Dtc P0340 Camshaft Position Sensor Circuit Malfunction

Engine. Lexus Gs430, Gs300. Uzs190 Grs190

DESCRIPTION

MONITOR DESCRIPTION

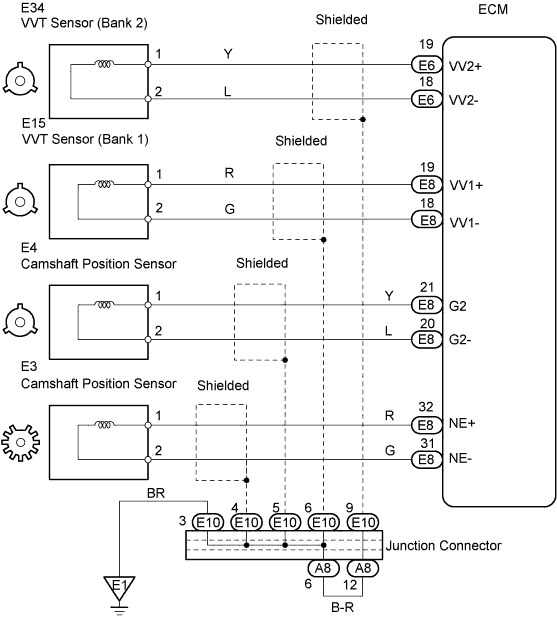

WIRING DIAGRAM

INSPECTION PROCEDURE

INSPECT VVT SENSOR (RESISTANCE)

CHECK WIRE HARNESS (VVT SENSOR - ECM)

CHECK SENSOR INSTALLATION (VVT SENSOR)

CHECK CRANKSHAFT TIMING PULLEY

DTC P0340 Camshaft Position Sensor Circuit Malfunction |

DTC P0341 Camshaft Position Sensor "A" Circuit Range / Performance (Bank 1 or Single Sensor) |

DTC P0345 Camshaft Position Sensor "A" Circuit (Bank 2) |

DTC P0346 Camshaft Position Sensor "A" Circuit Range / Performance (Bank 2) |

DESCRIPTION

The Variable Valve Timing (VVT) sensor consists of a magnet, iron core and pickup coil. The VVT signal plate has 3 teeth on its outer circumference and is installed on the camshaft timing pulley. When the camshafts rotate, changes occur on the camshaft protrusions and in the pickup coil air gaps. These changes cause fluctuations in the magnetic field and generate voltage in the pickup coil.Each sensor monitors its timing rotor, which is located on the camshaft. The ECM uses the sensor to detect the camshaft angle. The camshaft rotation synchronizes with the crankshaft rotation, and this sensor communicates the rotation of the camshaft timing rotor as a pulse signal to the ECM. Based on the signal, the ECM controls the camshaft positions.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0340

P0345

| - No VVT sensor signal to ECM during cranking (2 trip detection logic)

- No VVT sensor signal to ECM with engine speed 600 rpm or more (1 trip detection logic)

| - Open or short in VVT sensor circuit

- VVT sensor

- Camshaft timing pulley

- Timing belt has a jumped tooth

- ECM

|

P0341

P0346

| When crankshaft rotates twice, VVT sensor signal is input to ECM 12 times or more (1 trip detection logic)

| Same as DTC No. P0340/P0345

|

- HINT:

- DTC P0340 and P0345 indicate a malfunction related to the VVT sensor (+) circuit

(wire harness (from ECM to VVT sensor) and VVT sensor).

- DTC P0341 and P0346 indicate a malfunction related to the VVT sensor (-) circuit

(wire harness (from ECM to VVT sensor) and VVT sensor).

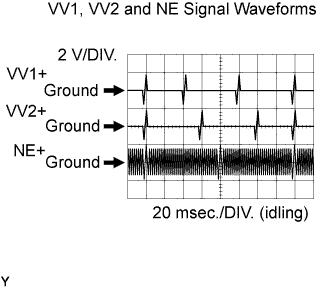

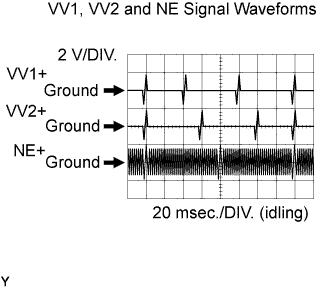

- Reference: Inspection using an oscilloscope.

During cranking or idling, check the waveform of the ECM connector.

Tester Connection

| Specified Condition

|

VV1+ (E8-19) - VV1- (E8-18)

| Correct waveform is as shown

|

VV2+ (E6-19) - VV2- (E6-18)

| Correct waveform is as shown

|

NE+ (E8-32) - NE- (E8-31)

| Correct waveform is as shown

|

MONITOR DESCRIPTION

If there is no signal from the VVT sensor even though the engine is running, or if the rotation of the camshaft and the crankshaft is not synchronized, the ECM interprets this as a malfunction of the sensor.This monitor runs for 10 seconds (the first 10 seconds of engine idle) after the engine is started.

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- If DTC P0340 and P0341 are displayed, check the left bank VVT sensor.

- If DTC P0345 and P0346 are displayed, check the right bank VVT sensor.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was LEAN or RICH, and other data from the time the malfunction occurred.

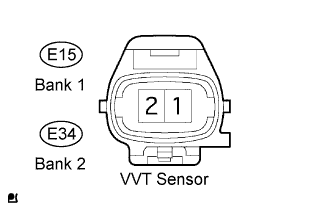

| 1.INSPECT VVT SENSOR (RESISTANCE) |

Disconnect the E15 and E34 VVT sensor connectors.

Measure the resistance of the VVT sensor.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - 2

| Cold

| 835 to 1,400 Ω

|

1 - 2

| Hot

| 1,060 to 1,645 Ω

|

- NOTICE:

- In the above chart, the terms "cold" and "hot" refer to the temperature of the coils.

- "Cold" means approximately -10 to 50°C (14 to 122°F).

- "Hot" means approximately 50 to 100°C (122 to 212°F).

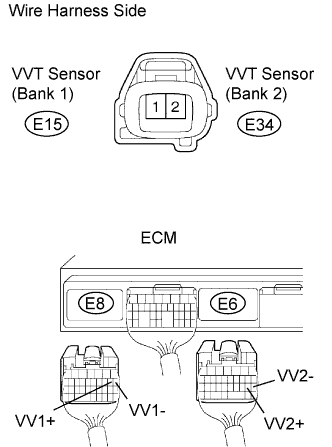

| 2.CHECK WIRE HARNESS (VVT SENSOR - ECM) |

Disconnect the E15 and E34 VVT sensor connectors.

Disconnect the E6 and E8 ECM connectors.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

E15-1 - E8-19 (VV1+)

| Below 1 Ω

|

E15-2 - E8-18 (VV1-)

| Below 1 Ω

|

E34-1 - E6-19 (VV2+)

| Below 1 Ω

|

E34-2 - E6-18 (VV2-)

| Below 1 Ω

|

E15-1 or E8-19 (VV1+) - Body ground

| 10 kΩ or higher

|

E15-2 or E8-18 (VV1-) - Body ground

| 10 kΩ or higher

|

E34-1 or E6-19 (VV2+) - Body ground

| 10 kΩ or higher

|

E34-2 or E6-18 (VV2-) - Body ground

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

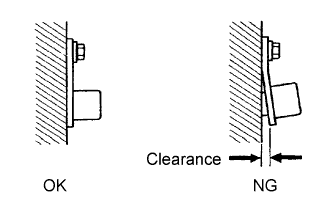

| 3.CHECK SENSOR INSTALLATION (VVT SENSOR) |

Check the sensor installation.

- OK:

- Sensor is installed correctly.

| | SECURELY REINSTALL SENSOR |

|

|

| 4.CHECK CRANKSHAFT TIMING PULLEY |

Check the teeth of the crankshaft timing pulley.

- OK:

- Timing pulley's teeth have no deformation or cracks.

| | REPLACE CRANKSHAFT TIMING PULLEY |

|

|