Fuel Injector Installation

Engine. Lexus Gs430, Gs300. Uzs190 Grs190

INSTALL FUEL INJECTOR ASSEMBLY

INSTALL NO. 2 FUEL DELIVERY PIPE SUB-ASSEMBLY

INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

INSTALL FUEL PRESSURE PULSATION DAMPER ASSEMBLY

INSTALL INTAKE MANIFOLD

INSTALL NO. 2 FUEL PIPE ASSEMBLY

INSTALL ENGINE WIRE

INSTALL NO. 3 V-BANK COVER BRACKET

INSTALL NO. 2 V-BANK COVER BRACKET

INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

INSTALL NO. 1 V-BANK COVER BRACKET

INSTALL NO. 4 V-BANK COVER BRACKET

INSTALL THROTTLE BODY ASSEMBLY

INSTALL INTAKE AIR CONNECTOR PIPE

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

CHECK FOR FUEL LEAKS

ADD COOLANT

CHECK FOR COOLANT LEAKS

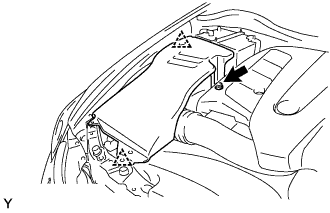

INSTALL V-BANK COVER

INSTALL ENGINE ROOM SIDE COVER RH

INSTALL ENGINE ROOM SIDE COVER LH

INSTALL AIR INTAKE DUCT SEAL

PERFORM INITIALIZATION

Fuel Injector -- Installation |

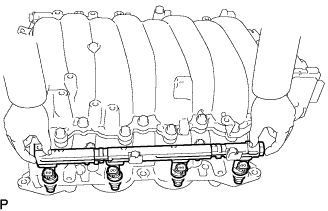

| 1. INSTALL FUEL INJECTOR ASSEMBLY |

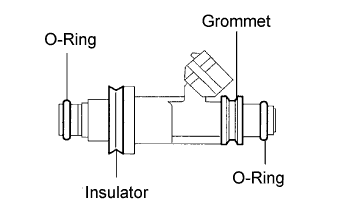

Install a new O-ring, grommet and insulator to the injector.

- NOTICE:

- Check that there is no damage or foreign material in the groove of the injector when installing the injector's O-ring.

- Apply gasoline to a new O-ring and install it to the injector.

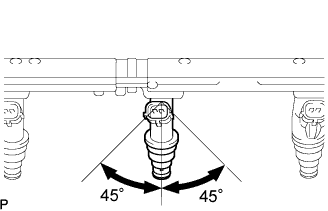

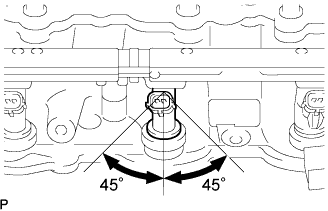

Push and rotate the injector 45° clockwise and counterclockwise to install it to the delivery pipe.

Check that the injector rotates smoothly.

- NOTICE:

- When the injector does not rotate smoothly, the O-ring may be pinched. Remove the injector and install a new O-ring to the injector.

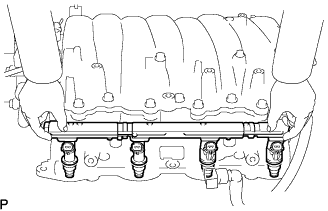

| 2. INSTALL NO. 2 FUEL DELIVERY PIPE SUB-ASSEMBLY |

Install the delivery pipe (with injector) to the intake manifold.

With the condition as stated above, rotate the injector 45° clockwise and counterclockwise.

- NOTICE:

- When the injector does not rotate smoothly, the O-ring may be pinched. Remove the injector and install a new O-ring to the injector.

With the spacer contacting the delivery pipe, install the delivery pipe with the 2 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 3. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY |

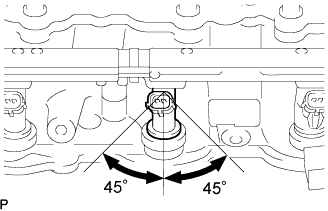

Install the delivery pipe (with injector) to the intake manifold.

With the condition as stated above, rotate the injector 45° clockwise and counterclockwise.

- NOTICE:

- When the injector does not rotate smoothly, the O-ring may be pinched. Remove the injector and install a new O-ring to the injector.

With the spacer contacting the delivery pipe, install the delivery pipe with the 2 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 4. INSTALL FUEL PRESSURE PULSATION DAMPER ASSEMBLY |

Using a wrench, install 4 new gaskets and 2 fuel pulsation dampers to the fuel pipe with the 2 bolts.

- Torque:

- 39 N*m{398 kgf*cm, 29 ft.*lbf}for use without SST33 N*m{337 kgf*cm, 24 ft.*lbf}for use with SST

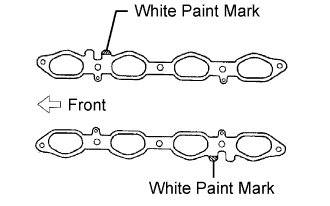

| 5. INSTALL INTAKE MANIFOLD |

Set 2 new gaskets on the cylinder head.

- HINT:

- Make sure the white paint marks are facing upward.

Install the intake manifold to the gasket and cylinder head with the 6 bolts and 4 nuts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

Connect the 8 injector connectors.

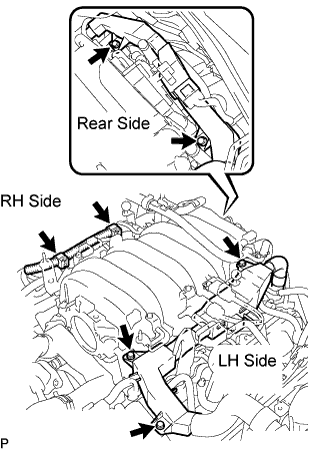

| 6. INSTALL NO. 2 FUEL PIPE ASSEMBLY |

Install the wire protector (LH side) with the 3 bolts.

Install the 2 wire clamps on the engine wire (RH side) to the brackets on the RH delivery pipe.

Install the engine wire protector (rear side) to the rear water by-pass joint and RH cylinder head with the 2 bolts.

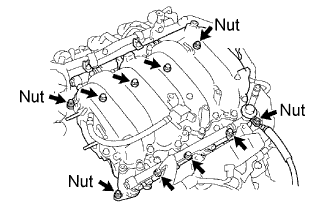

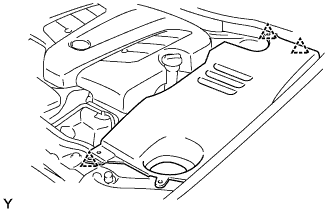

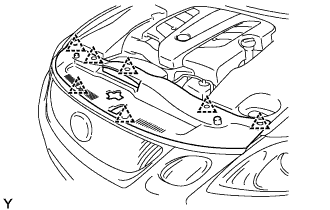

| 8. INSTALL NO. 3 V-BANK COVER BRACKET |

Install the bracket to the manifold with the bolt, as shown in E in the illustration below.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

Connect the connector.

| 9. INSTALL NO. 2 V-BANK COVER BRACKET |

Install the bracket to the manifold with the bolt, as shown in D in the illustration below.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

| 10. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY |

Install the bracket of the VSV to the manifold with the bolt, as shown in C in the illustration below.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

Connect the vacuum hose to the VSV, as shown in C in the illustration below.

Connect the connector to the VSV, as shown in C in the illustration below.

| 11. INSTALL NO. 1 V-BANK COVER BRACKET |

Install the bracket to the manifold with the bolt, as shown in B in the illustration below.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

| 12. INSTALL NO. 4 V-BANK COVER BRACKET |

Install the bracket to the manifold with the 2 nuts, as shown in A in the illustration below.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

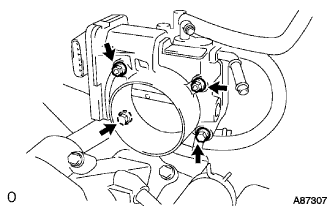

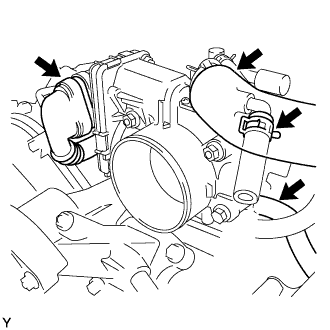

| 13. INSTALL THROTTLE BODY ASSEMBLY |

Install a new gasket and the throttle body with the 2 bolts and 2 nuts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

Connect the 2 water by-pass hoses.

Connect the connector and wire.

Connect the PCV hose.

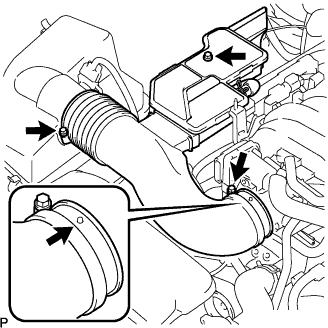

| 14. INSTALL INTAKE AIR CONNECTOR PIPE |

Install the connector pipe with the bolt and 2 hose clamps.

- Torque:

- 4.0 N*m{41 kgf*cm, 35 ft.*lbf} for hose clamps

- 5.0 N*m{51 kgf*cm, 44 ft.*lbf} for bolt

Connect the air hose and No. 1 ventilation hose.

| 15. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

Check for fuel leaks (Click here).

| 18. CHECK FOR COOLANT LEAKS |

Check for engine coolant leaks (Click here).

Install the cover with the 2 nuts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

| 20. INSTALL ENGINE ROOM SIDE COVER RH |

Install the side cover with the 2 clips and nut.

| 21. INSTALL ENGINE ROOM SIDE COVER LH |

Install the side cover with the 3 clips.

| 22. INSTALL AIR INTAKE DUCT SEAL |

Install the intake duct seal with the 7 clips.

| 23. PERFORM INITIALIZATION |

Perform initialization (Click here).

- NOTICE:

- Certain systems need to be initialized after disconnecting and reconnecting the cable from the negative (-) battery terminal.