Система Механической Трансмиссии 'Multimode' -- Описание Системы |

| MULTI-MODE MANUAL TRANSAXLE SYSTEM OUTLINE |

The multi-mode manual transaxle has been developed from the conventional manual transaxle by adding actuators that are directly controlled by electric motors. The transaxle control system consists of an electronic throttle control system, clutch actuator, shift and select actuator, sensors, a shift lever, and a TCM. The system offers automatic clutch operation and two driving modes: automatic shifting E mode and manual shifting M mode.

The stroke sensors, which are mounted on each actuator and detect the actuator operating position, are double non-contact type.

The multi-mode manual transaxle is equipped with a clutch actuator, which has a motor for clutch engagement, and a shift and select actuator, which has two motors for shifting and selecting gear shafts that have been used on the conventional manual transaxle. Each actuator operates in accordance with signals from the TCM. The TCM receives information from the ECM and sensors, and controls the engine and multi-mode manual transaxle.

The shift lever features a Shift-by-Wire System that electrically detects the shift lever position chosen by the driver and sends a shift lever position signal to the TCM to control the transaxle.

The shift lever has an electrical shift lock mechanism. When the ignition switch is turned off or the shift lever is in the N position with the engine running and the brake pedal released, the shift lever is locked in the current shift position.

The multi-mode manual transaxle system has fail-safe functions. When the TCM detects a malfunction in the system, the ECU illuminates the Multi-mode Manual Transmission Warning Light (MMT Warning Light) to inform the driver that a malfunction has occurred. If necessary, the ECU illuminates the Malfunction Indicator Lamp (MIL) and MMT Warning Light simultaneously. Under such conditions, the fail-safe function allows the vehicle to be operated in order to avoid emergency situations.

If the clutch temperature exceeds the specified level, the multi-mode manual transaxle system will sound a buzzer (intermittently sound) and blink the MMT Warning Light (the blinks do not indicate a malfunction) to warn the driver.

| FUNCTIONS OF MAIN COMPONENTS |

|

- УКАЗАНИЕ:

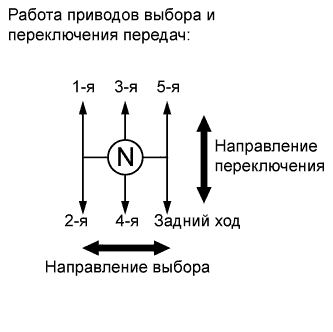

- *: Shift and select directions are as shown in the illustration.

| Components | Outlines |

| Combination meter (meter ECU) | Controls the operation of the indicator lights, warning light and buzzer. |

| Multi-mode manual transmission warning light (built into combination meter) | Illuminates to alert the driver when a malfunction occurs in the multi-mode manual transaxle system. |

| Gear position indicator (built into combination meter) | Indicates the present gear position. The indicator flashes if the actual gear position and the shift lever position do not match. |

| Mode indicator (built into combination meter) |

|

| Buzzer (built into combination meter) | Sounds if the following conditions are met simultaneously.

|

| Shift lever position sensor (built into shift lever assembly) | Outputs the shift lever position and shift request (+ or -) through the ON/OFF combination of the 6-contact switch and the 2-contact switch. |

| Transmission shift main switch (built into shift lever assembly) | Outputs the shift mode signal (E-mode or M-mode). |

| Shift lock solenoid (built into shift lever assembly) | Actuated by the TCM. Restricts the movement of the shift lever. |

| Shift motor (built into shift and select actuator) | Actuated by the TCM. Effects the shift operation of the shift and select lever shaft.* |

| Shift stroke sensor (built into shift and select actuator) | Detects the shift and select actuator operation position (shift direction).* |

| Select motor (built into shift and select actuator) | Actuated by the TCM. Effects the select operation of the shift and select lever shaft.* |

| Select stroke sensor (built into shift and select actuator) | Detects the shift and select actuator operation position (select direction).* |

| Clutch motor (built into clutch actuator) | Actuated by the TCM. Engages and disengages the clutch. |

| Clutch stroke sensor (built into clutch actuator) | Detects the pull rod position of the clutch actuator from the rotational angle of the worm wheel in the clutch actuator, and sends the signal to the TCM. |

| LCC (Load Controlled Clutch cover) | The diaphragm spring height of the LCC is adjusted to a predetermined position automatically, in order to apply a constant load to the clutch motor. |

| Transmission revolution sensor | Detects the input shaft speed of the transaxle and transmits it to the TCM. |

| Park/neutral position switch (built into transaxle assembly) | Detects whether the transaxle gear is in neutral. |

| Back-up light switch (built into transaxle assembly) | Detects whether the transaxle gear is in reverse, and illuminates the back-up lights. |

| Stop light switch | Detects whether the brake pedal is depressed or released. |

| Parking brake switch | Detects whether the parking brake lever is applied. |

| Pattern select [Es] switch | Outputs the driving pattern (Normal [E] pattern or Sporty [Es] pattern) in E-mode from the ON/OFF condition to the TCM. |

| TCM (Transmission control ECU) | Controls the multi-mode manual transaxle system and signals the ECM to effect engine control during up-shifting or down-shifting via CAN (Controller Area Network) communication. When the multi-mode manual transaxle system malfunctions, the TCM diagnoses and stores the malfunctioning areas. Furthermore, the multi-mode manual transmission warning light and malfunction indicator lamp are illuminated to inform the driver of malfunctions in the system. |

| Buzzer (built into TCM) | Sounds during system warning. While performing the initialization and learning or the clamp position adjustment without using the intelligent tester, the buzzer sounds to indicate the ECU mode change. |

| ECM | Outputs sensor information via CAN communication to the TCM. Performs engine control in accordance with signals from the TCM. |

| Accelerator pedal position sensor | Detects the accelerator pedal position and transmits signals to the ECM. |

| Crankshaft position sensor | Detects the engine speed and transmits signals to the TCM via the ECM. |

| Shift paddle switch | Moving the shift lever to the M or E position enables gear selection. The driver can select gears optionally by shifting the paddle to the [+] or [-]. |

| MULTI-MODE MANUAL TRANSAXLE SYSTEM CONTROL |

System start:

The multi-mode manual transaxle system starts when the ignition switch is turned on (IG). The shift lever can be operated when the ignition switch is on and the brake pedal is depressed. The engine starts when the ignition switch is turned to the START position (the engine switch is operated) with the brake pedal depressed and the gear in neutral.Start off/reverse assist control:

When the brake pedal is not depressed with the gear in 1st, 2nd or reverse, the clutch is half-engaged, even if the accelerator pedal is not depressed. As a result, the vehicle can creep slowly like an automatic transaxle vehicle. This will assist the vehicle in preparing to move. The take off assist control is cancelled while the parking brake switch is ON.- УКАЗАНИЕ:

- When shifting to reverse at a vehicle speed of 6 km/h (3.7 mph) or more, the reverse warning buzzer sounds, and the gear does not shift to reverse.

Shift control:

When up-shifting with the accelerator pedal depressed, the ECM restrains engine rev up in accordance with the request signal from the TCM.

[Automatic shift control (E and Es mode)]

When the shift lever is in the E position, the most appropriate gear is automatically selected in accordance with the accelerator pedal opening angle and vehicle speed. Turning the paddle switch to either "+" or "-" during automatic shift control enables the vehicle to run temporarily in a gear selected by the driver. (Automatic shift control will automatically resume.) In addition to this automatic shift control, LHD (Left Hand Drive) vehicles have kick down control. When the accelerator pedal is fully depressed until it is felt to click, the ECM for LHD vehicles interprets this as the kick down signal being received. The kick down signal affects the transmission shift control.

Shift control can be switched between normal (E) and sports (Es) modes by pressing the pattern select switch.

Normal (E) mode: Economical automatic shift control with emphasis on fuel economy

Sports (Es) mode: Automatic shift control with emphasis on driving performance

[Sequential shift control (M-mode)]

Moving the shift lever to the M position enables the gear selection. The driver can select any gear by shifting the shift lever to the [+] or [-] position, or by pulling [+] or [-] on the paddle switch.Ascent/descent shift control:

While driving in E-mode or Es-mode, the system operates to prevent excess shifting and obtain the proper driving force and engine brake power by estimating the road inclination based on the vehicle conditions.

[Ascent shift control]

On an ascent, up-shifting to the 3rd, 4th or 5th gear is prohibited, depending on the degree of road inclination.

[Descent shift control]

On a descent, the current gear position is maintained, depending on the degree of road inclination, to obtain engine brake power. When the brake pedal is depressed, the TCM automatically down shifts to improve the vehicle (driving force) control performance.Delta throttle accelerate control:

The TCM interprets a sudden ON or OFF operation of the accelerator pedal as a request by the driver to accelerate or decelerate, and makes the transaxle down-shift or shift-hold.

[Accelerator pedal rapid open control]

When the accelerator pedal is rapidly depressed, the system interprets it as an acceleration demand and advances the down-shift timing.

[Accelerator pedal sudden close control]

When the accelerator pedal is suddenly released, the system interprets it as a deceleration demand and ensures the engine brake power without changing gear. This also ensures there is sufficient driving force for the next acceleration stage.Control when the vehicle stops (stopping control):

The TCM automatically disengages the clutch when the input speed of the transmission revolution sensor falls below a specified speed. This enables the vehicle to stop without stalling. If the shift lever is in the E or M positions, the TCM shifts the gear to the most appropriate position when the vehicle speed decreases to less than a specified speed.- УКАЗАНИЕ:

- If the shift lever is kept in the N position for 2 seconds with the brake pedal released at a specified vehicle speed or less, the TCM locks the shift lever to prevent improper shift lever operation. When depressing the brake pedal, the shift lever is unlocked.

Control when the vehicle is parked (parking control):

When the ignition switch is turned off, the TCM locks the shift lever in the current position and engages the clutch to park the vehicle with the gear engaged.- УКАЗАНИЕ:

- The multi-mode manual transaxle system does not have a park position. The vehicle can be parked with the shift lever in any position (N, E, M or R). When the vehicle is parked with the shift lever in a position other than N, the vehicle is parked with the gear engaged. The gear may not engage when the ignition switch is turned off before the gearshift is complete. If the gear is not engaged when the ignition switch is turned off, a buzzer will sound and the gear position indicator will blink to warn the driver.

| MULTI-MODE MANUAL TRANSAXLE SYSTEM REMOVAL AND INSTALLATION PROCEDURES |

CLAMP POSITION ADJUSTMENT

- Preload is applied to the clutch actuator pull rod installed on the vehicle.

- Clamp position adjustment is necessary to position the pull rod when the clutch actuator is reinstalled.

- The pull rod position of a new clutch actuator is not suitable for clutch actuator installation. When installing a new clutch actuator, Clamp Position Adjustment must be performed before the installation.

- The pull rod position of a clutch actuator that has been installed on the vehicle is not suitable for clutch actuator reinstallation. Clamp Position Adjustment must be performed when removing the clutch actuator.

- For details of replacement, refer to CLAMP POSITION ADJUSTMENT (See page Нажмите здесь).

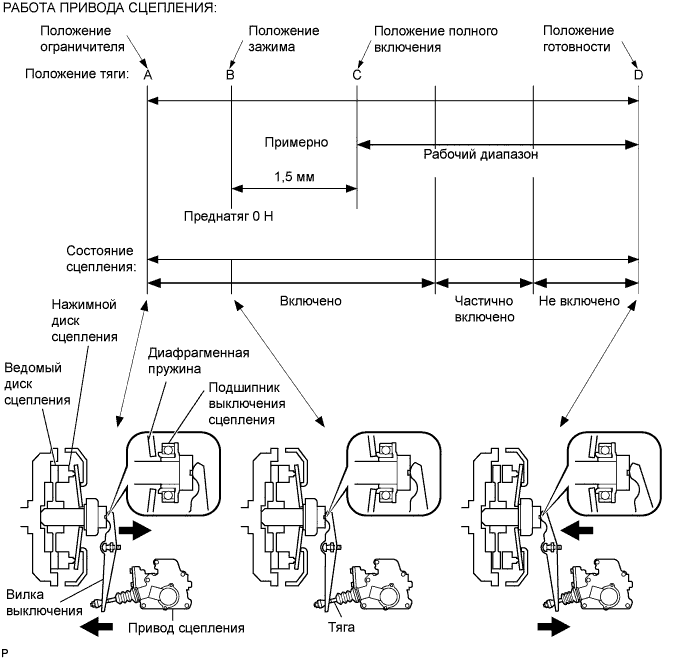

- Pull rod position A (Stopper position):

The stopper position is where the clutch actuator pull rod is fully extended. Clearance exists between the release bearing and diaphragm spring. - Pull rod position B (Clutch clamp position):

The clutch clamp position is where 0 N [newton] of preload is applied to the diaphragm spring. Removal or installation of the clutch actuator is possible at this point. No clearance exists between the release bearing and diaphragm spring. - Pull rod position C (Complete engagement position):

During normal clutch operation, the pull rod alternates between this position and the standby position (between C and D). When the system is stopped (while the ignition switch is off), the pull rod maintains this position. - Pull rod position D (Standby position):

The standby position is where the clutch actuator pull rod is retracted and the clutch is not engaged.

- Preload is applied to the clutch actuator pull rod installed on the vehicle.

REPLACEMENT OR REMOVAL/INSTALLATION OF MULTI-MODE MANUAL TRANSAXLE SYSTEM PARTS

Refer to the respective pages for each part.INITIALIZATION AND LEARNING

INITIALIZATION OF TRANSAXLE SYSTEM:

- The TCM stores information from each component, such as sensors and motors, to control the system.

- Sensors and motors that comprise the multi-mode manual transaxle system have individual specification values. The TCM learns and stores these values, and controls the multi-mode manual transaxle system. Therefore, the values stored in the TCM must be cleared when the sensor or actuator is replaced.

- Learning of the multi-mode manual transaxle system can be performed when there is no learning value in the ECU. It is therefore necessary to perform initialization of the TCM before performing learning of the multi-mode manual transaxle system.

- For details of replacement, refer to INITIALIZATION AND LEARNING (See page Нажмите здесь).

- The TCM stores information from each component, such as sensors and motors, to control the system.

LEARNING OF MULTI-MODE MANUAL TRANSAXLE SYSTEM:

- This operation is performed to store the individual specification values of components, such as sensors and actuators, in the TCM.

- For details of replacement, refer to INITIALIZATION AND LEARNING (See page Нажмите здесь).

- ПРИМЕЧАНИЕ:

- Perform this operation after initialization of the multi-mode manual transaxle system.

- This operation is performed to store the individual specification values of components, such as sensors and actuators, in the TCM.

SYNCHRONIZATION POSITION CALIBRATION

- The transaxle components have individual specification values. The TCM learns and stores those values, and controls the gearshift accurately. Synchronization position calibration corrects and adjusts the shift points appropriately in accordance with the individual specification values of the components.

- For details of replacement, (See page Нажмите здесь).

- The transaxle components have individual specification values. The TCM learns and stores those values, and controls the gearshift accurately. Synchronization position calibration corrects and adjusts the shift points appropriately in accordance with the individual specification values of the components.