Dtc P0660 Intake Manifold Tuning Valve Control Circuit / Open (Bank 1)

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (OPERATE VSV FOR ACIS)

CHECK VACUUM HOSE

INSPECT INTAKE MANIFOLD (INTAKE AIR CONTROL VALVE)

INSPECT VSV FOR ACIS (OPERATION)

INSPECT VSV FOR ACIS (POWER SOURCE VOLTAGE)

CHECK HARNESS AND CONNECTOR (VSV FOR ACIS - ECM)

DTC P0660 Intake Manifold Tuning Valve Control Circuit / Open (Bank 1)

DESCRIPTION

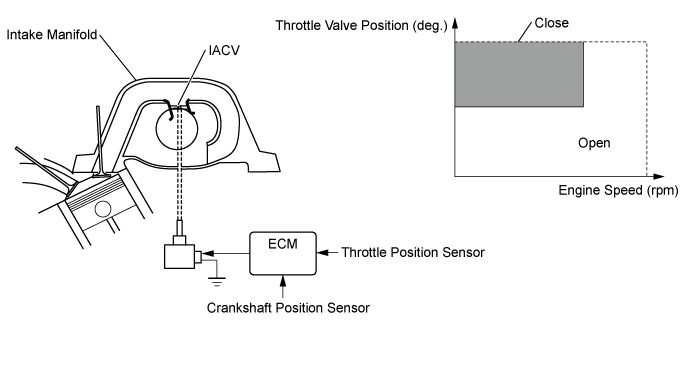

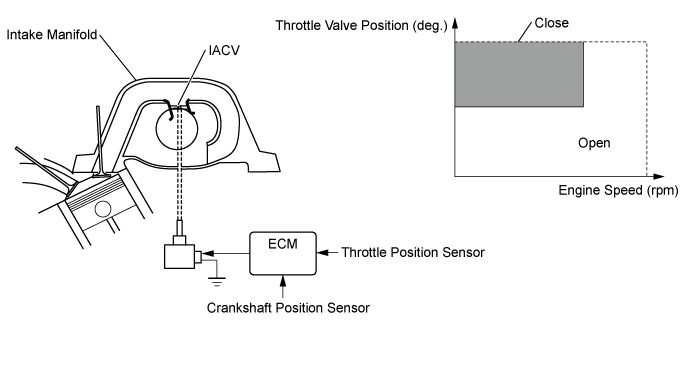

This circuit opens and closes the Intake Air Control Valve (IACV) in response to the engine load in order to increase the intake efficiency (ACIS: Acoustic Control Induction System).

| DTC Code | DTC Detection Condition | Trouble Area |

| P0660 | Conditions (a) and (b) are met for 0.5 sec. or more (2 trip detection logic):

(a) The voltage of terminal ACIS of the ECM is low when the VSV is OFF.

(b) The engine has started. | Open or short in VSV for ACIS circuit

VSV for ACIS

ECM

|

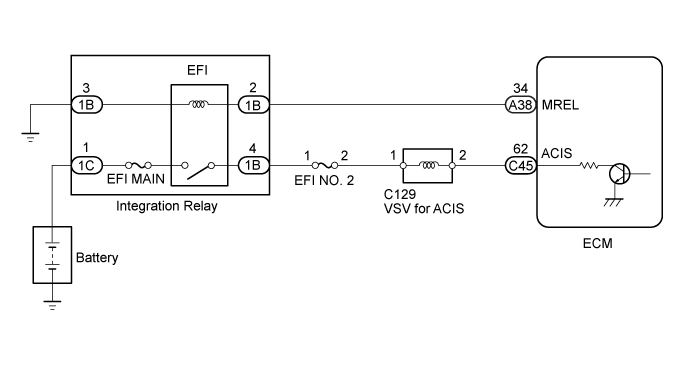

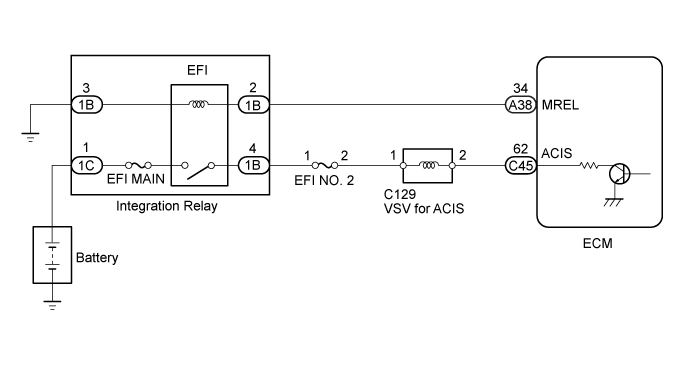

WIRING DIAGRAM

INSPECTION PROCEDURE

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (OPERATE VSV FOR ACIS) |

Disconnect the vacuum hose.

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG) and turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VSV for Intake Control. Operate the VSV for ACIS.

Check the VSV operation when it is operated using the tester.

- Standard:

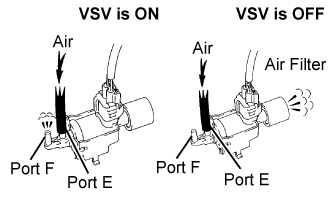

| Tester Operation | Specified Condition |

| VSV ON | Air from port E flows out through port F |

| VSV OFF | Air from port E flows out through air filter |

Check that the vacuum hose is connected correctly, and that there are no cracks, holes, damage, or looseness.

- OK:

- Vacuum hose is normal.

| | REPAIR OR REPLACE VACUUM HOSE |

|

|

| 3.INSPECT INTAKE MANIFOLD (INTAKE AIR CONTROL VALVE) |

Inspect the intake air control valve ().

| | REPLACE INTAKE MANIFOLD (INTAKE AIR CONTROL VALVE) ()

|

|

|

| OK | |

| |

| PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE ()

|

|

| 4.INSPECT VSV FOR ACIS (OPERATION) |

Inspect the VSV for ACIS ().

| 5.INSPECT VSV FOR ACIS (POWER SOURCE VOLTAGE) |

Disconnect the VSV for ACIS connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

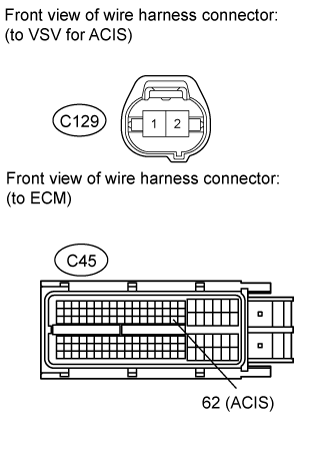

| Tester Connection | Condition | Specified Condition |

| C129-1 - Body ground | Engine switch on (IG) | 11 to 14 V |

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (VSV FOR ACIS - INTEGRATION RELAY) |

|

|

| 6.CHECK HARNESS AND CONNECTOR (VSV FOR ACIS - ECM) |

Disconnect the VSV for ACIS connector.

Disconnect the ECM connector.

Measure the resistance between the terminals of the wire harness side connectors.

- Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| C129-2 - C45-62 (ACIS) | Always | Below 1 Ω |

| C129-2 or C45-62 (ACIS) - Body ground | Always | 10 kΩ or higher |

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|