Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1VD-FTV ENGINE CONTROL

REPLACE THE PART WHICH IS LEAKING OIL

REPLACE TURBOCHARGER SUB-ASSEMBLY

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

ECD SYSTEM (w/ DPF) - Turbocharger Oil Leak and White Smoke

DESCRIPTION

| Oil Leak Type | Description | Main Trouble Area |

| Internal oil leak (White smoke) | Oil leak from bearing housing to compressor housing (intake side) or turbine housing (exhaust side) through seal rings. Internal oil leak is not visible from outside of turbocharger. If oil leak occurs from turbine side seal, large amount of white smoke will be emitted from exhaust pipe. | Compressor side seal ring Turbine side seal ring Clogging of oil drain Shaft breakage Shaft and bearing seizure Compressor impeller damage Low quality fuel |

| External oil leak | Oil leak from inside of turbocharger to outside of turbocharger (e.g. from FIPG seal, oil pipe flange or oil pipe union). Includes oil leak visible from outside of turbocharger. | FIPG sealing part Oil pipe flange Oil pipe union Hose connection of intake pipe |

- HINT:

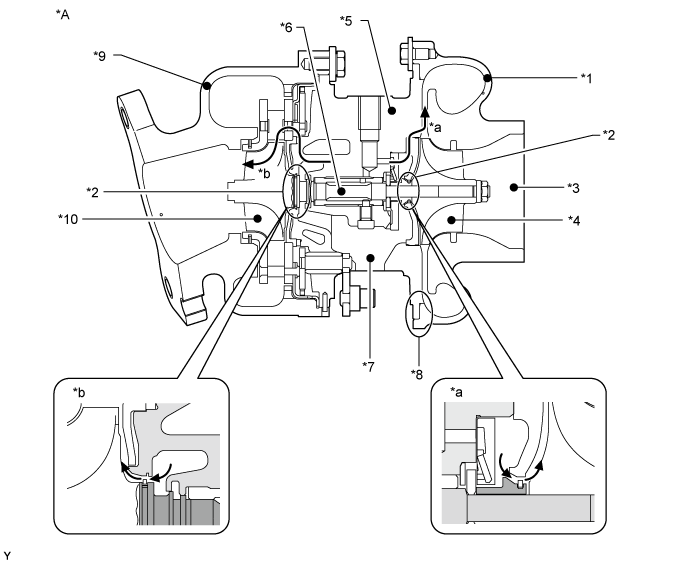

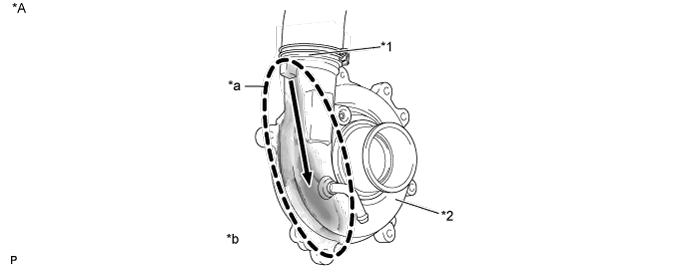

| *A | DC Motor Type Turbocharger (No. 1) | - | - |

| *1 | Compressor Housing | *2 | Seal Ring |

| *3 | Compressor Inlet | *4 | Compressor Impeller |

| *5 | Bearing Housing | *6 | Turbine Shaft |

| *7 | Oil Drain (Outlet) | *8 | FIPG Sealing Part |

| *9 | Turbine Housing | *10 | Turbine Wheel |

| *a | Internal oil leak to compressor housing | *b | Internal oil leak to turbine housing |

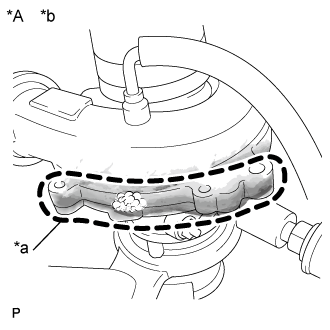

| *A | Fig. 1 | - | - |

- HINT:

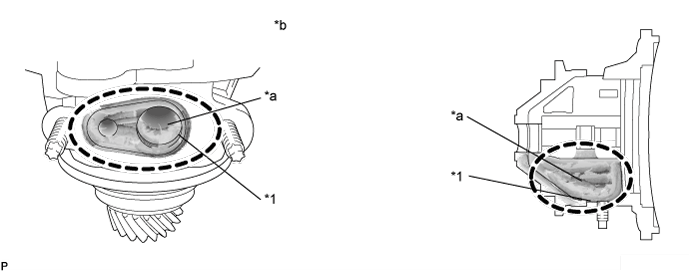

| *A | Fig. 2 | *B | Fig. 3 |

| *a | Oil Existence at Compressor Inlet (Max. 5 cm3) | *b | Oil Existence at Compressor Outlet |

- HINT:

| *A | Fig. 4 | - | - |

| *a | In the case of an actual oil leak, oil leaks from the sealed part | *b | Oil Leak Check Point (FIPG Sealing Part) |

- HINT:

| Faults and Symptoms of Turbocharger Parts |

| Main fault | Seal ring breakage |

| Symptoms | Oil leak to compressor housing Excessive oil consumption |

| Note | In case of compressor seal ring failure, large amount of oil would be found between compressor outlet and intercooler, and between intercooler and intake manifold, but not found at compressor inlet. If large amount of oil is found at compressor inlet, it is not from turbocharger and may indicate a problem in the PCV system. |

| Main fault | Seal ring breakage |

| Symptoms | Oil leak to turbine housing Large amount of white smoke from exhaust pipe Excessive oil consumption |

| Note | In case of turbine seal ring failure, large amount of white smoke would be emitted continuously. If white smoke is emitted only just after engine start (and it disappears later), or small amount of white smoke is emitted intermittently, it is not from turbocharger. It is due to failure of other parts. If wet oil is found at turbine inlet, it is not from turbocharger. It is due to problem in other parts. |

| Main fault | Oil drain clogging by coked oil |

| Symptoms | Large amount of white smoke from exhaust pipe |

- HINT:

| *1 | Oil Drain | - | - |

| *a | Coked Oil | *b | Oil Drain Clogged with Coked Oil |

- HINT:

- This illustration is not the turbocharger of the 1VD-FTV engine.

| Main fault | Breakage Seizure |

| Symptoms | Shaft does not rotate Oil leak to compressor housing Large amount of white smoke from exhaust pipe Lack of power Turbocharger noise changes |

| Note | In case of turbine shaft failure, lack of power due to lack of boost pressure will be felt. In cold conditions, shaft rotation can feel somewhat clingy due to viscosity of oil. Be sure not to mistake it for unsmooth shaft rotation. |

| Main fault | Breakage |

| Symptoms | Shaft does not rotate Oil leak to compressor housing Lack of power |

| Note | In case of compressor impeller failure, large amount of oil would be found between compressor outlet and intercooler, and between intercooler and intake manifold, but not found at compressor inlet. Oil is blocked by boost pressure at compressor seal ring. Therefore, if boost pressure does not increase due to breakage of compressor impeller, oil flows out to compressor housing. |

| Symptoms | Oil leak from FIPG sealing part |

| Note | If oil stain is separated from FIPG sealing part, it can be determined to be due to oil spray from other parts surrounding turbocharger. If oil stain is traced to hose connection part, it can be determined to be due to hose connection failure. |

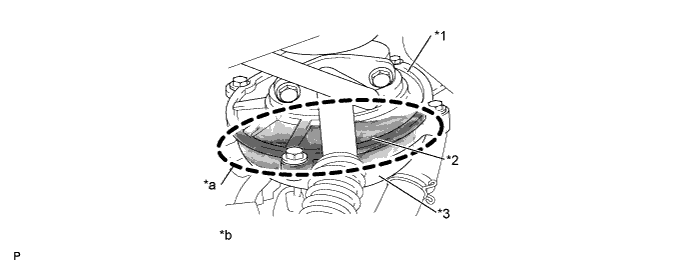

| *1 | Compressor Back Plate | *2 | FIPG Sealing Part |

| *3 | Compressor Housing | - | - |

| *a | Oil Leak | *b | Oil Leak from FIPG Sealing Part |

- HINT:

- This illustration is not the turbocharger of the 1VD-FTV engine.

| Symptoms | Oil leak from hose connection between hose and compressor housing |

| Note | If oil stain is traced to hose connection part, it can be determined to be due to hose connection failure. |

| *A | Fig. 5 | - | - |

| *1 | Compressor Outlet | *2 | Compressor Housing |

| *a | Trace of Oil Leak from Hose Connection Part | *b | Oil Leak from Hose Connection Part |

- HINT:

- This illustration is not the turbocharger of the 1VD-FTV engine.

INSPECTION PROCEDURE

| 1.CHECK TYPE OF OIL LEAK |

Check whether the oil leak is an internal or external oil leak.

- HINT:

- White smoke is not related to an external oil leak.

| Oil Leak Type | Description |

| Internal oil leak (White smoke) | Oil leak from bearing housing to compressor housing (intake side) or turbine housing (exhaust side) through seal rings. Internal oil leak is not visible from outside of turbocharger. If oil leak occurs from turbine side seal, large amount of white smoke will be emitted from exhaust pipe. |

| External oil leak | Oil leak from inside of turbocharger to outside of turbocharger (e.g. from FIPG seal, oil pipe flange or oil pipe union). Includes oil leaks visible from outside of turbocharger. |

| Result | Proceed to |

| External oil leak | A |

| Internal oil leak | B |

|

| ||||

| A | |

| 2.REPLACE THE PART WHICH IS LEAKING OIL |

Replace the part which is leaking oil.

| NEXT | ||

| ||

| 3.CHECK WHITE SMOKE |

Fully depress the accelerator pedal, and then release it.

Check whether white smoke is emitted or not when racing the engine.

| *a | Example |

- CAUTION:

- Be sure not to check for white smoke indoors.

| Result | Proceed to |

| White smoke is emitted | A |

| White smoke is not emitted | B |

- HINT:

|

| ||||

| B | |

| 4.INSPECT COMPRESSOR INLET |

Remove the engine assembly from the vehicle ().

Remove the intake air connector pipe and inlet compressor elbow ().

Check whether an excessive amount of oil is present or not, and whether excessive oil deposits are attached to the compressor impeller or not.

- HINT:

Reinstall the intake air connector pipe and inlet compressor elbow ().

| NEXT | |

| 5.INSPECT COMPRESSOR OUTLET |

Check whether or not an excessive amount of oil or excessive oil deposits are present at the compressor outlet.

- HINT:

- A certain amount of oil may be present as shown in fig. 3 in "Description", because a certain amount of oil mist is contained in the PCV gas.

| Result | Proceed to |

| Excessive amount of oil present at both compressor inlet and outlet | A |

| Excessive amount of oil present only at compressor outlet | B |

| Excessive amount of oil not present at compressor inlet or outlet | C |

Reinstall the air tube assembly.

|

| ||||

|

| ||||

| C | |

| 6.INSPECT TURBINE INLET |

Remove the turbocharger sub-assembly (for bank 1 or bank 2) ().

Check whether an excessive amount of wet oil or excessive oil deposits are present at the turbine inlet.

- HINT:

- Be sure not to mistake carbon soot for oil.

| NEXT | |

| 7.INSPECT TURBINE OUTLET |

Check whether an excessive amount of wet oil or excessive oil deposits are present at the turbine outlet.

- HINT:

| Result | Proceed to |

| Excessive amount of oil present at both turbine inlet and outlet | A |

| Excessive amount of oil present only at turbine outlet | B |

|

| ||||

| B | |

| 8.REPLACE TURBOCHARGER SUB-ASSEMBLY |

Replace the turbocharger sub-assembly (for bank 1 or bank 2) which is on the bank confirmed to be malfunctioning ().

| NEXT | |

| 9.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

| NEXT | ||

| ||