Exhaust Manifold -- Installation |

| 1. INSTALL AIR FUEL RATIO SENSOR (for Bank 2 Sensor 1) |

Temporarily install the sensor to the exhaust pipe by hand.

|

Using SST, tighten the sensor.

- SST

- 09224-00010

- Torque:

- without SST:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

- with SST:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

Text in Illustration *1 Fulcrum Length - HINT:

- Use a torque wrench with a fulcrum length of 300 mm (11.8 in.). If using a torque wrench with a length that is not 300 mm (11.8 in.), calculate the torque specification for the torque wrench and SST based on the "without SST" torque specification (Click here).

- Make sure SST and the wrench are connected in a straight line.

|

| 2. INSTALL AIR FUEL RATIO SENSOR (for Bank 1 Sensor 1) |

Temporarily install the sensor to the exhaust pipe by hand.

Using SST, tighten the sensor.

- SST

- 09224-00010

- Torque:

- without SST:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

- with SST:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

Text in Illustration *1 Fulcrum Length - HINT:

- Use a torque wrench with a fulcrum length of 300 mm (11.8 in.). If using a torque wrench with a length that is not 300 mm (11.8 in.), calculate the torque specification for the torque wrench and SST based on the "without SST" torque specification (Click here).

- Make sure SST and the wrench are connected in a straight line.

|

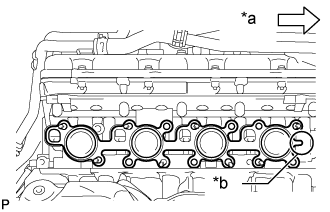

| 3. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH |

Install a new gasket to the cylinder head.

Text in Illustration *a Front *b Tab - HINT:

- Install the exhaust manifold gasket with the gasket tab facing toward the front of the engine.

|

Temporarily install the exhaust manifold sub-assembly RH with the 8 new nuts.

Uniformly tighten the 8 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Attach the wire harness clamp to the bracket and connect the connector.

| 4. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with the 3 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

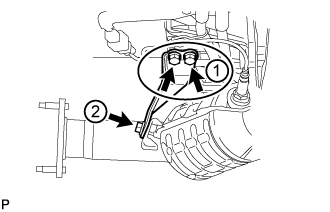

| 5. INSTALL NO. 1 MANIFOLD STAY |

Temporarily install the No. 1 manifold stay with the 3 bolts.

Tighten the 3 bolts in the order shown in the illustration.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

|

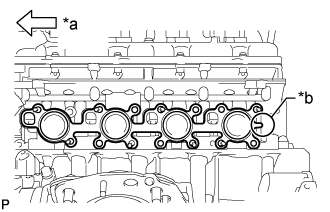

| 6. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH |

Install a new gasket to the cylinder head.

Text in Illustration *a Front *b Tab - HINT:

- Install the exhaust manifold gasket with the gasket tab facing toward the rear of the engine.

|

Temporarily install the exhaust manifold sub-assembly LH with the 8 new nuts.

Uniformly tighten the 8 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Attach the wire harness clamp to the bracket and connect the connector.

| 7. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with the 3 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 8. INSTALL NO. 2 MANIFOLD STAY |

Temporarily install the No. 2 manifold stay with the 3 bolts.

Tighten the 3 bolts in the order shown in the illustration.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

|

| 9. INSTALL PROPELLER SHAFT HEAT INSULATOR |

Install the heat insulator with the 2 bolts.

- Torque:

- 16 N*m{160 kgf*cm, 12 ft.*lbf}

| 10. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Install a new gasket and the front exhaust pipe to the exhaust manifold RH with 2 new nuts.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

Install the wire harness clamp bracket of the oxygen sensor to the transmission with the bolt.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

Connect the heated oxygen sensor connector.

| 11. INSTALL FRONT NO. 2 EXHAUST PIPE ASSEMBLY |

Install a new gasket and the front No. 2 exhaust pipe to the exhaust manifold LH with 2 new nuts.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

Install the wire harness clamp bracket of the oxygen sensor to the transmission with the bolt.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

Connect the heated oxygen sensor connector.

| 12. INSTALL CENTER EXHAUST PIPE ASSEMBLY |

Install 2 new gaskets to the front exhaust pipe and front No. 2 exhaust pipe.

Install the center exhaust pipe to the 3 exhaust pipe supports, and then install the 4 bolts.

- Torque:

- 48 N*m{489 kgf*cm, 35 ft.*lbf}

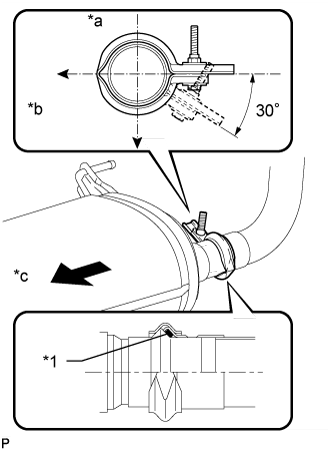

| 13. INSTALL TAILPIPE ASSEMBLY |

Install the tailpipe to the 2 exhaust pipe supports.

Install a new gasket to the center exhaust pipe.

Connect the tailpipe to the center exhaust pipe.

Attach a new clamp to the tailpipe and center exhaust pipe. Then install the bolt to the clamp.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf}

Text in Illustration *1 Gasket *a Top *b LH Side *c Front - HINT:

- Install the clamp within the angle range shown in the illustration.

|

| 14. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE |

Apply a light coat of engine oil to a new O-ring.

Install the O-ring to the guide.

Install the dipstick guide with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the dipstick.

Connect the wire harness clamp.

| 15. INSPECT FOR EXHAUST GAS LEAK |

| 16. INSTALL FRONT FENDER APRON SEAL LH |

Install the fender apron seal with the 3 clips.

| 17. INSTALL FRONT FENDER APRON SEAL REAR LH |

Install the fender apron seal with the 4 clips.

| 18. INSTALL FRONT FENDER APRON SEAL FRONT RH |

Install the fender apron seal with the 3 clips.

| 19. INSTALL FRONT FENDER APRON SEAL REAR RH |

Install the fender apron seal with the 4 clips.

| 20. INSTALL NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY |

Install the No. 1 engine under cover with the 10 bolts.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 21. INSTALL FRONT FENDER SPLASH SHIELD SUB-ASSEMBLY LH |

Push in the clip to install the front fender splash shield sub-assembly LH.

Install the 3 bolts and screw.

| 22. INSTALL FRONT FENDER SPLASH SHIELD SUB-ASSEMBLY RH |

Push in the clip to install the front fender splash shield sub-assembly RH.

Install the 3 bolts and 2 screws.

| 23. INSTALL NO. 2 ENGINE UNDER COVER |

Install the No. 2 engine under cover with the 2 bolts.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}