Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1GR-FE ENGINE MECHANICAL

CYLINDER HEAD GASKET - INSTALLATION

| 1. INSPECT CYLINDER HEAD SET BOLT |

Using a vernier caliper, measure the length of the cylinder head set bolt from the seat to the end.

- Standard length:

- 141.3 to 142.7 mm (5.56 to 5.62 in.)

- Maximum length:

- 143.7 mm (5.66 in.)

| *1 | Measurement Length |

If the length is more than the maximum, replace the cylinder head set bolt.

Using a vernier caliper, measure the diameter of the elongated thread at the narrowest visible area.

- Standard diameter:

- 10.73 to 10.97 mm (0.422 to 0.432 in.)

- Minimum diameter:

- 10.40 mm (0.409 in.)

If the diameter is less than the minimum, replace the cylinder head set bolt.

- HINT:

- If a visual check reveals no excessively thin areas, check the center of the bolt (refer to illustration) and find the area that has the smallest diameter.

| 2. INSPECT CYLINDER HEAD SUB-ASSEMBLY |

Using a precision straightedge and feeler gauge, measure the warpage of the surfaces which contact the cylinder block sub-assembly and manifolds.

- Standard Warpage:

Item Specified Condition Cylinder block side 0.05 mm (0.00197 in.) Intake side 0.08 mm (0.00315 in.) Exhaust side 0.08 mm (0.00315 in.)

- Maximum Warpage:

Item Specified Condition Cylinder block side 0.10 mm (0.00394 in.) Intake side 0.10 mm (0.00394 in.) Exhaust side 0.10 mm (0.00394 in.)

| *a | Cylinder Block Side |

| *b | Intake Side |

| *c | Exhaust Side |

If the warpage is more than the maximum, replace the cylinder head sub-assembly.

Using a dye penetrant, check the intake ports, exhaust ports and cylinder surface for cracks.

If cracked, replace the cylinder head sub-assembly.

| 3. INSTALL CYLINDER HEAD GASKET |

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the cylinder head or cylinder block.

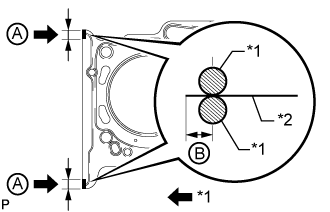

Apply seal packing to a new cylinder head gasket as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 2.5 to 3.0 mm (0.0984 to 0.118 in.)

| A | 10 to 15 mm (0.394 to 0.591 in.) |

| B | 1.25 to 1.5 mm (0.0492 to 0.0591 in.) |

| *1 | Seal Packing |

| *2 | Gasket |

- NOTICE:

Place the cylinder head gasket on the cylinder block surface with the front face of the Lot No. stamp upward.

| *1 | Lot No. |

| Engine Front |

- NOTICE:

- Make sure that the gasket is installed facing the proper direction.

| 4. INSTALL CYLINDER HEAD SUB-ASSEMBLY |

Place the cylinder head on the cylinder block.

- NOTICE:

- HINT:

- The cylinder head bolts are tightened in 3 progressive steps.

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

Step 1:

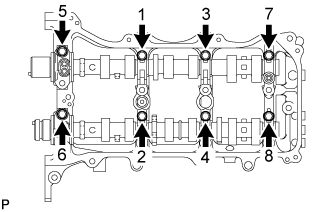

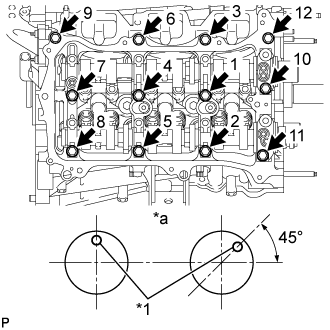

Using a 10 mm bi-hexagon wrench, install and uniformly tighten the 8 cylinder head bolts with the plate washers in several steps in the sequence shown in the illustration.

- Torque:

- 36 N*m{ 367 kgf*cm, 27 ft.*lbf}

Step 2:

Mark the front side of each cylinder head bolt head with paint.

Tighten the cylinder head bolts another 90°.

Step 3:

Tighten the cylinder head bolts an additional 90°.

Check that the paint marks are now at a 180° angle to the front.

- NOTICE:

- Thoroughly wipe clean any seal packing.

| 5. INSTALL NO. 2 CYLINDER HEAD GASKET |

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the cylinder head or cylinder block.

Apply seal packing to a new cylinder head gasket as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 2.5 to 3.0 mm (0.0984 to 0.118 in.)

| A | 10 to 15 mm (0.394 to 0.591 in.) |

| B | 1.25 to 1.5 mm (0.0492 to 0.0591 in.) |

| *1 | Seal Packing |

| *2 | Gasket |

- NOTICE:

Place the cylinder head gasket on the cylinder block surface with the front face of the Lot No. stamp upward.

| *1 | Lot No. |

| Engine Front |

- NOTICE:

- Make sure that the gasket is installed facing the proper direction.

| 6. INSTALL CYLINDER HEAD LH |

Place the cylinder head on the cylinder block.

- NOTICE:

- HINT:

- The cylinder head bolts are tightened in 3 progressive steps.

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

Step 1:

Using a 10 mm bi-hexagon wrench, install and uniformly tighten the 8 cylinder head bolts with the plate washers in several steps in the sequence shown in the illustration.

- Torque:

- 36 N*m{ 367 kgf*cm, 27 ft.*lbf}

Step 2:

Mark the front side of each cylinder head bolt head with paint.

Tighten the cylinder head bolts another 90°.

Step 3:

Tighten the cylinder head bolts an additional 90°.

Check that the paint marks are now at a 180° angle to the front.

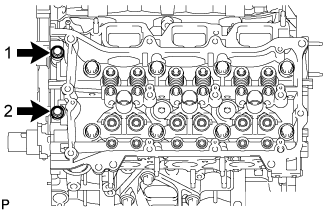

Install the 2 bolts in the order shown in the illustration.

- Torque:

- 30 N*m{ 306 kgf*cm, 22 ft.*lbf}

- NOTICE:

- Thoroughly wipe clean any seal packing.

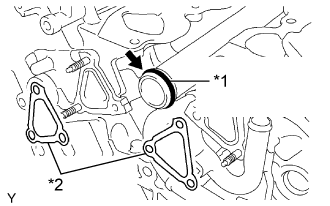

| 7. INSTALL REAR WATER BY-PASS JOINT |

Apply soapy water to a new O-ring and install it to the water outlet pipe. Then install 2 new gaskets to the water ports LH and RH.

| *1 | New O-Ring |

| *2 | New Gasket |

Install the rear water by-pass joint with the 2 bolts and 4 nuts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 8. INSTALL VALVE STEM CAP |

Apply a light coat of engine oil to the valve stem caps.

Install the 24 valve stem caps to the cylinder head.

| 9. INSTALL VALVE LASH ADJUSTER ASSEMBLY |

Inspect the valve lash adjuster ().

Install the 24 valve lash adjusters to the cylinder head.

- NOTICE:

- Install the lash adjuster at the same place it was removed from.

| 10. INSTALL NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

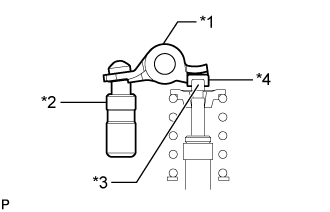

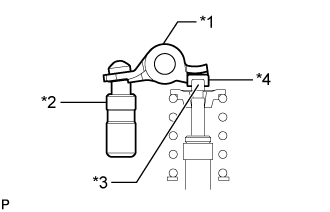

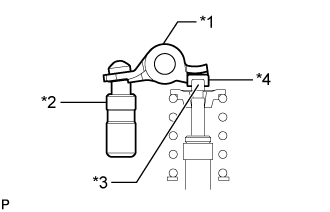

Apply engine oil to the lash adjuster tips and valve stem cap ends.

Install the 24 valve rocker arms as shown in the illustration.

| *1 | Valve Rocker Arm |

| *2 | Lash Adjuster |

| *3 | Valve Stem |

| *4 | Valve Stem Cap |

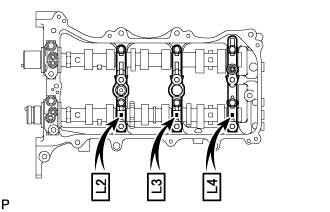

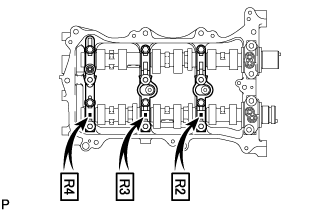

| 11. INSTALL CAMSHAFT BEARING CAP (for Bank 2) |

Apply a light coat of engine oil to the camshaft journals, camshaft housings and bearing caps.

Install the No. 3 camshaft and No. 4 camshaft to the camshaft housing.

Check the marks and numbers on the camshaft bearing caps and place each of them in the proper position facing the proper direction.

Temporarily install the 8 bolts in the order shown in the illustration.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 12. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY LH |

Make sure that the valve rocker arm is installed as shown in the illustration.

| *1 | Valve Rocker Arm |

| *2 | Lash Adjuster |

| *3 | Valve Stem |

| *4 | Valve Stem Cap |

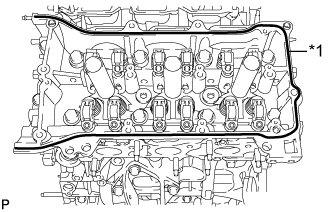

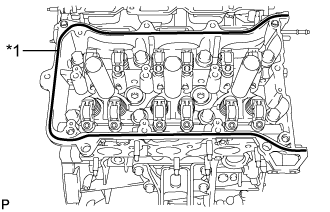

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Seal diameter:

- 3.5 to 4.5 mm (0.138 to 0.177 in.)

| *1 | Seal Packing |

- NOTICE:

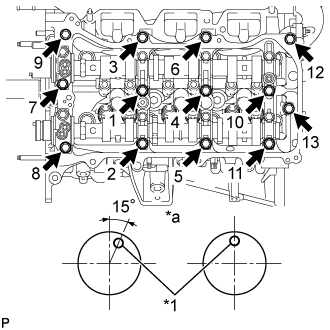

Install the camshaft housing sub-assembly LH and tighten the 13 bolts in the order shown in the illustration.

- Torque:

- 28 N*m{ 286 kgf*cm, 21 ft.*lbf}

| *1 | Knock Pin |

| *a | Front View |

- NOTICE:

Tighten the 8 bolts in the order shown in the illustration.

- Torque:

- 16 N*m{ 163 kgf*cm, 12 ft.*lbf}

- NOTICE:

- Thoroughly wipe clean any seal packing.

| 13. INSTALL CAMSHAFT BEARING CAP (for Bank 1) |

Apply a light coat of engine oil to the camshaft journals, camshaft housings and bearing caps.

Install the camshaft and No. 2 camshaft to the camshaft housing.

Check the marks and numbers on the camshaft bearing caps and place each of them in the proper position facing the proper direction.

Temporarily install the 8 bearing cap bolts in the order shown in the illustration.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 14. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY RH |

Make sure that the No. 1 valve rocker arm sub-assembly is installed as shown in the illustration.

| *1 | Valve Rocker Arm |

| *2 | Lash Adjuster |

| *3 | Valve Stem |

| *4 | Valve Stem Cap |

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Seal diameter:

- 3.5 to 4.5 mm (0.138 to 0.177 in.)

| *1 | Seal Packing |

- NOTICE:

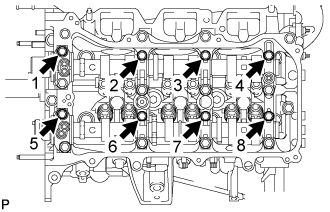

Install the camshaft housing sub-assembly RH and tighten the 12 bolts in the order shown in the illustration.

- Torque:

- 28 N*m{ 286 kgf*cm, 21 ft.*lbf}

| *1 | Knock Pin |

| *a | Front View |

- NOTICE:

Failure to correctly position these parts may result in damage due to contact between the pistons and valves. If a camshaft is rotated with a piston at TDC, valve contact will occur.

Tighten the 8 bolts in the order shown in the illustration.

- Torque:

- 16 N*m{ 163 kgf*cm, 12 ft.*lbf}

- NOTICE:

- Thoroughly wipe clean any seal packing.

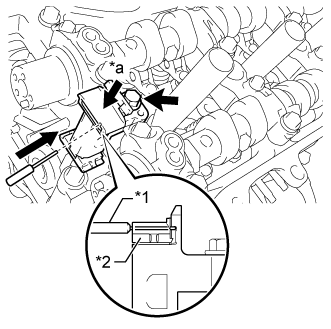

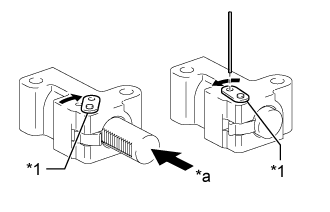

| 15. INSTALL NO. 3 CHAIN TENSIONER ASSEMBLY |

Install the No. 3 chain tensioner assembly with the bolt.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Push in the tensioner and insert a pin with a diameter of 1.0 mm (0.0394 in.) into the hole to hold the tensioner.

| *1 | Pin |

| *2 | Plunger |

| *a | Push |

| 16. INSTALL CAMSHAFT TIMING GEARS AND NO. 2 CHAIN (for Bank 2) |

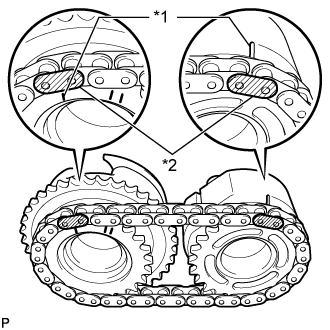

Align the mark plates (yellow) with the timing marks of the camshaft timing gear assemblies as shown in the illustration.

| *1 | Timing Mark |

| *2 | Mark Plate |

Apply a light coat of engine oil to the bolt threads and bolt-seating surface.

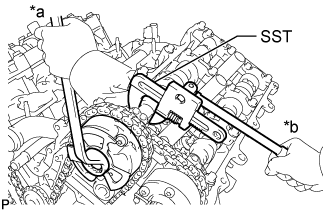

Align the knock pin of the camshaft with the pin hole of the camshaft timing gear assembly. Install the camshaft timing gear assembly and camshaft timing exhaust gear LH with the No. 2 chain sub-assembly installed.

Using SST to hold the hexagonal portion of each camshaft, tighten the bolts of the camshaft timing gear assembly and camshaft timing exhaust gear assembly.

- SST

- 09922-10010

- Torque:

- 100 N*m{ 1020 kgf*cm, 74 ft.*lbf}

| *a | Turn |

| *b | Hold |

Remove the pin from the No. 3 chain tensioner assembly.

| 17. INSTALL NO. 2 CHAIN TENSIONER ASSEMBLY |

Install the No. 2 chain tensioner assembly with the bolt.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Push in the No. 2 chain tensioner assembly and insert a pin with a diameter of 1.0 mm (0.0394 in.) into the hole to hold the tensioner.

| *1 | Pin |

| *2 | Plunger |

| *a | Push |

| 18. INSTALL CAMSHAFT TIMING GEARS AND NO. 2 CHAIN (for Bank 1) |

Align the mark plates (yellow) with the timing marks of the camshaft timing gear assemblies as shown in the illustration.

| *1 | Timing Mark |

| *2 | Mark Plate |

Apply a light coat of engine oil to the bolt threads and bolt-seating surface.

Align the knock pin of the camshaft with the pin hole of the camshaft timing gear assembly. Install the camshaft timing gear assembly and camshaft timing exhaust gear assembly with the No. 2 chain sub-assembly installed.

Using SST to hold the hexagonal portion of each camshaft, tighten the bolts of the camshaft timing gear assembly and camshaft timing exhaust gear assembly.

- SST

- 09922-10010

- Torque:

- 100 N*m{ 1020 kgf*cm, 74 ft.*lbf}

| *a | Turn |

| *b | Hold |

Remove the pin from the No. 2 chain tensioner assembly.

| 19. INSTALL NO. 1 CHAIN VIBRATION DAMPER |

Install the No. 1 chain vibration damper with the 2 bolts.

- Torque:

- 23 N*m{ 229 kgf*cm, 17 ft.*lbf}

| 20. INSTALL NO. 2 CHAIN VIBRATION DAMPER |

Install the 2 No. 2 chain vibration dampers.

| 21. INSTALL CRANKSHAFT TIMING SPROCKET |

Align the key groove of the timing sprocket with the timing sprocket set key.

Install the timing sprocket to the crankshaft with the sprocket facing inward as shown in the illustration.

| *a | Inward |

| 22. INSTALL NO. 1 IDLE GEAR SHAFT |

Apply a light coat of engine oil to the sliding surface of the No. 1 idle gear shaft.

Temporarily install the No. 1 idle gear shaft and No. 1 idle gear with the No. 2 idle gear shaft while aligning the knock pin of the No. 1 idle gear shaft with the knock pin groove of the cylinder block.

| *1 | Knock Pin |

- NOTICE:

- Make sure that the idle gear is installed facing the proper direction.

Using a 10 mm hexagon wrench, tighten the No. 2 idle gear shaft.

- Torque:

- 60 N*m{ 612 kgf*cm, 44 ft.*lbf}

Remove the bar from the chain tensioner.

| 23. INSTALL CHAIN SUB-ASSEMBLY |

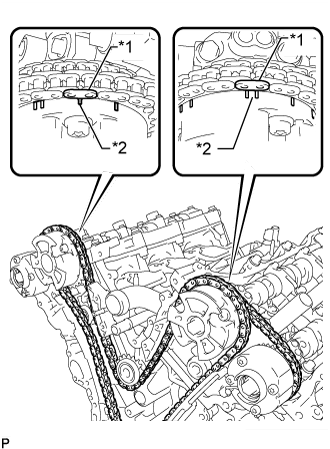

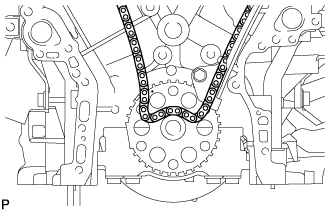

Align the mark plate and timing marks as shown in the illustration and install the chain.

| *1 | Mark Plate |

| *2 | Timing Mark |

- HINT:

- The camshaft mark plates are orange.

Do not pass the chain around the crankshaft, just temporarily place it on the crankshaft.

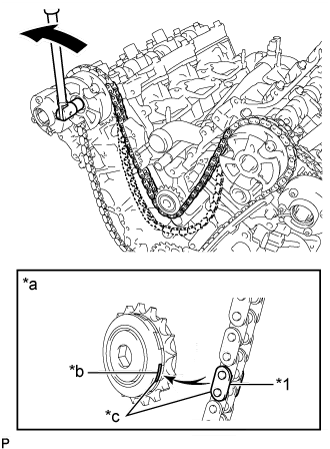

Turn the camshaft timing gear assembly on bank 1 counterclockwise to tighten the chain between the banks.

| *1 | Chain Plate |

| *a | When idle sprocket is reused |

| *b | Mark |

| *c | Align |

| Turn |

- NOTICE:

- When the idle sprocket assembly is reused, align the chain plate with the mark where the plate had been when tightening the chain between the banks.

Align the mark plate and timing marks as shown in the illustration and install the chain to the crankshaft timing sprocket.

| *1 | Mark Plate |

| *2 | Timing Mark |

- HINT:

- The crankshaft mark plate is yellow.

Temporarily install the pulley set bolt.

Turn the crankshaft clockwise to set it to the RH block bore center line (TDC/compression).

| *1 | Center Line |

| *2 | Timing Mark |

| *3 | Sensor Plate |

| 24. INSTALL CHAIN TENSIONER SLIPPER |

Install the chain tensioner slipper.

| 25. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY |

Turn the stopper plate of the tensioner clockwise and push in the plunger of the tensioner as shown in the illustration.

| *1 | Stopper Plate |

| *a | Push |

Turn the stopper plate of the tensioner counterclockwise and insert a pin with a diameter of 1.27 mm (0.0500 in.) into the holes on the stopper plate and tensioner to fix the stopper plate in place.

Install the chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Remove the pin from the No. 1 chain tensioner.

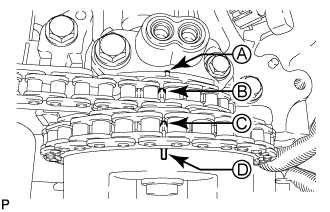

| 26. INSPECT VALVE TIMING |

Check the camshaft timing marks.

- NOTICE:

Check that each camshaft timing mark is positioned as shown in the illustration.

| *1 | Timing Mark | - | - |

| *a | Viewpoint | - | - |

- HINT:

- for Intake Camshaft:

- Be sure to check mark A at the point when marks B, C and D are positioned in line. If the marks are checked from any other viewpoint, they cannot be checked correctly.

If the valve timing is misaligned, reinstall the timing chain.

Remove the pulley set bolt.

| 27. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY |

()