Lighting System Headlight Beam Level Control Actuator Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING GTS (HEADLIGHT LEVELING MOTOR)

CHECK VEHICLE TYPE

CHECK HARNESS AND CONNECTOR (HEADLIGHT UNIT ASSEMBLY - HEADLIGHT LEVELING ECU ASSEMBLY)

CHECK HARNESS AND CONNECTOR (HEADLIGHT UNIT ASSEMBLY - HEADLIGHT SWIVEL ECU ASSEMBLY)

INSPECT HEADLIGHT UNIT ASSEMBLY

CHECK HEADLIGHT LEVELING MOTOR

LIGHTING SYSTEM - Headlight Beam Level Control Actuator Circuit |

DESCRIPTION

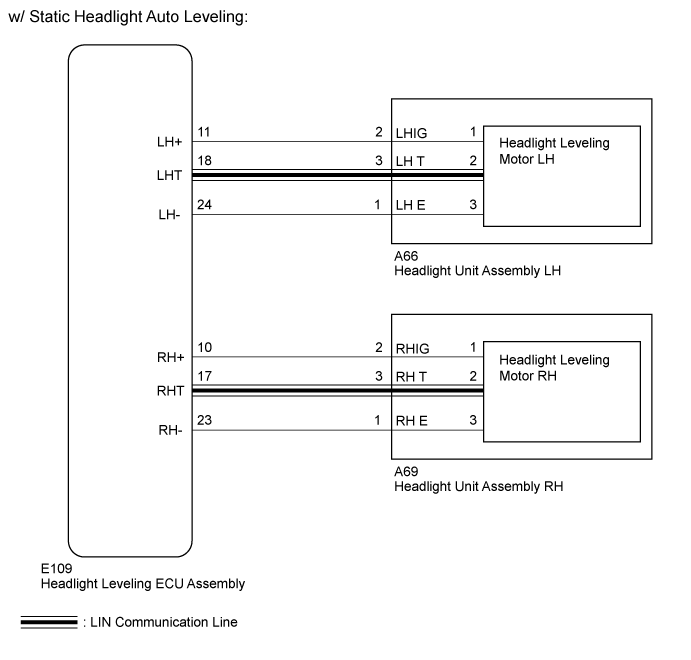

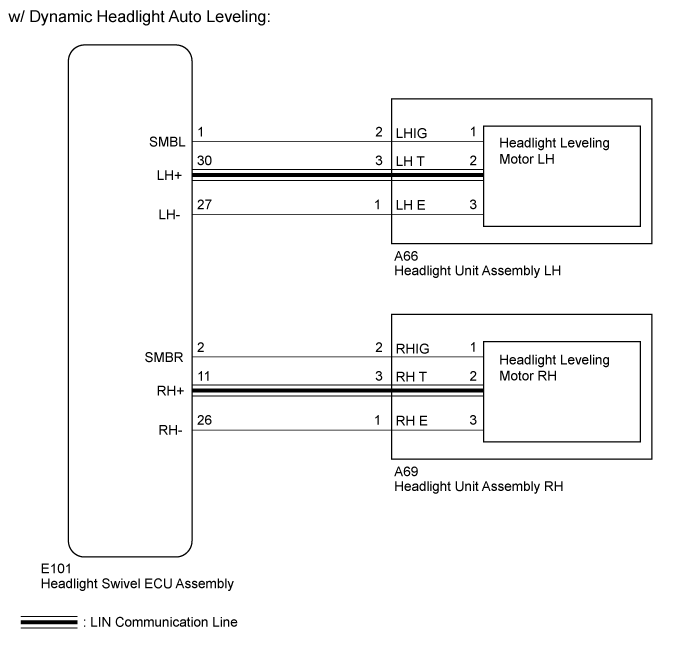

The headlight leveling ECU*1 or headlight swivel ECU*2 actuates the headlight leveling motors according to the vehicle conditions.- *1: w/ Static Headlight Auto Leveling

- *2: w/ Dynamic Headlight Auto Leveling

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- After replacing the headlight leveling ECU*1 or headlight swivel ECU*2, initialization of the ECU is necessary (Click here).

- *1: w/ Static Headlight Auto Leveling

- *2: w/ Dynamic Headlight Auto Leveling

| 1.PERFORM ACTIVE TEST USING GTS (HEADLIGHT LEVELING MOTOR) |

Using the GTS, perform the Active Test (Click here).

HL Auto Leveling (w/ Static Headlight Auto Leveling)Tester Display

| Test Part

| Control Range

| Diagnostic Note

|

HL Auto Leveling

| This test activates the Leveling Motor of the LH and RH headlights. By activating the Leveling Motor, illumination direction of the headlights can be moved up/down.

| Up, Down, Stop

| Perform the Active Test with the vehicle stopped, the ignition switch ON and the low beam headlights on.

|

AFS (w/ Dynamic Headlight Auto Leveling)Tester Display

| Test Part

| Control Range

| Diagnostic Note

|

HL Auto Leveling

| This test activates the Leveling Motor of the LH and RH headlights. By activating the Leveling Motor, illumination direction of the headlights can be moved up/down.

| Up, Down, Stop

| Perform the Active Test with the vehicle stopped, the ignition switch ON and the low beam headlights on.

|

- *: Perform the Active Test with the engine running and vehicle stopped.

- OK:

- Headlight leveling motors operate normally.

| OK |

|

|

|

| PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE (Click here) |

|

Check the vehicle type.

ResultResult

| Proceed to

|

w/ Static Headlight Auto Leveling

| A

|

w/ Dynamic Headlight Auto Leveling

| B

|

| 3.CHECK HARNESS AND CONNECTOR (HEADLIGHT UNIT ASSEMBLY - HEADLIGHT LEVELING ECU ASSEMBLY) |

Disconnect the E109 headlight leveling ECU connector.

Disconnect the A66*1 or A69*2 headlight leveling motor connector.

- *1: for LH

- *2: for RH

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHTester Connection

| Condition

| Specified Condition

|

E109-11 (LH+) - A66-2 (LHIG)

| Always

| Below 1 Ω

|

E109-18 (LHT) - A66-3 (LH T)

| Always

| Below 1 Ω

|

E109-24 (LH-) - A66-1 (LH E)

| Always

| Below 1 Ω

|

E109-11 (LH+) - Body ground

| Always

| 10 kΩ or higher

|

E109-18 (LHT) - Body ground

| Always

| 10 kΩ or higher

|

E109-24 (LH-) - Body ground

| Always

| 10 kΩ or higher

|

for RHTester Connection

| Condition

| Specified Condition

|

E109-10 (RH+) - A69-2 (RHIG)

| Always

| Below 1 Ω

|

E109-17 (RHT) - A69-3 (RH T)

| Always

| Below 1 Ω

|

E109-23 (RH-) - A69-1 (RH E)

| Always

| Below 1 Ω

|

E109-10 (RH+) - Body ground

| Always

| 10 kΩ or higher

|

E109-17 (RHT) - Body ground

| Always

| 10 kΩ or higher

|

E109-23 (RH-) - Body ground

| Always

| 10 kΩ or higher

|

| |

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 4.CHECK HARNESS AND CONNECTOR (HEADLIGHT UNIT ASSEMBLY - HEADLIGHT SWIVEL ECU ASSEMBLY) |

Disconnect the E101 headlight swivel ECU connector.

Disconnect the A66*1 or A69*2 headlight leveling motor connector.

- *1: for LH

- *2: for RH

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHTester Connection

| Condition

| Specified Condition

|

E101-1 (SMBL) - A66-2 (LHIG)

| Always

| Below 1 Ω

|

E101-30 (LH+) - A66-3 (LH T)

| Always

| Below 1 Ω

|

E101-27 (LH-) - A66-1 (LH E)

| Always

| Below 1 Ω

|

E101-1 (SMBL) - Body ground

| Always

| 10 kΩ or higher

|

E101-30 (LH+) - Body ground

| Always

| 10 kΩ or higher

|

E101-27 (LH-) - Body ground

| Always

| 10 kΩ or higher

|

for RHTester Connection

| Condition

| Specified Condition

|

E101-2 (SMBR) - A69-2 (RHIG)

| Always

| Below 1 Ω

|

E101-11 (RH+) - A69-3 (RH T)

| Always

| Below 1 Ω

|

E101-26 (RH-) - A69-1 (RH E)

| Always

| Below 1 Ω

|

E101-2 (SMBR) - Body ground

| Always

| 10 kΩ or higher

|

E101-11 (RH+) - Body ground

| Always

| 10 kΩ or higher

|

E101-23 (RH-) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

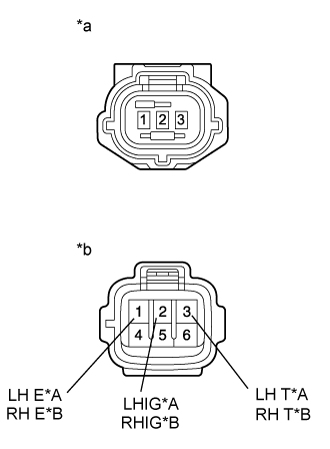

| 5.INSPECT HEADLIGHT UNIT ASSEMBLY |

Remove the headlight unit.

for LED Headlight (Click here).

for Halogen Headlight and LED Headlight (Click here).

Disconnect the headlight leveling motor connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

- for LH:

Tester Connection

| Condition

| Specified Condition

|

2 (LHIG) - 1

| Always

| Below 1 Ω

|

3 (LH T) - 2

|

1 (LH E) - 3

|

- for RH:

Tester Connection

| Condition

| Specified Condition

|

2 (RHIG) - 1

| Always

| Below 1 Ω

|

3 (RH T) - 2

|

1 (RH E) - 3

|

Text in Illustration*A

| for LH

|

*B

| for RH

|

*a

| Front view of wire harness connector

(to Headlight Leveling Motor)

|

*b

| Component without harness connected

(Headlight Unit Assembly)

|

ResultResult

| Proceed to

|

OK

| A

|

NG (for LED Headlight)

| B

|

NG (for Halogen Headlight and LED Headlight)

| C

|

| 6.CHECK HEADLIGHT LEVELING MOTOR |

Temporarily replace the headlight leveling motor with a new or normally functioning one (Click here).

Perform the Active Test of the leveling motors (Click here).

- OK:

- Headlight leveling motors operate normally.

ResultResult

| Proceed to

|

OK

| A

|

NG (w/ Static Headlight Auto Leveling)

| B

|

NG (w/ Dynamic Headlight Auto Leveling) (for LHD)

| C

|

NG (w/ Dynamic Headlight Auto Leveling) (for RHD)

| D

|

| | REPLACE HEADLIGHT LEVELING ECU ASSEMBLY (Click here) |

|

|

| | REPLACE HEADLIGHT SWIVEL ECU ASSEMBLY (Click here) |

|

|

| | REPLACE HEADLIGHT SWIVEL ECU ASSEMBLY (Click here) |

|

|

| A |

|

|

|

| END (HEADLIGHT LEVELING MOTOR WAS DEFECTIVE) |

|