Dtc P0335 Crankshaft Position Sensor A Circuit. Corolla Auris

Двигатель. COROLLA, AURIS. ZZE150 ZRE151,152 NDE150

DESCRIPTION

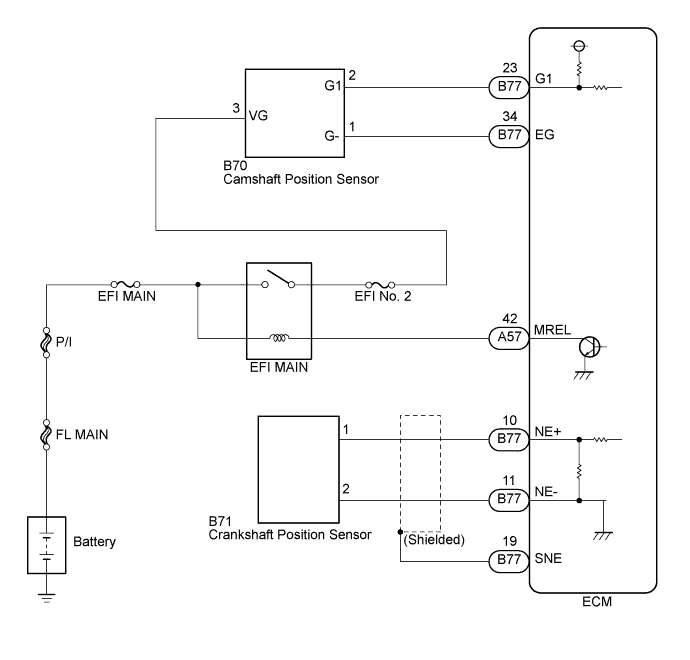

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT CRANKSHAFT POSITION SENSOR (RESISTANCE)

CHECK HARNESS AND CONNECTOR (CRANKSHAFT POSITION SENSOR - ECM)

CHECK SENSOR INSTALLATION (CRANKSHAFT POSITION SENSOR)

CHECK CRANKSHAFT POSITION SENSOR PLATE (TEETH OF SENSOR PLATE)

REPLACE CRANKSHAFT POSITION SENSOR

CHECK WHETHER DTC OUTPUT RECURS (DTC P0335)

DTC P0335 Crankshaft Position Sensor "A" Circuit |

DESCRIPTION

The crankshaft position sensor system consists of a crankshaft position sensor plate and a pickup coil. The sensor plate has 58 teeth and is installed on the crankshaft. The pickup coil is made of an iron core and magnet. The sensor plate rotates and as each tooth passes through the pickup coil, a pulse signal is created.The pickup coil generates 58 signals per engine revolution. Based on these signals, the ECM calculates the crankshaft position and engine speed. Using these calculations, the common rail system is controlled.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0335

| No crankshaft position sensor signal is sent to ECM while cranking

(The MIL is illuminated and a DTC is immediately set when a malfunction is detected)

| - Open or short in crankshaft position sensor circuit

- Crankshaft position sensor

- Crankshaft position sensor plate

- ECM

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- УКАЗАНИЕ:

- Check the value on an intelligent tester.

- Connect the intelligent tester to the DLC3.

- Start the engine.

- Turn the tester on.

- Enter the following menu items: Powertrain / Engine and ECT / Data List / Engine SPD.

- The engine speed can be confirmed in the Data List using the intelligent tester. If there are no NE signals from the crankshaft position sensor despite the engine revolving, the engine speed will be indicated as zero. If the voltage output of the crankshaft position sensor is insufficient, the engine speed will be indicated as lower than the actual engine rpm.

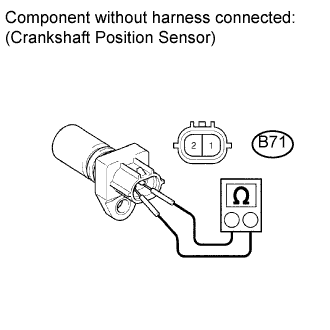

| 1.INSPECT CRANKSHAFT POSITION SENSOR (RESISTANCE) |

Disconnect the crankshaft position sensor connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

B71-1 - B71-2

| Cold

| 1630 to 2740 Ω

|

B71-1 - B71-2

| Hot

| 2065 to 3225 Ω

|

- УКАЗАНИЕ:

- Terms "cold" and "hot" refer to the temperature of the coils. "Cold" means approximately -10 to 50°C (14 to 122°F). "Hot" means approximately 50 to 100°C (122 to 212°F).

Reconnect the crankshaft position sensor connector.

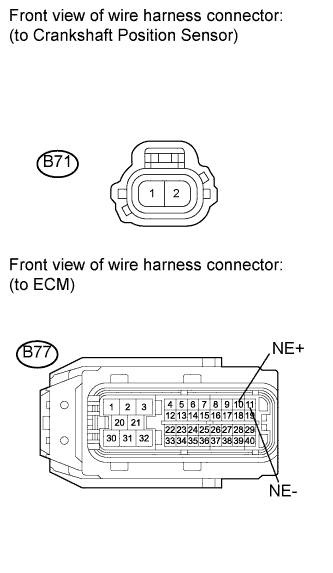

| 2.CHECK HARNESS AND CONNECTOR (CRANKSHAFT POSITION SENSOR - ECM) |

Disconnect the crankshaft position sensor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance (Check for open):

Tester Connections

| Condition

| Specified Conditions

|

B71-1 - B77-10 (NE+)

| Always

| Below 1 Ω

|

B71-2 - B77-11 (NE-)

| Always

| Below 1 Ω

|

- Standard resistance (Check for short):

Tester Connections

| Condition

| Specified Conditions

|

B71-1 or B77-10 (NE+) - Body ground

| Always

| 10 kΩ or higher

|

B71-2 or B77-11 (NE-) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the crankshaft position sensor connector.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (CRANKSHAFT POSITION SENSOR - ECM) |

|

|

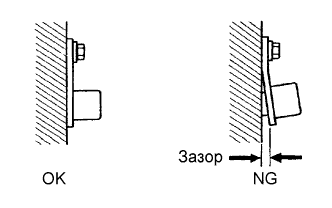

| 3.CHECK SENSOR INSTALLATION (CRANKSHAFT POSITION SENSOR) |

Check the crankshaft position sensor installation.

- OK:

- The sensor is installed correctly.

| 4.CHECK CRANKSHAFT POSITION SENSOR PLATE (TEETH OF SENSOR PLATE) |

Check the teeth of the sensor plate.

- OK:

- The sensor plate does not have any cracks or deformation.

| 5.REPLACE CRANKSHAFT POSITION SENSOR |

Replace crankshaft position sensor (See page Нажмите здесь).

| 6.CHECK WHETHER DTC OUTPUT RECURS (DTC P0335) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to the ON position.

Turn the tester on.

Clear the DTCs (See page Нажмите здесь).

Start the engine.

Enter the following menu item: Powertrain / Engine and ECT / DTC.

Read the DTCs.

- Result:

Result

| Proceed to

|

DTC is not output

| A

|

DTC P0335 is output

| B

|

- УКАЗАНИЕ:

- If the engine does not start, replace the ECM.