Wiper And Washer System Wiper Motor Power Source Circuit

DESCRIPTION

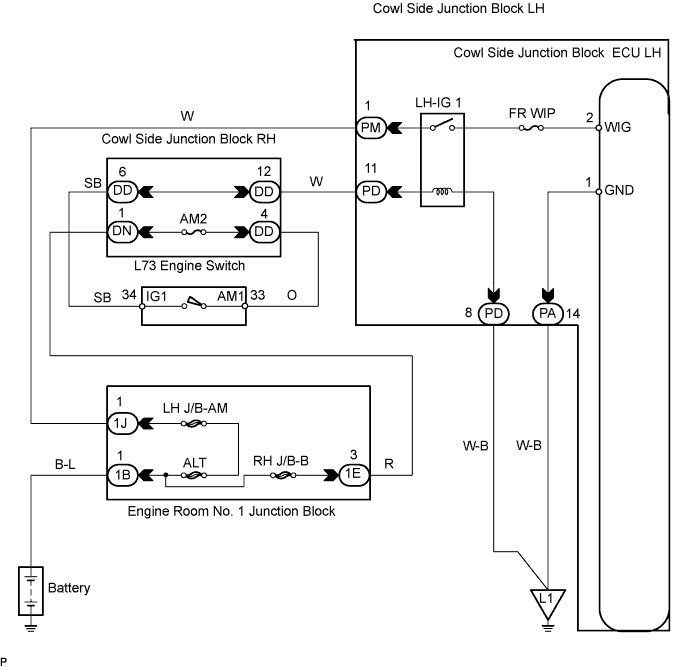

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK COWL SIDE JUNCTION BLOCK LH (COWL SIDE JUNCTION BLOCK ECU LH)

CHECK WIRE HARNESS (COWL SIDE JUNCTION BLOCK LH - BODY GROUND)

WIPER AND WASHER SYSTEM - Wiper Motor Power Source Circuit |

DESCRIPTION

This circuit provides power to the front wiper motor and operates the cowl side junction block ECU LH.

WIRING DIAGRAM

INSPECTION PROCEDURE

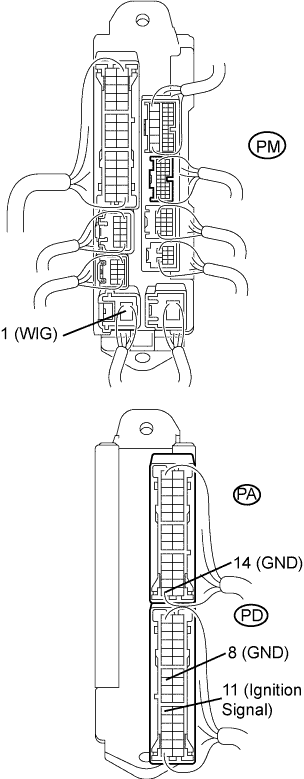

| 1.CHECK COWL SIDE JUNCTION BLOCK LH (COWL SIDE JUNCTION BLOCK ECU LH) |

Measure the voltage of the connectors.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

PD-11 - PD-8

| Engine switch off

| Below 1 V

|

PD-11 - PD-8

| Engine switch on (IG)

| 10 to 14 V

|

PM-1 (WIG) - PA-14 (GND)

| Engine switch off

| Below 1 V

|

PM-1 (WIG) - PA-14 (GND)

| Engine switch on (IG)

| 10 to 14 V

|

| OK |

|

|

|

| PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE |

|

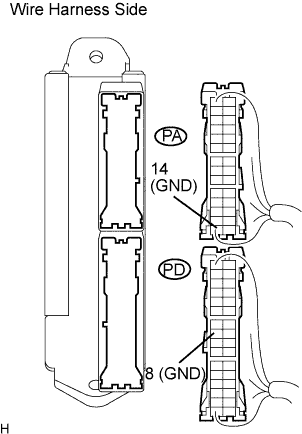

| 2.CHECK WIRE HARNESS (COWL SIDE JUNCTION BLOCK LH - BODY GROUND) |

Disconnect the PD and PA junction block connectors.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

PA-14 (GND) - Body ground

| Always

| Below 1 Ω

|

PD-8 - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR (GROUND CIRCUIT) |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS AND CONNECTOR (ENGINE SWITCH CIRCUIT) |

|