Dtc C1235/35 Foreign Object Is Attached On Tip Of Front Speed Sensor Rh

Brake. Lexus Is250, Is220D. Gse20 Ale20

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK SENSOR AND SENSOR ROTOR SERRATIONS

RECONFIRM DTC

CHECK HARNESS AND CONNECTOR (SKID CONTROL ECU - EACH SPEED SENSOR)

CHECK REAR SPEED SENSOR TIP

CHECK EACH SPEED SENSOR ROTOR

RECONFIRM DTC

REPLACE EACH SPEED SENSOR

RECONFIRM DTC

DTC C1235/35 Foreign Object is Attached on Tip of Front Speed Sensor RH |

DTC C1236/36 Foreign Object is Attached on Tip of Front Speed Sensor LH |

DTC C1238/38 Foreign Object is Attached on Tip of Rear Speed Sensor RH |

DTC C1239/39 Foreign Object is Attached on Tip of Rear Speed Sensor LH |

DTC C1275/75 Abnormal Change in Output Signal of Front Speed Sensor RH (Test Mode DTC) |

DTC C1276/76 Abnormal Change in Output Signal of Front Speed Sensor LH (Test Mode DTC) |

DTC C1277/77 Abnormal Change in Output Signal of Rear Speed Sensor RH (Test Mode DTC) |

DTC C1278/78 Abnormal Change in Output Signal of Rear Speed Sensor LH (Test Mode DTC) |

DESCRIPTION

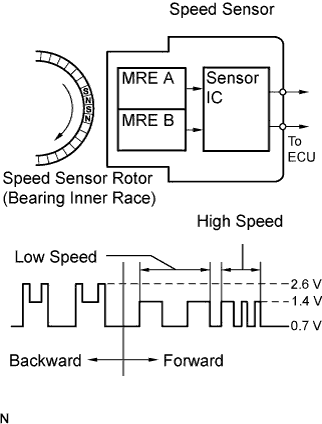

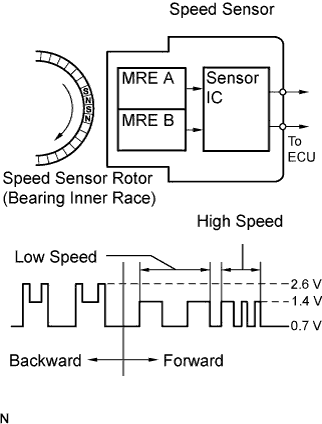

The speed sensor detects wheel speed and sends the appropriate signals to the skid control ECU. These signals are used for the ABS control system. This speed sensor contains a sensor IC, which consists of 2 MREs (Magnetic Resistance Element). The speed sensor rotor, which consists of 48 sets of N and S poles that are arranged in a circle, is integrated with the inner race of the hub bearing.To detect the rotation direction, the output waves are used to determine the relationship of the pulses that are generated by 2 MREs. Upon receiving this signal, the sensor IC outputs a forward or backward wave to the ECU.DTCs C1275/75 to C1278/78 can be deleted when the speed sensor sends a vehicle speed signal or the Test Mode ends. DTCs C1275/75 to C1278/78 are output only in the Test Mode.

DTC No.

| DTC Detection Condition

| Trouble Area

|

C1235/35

C1236/36

C1238/38

C1239/39

| When either of the following is detected:

- At a vehicle speed of 12 mph (20 km/h) or more, noise occurs in the sensor signal from the abnormal wheel for 5 seconds or more.

- At a vehicle speed of 6 mph (10 km/h) or more, noise is input once per rotor rotation for 15 seconds or more.

| - Speed sensor

- Speed sensor rotor

- Sensor installation

- Skid control ECU

|

- HINT:

- DTC C1235/35 is for the front speed sensor RH.

- DTC C1236/36 is for the front speed sensor LH.

- DTC C1238/38 is for the rear speed sensor RH.

- DTC C1239/39 is for the rear speed sensor LH.

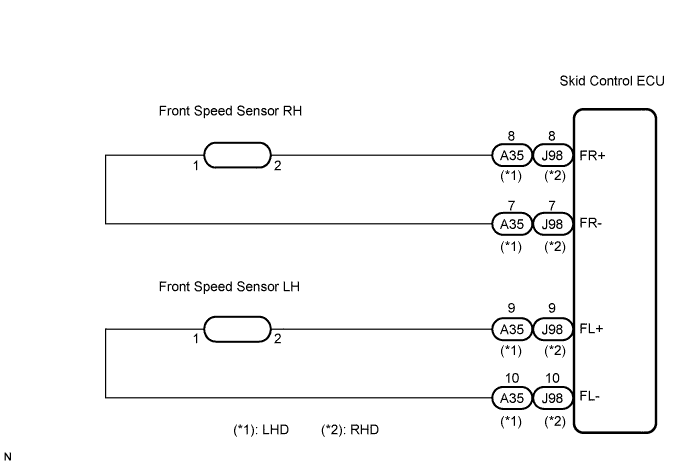

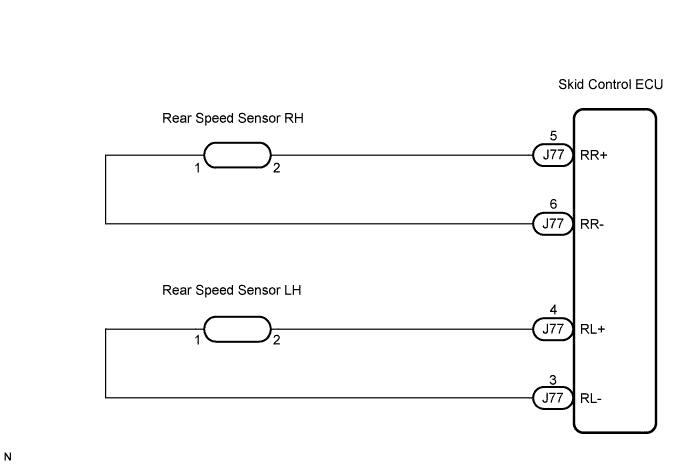

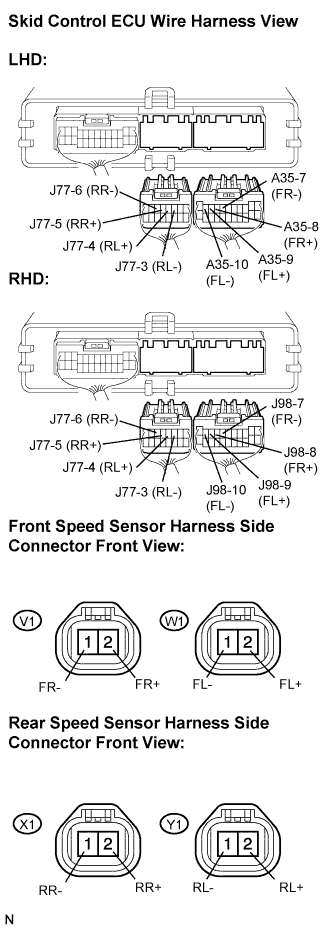

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- When replacing the skid control ECU, perform zero point calibration and store system information (Click here).

- HINT:

- When C0200/31, C0205/32, C0210/33 or C0215/34 is output together with C1235/35, C1236/36, C1238/38 or C1239/39, inspect and repair the trouble areas indicated by C0200/31, C0205/32, C0210/33, or C0215/34 first.

| 1.CHECK SENSOR AND SENSOR ROTOR SERRATIONS |

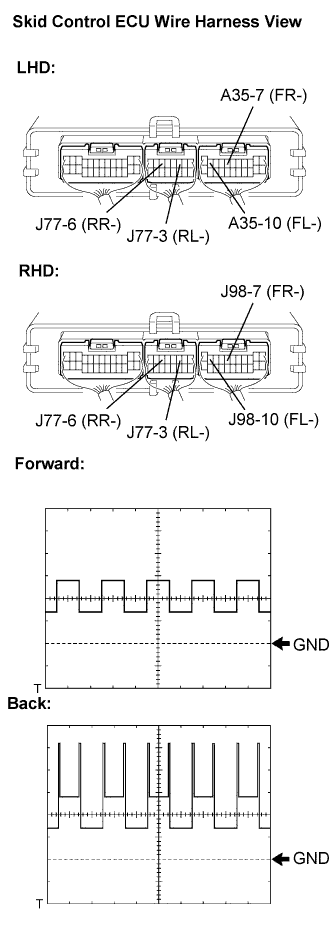

Connect the oscilloscope to terminals FR-, FL-, RR-, and RL- of the skid control ECU and body ground.

Check the signal waveform.

- OK:

- The same waveform is output from all the 4 wheels and there is no noise or interference in the waveform.

Check that the waveform does not change while jiggling a connector or wire harness.

- OK:

- The waveform does not change.

- HINT:

- As the vehicle speed (wheel revolution speed) increases, a cycle of the waveform narrows and the fluctuation in the output voltage becomes greater.

- When noise is identified in the waveform on the oscilloscope, error signals are generated due to the speed sensor rotor's scratches, looseness or foreign matter attached to it.

Clear the DTC (Click here).

Start the engine.

Drive the vehicle at the speed of 12 mph (20 km/h) or more for at least 60 seconds.

Check if the same DTC is recorded (Click here).

- Result:

Condition

| Proceed to

|

DTCs (C1235/35, C1236/36, C1238/38 and/or C1239/39) are not output

| A

|

DTCs (C1235/35, C1236/36, C1238/38 and/or C1239/39) are output

| B

|

| A |

|

|

|

| USE SIMULATION METHOD TO CHECK |

|

| 3.CHECK HARNESS AND CONNECTOR (SKID CONTROL ECU - EACH SPEED SENSOR) |

Disconnect the skid control ECU connector and each speed sensor connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

- RH (LHD):

Tester Connection

| Condition

| Specified Condition

|

A35-8 (FR+) - V1-2 (FR+)

| Always

| Below 1 Ω

|

A35-8 (FR+) - Body ground

| Always

| 10 kΩ or higher

|

A35-7 (FR-) - V1-1 (FR-)

| Always

| Below 1 Ω

|

A35-7 (FR-) - Body ground

| Always

| 10 kΩ or higher

|

J77-5 (RR+) - X1-2 (RR+)

| Always

| Below 1 Ω

|

J77-5 (RR+) - Body ground

| Always

| 10 kΩ or higher

|

J77-6 (RR-) - X1-1 (RR-)

| Always

| Below 1 Ω

|

J77-6 (RR-) - Body ground

| Always

| 10 kΩ or higher

|

- RH (RHD):

Tester Connection

| Condition

| Specified Condition

|

J98-8 (FR+) - V1-2 (FR+)

| Always

| Below 1 Ω

|

J98-8 (FR+) - Body ground

| Always

| 10 kΩ or higher

|

J98-7 (FR-) - V1-1 (FR-)

| Always

| Below 1 Ω

|

J98-7 (FR-) - Body ground

| Always

| 10 kΩ or higher

|

J77-5 (RR+) - X1-2 (RR+)

| Always

| Below 1 Ω

|

J77-5 (RR+) - Body ground

| Always

| 10 kΩ or higher

|

J77-6 (RR-) - X1-1 (RR-)

| Always

| Below 1 Ω

|

J77-6 (RR-) - Body ground

| Always

| 10 kΩ or higher

|

- LH (LHD):

Tester Connection

| Condition

| Specified Condition

|

A35-9 (FL+) - W1-2 (FL+)

| Always

| Below 1 Ω

|

A35-9 (FL+) - Body ground

| Always

| 10 kΩ or higher

|

A35-10 (FL-) - W1-1 (FL-)

| Always

| Below 1 Ω

|

A35-10 (FL-) - Body ground

| Always

| 10 kΩ or higher

|

J77-4 (RL+) - Y1-2 (RL+)

| Always

| Below 1 Ω

|

J77-4 (RL+) - Body ground

| Always

| 10 kΩ or higher

|

J77-3 (RL-) - Y1-1 (RL-)

| Always

| Below 1 Ω

|

J77-3 (RL-) - Body ground

| Always

| 10 kΩ or higher

|

- LH (RHD):

Tester Connection

| Condition

| Specified Condition

|

J98-9 (FL+) - W1-2 (FL+)

| Always

| Below 1 Ω

|

J98-9 (FL+) - Body ground

| Always

| 10 kΩ or higher

|

J98-10 (FL-) - W1-1 (FL-)

| Always

| Below 1 Ω

|

J98-10 (FL-) - Body ground

| Always

| 10 kΩ or higher

|

J77-4 (RL+) - Y1-2 (RL+)

| Always

| Below 1 Ω

|

J77-4 (RL+) - Body ground

| Always

| 10 kΩ or higher

|

J77-3 (RL-) - Y1-1 (RL-)

| Always

| Below 1 Ω

|

J77-3 (RL-) - Body ground

| Always

| 10 kΩ or higher

|

- Result:

Result

| Proceed to

|

OK (for rear)

| A

|

OK (for front)

| B

|

NG

| C

|

| |

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 4.CHECK REAR SPEED SENSOR TIP |

Remove the rear speed sensor (Click here).

Check the speed sensor tip.

- OK:

- No scratches or foreign matter on the sensor tip.

- NOTICE:

- Check the speed sensor signal after cleaning/replacement (Click here).

| | CLEAN OR REPLACE REAR SPEED SENSOR |

|

|

| 5.CHECK EACH SPEED SENSOR ROTOR |

Remove each speed sensor rotor.

Check the speed sensor rotor.

- OK:

- No scratches, oil, or foreign matter on the rotors.

- NOTICE:

- Check the speed sensor signal after cleaning/replacement (Click here).

| | CLEAN OR REPLACE EACH SPEED SENSOR ROTOR |

|

|

Install the rear speed sensor and the speed sensor rotor.

Reconnect the skid control ECU connector and the speed sensor connector.

Clear the DTC (Click here).

Start the engine.

Drive the vehicle at the speed of 12 mph (20 km/h) or more for at least 60 seconds.

Check if the same DTC is recorded (Click here).

- Result:

Result

| Proceed to

|

DTCs (C1235/35, C1236/36, C1238/38 and/or C1239/39) are output

| A

|

DTCs (C1235/35, C1236/36, C1238/38 and/or C1239/39) are not output

| B

|

| | USE SIMULATION METHOD TO CHECK |

|

|

| 7.REPLACE EACH SPEED SENSOR |

Turn the engine switch off.

Replace each speed sensor (Click here for front, or Click here for rear).

- NOTICE:

- Check the speed sensor signal after replacement (Click here).

Clear the DTC (Click here).

Start the engine.

Drive the vehicle at the speed of 12 mph (20 km/h) or more for at least 60 seconds.

Check if the same DTC is recorded (Click here).

- Result:

Result

| Proceed to

|

DTCs (C1235/35, C1236/36, C1238/38 and/or C1239/39) are output

| A

|

DTCs (C1235/35, C1236/36, C1238/38 and/or C1239/39) are not output

| B

|