Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - JF2A TRANSFER / 4WD / AWD

TRANSFER ASSEMBLY - INSPECTION

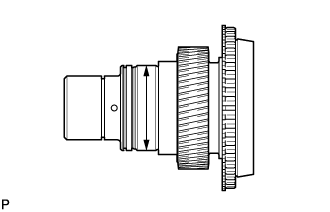

| 1. INSPECT TRANSFER INPUT SHAFT |

Using a micrometer, measure the diameter of the input shaft journal surface.

- Minimum Diameter:

- 68 mm (2.68 in.)

If the diameter is less than the minimum, replace the input shaft.

Using a dial indicator, measure the inside diameter of the input shaft bush.

- Maximum Inside Diameter:

- 46 mm (1.81 in.)

If the inside diameter is more than the maximum, replace the input shaft.

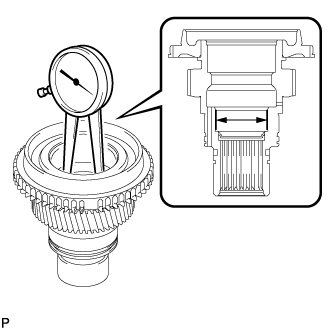

| 2. INSPECT TRANSFER LOW PLANETARY GEAR ASSEMBLY |

Using a feeler gauge, measure the thrust clearance of the pinion gear.

- Standard Clearance:

- 0.11 to 0.85 mm (0.00434 to 0.0334 in.)

- Maximum Clearance:

- 0.85 mm (0.0334 in.)

If the clearance is more than the maximum, replace the low planetary gear assembly.

Using a dial indicator, measure the radial clearance of the pinion gear.

- Standard Clearance:

- 0.01 to 0.04 mm (0.000434 to 0.00150 in.)

- Maximum Clearance:

- 0.04 mm (0.00150 in.)

If the clearance is more than the maximum, replace the low planetary gear assembly.

| 3. INSPECT REAR TRANSFER OUTPUT SHAFT |

Using a micrometer, measure the diameter of the output shaft journals.

- Minimum Diameter:

Journal Specified Condition A 38 mm (1.50 in.) B 42 mm (1.65 in.) C 49 mm (1.93 in.)

If the diameter is less than the minimum, replace the output shaft.

| 4. INSPECT NO. 1 TRANSFER GEAR SHIFT FORK AND FRONT DRIVE CLUTCH SLEEVE |

Using a feeler gauge, measure the clearance between the clutch sleeve and gear shift fork.

- Maximum Clearance:

- 0.8 mm (0.0315 in.)

If the clearance is more than the maximum, replace the clutch sleeve or shift fork.

| 5. INSPECT NO. 2 TRANSFER GEAR SHIFT FORK AND HIGH AND LOW CLUTCH SLEEVE |

Using a feeler gauge, measure the clearance between the clutch sleeve and gear shift fork.

- Maximum Clearance:

- 3.15 mm (0.124 in.)

If the clearance is more than the maximum, replace the clutch sleeve or shift fork.

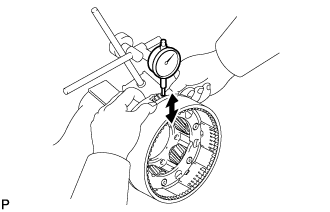

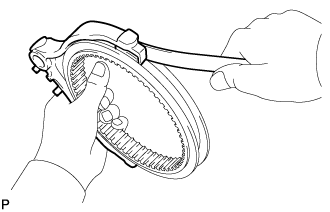

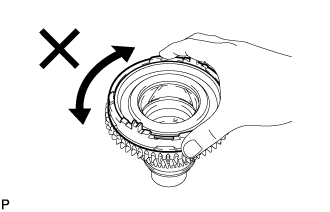

| 6. INSPECT NO. 1 SYNCHRONIZER RING (for Manual Transmission) |

Apply gear oil to the cone of the input shaft, and check that it does not turn in both directions while pushing the No. 1 synchronizer ring.

If it can turn, replace the No. 1 synchronizer ring.

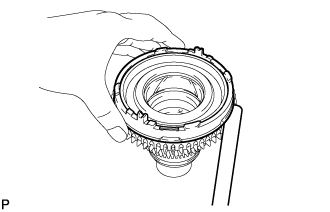

Push the No. 1 synchronizer ring to the cone of the input shaft. Measure the clearance between the No. 1 synchronizer ring and input shaft.

- Standard Clearance:

- 0.86 to 1.54 mm (0.0339 to 0.0606 in.)

- Minimum Clearance:

- 0.86 mm (0.0339 in.)

If the clearance is not as specified, replace the No. 1 synchronizer ring with a new one.