front bearing outer race to the front transaxle case.

- SST

- 09950-70010(09951-07100)

09950-60020(09951-00710)

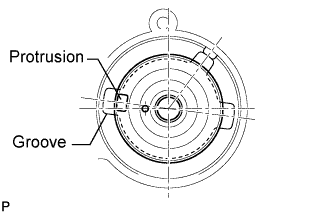

| 4. INSTALL OUTPUT SHAFT COVER |

Align the protrusion on the output shaft cover with the groove in the transaxle case, as shown in the illustration, and install the cover to the transaxle case.

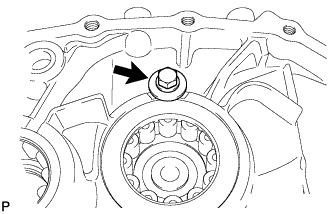

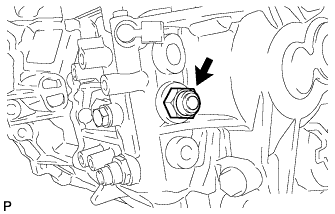

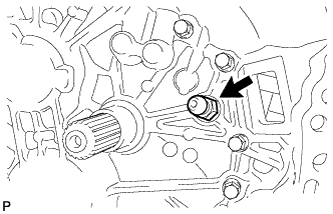

| 5. INSTALL OUTPUT SHAFT FRONT BEARING |

Coat a new output shaft front bearing with gear oil. Using SST and a press, install the bearing to the front transaxle case.

- SST

- 09223-15020

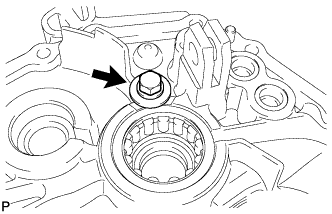

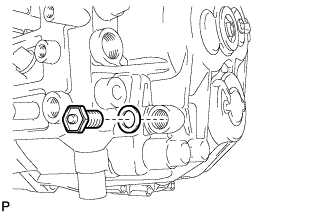

Install the bolt to the front transaxle case.

- Момент затяжки:

- 11 Н*м{112 кгс*см, 8 фунт-сила-футов}

| 6. INSTALL TRANSAXLE CASE OIL SEAL |

Using SST and a hammer, install a new transaxle case oil seal to the front transaxle case.

- SST

- 09950-60010(09951-00580)

- Drive in depth:

- 4.4 to 5.0 mm (0.1732 to 0.1969 in.)

Coat a new oil seal lip with MP grease.

| 7. INSTALL INPUT SHAFT FRONT BEARING |

Coat a new input shaft front bearing with gear oil. Using SST and a press, install the bearing to the front transaxle case.

- SST

- 09223-00010

Install the bearing lock plate bolt.

- Момент затяжки:

- 11 Н*м{112 кгс*см, 8 фунт-сила-футов}

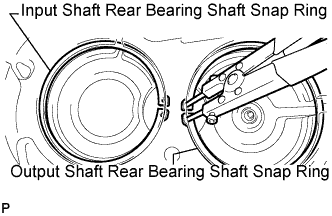

| 8. INSTALL INPUT SHAFT REAR BEARING SHAFT SNAP RING |

Using snap ring pliers, install the snap ring.

| 9. INSTALL OUTPUT SHAFT REAR BEARING SHAFT SNAP RING |

Using snap ring pliers, install the snap ring.

| 10. INSTALL SHIFT AND SELECT LEVER SHAFT NEEDLE ROLLER BEARING |

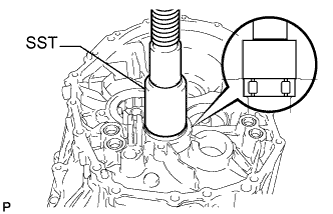

Using SST and a press, press in a new shift and select lever shaft needle roller bearing to the manual transmission case.

- SST

- 09285-76010

- Clearance:

- 177.8 to 178.7 mm (7.0000 to 7.0354 in.)

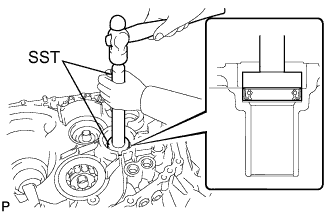

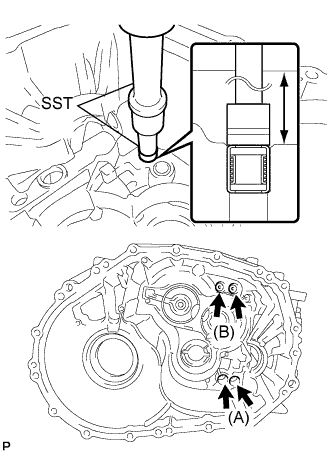

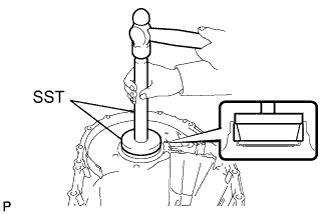

| 11. INSTALL SHIFT FORK SHAFT BEARING |

Using SST and a press, press in 4 new shift fork shaft bearings.

- SST

- 09307-12010

09820-00031

- Clearance A:

- 168.2 to 169.3 mm (6.6220 to 6.6653 in.)

- Clearance B:

- 162.2 to 163.3 mm (6.3858 to 6.4291 in.)

| 12. INSTALL FRONT DIFFERENTIAL CASE FRONT BEARING OUTER RACE |

Using SST and a hammer, install the front differential case front bearing outer race.

- SST

- 09950-60020(09951-00910)

09950-70010(09951-07150)

| 13. INSTALL FRONT DIFFERENTIAL CASE REAR SHIM |

Install the front differential case rear shim into the manual transmission case.

| 14. INSTALL FRONT DIFFERENTIAL CASE REAR BEARING OUTER RACE |

Using SST and a hammer, install the front differential case rear bearing outer race to the manual transmission case.

- SST

- 09950-60020(09951-00910)

09950-70010(09951-07100)

| 15. ADJUST DIFFERENTIAL SIDE BEARING PRELOAD |

Install the differential case assembly to the front transaxle case.

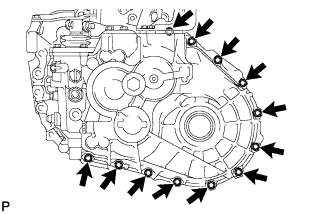

Install the manual transmission case to the front transaxle case with the 12 bolts.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

Install the 6 bolts on the manual transaxle case side.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

Turn the differential case in both directions to settle it.

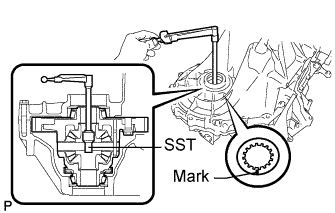

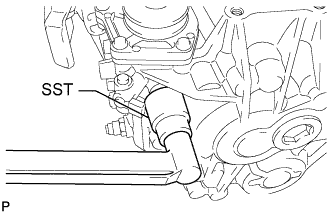

Using SST and a torque wrench, measure the starting preload.

- SST

- 09564-32011

- Bearing preload:

- 1.00 to 2.49 N*m (10.2 to 25.4 kgf*cm, 8.85 to 22.04 in.*lbf)

Select a new shim.

Mark

| Thickness mm (in.)

| Mark

| Thickness mm (in.)

| Mark

| Thickness mm (in.)

|

0

| 1.99 to 2.01

(0.0783 to 0.0791)

| 6

| 2.29 to 2.31

(0.0902 to 0.0909)

| C

| 2.59 to 2.61

(0.1020 to 0.1028)

|

1

| 2.04 to 2.06

(0.0803 to 0.0811)

| 7

| 2.34 to 2.36

(0.0921 to 0.0929)

| D

| 2.64 to 2.66

(0.1039 to 0.1047)

|

2

| 2.09 to 2.11

(0.0823 to 0.0831)

| 8

| 2.39 to 2.41

(0.0941 to 0.0949)

| E

| 2.69 to 2.71

(0.1059 to 0.1067)

|

3

| 2.14 to 2.16

(0.0843 to 0.0850)

| 9

| 2.44 to 2.46

(0.0961 to 0.0969)

| F

| 2.74 to 2.76

(0.1079 to 0.1087)

|

4

| 2.19 to 2.21

(0.0862 to 0.0870)

| A

| 2.49 to 2.51

(0.0980 to 0.0988)

| G

| 2.79 to 2.81

(0.1098 to 0.1106)

|

5

| 2.24 to 2.26

(0.0882 to 0.0890)

| B

| 2.54 to 2.56

(0.1000 to 0.1008)

| H

| 2.84 to 2.86

(0.1118 to 0.1126)

|

Remove the manual transmission case from the front transaxle case.

Remove the 18 bolts and manual transmission case.

| 16. INSTALL NO. 2 OUTPUT SHAFT REAR BEARING OUTER RACE |

Install the output shaft rear bearing shim onto the manual transmission case.

- УКАЗАНИЕ:

- When reusing the output shaft rear bearing, first install a shim of the same thickness as the original. When installing a new output shaft rear bearing, first select and install a shim which is thinner than the original.

Using SST and a press, press in the No. 2 output shaft rear bearing outer race.

- SST

- 09950-60010(09951-00650)

09950-70010(09951-07200)

| 17. ADJUST NO. 2 OUTPUT SHAFT REAR BEARING PRELOAD |

Install the No. 2 output shaft and differential case onto the front transaxle case.

Install the manual transmission case to the front transaxle case with the 12 bolts.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

Install the 6 bolts on the manual transaxle case side.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

Using SST, measure the No. 2 output shaft rear bearing preload. Subtract the value of the differential side bearing preload from the measured No. 2 output shaft rear bearing preload. Select a shim that will set the preload within the specified range below and install the shim.

- SST

- 09564-32011

- Bearing preload:

- 3.89 to 5.51 N*m (40 to 56 kgf*cm, 34 to 49 in.*lbf)

Mark

| Thickness mm (in.)

| Mark

| Thickness mm (in.)

| Mark

| Thickness mm (in.)

|

A

| 1.79 to 1.81

(0.0705 to 0.0713)

| G

| 2.09 to 2.11

(0.0823 to 0.0831)

| N

| 2.39 to 2.41

(0.0941 to 0.0949)

|

B

| 1.84 to 1.86

(0.0724 to 0.0732)

| H

| 2.14 to 2.16

(0.0843 to 0.0850)

| P

| 2.44 to 2.46

(0.0961 to 0.0969)

|

C

| 1.89 to 1.91

(0.0744 to 0.0752)

| J

| 2.19 to 2.21

(0.0862 to 0.0870)

| Q

| 2.49 to 2.51

(0.0980 to 0.0988)

|

D

| 1.94 to 1.96

(0.0764 to 0.0772)

| K

| 2.24 to 2.26

(0.0882 to 0.0890)

| R

| 2.54 to 2.56

(0.1000 to 0.1008)

|

E

| 1.99 to 2.01

(0.0783 to 0.0791)

| L

| 2.29 to 2.31

(0.0902 to 0.0909)

| S

| 2.59 to 2.61

(0.1020 to 0.1028)

|

F

| 2.04 to 2.06

(0.0803 to 0.0811)

| M

| 2.34 to 2.36

(0.0921 to 0.0929)

| T

| 2.64 to 2.66

(0.1039 to 0.1047)

|

Remove the manual transmission case.

Remove the 18 bolts and manual transmission case.

Remove the output shaft assembly from the front transaxle case.

Remove the differential case from the front transaxle case.

| 18. INSTALL TRANSMISSION MAGNET |

Clean and reinstall the transmission magnet to the front transaxle case.

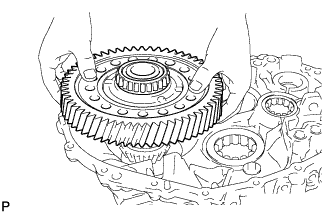

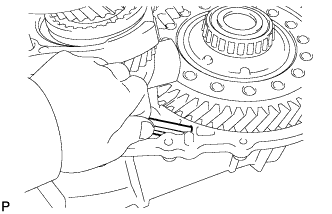

| 19. INSTALL FRONT DIFFERENTIAL CASE ASSEMBLY |

Coat the differential case tapered roller bearing with gear oil and install it to the front transaxle case.

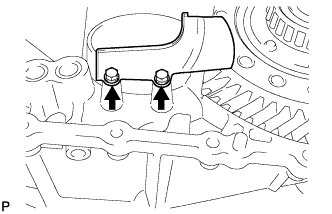

| 20. INSTALL TRANSMISSION OIL SEPARATOR |

Install the transmission oil separator onto the front transaxle case with the 2 bolts.

- Момент затяжки:

- 8.5 Н*м{87 кгс*см, 75 фунт-сила-дюймов}

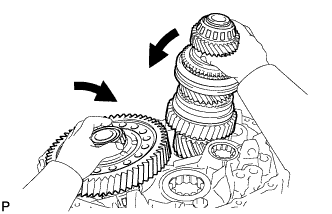

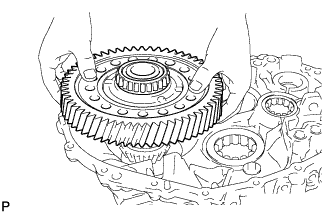

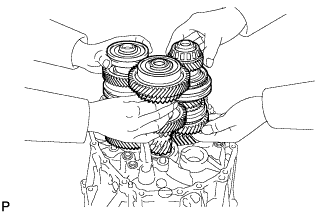

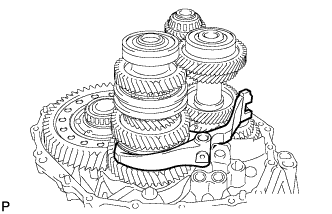

| 21. INSTALL INPUT SHAFT, NO. 1 OUTPUT SHAFT AND NO. 2 OUTPUT SHAFT |

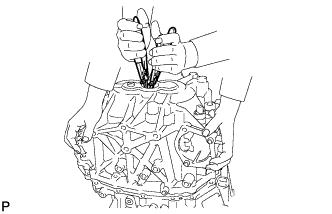

Install the 3 shafts at the same time.

- УКАЗАНИЕ:

- Use an assistant if necessary.

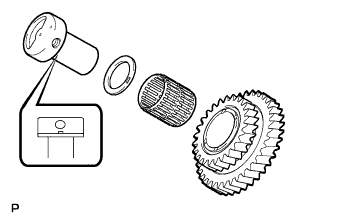

| 22. INSTALL REVERSE IDLER GEAR |

Coat the reverse idler gear, needle roller bearing, and reverse idler thrust washer with MP grease, and install them to the reverse idler gear shaft.

- УКАЗАНИЕ:

- Make sure that the protruding part on the reverse idler thrust washer is fitted into the groove of the reverse idler shaft.

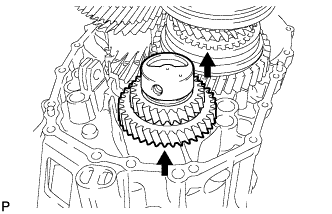

Install the reverse idler gear shaft by sliding and lifting it.

- УКАЗАНИЕ:

- Slide the gear in from the side with the reverse idler gear shaft lifted.

- After installing the gear and shaft, make sure that the protruding part of the reverse idler thrust washer is correctly fitted into the groove of the reverse idler gear shaft.

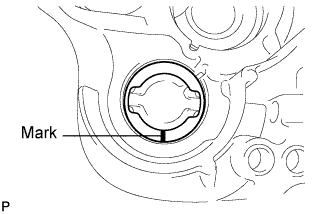

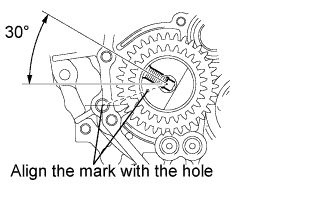

Align the mark of the reverse idler gear shaft with the knock pin hole.

| 23. INSTALL REVERSE SHIFT FORK |

Install the reverse shift fork onto the No. 4 hub sleeve.

| 24. INSTALL NO. 3 GEAR SHIFT FORK |

Install the No. 3 gear shift fork onto the No. 3 hub sleeve.

| 25. INSTALL 5TH AND 6TH SHIFT FORK SHAFT |

Install the 5th and 6th shift fork shaft onto the front transaxle case.

Install the bolt to the No. 3 gear shift fork.

- Момент затяжки:

- 20 Н*м{204 кгс*см, 14 фунт-сила-футов}

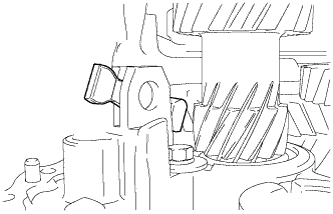

| 26. INSTALL REVERSE SHIFT FORK SHAFT |

Install the reverse shift fork shaft into the front transaxle case.

Install the bolt to the reverse shift fork.

- Момент затяжки:

- 20 Н*м{204 кгс*см, 14 фунт-сила-футов}

Install the shift arm into the front transaxle case.

| 28. INSTALL NO. 1 GEAR SHIFT FORK |

Install the No. 1 gear shift fork onto the No. 1 hub sleeve.

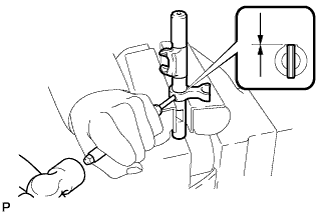

| 29. INSTALL NO. 5 GEAR SHIFT FORK SHAFT |

Install the No. 3 gear shift head to the No. 5 gear shift fork shaft.

Using a pin punch and hammer, drive the slotted pin into the No. 3 gear shift head.

- Depth:

- -0.5 to 0.5 mm (-0.0197 to 0.0197 in.)

Install the No. 5 gear shift fork shaft into the front transaxle case.

Assemble the shift arm and No. 5 gear shift fork shaft.

Install the shift arm pin to the shift arm.

Using a brass bar and hammer, install a new E-ring onto the shift arm pin.

| 30. INSTALL NO. 2 GEAR SHIFT FORK |

Install the No. 2 gear shift fork onto the No. 2 hub sleeve.

| 31. INSTALL 3RD AND 4TH SHIFT FORK SHAFT |

Install the No. 2 gear shift head to the 3rd and 4th shift fork shaft.

Install the 3rd and 4th shift fork shaft to the transmission case.

Using a pin punch and hammer, drive a new slotted spring pin into the No. 2 gear shift fork.

- Drive in depth :

- -0.5 to 0.5 mm (-0.0197 to 0.0197 in.)

Using a pin punch and hammer, drive the slotted spring pin into the No. 2 gear shift head.

- Drive in depth :

- -0.5 to 0.5 mm (-0.0197 to 0.0197 in.)

| 32. INSTALL 1ST AND 2ND SHIFT FORK SHAFT |

Install the 1st and 2nd shift fork shaft into the front transaxle case.

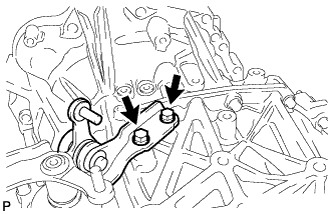

Install the bolt to the No. 1 gear shift fork.

- Момент затяжки:

- 20 Н*м{204 кгс*см, 14 фунт-сила-футов}

| 33. INSTALL TRANSMISSION OIL SEPARATOR |

Install the transmission oil separator onto the manual transmission case with the 2 bolts.

- Момент затяжки:

- 8.5 Н*м{87 кгс*см, 75 фунт-сила-дюймов}

| 34. INSTALL NO. 1 OIL RECEIVER PIPE |

Install the No. 1 oil receiver pipe onto the manual transmission case.

- ПРИМЕЧАНИЕ:

- Do not damage the No. 1 oil receiver pipe.

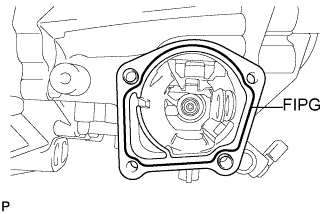

| 35. INSTALL MANUAL TRANSMISSION CASE |

Clean the seal packing off of on the manual transmission case and front transaxle case using a scraper and wire brush. Then remove the oil with non-residue solvent.

- ПРИМЕЧАНИЕ:

- Do not scratch the fitting surface.

- Confirm that the mark on the reverse idler gear shaft is correctly aligned before installing the transmission case.

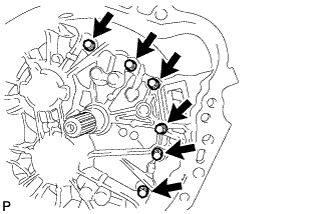

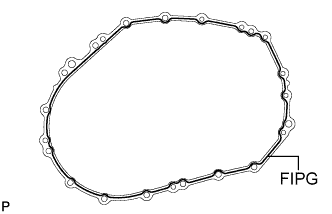

Apply FIPG to the manual transmission case as shown in the illustration.

- FIPG:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- ПРИМЕЧАНИЕ:

- Assemble the parts within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

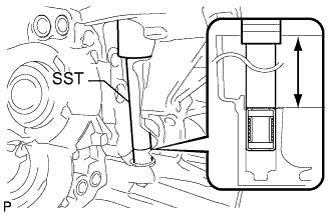

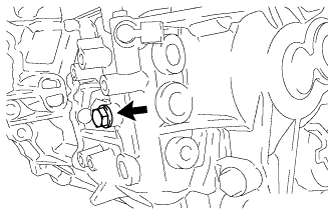

Use 2 pairs of snap ring pliers to keep the snap rings stretched and install the manual transmission case.

- УКАЗАНИЕ:

- Use an assistant if necessary.

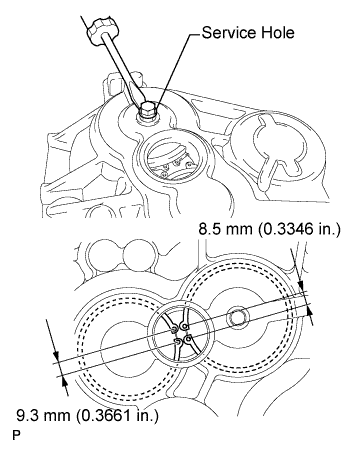

Install the bolt to the No. 1 output shaft and lift the bolt from the service hole as shown in the illustration. Make sure that the snap rings are positioned correctly in the bearing grooves by checking that the distances between the centers of the snap ring holes are as shown in the illustration.

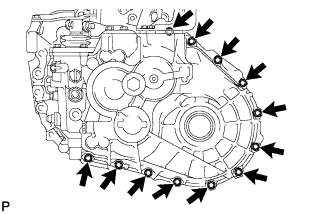

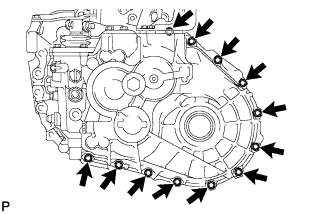

Install the manual transmission case to the front transaxle case with the 12 bolts.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

Install the manual transmission case to the front transaxle case with the 6 bolts.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

| 36. INSTALL REVERSE IDLER GEAR SHAFT BOLT |

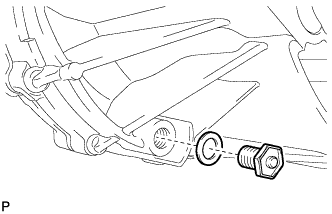

Coat the threads of the reverse idler gear shaft bolt with sealant and install it with a new gasket.

- Sealant:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

- Момент затяжки:

- 80 Н*м{816 кгс*см, 59 фунт-сила-футов}

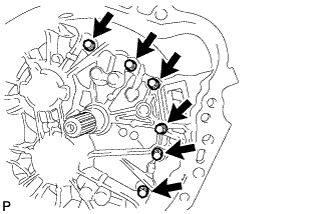

| 37. INSTALL SHIFT DETENT BALL |

Coat the threads of the 4 shift detent ball plugs with sealant.

- Sealant:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the 4 balls, 4 springs, 4 spring seats, and 4 shift detent ball plugs using a hexagon wrench (6 mm).

- Момент затяжки:

- 22 Н*м{228 кгс*см, 17 фунт-сила-футов}

| 38. INSTALL MANUAL TRANSMISSION CASE PLUG |

Clean the seal packing off of the manual transmission case using a scraper and wire brush. Then remove the oil with non-residue solvent or equivalent.

- ПРИМЕЧАНИЕ:

- Do not scratch the fitting surface.

Apply FIPG to the manual transmission case as shown in the illustration.

- FIPG:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- ПРИМЕЧАНИЕ:

- Assemble the parts within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

Coat the threads of the transmission case plugs with sealant.

- Sealant:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the manual transmission case plugs to the manual transmission case.

- Момент затяжки:

- Case plug *1:

- 55 Н*м{561 кгс*см, 41 фунт-сила-футов}

- Case plug *2:

- 22 Н*м{228 кгс*см, 17 фунт-сила-футов}

| 39. INSTALL MANUAL TRANSMISSION FILLER PLUG |

Install the manual transmission filler plug with a new gasket.

- Момент затяжки:

- 39 Н*м{400 кгс*см, 29 фунт-сила-футов}

Install the manual transmission drain plug sub-assembly with a new gasket.

- Момент затяжки:

- 39 Н*м{400 кгс*см, 29 фунт-сила-футов}

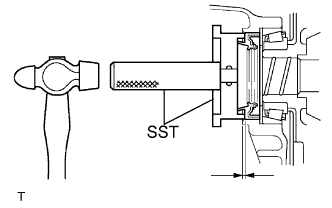

| 41. INSTALL TRANSMISSION CASE OIL SEAL |

Coat a new oil seal lip with MP grease.

Using SST and a hammer, install the transmission case oil seal.

- SST

- 09608-10010

09950-70010(09951-07200)

- Drive in depth:

- -0.5 to 0.5 mm (-0.0197 to 0.0197 in.)

- ПРИМЕЧАНИЕ:

- Do not damage the oil seal lip.

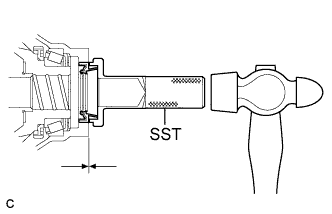

| 42. INSTALL TRANSAXLE CASE OIL SEAL |

Coat a new oil seal lip with MP grease.

Using SST and a hammer, install the transaxle case oil seal.

- SST

- 09554-22010

- Drive in depth:

- -0.5 to 0.5 mm (-0.0197 to 0.0197 in.)

- ПРИМЕЧАНИЕ:

- Do not damage the oil seal lip.

| 43. INSTALL CONTROL SHAFT COVER |

Align the 4 shift fork shafts as shown in the illustration.

Clean the seal packing off of the manual transmission case and control shaft cover using a scraper and wire brush. Then remove the oil with non-residue solvent.

- ПРИМЕЧАНИЕ:

- Do not scratch the fitting surface.

Apply FIPG to the manual transmission case as shown in the illustration.

- FIPG:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent

- ПРИМЕЧАНИЕ:

- Assemble the parts within 10 minutes of application. Otherwise, the packing (FIPG) material must be removed and reapplied.

Coat the threads of the 4 bolts with sealant.

- Sealant:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the shift and select lever assembly to the manual transmission case with the 4 bolts.

- Момент затяжки:

- 19 Н*м{190 кгс*см, 14 фунт-сила-футов}

| 44. INSTALL SHIFT GATE PIN |

Coat the threads of the shift gate pin with sealant.

- Sealant:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the shift gate pin to the manual transmission case.

- Момент затяжки:

- 30 Н*м{306 кгс*см, 22 фунт-сила-футов}

| 45. INSTALL NO. 2 LOCK BALL ASSEMBLY |

Coat the threads of the No. 2 lock ball assembly with sealant.

- Sealant:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the No. 2 lock ball assembly to the manual transmission case.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

| 46. INSTALL NO. 1 LOCK BALL ASSEMBLY |

Coat the threads of the No. 1 lock ball assembly with sealant.

- Sealant:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

Install the No. 1 lock ball assembly to the manual transmission case.

- Момент затяжки:

- 39 Н*м{400 кгс*см, 29 фунт-сила-футов}

| 47. INSTALL BACK-UP LIGHT SWITCH ASSEMBLY |

Install the back-up light switch assembly to the manual transmission case with a new gasket.

- SST

- 09816-30010

- Момент затяжки:

- 40 Н*м{410 кгс*см, 30 фунт-сила-футов}

| 48. INSTALL SELECTING BELL CRANK ASSEMBLY |

Coat the threads of the 2 bolts with sealant and install the selecting bell crank assembly to the manual transmission case with the 2 bolts.

- Sealant:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

- Момент затяжки:

- 20 Н*м{204 кгс*см, 15 фунт-сила-футов}

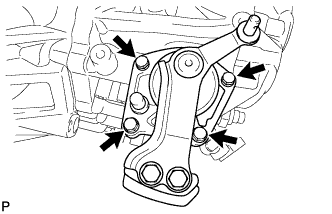

| 49. INSTALL CONTROL CABLE BRACKET |

Install the control cable bracket onto the manual transaxle case with the 3 bolts.

- Sealant:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

- Момент затяжки:

- 17 Н*м{173 кгс*см, 13 фунт-сила-футов}

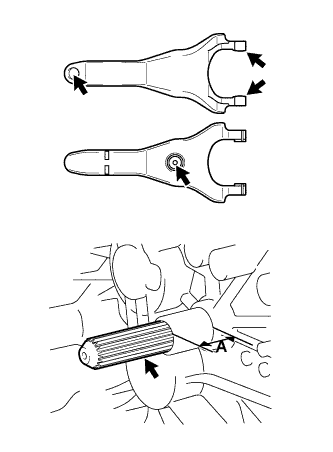

| 50. INSTALL CLUTCH RELEASE FORK BOOT |

Install the clutch release fork boot onto the manual transaxle case.

| 51. INSTALL RELEASE FORK SUPPORT |

Using a deep socket wrench, install the release fork support to the front transaxle case.

- Момент затяжки:

- 37 Н*м{375 кгс*см, 27 фунт-сила-футов}

| 52. INSTALL CLUTCH RELEASE BEARING ASSEMBLY |

Apply release hub grease to the release fork and release bearing assembly contact, release fork sub-assembly and push rod contact, and release fork pivot points.

- Sealant:

- Toyota Genuine Release Hub Grease or equivalent

Apply clutch sealant grease to the spline coupling part.

- Sealant:

- Toyota Genuine Clutch Spline Grease or equivalent

- ПРИМЕЧАНИЕ:

- Do not apply grease to portion A shown in the illustration.

Install the clutch release bearing assembly to the clutch release fork sub-assembly with the clutch release bearing clip.

| 53. INSTALL CLUTCH RELEASE FORK SUB-ASSEMBLY |

Install the bearing to the release fork, and then install them to the transaxle assembly.