Система Механической Трансмиссии 'Multimode' Меры Предосторожности. Corolla ZZE150

IGNITION SWITCH EXPRESSIONS

PRECAUTION REGARDING ON-VEHICLE INSPECTION

PRECAUTION REGARDING PARTS REMOVAL AND INSTALLATION

TROUBLESHOOTING INITIALIZATION AND LEARNING (ENGINE DOES NOT START)

Check for DTC output

Check clutch position learning condition

Check T/M gear position learning condition

Check whether gear is in neutral

Check whether park/neutral position switch is ON

Check whether T/M up-lock has occurred during gear position learning

TROUBLESHOOTING INITIALIZATION AND LEARNING (VEHICLE DOES NOT START OFF)

Check for DTC output

Check clutch position learning condition

Check T/M gear position learning condition

Check clutch standby point learning condition

Confirm that gear position in [1st] or [R] when shift lever in [E], [M] or [R]

Inspect accelerator pedal position sensor signal

Rev up engine with transaxle in neutral

Check whether T/M up-lock has occurred during gear position learning

Check whether clutch disengaged when shift lever in [E], [M] or [R]

PRECAUTIONS REGARDING USE OF SHIFT LOCK RELEASE BUTTON

OTHER PRECAUTIONS REGARDING MULTI-MODE MANUAL TRANSAXLE SYSTEM

PRECAUTION REGARDING USE OF INTELLIGENT TESTER

Система Механической Трансмиссии 'Multimode' -- Меры Предосторожности |

| 1.IGNITION SWITCH EXPRESSIONS |

The type of ignition switch used on this model differs according to the specifications of the vehicle. The expressions listed in the table below are used in this section.

Expression

| Ignition Switch

(position)

| Engine Switch

(condition)

|

Ignition Switch off

| LOCK

| Off

|

Ignition Switch on (IG)

| ON

| On (IG)

|

Ignition Switch on (ACC)

| ACC

| On (ACC)

|

Engine Start

| START

| Start

|

| 2.PRECAUTION REGARDING ON-VEHICLE INSPECTION |

When racing the engine, make sure that the gear is in neutral.

| 3.PRECAUTION REGARDING PARTS REMOVAL AND INSTALLATION |

When removing or installing parts related to the multi-mode manual transaxle system, perform [Clamp Position Adjustment], [Initialization and Learning] and/or [Synchronization Position Calibration]. In addition, the required operations differ according to the parts to be removed and installed. Proceed with the operation in the order shown in the table below.

Before removalParts to be removed

| Operation order

| See procedure

|

- Clutch actuator

- Transaxle assembly

- Transaxle parts (inside gear box)

- Clutch disc and clutch cover

- Clutch release bearing

- Clutch release fork

- Flywheel

- Crankshaft

| CLAMP POSITION ADJUSTMENT

| Нажмите здесь

|

Before installationParts to be installed

| Operation order

| See procedure

|

New clutch actuator

| CLAMP POSITION ADJUSTMENT

| Нажмите здесь

|

- ПРИМЕЧАНИЕ:

- Pull rods of brand new clutch actuators (service supply parts) are not set to the clutch clamp position. Therefore, adjust the clamp positions before installing new clutch actuators.

After installationParts installed

| Operation order

| See procedure

|

- Transaxle assembly

- Transaxle parts (inside gear box)

- TCM

| 1. INITIALIZATION OF MULTI-MODE MANUAL TRANSAXLE SYSTEM

[Initialization of ECU]

| Нажмите здесь

|

2. LEARNING OF MULTI-MODE MANUAL TRANSAXLE SYSTEM

| Нажмите здесь

|

3. SYNCHRONIZATION POSITION CALIBRATION

| Нажмите здесь

|

- Shift and select actuator

- Shift stroke sensor

- Select stroke sensor

| 1. INITIALIZATION OF MULTI-MODE MANUAL TRANSAXLE SYSTEM

[Initialization of transmission]

| Нажмите здесь

|

2. LEARNING OF MULTI-MODE MANUAL TRANSAXLE SYSTEM

| Нажмите здесь

|

3. SYNCHRONIZATION POSITION CALIBRATION

| Нажмите здесь

|

- Clutch actuator

- Clutch stroke sensor

- Clutch disc and clutch cover

- Clutch release bearing

- Clutch release fork

- Flywheel

- Crankshaft

| 1. INITIALIZATION OF MULTI-MODE MANUAL TRANSAXLE SYSTEM

[Initialization of clutch]

| Нажмите здесь

|

2. LEARNING OF MULTI-MODE MANUAL TRANSAXLE SYSTEM

| Нажмите здесь

|

- ПРИМЕЧАНИЕ:

- Replace the clutch disc and clutch cover together. If only one is replaced, the adjustment system of the clutch cover does not function properly. This may cause clutch drag or clutch slippage, which may result in deterioration of drivability or malfunctions of the system parts.

- After replacing any system components, perform initialization and learning of related components (refer to the operations listed above). If initialization and learning are not performed, the transaxle system will not function properly.

- Before proceeding with learning of the multi-mode manual transaxle system, clear (initialize) the previously stored learning values. Since the multi-mode manual transaxle system does not have an overwrite function, clearing (initializing) stored data is necessary to allow the system to learn.

- Do not clear (initialize) parts other than those specified in the "Parts installed" column in the table above.

| 4.TROUBLESHOOTING INITIALIZATION AND LEARNING (ENGINE DOES NOT START) |

- УКАЗАНИЕ:

- If any malfunctions are suspected in the transaxle control system after reassembling or repairing transaxle system components, perform troubleshooting in accordance with the following chart.

Using an intelligent tester, check for output DTCs.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / DTC.

Read any DTCs.

- Result:

Result

| Proceed to

|

No DTC output

| A

|

DTC output

| B

|

| 2.Check clutch position learning condition |

Check that the clutch position learning has been completed.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / Data List.

Read the Learn-Clutch Stopper Point result.

- Result:

Result

| Proceed to

|

Exec (Executed)

| A

|

Notexec (Not executed)

| B

|

Fail (Failure)

| C

|

| 3.Check T/M gear position learning condition |

Check that the T/M gear position learning has been completed.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / Data List.

Read the Learning-T/M results.

- Result:

Result

| Proceed to

|

Exec (Executed)

| A

|

Notexec (Not executed)

| B

|

Fail (Failure)

| C

|

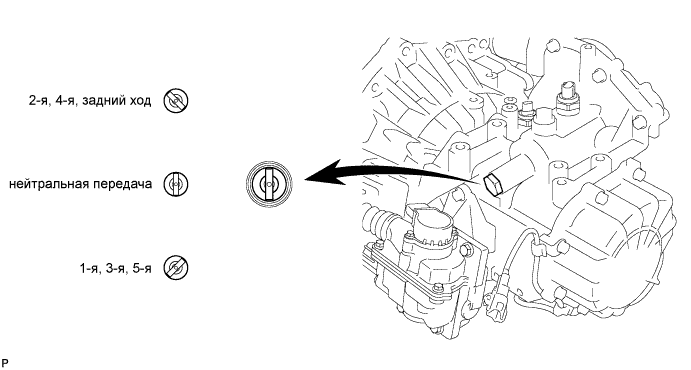

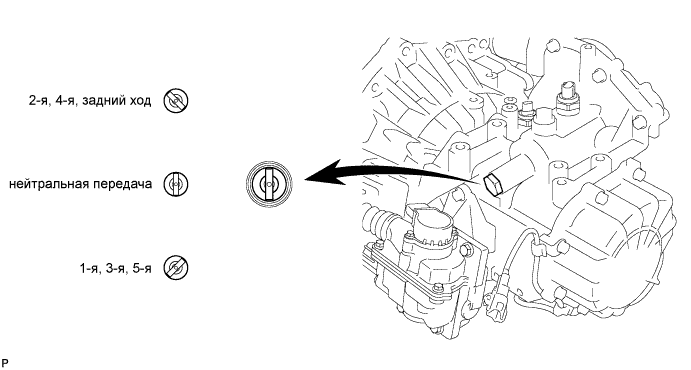

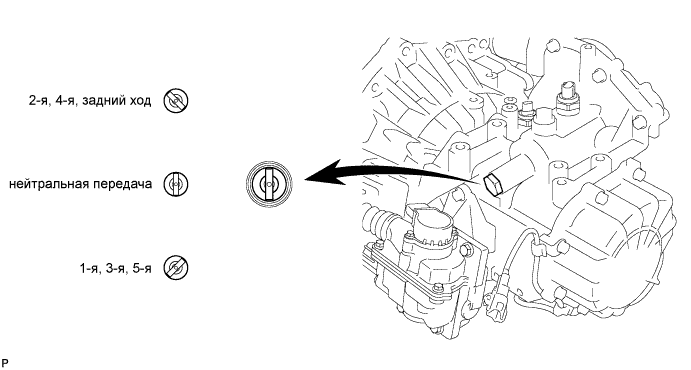

| 4.Check whether gear is in neutral |

Shift the shift lever to the N position.

Referring to the shift slit position of the shift and select actuator, check whether the actual transaxle gear position is in neutral.

- Result:

Result

| Proceed to

|

Neutral

| A

|

Other than Neutral

| B

|

| 5.Check whether park/neutral position switch is ON |

Check whether the park/neutral position switch is ON (See page Нажмите здесь).

- Result:

| | Replace park/neutral position switch |

|

|

| Check starter system and brake system |

|

|---|

| 6.Check whether T/M up-lock has occurred during gear position learning |

Check whether the T/M up-lock has occurred during gear position learning.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / Data List.

Read the Possibility of T/M Uplock results.

- УКАЗАНИЕ:

- T/M up-lock: The transaxle gear momentarily cannot be engaged due to mechanical reasons during gear position learning.

- Result:

Result

| Proceed to

|

No (Not occurred)

| A

|

Yes (Occurred)

| B

|

| | Perform initialization and learning again (If gear position learning fails twice or more, check transaxle assembly) |

|

|

|

|---|

| 5.TROUBLESHOOTING INITIALIZATION AND LEARNING (VEHICLE DOES NOT START OFF) |

- УКАЗАНИЕ:

- If any malfunctions are suspected in the transaxle control system after reassembling or repairing transaxle system components, perform troubleshooting in accordance with the following chart.

Using an intelligent tester, check for output DTCs.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / DTC.

Read any DTCs.

- Result:

Result

| Proceed to

|

No DTC output

| A

|

DTC output

| B

|

| 2.Check clutch position learning condition |

Check that the clutch position learning has been completed.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / Data List.

Read the Learn-Clutch Stopper Point results.

- Result:

Result

| Proceed to

|

Exec (Executed)

| A

|

Notexec (Not executed)

| B

|

Fail (Failure)

| C

|

| 3.Check T/M gear position learning condition |

Check that the T/M gear position learning has been completed.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / Data List.

Read the Learning-T/M results.

- Result:

Result

| Proceed to

|

Exec (Executed)

| A

|

Notexec (Not executed)

| B

|

Fail (Failure)

| C

|

| 4.Check clutch standby point learning condition |

Check that the clutch standby point learning has been completed.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / Data List.

Read the Learn-Clutch Standby Point results.

- Result:

Result

| Proceed to

|

Exec (Executed)

| A

|

Notexec (Not executed)

| B

|

Fail (Failure)

| C

|

| | Execute learning again (Ignition switch off to on (IG) and start engine) |

|

| |

|

| 5.Confirm that gear position in [1st] or [R] when shift lever in [E], [M] or [R] |

Start the engine.

Referring to the shift slit position of the shift and select actuator, check that the actual transaxle gear position is in the 1st or R position when the shift lever position is changed from N to E, M or R.

| 6.Inspect accelerator pedal position sensor signal |

Check the accelerator pedal position sensor signal circuit.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / Data List.

Check that the value of Accelerator Pedal Angle changes according to the accelerator pedal operation.

Read the Accelerator Pedal Angle results.

Check the CAN communication circuit (See page Нажмите здесь).

- Standard:

Accelerator Pedal Operation

| Tester Display

|

Fully depressed

| 90 to 100 %

|

Fully released

| 0 to 10 %

|

| | Check engine control system and CAN communication system |

|

|

| 7.Rev up engine with transaxle in neutral |

Check that the engine can be revved up when the transaxle gear is in neutral.

- Result:

Result

| Proceed to

|

Possible

| A

|

Impossible

| B

|

| | Check engine control system |

|

|

| Check clutch system and TCM |

|

|---|

| 8.Check whether T/M up-lock has occurred during gear position learning |

Check whether the T/M up-lock has occurred during gear position learning.

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / Data List.

Read the Possibility of T/M Uplock results.

- УКАЗАНИЕ:

- T/M up-lock: The transaxle gear momentarily cannot be engaged due to mechanical reasons during gear position learning.

- Result:

Result

| Proceed to

|

No (Not occurred)

| A

|

Yes (Occurred)

| B

|

| | Perform initialization and learning again (If gear position learning fails twice or more, check transaxle assembly) |

|

|

|

|---|

| 9.Check whether clutch disengaged when shift lever in [E], [M] or [R] |

Turn the ignition switch off.

Connect an intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Select the following menu items: Powertrain / Multi-Mode M/T / Data List / Clutch Touch Position and Clutch Position (Current).

Tester Display

| Test Part

| Control Range

| Diagnostic Notes

|

Clutch Position (Current)

[Clutch Pos-Cur]

| Current clutch position:

Min.: 0 mm, Max.: 127.998 mm

| 23.75 mm (0.94 in.) to 42.47 mm (1.67 in.)

| Current clutch position displayed

|

Clutch Touch Position

[Clt Touch Pos]

| Clutch touch position:

Min.: 0 mm, Max.: 127.998 mm

| Learning value shown

| -

|

Move the shift lever to the E, M, or R position.

Read the Clutch Position (Current) value comparing to the Clutch Touch Position value.

- Result:

Result

| Proceed to

|

Clutch Position (Current) value is small (the clutch is disengaged). : OK

| A

|

Clutch Position (Current) value is large (the clutch is not disengaged). : NG

| B

|

| 6.PRECAUTIONS REGARDING USE OF SHIFT LOCK RELEASE BUTTON |

When the vehicle is parked with the shift lever in any position other than N:

- The engine cannot be started if the shift lever is moved to a position other than N by operating the shift lock release button.

The shift lever should be moved back to the N position to start the engine.

- The engine cannot be started if the shift lever is in the position it was in when the vehicle was parked.

The shift lever should be moved back to the N position to start the engine.

- If the shift lever is returned to the N position by operating the shift lock release button, turning the ignition switch on (IG) with the brake pedal depressed will shift the gear to neutral, so that the engine can be started.

When the vehicle is parked with the shift lever in the N position:

- The engine can be started even if the shift lever is moved to a position other than N by operating the shift lock release button. In this case, the gear is shifted to the position in accordance with the shift lever position after the engine starts.

Shift lever position when vehicle parked

| Current shift lever position

| Engine cranking operation

| Note

|

Other than N

| Other than N*

| Impossible

| -

|

Other than N

| Same position as when vehicle parked

| Impossible

| -

|

Other than N

| N*

| Possible

| Gear shifted to neutral when ignition switch on (IG) with brake pedal depressed

|

N

| Other than N*

| Possible

| Gear shifted to position in accordance with shift lever position after engine start

|

N

| N

(Same position as when vehicle parked)

| Possible

| -

|

*: The shift lever was moved with the shift lock release button operation.

| 7.OTHER PRECAUTIONS REGARDING MULTI-MODE MANUAL TRANSAXLE SYSTEM |

- Set the gear in neutral when racing the engine.

- Set the gear to the neutral position before removing the shift and select actuator. If the gear cannot be shifted to the neutral position due to malfunctions of the actuator and/or transaxle gear, remove the plug from the shift and select actuator and observe the position of the shift slit within. If the slit is in a position other than neutral, use a screwdriver to set it to neutral.

| 8.PRECAUTION REGARDING USE OF INTELLIGENT TESTER |

- ПРИМЕЧАНИЕ:

Observe the following items for safety reasons:

- Read its instruction books before using the tester.

- Prevent the tester cable from being caught on the pedals, shift lever and steering wheel when driving with the tester connected to the vehicle.

- When driving the vehicle for testing purposes using the tester, two people are required. One drives the vehicle, and the other operates the tester.