CHECK WIRE HARNESS (SOURCE VOLTAGE OF CENTER AIRBAG SENSOR ASSEMBLY)

CHECK WIRE HARNESS (SOURCE VOLTAGE OF COMBINATION METER)

AIRBAG SYSTEM - SRS Warning Light Remains ON |

DESCRIPTION

The SRS warning light is located on the combination meter.When the SRS is normal, the SRS warning light comes on for approximately 6 seconds after the engine switch is turned from off to on (IG), and then goes off automatically.

If there is a malfunction in the SRS, the SRS warning light comes on to inform the driver of a problem.

When terminals TC and CG of the DLC3 are connected, the DTC is displayed blinking the SRS warning light.

The SRS is equipped with a voltage-increase circuit (DC-DC converter) in the center airbag sensor assembly in case the source voltage drops.

When the battery voltage drops, the voltage-increase circuit (DC-DC converter) functions to increase the voltage of the SRS to normal voltage.

A malfunction in this circuit is not recorded in the center airbag sensor assembly. The SRS warning light automatically goes off when the source voltage returns to normal.

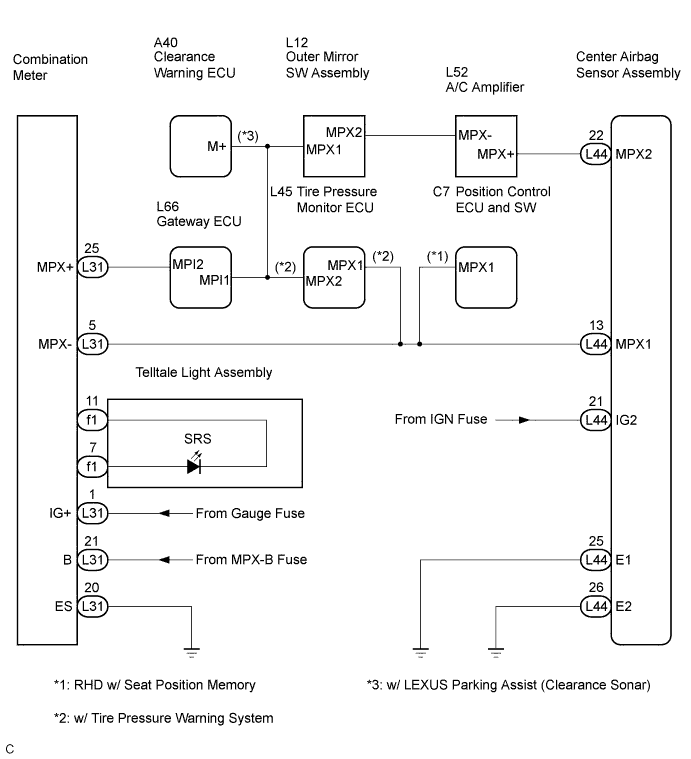

The signal to illuminate the SRS warning light is transmitted from the center airbag sensor assembly to the combination meter through the multiplex communication system.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK BATTERY |

Measure the voltage of the battery.

- Voltage:

- 11 to 14 V

|

| ||||

| OK | |

| 2.CHECK CONNECTORS |

Turn the engine switch off.

Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

Check that the connectors are properly connected to the center airbag sensor assembly and combination meter.

- OK:

- The connectors are connected.

|

| ||||

| OK | |

| 3.CHECK WIRE HARNESS (SOURCE VOLTAGE OF CENTER AIRBAG SENSOR ASSEMBLY) |

Disconnect the connectors from the center airbag sensor assembly.

|

Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

Turn the engine switch on (IG).

Operate all components of the electrical system (defogger, wipers, headlight, heater blower, etc.).

Measure the voltage according to the value(s) in the table below.

- Voltage:

Tester connection Condition Specified condition L44-21 (IG2) -

Body groundEngine switch on (IG) 10 to 14 V

Turn the engine switch off.

Measure the resistance according to the value(s) in the table below.

- Resistance:

Tester connection Condition Specified condition L44-25 (E1) -

Body groundAlways Below 1 Ω L44-26 (E2) -

Body groundAlways Below 1 Ω

|

| ||||

| OK | |

| 4.CHECK WIRE HARNESS (SOURCE VOLTAGE OF COMBINATION METER) |

Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

|

Disconnect the connector from the combination meter.

Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

Turn the engine switch on (IG).

Measure the voltage and resistance according to the value(s) in the table below.

- Voltage:

Tester connection Condition Specified condition L31-1 (IG+) -

Body groundEngine switch on (IG) 10 to 14 V L31-22 (B) -

Body groundAlways 10 to 14 V

Turn the engine switch off.

Measure the resistance according to the value(s) in the table below.

- Resistance:

Tester connection Condition Specified condition L31-28 (ES) -

Body groundAlways Below 1 Ω

|

| ||||

| OK | |

| 5.CHECK SRS WARNING LIGHT |

Turn the engine switch off.

Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

Connect the connector to the combination meter.

Connect the negative (-) terminal cable to the battery, and wait for at least 2 seconds.

Turn the engine switch on (IG).

Check the SRS warning light condition.

- OK:

- After the primary check period, SRS warning light goes off for approximately 10 seconds, and turning it on is continued.

- HINT:

- The primary check period shows approximately 6 seconds after the engine switch is turned on (IG).

|

| ||||

| OK | ||

| ||