Dtc P0327 Knock Sensor 1 Circuit Low Input (Bank 1 Or Single Sensor)

Engine. Lexus Gs430, Gs300. Uzs190 Grs190

DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

READ OUTPUT DTC (CHECK KNOCK SENSOR CIRCUIT)

CHECK WIRE HARNESS (FE1 FEMALE CONNECTOR - ECM)

CHECK ECM (KNK1, KNK2 VOLTAGE)

INSPECT KNOCK SENSOR (RESISTANCE)

CHECK WIRE HARNESS (FE1 MALE CONNECTOR - KNOCK SENSOR)

DTC P0327 Knock Sensor 1 Circuit Low Input (Bank 1 or Single Sensor) |

DTC P0328 Knock Sensor 1 Circuit High Input (Bank 1 or Single Sensor) |

DTC P0332 Knock Sensor 2 Circuit Low Input (Bank 2) |

DTC P0333 Knock Sensor 2 Circuit High Input (Bank 2) |

DESCRIPTION

A flat type knock sensor (non-resonant type) can detect vibration in a wide band of frequency (6 kHz to 15 kHz).The sensor, located on the cylinder block, detects spark knock. When spark knock occurs, the knock sensor picks up vibrations in a specific frequency range. When the ECM detects signal voltage in this frequency range, it retards the ignition timing to suppress the knocking. The ECM also senses background engine noise with the knock sensor and uses this noise to check for faults in the sensor.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0327

P0332

| Output voltage of knock sensor 1 or 2 is 0.5 V or less

(1 trip detection logic)

| - Short in knock sensor 1 or 2 circuit

- Knock sensor 1 or 2

- ECM

|

P0328

P0333

| Output voltage of knock sensor 1 or 2 is 4.5 V or more

(1 trip detection logic)

| - Open in knock sensor 1 or 2 circuit

- Knock sensor 1 or 2

- ECM

|

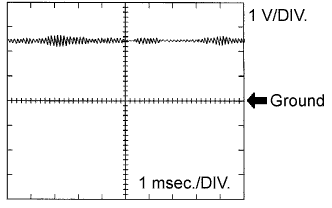

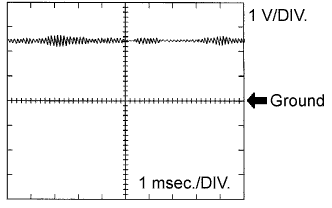

- Reference: Inspection using an oscilloscope.

The correct waveform is as shown.

Item

| Details

|

Tester Connection

| E7-28 (KNK1) - E7-30 (EKNK)

or

E7-29 (KNK2) - E-31 (EKN2)

|

Equipment Settings

| 0.01 to 10 V/DIV.,

0.01 to 10 msec./DIV.

|

Condition

| After warming up the engine,

keep the engine speed at 4,000 rpm.

|

MONITOR DESCRIPTION

If the output signal remains low or high for more than 10 seconds, the ECM interprets this as a fault in the knock sensor and sets a DTC.The monitors for DTC P0327, P0328, P0332 and P0333 run after the engine is started and 5 seconds have passed.

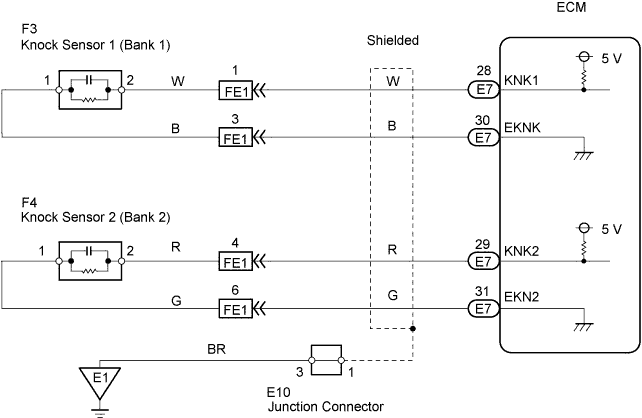

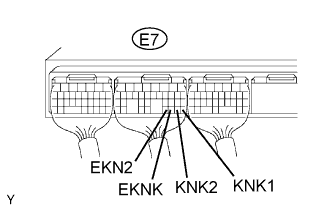

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- DTC P0327 and P0328 are for the bank 1 knock sensor circuit.

- DTC P0332 and P0333 are for the bank 2 knock sensor circuit.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was LEAN or RICH, and other data from the time the malfunction occurred.

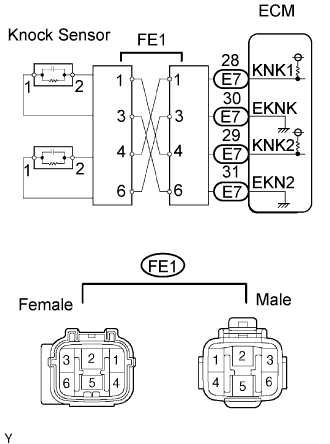

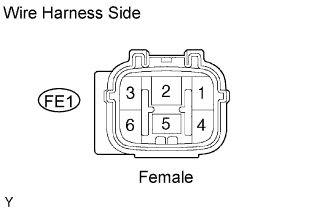

| 1.READ OUTPUT DTC (CHECK KNOCK SENSOR CIRCUIT) |

Disconnect the FE1 connector.

Using lead wires, connect the FE1 terminals as follows.

Male Connector - Female Connector

|

Terminal 1 - Terminal 4

|

Terminal 3 - Terminal 6

|

Terminal 4 - Terminal 1

|

Terminal 6 - Terminal 3

|

Warm up the engine.

Run the engine at 3,000 rpm for 10 seconds or more.

Read output DTC.

- Result:

Display

| Proceed to

|

DTC same as when vehicle brought in P0327, P0328 → P0327, P0328 or P0332, P0333 → P0332, P0333

| A

|

DTC different from when vehicle brought in P0327, P0328 → P0332, P0333 or P0332, P0333 → P0327, P0328

| B

|

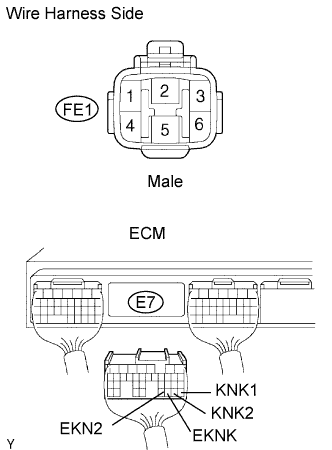

| 2.CHECK WIRE HARNESS (FE1 FEMALE CONNECTOR - ECM) |

Disconnect the FE1 connector.

Disconnect the E7 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

FE1 male connector 1 - E7-28 (KNK1)

| Below 1 Ω

|

FE1 male connector 3 - E7-30 (EKNK)

| Below 1 Ω

|

FE1 male connector 4 - E7-29 (KNK2)

| Below 1 Ω

|

FE1 male connector 6 - E7-31 (EKN2)

| Below 1 Ω

|

FE1 male connector 1 or E7-28 (KNK1) - Body ground

| 10 kΩ or higher

|

FE1 male connector 3 or E7-30 (EKNK) - Body ground

| 10 kΩ or higher

|

FE1 male connector 4 or E7-29 (KNK2) - Body ground

| 10 kΩ or higher

|

FE1 male connector 6 or E7-31 (EKN2) - Body ground

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| 3.CHECK ECM (KNK1, KNK2 VOLTAGE) |

Turn the engine switch on (IG).

Measure the voltage of the ECM connector.

- Standard voltage:

Tester Connection

| Specified Condition

|

E7-28 (KNK1) - E7-30 (EKNK)

| 4.5 to 5.5 V

|

E7-29 (KNK2) - E7-31 (EKN2)

| 4.5 to 5.5 V

|

| OK |

|

|

|

| CHECK FOR INTERMITTENT PROBLEMS |

|

| 4.INSPECT KNOCK SENSOR (RESISTANCE) |

Disconnect the FE1 connector.

Measure the resistance of the FE1 female connector.

- Standard resistance:

Tester Connection

| Specified Condition

|

FE1 female connector 1 - 3

| 120 to 280 kΩ

|

FE1 female connector 4 - 6

| 120 to 280 kΩ

|

| | CHECK FOR INTERMITTENT PROBLEMS |

|

|

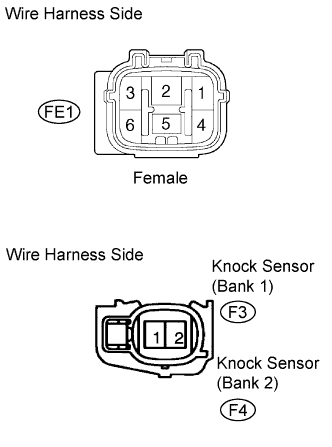

| 5.CHECK WIRE HARNESS (FE1 MALE CONNECTOR - KNOCK SENSOR) |

Disconnect the FE1 connector.

Disconnect the F3 and F4 knock sensor connectors.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

FE1 female connector 1 - F3-2

| Below 1 Ω

|

FE1 female connector 3 - F3-1

| Below 1 Ω

|

FE1 female connector 4 - F4-2

| Below 1 Ω

|

FE1 female connector 6 - F4-1

| Below 1 Ω

|

FE1 female connector 1 or F3-2 - Body ground

| 10 kΩ or higher

|

FE1 female connector 3 or F3-1 - Body ground

| 10 kΩ or higher

|

FE1 female connector 4 or F4-2 - Body ground

| 10 kΩ or higher

|

FE1 female connector 6 or F4-1 - Body ground

| 10 kΩ or higher

|

- HINT:

- If DTC P0327 or P0328 has changed to P0332 or P0333, check the knock sensor circuit on the bank 1 side.

- If DTC P0332 or P0333 has changed to P0327 or P0328, check the knock sensor circuit on the bank 2 side.

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|