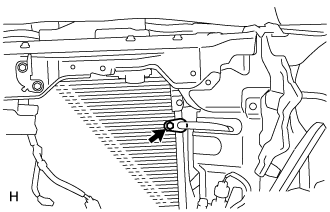

CONNECT OIL COOLER ASSEMBLY (w/ Air Cooled Transmission Oil Cooler)

INSTALL SHROUD BLOWER ASSEMBLY (w/ Rear Air Conditioning System)

Condenser -- Installation |

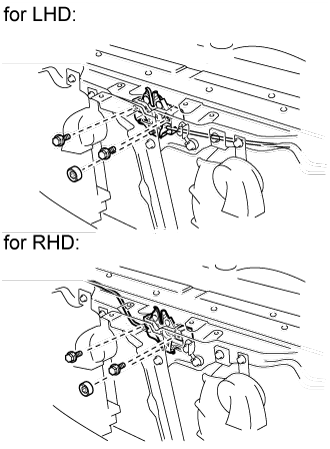

- HINT:

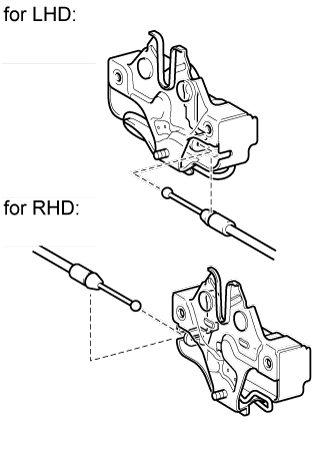

- Use the same procedures for LHD and RHD vehicles.

- The procedures listed below are for LHD vehicles.

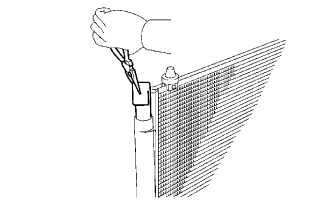

| 1. INSTALL COOLER DRYER |

Using pliers, install the cooler dryer.

|

Apply a sufficient amount of compressor oil to the contact surfaces of a new O-ring and the cap.

- Compressor oil:

- ND-OIL 8 or equivalent

|

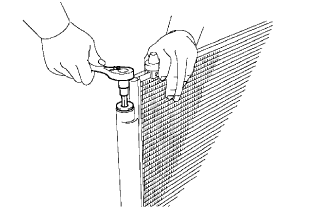

Install O-ring to the cap.

Using a 14 mm socket hexagon wrench, install the cap to the modulator.

- Torque:

- 2.9 N*m{30 kgf*cm, 26 in.*lbf}

|

| 2. INSTALL COOLER CONDENSER ASSEMBLY |

Install the cooler condenser as shown in the illustration.

|

| 3. INSTALL RADIATOR SUPPORT SUB-ASSEMBLY |

|

Install the radiator support with the 8 bolts.

- Torque:

- 21.7 N*m{221 kgf*cm, 16 ft.*lbf}for bolt A

- 9.8 N*m{100 kgf*cm, 7 ft.*lbf}for bolt B

| 4. INSTALL RADIATOR ASSEMBLY |

for 1UR-FE:

Click here

for 1GR-FE:

Click here

for 3UR-FE:

Click here

for 1VD-FTV:

Click here

| 5. INSTALL HOOD LOCK ASSEMBLY |

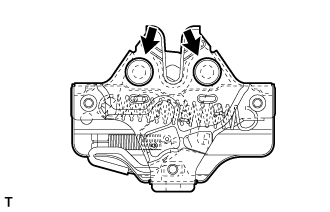

Apply MP grease to the sliding areas of the hood lock assembly.

|

Connect the hood lock control cable assembly.

|

Install the hood lock assembly.

Install the 2 bolts and nut.

- Torque:

- 5.5 N*m{56 kgf*cm, 49 in.*lbf}

|

Connect the connector.

| 6. INSTALL HOOD LOCK CONTROL CABLE COVER |

Attach the claw to install the hood lock control cable cover.

|

Install the 3 screws.

| 7. CONNECT OIL COOLER ASSEMBLY (w/ Air Cooled Transmission Oil Cooler) |

AB60F:

(Click here)

A750F:

(Click here)

AE80F:

(Click here)

| 8. INSTALL FRONT BUMPER CENTER UPPER RETAINER |

for Standard:

(Click here)

w/ Winch:

(Click here)

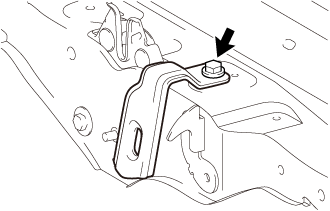

| 9. INSTALL HOOD LOCK SUPPORT BRACE SUB-ASSEMBLY |

|

Install the brace with the 3 bolts and nut.

- Torque:

- 21.7 N*m{221 kgf*cm, 16 ft.*lbf}for bolt A

- 5.5 N*m{56 kgf*cm, 49 in.*lbf}for nut

| 10. INSTALL LOWER NO. 1 RADIATOR MOUNTING BRACKET |

Install the lower No. 1 radiator mounting bracket with the bolt.

|

| 11. INSTALL SHROUD BLOWER ASSEMBLY (w/ Rear Air Conditioning System) |

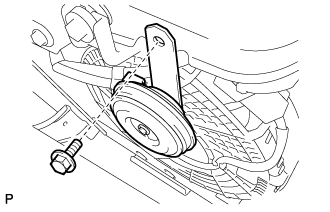

| 12. INSTALL LOW PITCHED HORN ASSEMBLY |

Connect the connector.

|

Install the low pitched horn assembly with the bolt.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

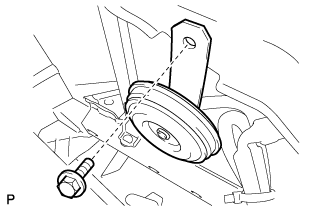

| 13. INSTALL HIGH PITCHED HORN ASSEMBLY |

Connect the connector.

Install the high pitched horn assembly with the bolt.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

|

| 14. CONNECT COOLER REFRIGERANT LIQUID PIPE A |

|

Remove the attached vinyl tape from the hose and the connecting part of the cooler condenser.

Sufficiently apply compressor oil to a new O-ring and the fitting surface of the pipe joint.

- Compressor oil:

- ND-OIL 8 or equivalent

Install O-ring on the liquid pipe A.

Connect the liquid pipe A to the cooler condenser with the bolt.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

- NOTICE:

- When tightening the bolt, do not allow any tools to contact the pipe.

- When tightening the bolt, hold a part of the pipe near the connector.

| 15. CONNECT NO. 1 COOLER REFRIGERANT DISCHARGE HOSE |

|

Remove the attached vinyl tape from the pipe and the connecting part of the cooler condenser.

Sufficiently apply compressor oil to a new O-ring and the fitting surface of the hose joint.

- Compressor oil:

- ND-OIL 8 or equivalent

Install O-ring on the discharge hose.

Connect the discharge hose to the cooler condenser with the 2 bolts.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

- NOTICE:

- When tightening the bolts, do not allow any tools to contact the pipe.

- When tightening the bolts, hold a part of the pipe near the connector.

| 16. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (Click here).

| 17. CHARGE REFRIGERANT |

- SST

- 09985-20010(09985-02130,09985-02150,09985-02090,09985-02110,09985-02010,09985-02050,09985-02060,09985-02070)

Perform vacuum purging using a vacuum pump.

Charge refrigerant HFC-134a (R134a).

Standard: Condenser Core Thickness Air Conditioning Type Cool Box Refrigerant Charging Amount 22 mm (0.866 in.) w/o Rear Cooler w/ Cool Box 870 +/-50 g (30.7 +/-1.76 oz.) w/o Cool Box 870 +/-50 g (30.7 +/-1.76 oz.) w/ Rear Cooler w/ Cool Box 1010 +/-50 g (35.6 +/-1.76 oz.) w/o Cool Box 970 +/-50 g (34.2 +/-1.76 oz.) 16 mm (0.630 in.) w/o Rear Cooler w/ Cool Box 770 +/-50 g (27.2 +/-1.76 oz.) w/o Cool Box 770 +/-50 g (27.2 +/-1.76 oz.) w/ Rear Cooler w/ Cool Box 970 +/-50 g (34.2 +/-1.76 oz.) w/o Cool Box 920 +/-50 g (32.5 +/-1.76 oz.)

- NOTICE:

- Do not operate the cooler compressor before charging refrigerant as the cooler compressor will not work properly without any refrigerant, and will overheat.

- Approximately 100g (3.53 oz.) of refrigerant may need to be charged after bubbles disappear. The refrigerant amount should be checked by measuring its quantity, and not with the sight glass.

| 18. WARM UP ENGINE |

Warm up the engine at less than 1850 rpm for 2 minutes or more after charging the refrigerant.

- NOTICE:

- Be sure to warm up the compressor when turning the A/C switch is on after removing and installing the cooler refrigerant lines (including the compressor), to prevent damage to the compressor.

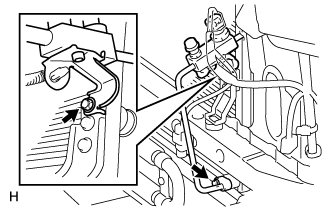

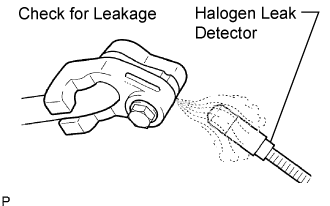

| 19. CHECK FOR REFRIGERANT GAS LEAK |

After recharging the refrigerant gas, check for refrigerant gas leakage using a halogen leak detector.

Perform the operation under these conditions:

- Stop the engine.

- Secure good ventilation (the halogen leak detector may react to volatile gases other than refrigerant, such as evaporated gasoline or exhaust gas).

- Repeat the test 2 or 3 times.

- Make sure that some refrigerant remains in the refrigeration system. When compressor is off: approximately 392 to 588 kPa (4.0 to 6.0 kgf/cm2, 57 to 85 psi).

- Stop the engine.

Using a halogen leak detector, check the refrigerant line for leakage.

|

If a gas leak is not detected on the drain hose, remove the blower motor control (blower resistor) from the cooling unit. Insert the halogen leak detector sensor into the unit and perform the test.

Disconnect the connector and wait for approximately 20 minutes. Bring the halogen leak detector close to the pressure switch and perform the test.

| 20. CHECK SRS WARNING LIGHT |

| 21. INSTALL FRONT BUMPER COVER |

for Standard:

(Click here)

w/ Winch:

(Click here)