CLOSE STABILIZER CONTROL WITH ACCUMULATOR HOUSING SHUTTER VALVE

PERFORM PERFORM VARIABLE GEAR RATIO STEERING SYSTEM CALIBRATION

Steering Linkage -- Installation |

- HINT:

- Use the same procedure for RHD and LHD vehicles.

- The procedure listed below is for LHD vehicles.

| 1. INSTALL POWER STEERING LINK ASSEMBLY |

Install the power steering link with the 3 bolts and 3 nuts.

- Torque:

- 120 N*m{1224 kgf*cm, 89 ft.*lbf}

- HINT:

- Hold the bolts and tighten the nuts to install the power steering link.

| 2. INSTALL FRONT SUSPENSION REBOUND STOPPER SUB-ASSEMBLY LH |

Install the suspension rebound stopper LH with the 3 bolts.

- Torque:

- 58 N*m{591 kgf*cm, 43 ft.*lbf}

|

| 3. INSTALL FRONT SUSPENSION REBOUND STOPPER SUB-ASSEMBLY RH |

Install the suspension rebound stopper RH with the 3 bolts.

- Torque:

- 58 N*m{591 kgf*cm, 43 ft.*lbf}

|

| 4. CONNECT PRESSURE FEED TUBE ASSEMBLY |

Install the pressure feed tube clamp with the 2 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 in.*lbf}

Connect the pressure feed tube (return tube side) to the power steering link with the clamp.

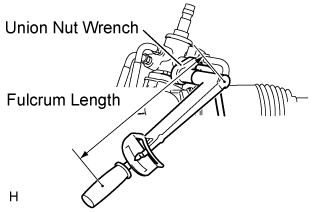

Using a union nut wrench, connect the pressure feed tube (pressure feed tube side) to the power steering link.

- Torque:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (Click here).

|

| 5. INSTALL TIE ROD END SUB-ASSEMBLY LH |

Align the matchmarks of the tie rod and rack end, and temporarily install the tie rod with the lock nut.

- HINT:

- After adjusting toe-in, tighten the lock nut.

- Torque:

- 82 N*m{836 kgf*cm, 60 ft.*lbf}

Check that length A is the same as the length measured previously.

| 6. INSTALL TIE ROD END SUB-ASSEMBLY RH |

- HINT:

- Use the same procedures described for the RH side.

| 7. INSTALL STEERING RACK BOOT PROTECTOR LH |

Install the steering rack boots protector with the 2 bolts.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 8. INSTALL STEERING RACK BOOT PROTECTOR RH |

- HINT:

- Use the same procedures described for the LH side.

| 9. CONNECT TIE ROD END SUB-ASSEMBLY LH |

Connect the tie rod end LH to the steering knuckle with a new nut.

- Torque:

- 69 N*m{704 kgf*cm, 51 ft.*lbf}

Install a new cotter pin.

- HINT:

- If the holes for the cotter pin are not aligned, tighten the nut up to another 60°.

| 10. CONNECT TIE ROD END SUB-ASSEMBLY RH |

- HINT:

- Use the same procedures described for the LH side.

| 11. CONNECT NO. 2 STEERING INTERMEDIATE SHAFT |

for Manual Tilt and Telescopic:

Connect the No. 2 steering intermediate shaft (Click here).

for Power Tilt and Power Telescopic:

Connect the No. 2 steering intermediate shaft (Click here).

| 12. TEMPORARILY INSTALL FRONT STABILIZER BAR |

w/ KDSS:

Temporarily install the stabilizer bar (Click here).

w/o KDSS:

Temporarily install the stabilizer bar (Click here).

| 13. TEMPORARILY INSTALL FRONT STABILIZER LINK ASSEMBLY LH |

w/ KDSS:

Temporarily install the stabilizer link (Click here).

w/o KDSS:

Temporarily install the stabilizer link (Click here).

| 14. TEMPORARILY INSTALL FRONT STABILIZER LINK ASSEMBLY RH |

- HINT:

- Use the same procedures described for the LH side.

| 15. INSTALL ENGINE ASSEMBLY |

for 1UR-FE:

Install the engine (Click here).

for 1GR-FE:

Install the engine (Click here).

for 1VD-FTV:

Install the engine (Click here).

for 3UR-FE:

Install the engine (Click here).

| 16. TIGHTEN FRONT NO. 1 STABILIZER BRACKET LH |

w/ KDSS:

Tighten the stabilizer bracket (Click here).

w/o KDSS:

Tighten the stabilizer bracket (Click here).

| 17. TIGHTEN FRONT NO. 1 STABILIZER BRACKET RH |

- HINT:

- Use the same procedures described for the LH side.

| 18. STABILIZE SUSPENSION |

Install the front wheels.

- Torque:

- for aluminum wheel:

- 131 N*m{1336 kgf*cm, 97 ft.*lbf}

- for steel wheel:

- 209 N*m{2131 kgf*cm, 154 ft.*lbf}

Lower the vehicle.

Press down on the vehicle several times to stabilize the suspension.

| 19. TIGHTEN FRONT STABILIZER LINK ASSEMBLY LH |

w/ KDSS:

Tighten the stabilizer link (Click here).

w/o KDSS:

Tighten the stabilizer link (Click here).

| 20. TIGHTEN FRONT STABILIZER LINK ASSEMBLY RH |

- HINT:

- Use the same procedures described for the LH side.

| 21. TIGHTEN FRONT STABILIZER BAR |

w/ KDSS:

Tighten the front stabilizer bar (Click here).

w/o KDSS:

Tighten the front stabilizer bar (Click here).

| 22. BLEED POWER STEERING FLUID |

Check the fluid level.

Jack up the front of the vehicle and support it with stands.

Turn the steering wheel.

With the engine stopped, turn the wheel slowly from lock to lock several times.

Lower the vehicle.

Start the engine.

Idle the engine for a few minutes.

Turn the steering wheel.

With the engine idling, turn the wheel left or right to the full lock position and keep it there for 2 to 3 seconds, then turn the wheel to the opposite full lock position and keep it there for 2 to 3 seconds. *1

Repeat *1 several times.

- NOTICE:

- For vehicles with VGRS, if the steering wheel is turned from lock to lock repeatedly, the system may stop operating and the amount of rotation before the steering wheel locks may increase due to operation of the overheating prevention function. When the system temperature drops, the system operation automatically returns to normal.

Stop the engine.

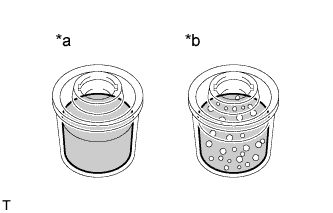

Check for foaming or emulsification.

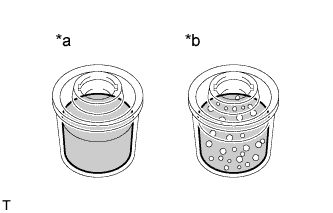

If the system has to be bled twice because of foaming or emulsification, check for fluid leaks in the system.Text in Illustration *a Correct *b Incorrect

|

Check the fluid level.

| 23. CHECK POWER STEERING FLUID LEVEL |

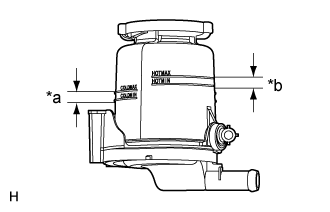

Keep the vehicle horizontal.

Text in Illustration *a COLD Range *b HOT Range

|

With the engine stopped, check the fluid level in the reservoir.

If necessary, add fluid.- Fluid:

- ATF DEXRON II or III, or equivalent

- HINT:

- If the fluid is hot, check that the fluid level is within the HOT range. If the fluid is cold, check that the fluid level is within the COLD range.

Start the engine and idle it.

Turn the steering wheel from lock to lock several times to raise the fluid temperature.

- Fluid temperature:

- 80°C (176°F)

Check for foaming or emulsification.

If foaming or emulsification is identified, bleed the power steering system.Text in Illustration *a Correct *b Incorrect

|

With the engine idling, measure the fluid level in the reservoir.

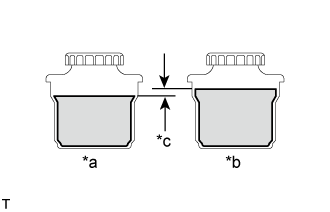

Text in Illustration *a Engine idling *b Engine stopped *c 5.0 mm (0.197 in.) or less

|

Stop the engine.

Wait a few minutes and remeasure the fluid level in the reservoir.

- Maximum fluid level rise:

- 5.0 mm (0.197 in.)

Check the fluid level.

| 24. CHECK FOR POWER STEERING FLUID LEAK |

| 25. INSTALL FRONT WHEELS |

| 26. PLACE FRONT WHEELS FACING STRAIGHT AHEAD |

- HINT:

- Perform this procedure with the front of the vehicle jacked up.

| 27. ADJUST FRONT WHEEL ALIGNMENT |

Adjust the front wheel alignment (Click here).

| 28. ADJUST HEADLIGHT ASSEMBLY |

for Standard Headlight:

Adjust the headlight (Click here).

for HID Headlight:

Adjust the headlight (Click here).

| 29. CLOSE STABILIZER CONTROL WITH ACCUMULATOR HOUSING SHUTTER VALVE |

- NOTICE:

- Perform the inspection on a level surface.

- Ensure that the wheels are on the ground and facing straight ahead.

- Perform the inspection with the vehicle load completely on the suspension.

- HINT:

- Perform this step with the fuel tank full.

- If there are any parts installed to the vehicle which place any unbalanced load on the left or right side of the vehicle, remove them.

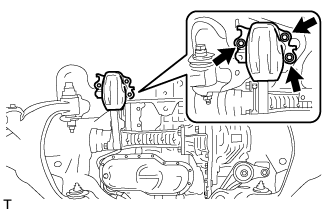

Using a 5 mm hexagon socket wrench, tighten the lower and upper chamber shutter valves of the stabilizer control with accumulator housing.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

| 30. PERFORM PERFORM VARIABLE GEAR RATIO STEERING SYSTEM CALIBRATION |