Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1GR-FE LUBRICATION

OIL PUMP - INSTALLATION

| 1. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY |

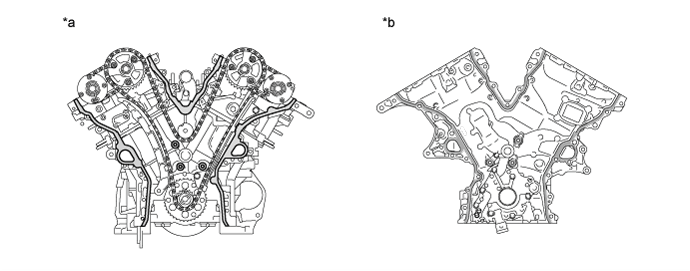

Remove any old packing (FIPG material) and be careful not to drop any oil on the contact surfaces of the timing chain cover, cylinder head and cylinder block.

| *a | Cylinder Head and Cylinder Block Side | *b | Timing Chain Cover Side |

| Clean and degrease | - | - |

- NOTICE:

- Be sure to clean and degrease the contact surfaces, especially the surfaces indicated in the illustration.

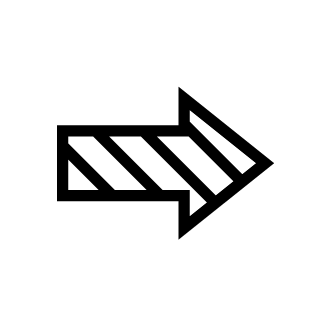

Apply a light coat of engine oil to a new oil pump gasket.

Install the oil pump gasket.

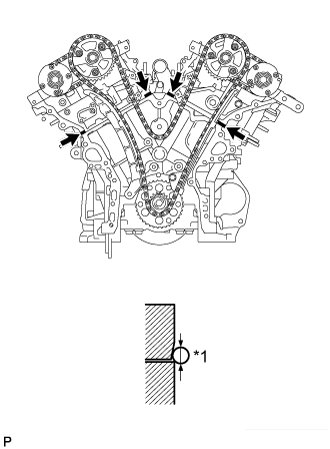

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.0 to 4.0 mm (0.118 to 0.157 in.)

| *1 | Seal Diameter |

| Seal Packing |

Apply seal packing to the timing chain cover in a continuous line as shown in the following illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent

| *a | 3.0 to 4.0 mm | *b | 2.0 to 3.0 mm |

| *c | Be sure to apply seal packing | *d | Dashed line area (Seal packing: Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent) |

| *e | Alternate long and short dashed line area (Seal packing: Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent) | *f | Continuous line area (Seal packing: Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent) |

| *g | Diagonal line area (Seal packing: Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent) | - | - |

- NOTICE:

- Application Specification:

Area Seal Packing Diameter Application Position from Inside Seal Line Continuous Line Area 4.5 mm (0.177 in.) or more 3.0 to 4.0 mm (0.118 to 0.158 in.) Alternate Long and Short Dashed Line Area 3.5 mm (0.138 in.) or more 2.0 to 3.0 mm (0.0787 to 0.118 in.) Dashed Line Area 3.5 mm (0.138 in.) or more 3.0 to 4.0 mm (0.118 to 0.158 in.) Diagonal Line Area 6.0 mm (0.236 in.) or more 5.0 mm (0.197 in.)

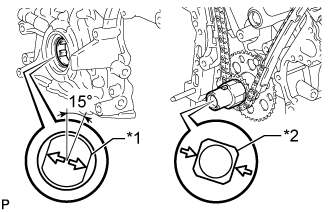

Align the oil pump drive rotor spline and crankshaft as shown in the illustration. Install the drive rotor and chain cover to the crankshaft.

| *1 | Drive Rotor Spline |

| *2 | Crankshaft |

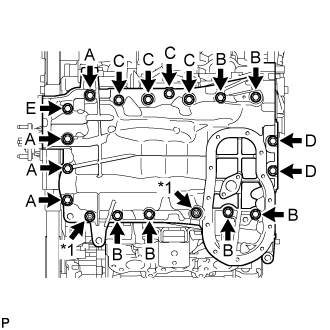

Install the timing chain cover with the 26 bolts, labeled A, B, C and D, and the 2 nuts. Tighten the bolts and nuts uniformly in several steps.

- Standard Bolt:

Item Length Bolt A 25 mm (0.984 in.) Bolt B 55 mm (2.17 in.) Bolt C 35 mm (1.38 in.) Bolt D 65 mm (2.56 in.)

| *1 | Nut | - | - |

| *a | Area 1 | *b | Area 2 |

| *c | Area 3 | *d | Area 4 |

- NOTICE:

- Make sure that there is no oil on the bolt threads.

Tighten the bolts in area 1.

- Torque:

- 47 N*m{ 479 kgf*cm, 35 ft.*lbf}

- HINT:

- Tighten the bolts from bottom to top as shown in the illustration.

Tighten the bolts in area 2.

- Torque:

- 23 N*m{ 235 kgf*cm, 17 ft.*lbf}

Tighten the bolts in area 3.

- Torque:

- 23 N*m{ 235 kgf*cm, 17 ft.*lbf}

- HINT:

- Tighten the bolts and nuts from top to bottom as shown in the illustration.

Tighten the bolts in area 4.

- Torque:

- 23 N*m{ 235 kgf*cm, 17 ft.*lbf}

- NOTICE:

- HINT:

- Tighten the bolts from bottom to top as shown in the illustration.

| 2. INSTALL FRONT CRANKSHAFT OIL SEAL |

Apply MP grease to the lip of a new oil seal.

Using SST and a hammer, tap in the oil seal until its surface is flush with the timing chain cover edge.

- SST

- 09226-10010

- NOTICE:

| 3. INSTALL OIL PAN SUB-ASSEMBLY |

Remove any old packing (FIPG material) and be careful not to drop any oil on the contact surfaces of the cylinder block, rear oil seal retainer and oil pan.

Install 3 new O-rings to the timing chain cover.

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.0 to 4.0 mm (0.118 to 0.157 in.)

| *1 | Seal Packing |

- NOTICE:

Install the oil pan with the 17 bolts (A, B, C, D and E) and 2 nuts. Tighten the bolts and nuts uniformly in several steps.

- Torque:

- for bolt A, B, C, E, and nut:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- for bolt D:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- Standard Bolt:

Item Length Bolt A 60 mm (2.36 in.) Bolt B 45 mm (1.77 in.) Bolt C 25 mm (0.984 in.) Bolt D 16 mm (0.630 in.) Bolt E 70 mm (2.76 in.)

| *1 | Nut |

- NOTICE:

- Do not start the engine for at least 2 hours after installation.

| 4. INSTALL OIL STRAINER SUB-ASSEMBLY |

Install the oil strainer with the 2 nuts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 5. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY |

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.0 to 4.0 mm (0.118 to 0.157 in.)

| *1 | Seal Packing |

- NOTICE:

Install the No. 2 oil pan with the 10 bolts and 2 nuts. Tighten the bolts and nuts uniformly in several steps.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| Bolt |

| Nut |

- NOTICE:

| 6. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

Remove any old packing (FIPG material) and be careful not to drop any oil on the contact surfaces of the camshaft housing, timing chain cover and cylinder head cover.

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 2.0 to 3.0 mm (0.0787 to 0.118 in.)

| Seal Packing |

- NOTICE:

Install 3 new gaskets.

Install a new gasket to the cylinder head cover.

Install new seal washers to the bolts.

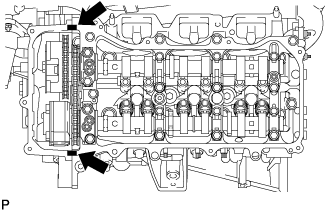

Temporarily install the cylinder head cover with the 12 bolts. Tighten the bolts uniformly in several steps.

- Torque:

- for bolt A and D:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- for bolt B and C:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- Standard Bolt:

Item Length A 25 mm (0.984 in.) B 35 mm (1.38 in.) C 65 mm (2.56 in.) D 60 mm (2.36 in.)

| Bolt A |

| Bolt B |

| Bolt C |

| Bolt D |

- NOTICE:

- Do not start the engine for at least 2 hours after installation.

| 7. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY LH |

Remove any old packing (FIPG material) and be careful not to drop any oil on the contact surfaces of the camshaft housing, timing chain cover and cylinder head cover.

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 2.0 to 3.0 mm (0.0787 to 0.118 in.)

| Seal Packing |

- NOTICE:

Install 3 new gaskets.

Install a new gasket to the cylinder head cover.

Install new seal washers to the bolts.

Temporarily install the cylinder head cover with the 12 bolts. Tighten the bolts uniformly in several steps.

- Torque:

- for bolt A and D:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- for bolt B and C:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- Standard Bolt:

Item Length A 25 mm (0.984 in.) B 35 mm (1.38 in.) C 70 mm (2.76 in.) D 60 mm (2.36 in.)

| Bolt A |

| Bolt B |

| Bolt C |

| Bolt D |

- NOTICE:

- Do not start the engine for at least 2 hours after installation.

| 8. CONNECT FUEL PIPE SUB-ASSEMBLY |

Connect the fuel pipe with the 2 bolts.

- Torque:

- 9.0 N*m{ 92 kgf*cm, 80 in.*lbf}

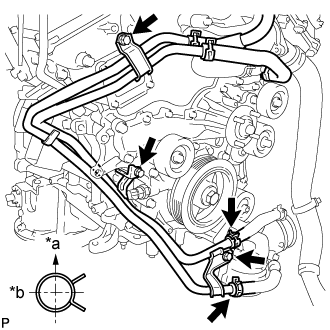

| 9. INSTALL NO. 2 OIL PIPE |

Make sure that there is no foreign matter on the mesh of the oil control valve filter RH.

- NOTICE:

- Do not touch the mesh when installing the oil control valve filter.

Install a new gasket and temporarily install the oil pipe (on the cylinder head side) with the oil check valve bolt.

Install the oil control valve filter RH to the oil pipe union. Install new gaskets and temporarily install the oil pipe (on the cylinder head cover side).

Tighten the oil pipe union (on the cylinder head side).

- Torque:

- 65 N*m{ 663 kgf*cm, 48 ft.*lbf}

- NOTICE:

- If the link that connects the gaskets is broken, remove the connecting link by using side cutters or a similar tool.

Tighten the oil pipe union (on the cylinder head cover side).

- Torque:

- 65 N*m{ 663 kgf*cm, 48 ft.*lbf}

| 10. INSTALL NO. 1 OIL PIPE |

Make sure that there is no foreign matter on the mesh of the oil control valve filter LH.

- NOTICE:

- Do not touch the mesh when installing the oil control valve filter.

Install a new gasket and temporarily install the oil pipe (on the cylinder head side) with the oil check valve bolt.

Install the oil control valve filter LH to the oil pipe union. Install new gaskets and temporarily install the oil pipe (on the cylinder head cover side).

Tighten the oil pipe union (on the cylinder head side).

- Torque:

- 65 N*m{ 663 kgf*cm, 48 ft.*lbf}

- NOTICE:

- If the link that connects the gaskets is broken, remove the connecting link by using side cutters or a similar tool.

Tighten the oil pipe union (on the cylinder head cover side).

- Torque:

- 65 N*m{ 663 kgf*cm, 48 ft.*lbf}

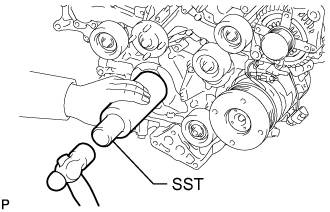

| 11. INSTALL CRANKSHAFT PULLEY |

Using SST, install the crankshaft pulley with the pulley set bolt.

- SST

- 09213-54015(91651-60855)

09330-00021

- Torque:

- 260 N*m{ 2651 kgf*cm, 192 ft.*lbf}

| 12. INSTALL OIL FILTER BRACKET |

Install the oil filter bracket and a new gasket with the 2 nuts and bolt.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

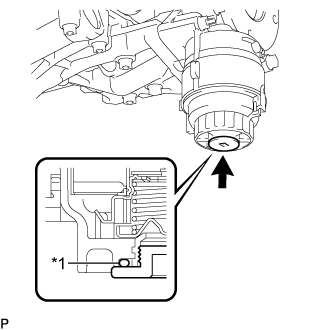

| 13. INSTALL OIL FILTER ELEMENT |

Clean the inside of the oil filter cap, the threads and O-ring groove.

Apply a light coat of engine oil to a new O-ring for the cap, and then install the O-ring to the groove of the oil filter cap.

| *1 | O-Ring |

| *a | CORRECT |

| *b | INCORRECT |

- NOTICE:

Set a new oil filter element in the oil filter cap.

Remove any dirt or foreign matter from the installation surface of the engine.

Apply a small amount of engine oil to the O-ring again and temporarily install the oil filter cap.

- NOTICE:

- Do not pinch the O-ring for the cap.

Using SST, tighten the oil filter cap.

- SST

- 09228-06501

- Torque:

- 25 N*m{ 255 kgf*cm, 18 ft.*lbf}

| *1 | Oil Filter Cap |

| *2 | O-Ring |

| *3 | Oil Filter Bracket |

| *a | No Gap |

- NOTICE:

- After tightening the oil filter cap, make sure that there is no gap and that the O-ring is not protruding.

Apply a small amount of engine oil to a new drain plug O-ring and install the O-ring to the oil filter cap.

| *1 | O-Ring |

- NOTICE:

- Before installing the O-ring, remove any dirt or foreign matter from the installation surface of the oil filter cap.

Install the oil filter drain plug.

- Torque:

- 13 N*m{ 133 kgf*cm, 10 ft.*lbf}

- NOTICE:

- Make sure that the O-ring does not get caught between the parts.

| 14. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY |

Temporarily install the V-ribbed belt tensioner with the 5 bolts.

- Standard Bolt:

Item Length A 70 mm (2.76 in.) B 33 mm (1.30 in.)

| Bolt A |

| Bolt B |

Tighten bolts 1 and 2 in numerical order.

- Torque:

- 36 N*m{ 367 kgf*cm, 27 ft.*lbf}

Tighten the other bolts.

- Torque:

- 36 N*m{ 367 kgf*cm, 27 ft.*lbf}

| 15. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY |

Install the 2 No. 2 idler pulleys with the 2 bolts.

- Torque:

- 54 N*m{ 551 kgf*cm, 40 ft.*lbf}

| 16. INSTALL NO. 1 IDLER PULLEY SUB-ASSEMBLY |

Install the No. 1 idler pulley with the bolt.

- Torque:

- 54 N*m{ 551 kgf*cm, 40 ft.*lbf}

| *1 | DOUBLE |

- HINT:

- "DOUBLE" is marked on the No. 1 idler pulley to distinguish it from the No. 2 idler pulley.

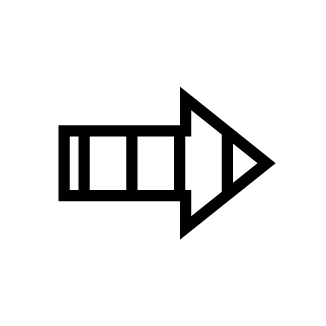

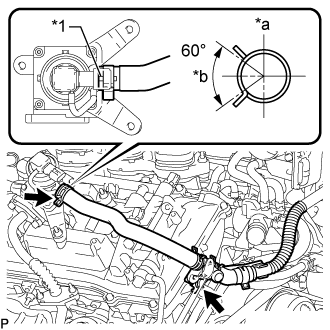

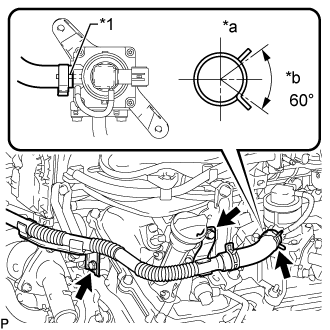

| 17. INSTALL WATER BY-PASS PIPE SUB-ASSEMBLY |

Install the water by-pass pipe with the 3 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Connect the 2 hoses.

| *a | Upward |

| *b | Rearward |

- HINT:

- The direction of the hose clamp is indicated in the illustration.

| 18. INSTALL WATER INLET HOUSING |

Install a new O-ring to the water outlet pipe.

Install a new gasket to the water pump.

Apply soapy water to the gasket of the water outlet pipe.

Install the water inlet with the 5 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Connect the 5 water by-pass hoses.

Connect the oil cooler hose.

Connect the No. 2 oil cooler hose.

Connect the throttle body connector.

| 19. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE |

Install a new O-ring to the engine oil level dipstick guide.

| *1 | New O-Ring |

Apply a light coat of engine oil to the O-ring.

Push the engine oil level dipstick guide end into the guide hole.

Install the engine oil level dipstick guide with the bolt.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Install the engine oil level dipstick.

| 20. INSTALL IGNITION COIL ASSEMBLY |

Install the 6 ignition coils with the 6 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Connect the 6 ignition coil connectors.

| 21. INSTALL NO. 2 EMISSION CONTROL VALVE SET (w/ Secondary Air Injection System) |

Install the No. 2 emission control valve set with the 3 nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Align the paint mark with the rib and connect the No. 1 air hose.

| *1 | Paint Mark |

| *2 | Rib |

| *a | Top |

| *b | LH Side |

- HINT:

- Make sure the direction of the hose clamp is as shown in the illustration.

Connect the No. 2 emission control valve set connector.

| 22. INSTALL NO. 1 EMISSION CONTROL VALVE SET (w/ Secondary Air Injection System) |

Install the No. 1 emission control valve set with the 3 nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Align the paint mark with the rib and connect the No. 1 air hose.

| *1 | Rib |

| *2 | Paint Mark |

| *a | RH Side |

| *b | Top |

- HINT:

- Make sure the direction of the hose clamp is as shown in the illustration.

Connect the No. 1 emission control valve set connector.

| 23. INSTALL AIR TUBE (w/ Secondary Air Injection System) |

for Bank 1 Side:

Align the paint mark with the projection and connect the air tube assembly to the emission control valve set.

| *1 | Paint Mark |

| *a | Top |

| *b | RH Side |

- HINT:

- Make sure the direction of the hose clamp is as shown in the illustration.

for Bank 2 Side:

Align the paint mark with the projection and connect the air tube assembly to the No. 2 emission control valve set.

| *1 | Paint Mark |

| *a | Top |

| *b | LH Side |

- HINT:

- Make sure the direction of the hose clamp is as shown in the illustration.

Install the 3 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Connect the No. 3 air hose.

| 24. INSTALL ENGINE ASSEMBLY |

()