Нагнетающий Топливный Насос -- Установка |

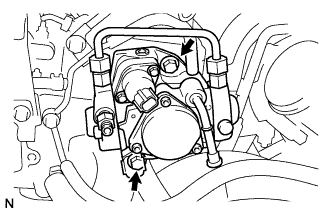

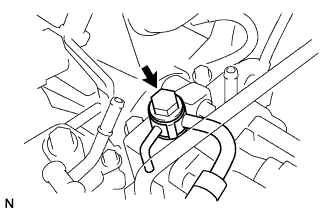

| 1. INSTALL FUEL SUPPLY PUMP ASSEMBLY |

Install a new O-ring to the injection or supply pump assembly.

Install the supply pump drive coupling.

- УКАЗАНИЕ:

- Line up the coupling with the groove in the camshaft end.

|

Install the fuel supply pump assembly with the 2 bolts.

- Момент затяжки:

- 21 Н*м{210 кгс*см, 15 фунт-сила-футов}

- ПРИМЕЧАНИЕ:

- Apply engine oil to the O-ring of the injection or supply pump assembly.

- УКАЗАНИЕ:

- Line up the end of the supply pump drive shaft with the supply pump drive coupling.

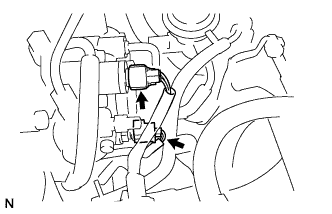

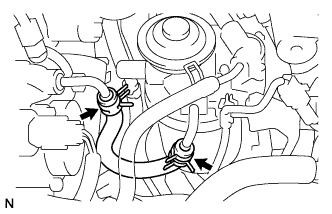

Connect the suction control valve connector.

|

Connect the fuel temperature sensor connector.

| 2. INSTALL FUEL INLET PIPE SUB-ASSEMBLY |

- ПРИМЕЧАНИЕ:

- In a case where the fuel supply pump is replaced, the fuel inlet pipe must also be replaced.

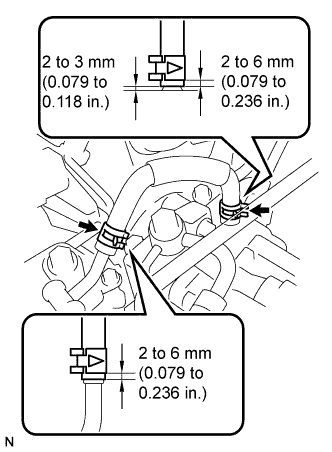

Temporarily install the fuel inlet pipe with the 2 clamps and nut.

|

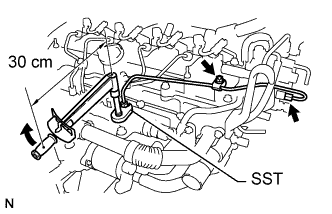

Using SST, first tighten the nut at the common rail end of the fuel inlet pipe.

- SST

- 09023-38401

- Момент затяжки:

- With SST:

- 27 Н*м{275 кгс*см, 20 фунт-сила-футов}

- Момент затяжки:

- Without SST:

- 30 Н*м{306 кгс*см, 22 фунт-сила-футов}

- УКАЗАНИЕ:

- Use of proper SST is required to ensure that the correct torque is applied to the fuel inlet pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation.

- If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new one.

Using SST, tighten the nut at the injection or supply pump end of the fuel inlet pipe.

- SST

- 09023-38401

- Момент затяжки:

- :

- 27 Н*м{275 кгс*см, 20 фунт-сила-футов}

- Момент затяжки:

- Without SST:

- 30 Н*м{306 кгс*см, 22 фунт-сила-футов}

- УКАЗАНИЕ:

- Use of proper SST is required to ensure that the correct torque is applied to the fuel inlet pipe nut.

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

- Make sure that the pipe is not deformed or twisted during installation.

- If the pipe is deformed or twisted, or if it cannot be installed properly, replace the pipe with a new one.

Tighten the fuel inlet pipe clamp nut.

- Момент затяжки:

- 5.0 Н*м{51 кгс*см, 44 фунт-сила-дюймов}

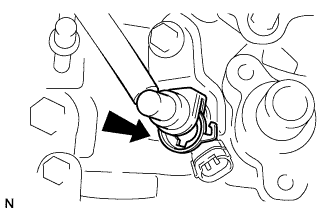

| 3. INSTALL FUEL TUBE SUB-ASSEMBLY |

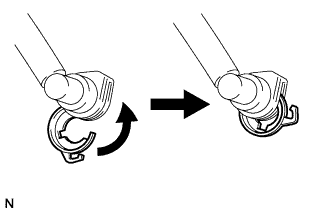

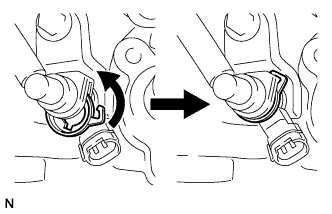

Turn the retainer in the direction indicated by the arrow until the retainer stops.

|

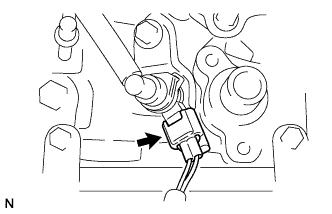

Install the fuel tube and gasket with the union bolt.

- Момент затяжки:

- 23 Н*м{235 кгс*см, 17 фунт-сила-футов}

|

Insert the fuel tube connector into the injector.

|

Turn the retainer in the direction indicated by the arrow until it makes a "click" sound.

- ПРИМЕЧАНИЕ:

- If the fuel tube connector is not inserted to the correct position of the injector, the retainer cannot be turned further in the direction of the arrow.

|

Connect the exhaust fuel addition injector connector.

|

| 4. INSTALL NO. 1 FUEL HOSE |

Using pliers, grip the claws of the 2 clips and slide the 2 clips to install the No. 1 fuel hose.

|

| 5. INSTALL NO. 3 FUEL HOSE |

Using pliers, grip the claws of the 2 clips and slide the 2 clips to install the No. 3 fuel hose as shown in the illustration.

|

| 6. INSTALL AIR CLEANER ASSEMBLY |

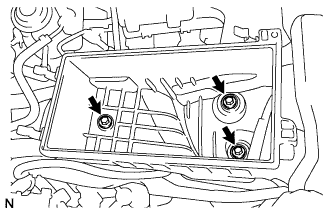

Install the cleaner case with the 3 bolts.

- Момент затяжки:

- 7.0 Н*м{71 кгс*см, 62 фунт-сила-дюймов}

|

Install the air filter element.

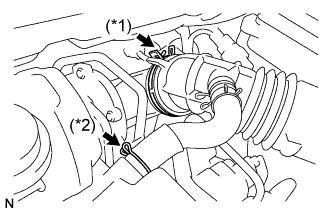

Using pliers, grip the claws of the clip to install the air cleaner cap sub-assembly (*1).

|

Using pliers, grip the claws of the clip and slide the clip to connect the PCV hose (*2).

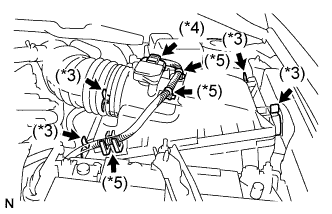

Engage the 4 air cleaner cap clamps (*3).

|

Connect the air flow sensor connector (*4).

Engage the 3 wire harness clamps (*5).

| 7. INSPECT FOR FUEL LEAK |

PERFORM ACTIVE TEST

Connect the intelligent tester to the DLC3.

Turn the ignition switch to the ON position.

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine / Active Test.

Perform the Active Test.

Tester Display Test Part Control Range Diagnostic Notes Test the Fuel Leak Pressurizing common rail internal fuel pressure, and checking for fuel leaks. Stop/Start - Fuel pressure inside common rail is pressurized to specified value and engine speed is increased to 2000 rpm when ON is selected.

- Above conditions are maintained while test is ON.

- Fuel pressure inside common rail is pressurized to specified value and engine speed is increased to 2000 rpm when ON is selected.

| 8. INSTALL NO. 1 ENGINE COVER |

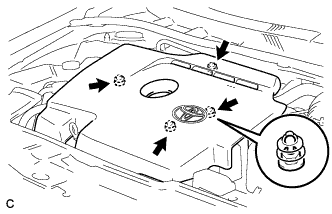

Attach the 4 clips to install the engine cover.

- ПРИМЕЧАНИЕ:

- Line up the 4 grommets using the oil filler cap and oil dipstick as guides.

- Push down on the four locations shown to install the cover.

|

| 9. PERFORM INITIALIZATION |

Perform initialization procedure (See page Нажмите здесь).