Fuel Sub Tank -- Installation |

| 1. INSTALL FUEL TANK TO FILLER PIPE HOSE |

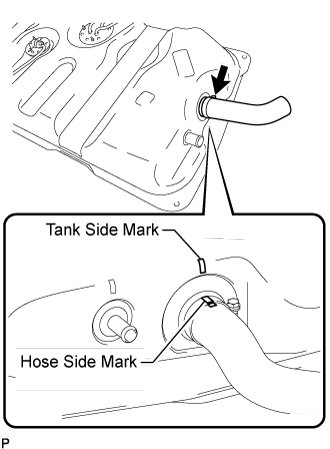

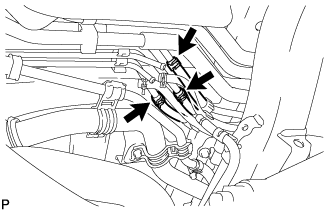

Install the hose to the fuel sub tank as shown in the illustration.

- HINT:

- Align the fuel sub tank side mark with the hose side mark when installing the hose.

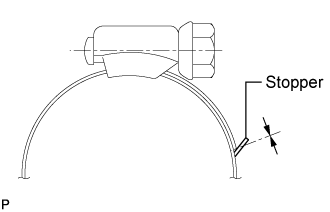

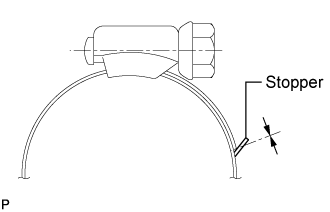

Tighten the hose clamp until the end of the hose clamp contacts the stopper as shown in the illustration.

|

| 2. INSTALL NO. 3 FUEL HOSE |

Install the fuel hose to the fuel sub tank as shown in the illustration.

- HINT:

- Align the fuel sub tank side mark with the hose side mark when installing the hose.

Tighten the hose clamp until the end of the hose clamp contacts the stopper as shown in the illustration.

|

| 3. INSTALL FUEL TANK BREATHER HOSE |

Install the breather hose to the fuel sub tank.

|

| 4. INSTALL FUEL AND EVAPORATION VENT TUBE SUB-ASSEMBLY |

Install a new gasket to the fuel and evaporation vent tube.

|

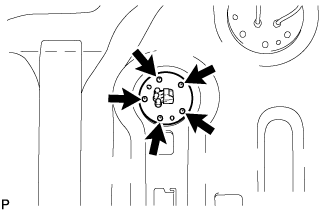

Install the fuel and evaporation vent tube with the 6 bolts.

- Torque:

- 3.5 N*m{36 kgf*cm, 31 in.*lbf}

| 5. INSTALL FUEL TANK EVAPORATION VENT TUBE SUB-ASSEMBLY |

Install the 2 fuel tank evaporation vent tubes.

|

| 6. INSTALL FUEL HOSE |

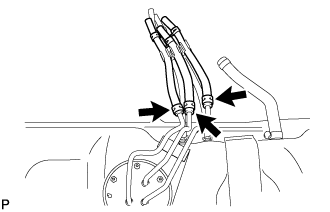

Install the 3 fuel hoses.

|

| 7. INSTALL FUEL SENDER GAUGE ASSEMBLY |

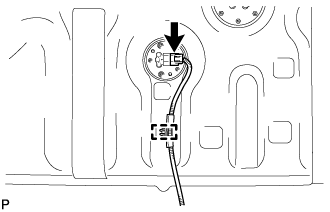

Install a new gasket to the sender gauge.

- NOTICE:

- Be careful not to bend the arm of the fuel sender gauge.

|

Install the sender gauge with the 5 screws.

- Torque:

- 1.5 N*m{15 kgf*cm, 13 in.*lbf}

| 8. INSTALL FLOOR NO. 3 WIRE |

Attach the wire harness clamp to the fuel sub tank.

|

Connect the sender gauge connector.

| 9. INSTALL FUEL SUB TANK SUB-ASSEMBLY |

Set the fuel sub tank on a transmission jack and raise the fuel sub tank.

- NOTICE:

- Do not allow the fuel sub tank to contact the vehicle, especially the differential.

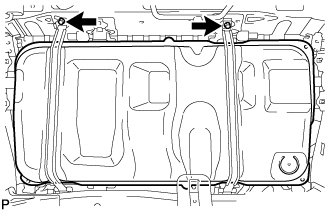

Connect the 2 fuel tank bands with the 2 bolts.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

|

Connect the floor No. 3 wire connector.

Attach the 3 wire harness clamps.

| 10. CONNECT FUEL TANK TO FILLER PIPE HOSE |

Connect the hose to the filler pipe.

|

| 11. CONNECT NO. 3 FUEL HOSE |

Connect the fuel hose to the filler pipe.

|

| 12. CONNECT FUEL TANK BREATHER HOSE |

Connect the breather hose to the filler pipe.

|

| 13. CONNECT FUEL HOSE |

Connect the 3 fuel hoses.

|

| 14. CONNECT FUEL TANK EVAPORATION VENT TUBE |

Connect the 2 fuel evaporation vent tubes.

|

| 15. INSTALL FUEL TANK CAP ASSEMBLY |

| 16. INSTALL NO. 1 SPARE WHEEL STOPPER |

Install the spare wheel stopper with the 2 bolts.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf}

|

| 17. INSTALL SPARE WHEEL CARRIER CROSSMEMBER AND SPARE WHEEL CARRIER BRACKET |

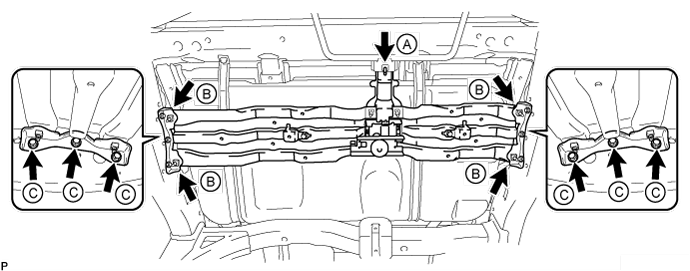

Install the spare wheel carrier crossmember and 2 brackets to the vehicle body with the 6 bolts labeled C.

- Torque:

- for bolt C:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Temporarily install the bolt labeled A, and then tighten the bolt labeled A and bolts labeled B.

- Torque:

- for bolt A:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

- for bolt B:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

| 18. INSTALL TAILPIPE ASSEMBLY |

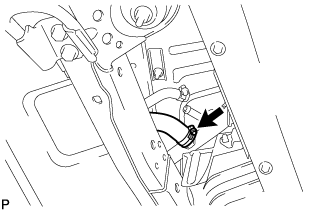

Connect the tailpipe to the 2 exhaust pipe supports.

|

Set a new gasket to the center exhaust pipe.

Connect the tailpipe to the center exhaust pipe with a new clamp.

- HINT:

- Install the clamp within the angle range shown in the illustration.

Tighten the bolt.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf}

| 19. BLEED AIR FROM FUEL SYSTEM |

Using the hand pump mounted on the fuel filter cap, bleed air from the fuel system. Continue pumping until the pump resistance increases.

- NOTICE:

- The maximum hand pump pumping speed is 2 strokes per second.

- The hand pump must be pushed with a full stroke during pumping.

- When the fuel pressure at the supply pump inlet port reaches a saturated pressure, the hand pump resistance increases.

- If pumping is interrupted during the air bleeding process, fuel in the fuel line may return to the fuel tank. Continue pumping until the hand pump resistance increases.

- If the hand pump resistance does not increase despite consecutively pumping 200 times or more, there may be a fuel leak between the fuel tank and fuel filter, the hand pump may be malfunctioning, or the vehicle may have run out of fuel.

- If air bleeding using the hand pump is incomplete, the common rail pressure does not rise to the pressure range necessary for normal use and the engine cannot be started.

|

Check if the engine starts.

- NOTICE:

- Even if air bleeding using the hand pump has been completed, the starter may need to be cranked for 10 seconds or more to start the engine.

- Do not crank the engine continuously for more than 20 seconds. The battery may be discharged.

- Use a fully-charged battery.

When the engine can be started, proceed to the next step.

If the engine cannot be started, bleed air again using the hand pump until the hand pump resistance increases (refer to the procedures above). Then start the engine.

Turn the engine switch off.

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON (IG) and turn the intelligent tester on.

Clear the DTCs (Click here).

Start the engine.*1

Enter the following menus: Powertrain / Engine and ECT / Active Test / Test the Fuel Leak.*2

|

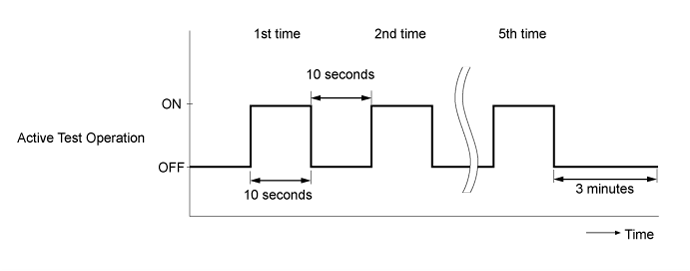

Perform the following test 5 times with on/off intervals of 10 seconds: Active Test / Test the Fuel Leak.*3

Allow the engine to idle for 3 minutes or more after performing the Active Test for the 5th time.

- HINT:

- When the Active Test "Test the Fuel Leak" is used to change the pump control mode, the actual fuel pressure inside the common rail drops below the target fuel pressure when the Active Test is off, but this is normal and does not indicate a pump malfunction.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read Current DTCs.

Clear the DTCs (Click here).

- HINT:

- It is necessary to clear the DTCs as DTC P1604 or P1605 may be stored when air is bled from the fuel system after replacing or repairing fuel system parts.

Repeat steps *1 to *3.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read Current DTCs.

- OK:

- No DTCs are output.

| 20. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (Click here).

Connect the cables to the negative (-) main battery and sub-battery terminals.

| 21. INSPECT FOR FUEL LEAK |

Perform Active Test.

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Start the engine.

Turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Active Test.

Perform the Active Test.

Tester Display Test Detail Control Range Diagnostic Note Test the Fuel Leak Pressurizes fuel inside common rail and checks for fuel leaks Stop/Start - The fuel inside the common rail is pressurized to the specified value and the engine speed increases to 2000 rpm when Start is selected.

- The above conditions are preserved while Start is selected.

- The fuel inside the common rail is pressurized to the specified value and the engine speed increases to 2000 rpm when Start is selected.

| 22. INSPECT FOR EXHAUST GAS LEAK |

| 23. INSTALL SPARE TIRE |