Dtc P0365 Camshaft Position Sensor B Circuit (Bank 1)

Engine. Lexus Is250, Is220D. Gse20 Ale20

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK ECM TERMINAL VOLTAGE

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE)

CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM)

CHECK VVT SENSOR FOR EXHAUST CAMSHAFT (SENSOR INSTALLATION)

CHECK EXHAUST CAMSHAFT

DTC P0365 Camshaft Position Sensor "B" Circuit (Bank 1) |

DTC P0367 Camshaft Position Sensor "B" Circuit Low Input (Bank 1) |

DTC P0368 Camshaft Position Sensor "B" Circuit High Input (Bank 1) |

DTC P0390 Camshaft Position Sensor "B" Circuit (Bank 2) |

DTC P0392 Camshaft Position Sensor "B" Circuit Low Input (Bank 2) |

DTC P0393 Camshaft Position Sensor "B" Circuit High Input (Bank 2) |

DESCRIPTION

The exhaust camshaft's Variable Valve Timing (VVT) sensor (G signal) consists of a magnet and MRE element.The exhaust camshaft has a sensor plate with 3 teeth on its outer circumference.When the exhaust camshaft rotates, changes occur in the air gaps between the 3 teeth and pickup coil, which affects the magnet. As a result, the resistance of the MRE material fluctuates. The VVT sensor converts the exhaust camshaft rotation data to pulse signals, and uses the pulse signals to determine the camshaft angle, which it sends to the ECM. Then the ECM uses this data to control fuel injection time and injection timing. The crankshaft angle sensor plate has 34 teeth. The pickup coil generates 34 signals for each engine revolution. Based the G signal and actual crankshaft angle, the ECM detects the normal crankshaft angle. Also, based on the NE signal, the ECM detects the engine speed.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0365

P0390

| - Input voltage to ECM remains 0.3 V or less, or 4.7 V or higher for more than 5 seconds, when 2 or more seconds have elapsed after turning engine switch on (IG)

(1 trip detection logic)

- No VVT sensor signal to ECM during cranking

(1 trip detection logic)

| - Open or short in VVT sensor for exhaust camshaft circuit

- VVT sensor for exhaust camshaft

- Exhaust camshaft

- Jumped tooth of timing chain

- ECM

|

P0367

P0392

| Output voltage of VVT sensor 0.3 V or less for 5 seconds

(1 trip detection logic)

| - Open or short in VVT sensor for exhaust camshaft circuit

- VVT sensor for exhaust camshaft

- Exhaust camshaft

- Jumped tooth of timing chain

- ECM

|

P0368

P0393

| Output voltage of VVT sensor 4.7 V or more for 5 seconds

(1 trip detection logic)

| - Open or short in VVT sensor for exhaust camshaft circuit

- VVT sensor for exhaust camshaft

- Exhaust camshaft

- Jumped tooth of timing chain

- ECM

|

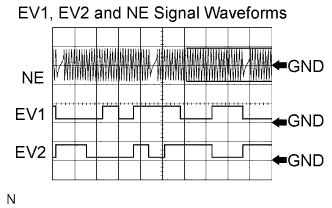

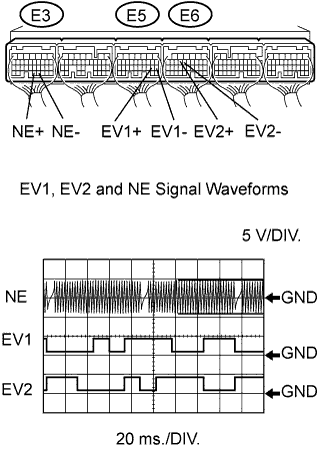

- Reference: Inspection using an oscilloscope

- HINT:

- The correct waveform is shown.

- EV1+ and EV2+ stand for the VVT sensor signal, and NE+ stands for the CKP sensor signal.

Item

| Content

|

Terminal

| NE+ - NE-

EV1+ - EV1-

EV2+ - EV2-

|

Equipment Setting

| 5 V/DIV.

20 ms./DIV.

|

Condition

| Cranking or idling

|

WIRING DIAGRAM

Refer to DTC P0335 (Click here).

INSPECTION PROCEDURE

Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred (Click here).

| 1.CHECK ECM TERMINAL VOLTAGE |

Inspect the ECM using an oscilloscope.

While the engine is idling, check the waveform between the terminals of the ECM connector.

- Standard:

Tester Connection

| Specified Condition

|

EV1+ (E5-19) - EV1- (E5-18)

| Correct waveform shown

|

EV2+ (E6-13) - EV2- (E6-12)

| Correct waveform shown

|

NE+ (E3-32) - NE- (E3-31)

| Correct waveform shown

|

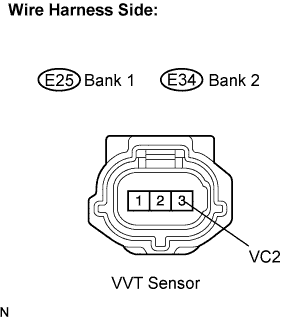

| 2.CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE) |

Disconnect the E25 or E34 VVT sensor connector.

Measure the voltage of the wire harness side connector.

- Standard voltage:

Tester Connection

| Specified Condition

|

VC2 (E25-3) - Body ground

| 4.5 to 5.0 V

|

VC2 (E34-3) - Body ground

| 4.5 to 5.0 V

|

Reconnect the VVT sensor connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

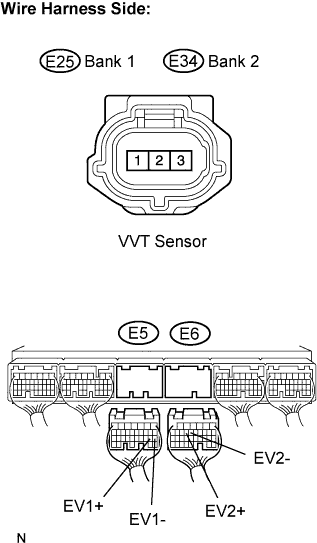

| 3.CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM) |

Disconnect the E25 or E34 VVT sensor connector.

Disconnect the E5 or E6 ECM connector.

Measure the resistance of the wire harness side connector.

- Standard resistance (Check for open):

Tester Connection

| Specified Condition

|

EX+ (E25-1) - EV1+ (E5-19)

| Below 1 Ω

|

EX- (E25-2) - EV1- (E5-18)

| Below 1 Ω

|

EX+ (E34-1) - EV2+ (E6-13)

| Below 1 Ω

|

EX- (E34-2) - EV2- (E6-12)

| Below 1 Ω

|

- Standard resistance (Check for short):

Tester Connection

| Specified Condition

|

EX+ (E25-1) or EV1+ (E5-19) - Body ground

| 10 kΩ or higher

|

EX- (E25-2) or EV1- (E5-18) - Body ground

| 10 kΩ or higher

|

EX+ (E34-1) or EV2+ (E6-13) - Body ground

| 10 kΩ or higher

|

EX- (E34-2) or EV2- (E6-12) - Body ground

| 10 kΩ or higher

|

Reconnect the VVT sensor connector.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

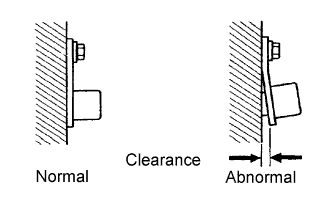

| 4.CHECK VVT SENSOR FOR EXHAUST CAMSHAFT (SENSOR INSTALLATION) |

Check the VVT sensor installation.

- OK:

- Sensor is installed correctly.

| | REPAIR OR REPLACE VVT SENSOR |

|

|

Check the teeth of the camshaft.