Cylinder Block Disassembly

INSPECT CONNECTING ROD THRUST CLEARANCE

REMOVE PISTON SUB-ASSEMBLY WITH CONNECTING ROD

REMOVE CONNECTING ROD BEARING

REMOVE PISTON RING SET

REMOVE PISTON WITH PIN SUB-ASSEMBLY

CLEAN PISTON

INSPECT CRANKSHAFT THRUST CLEARANCE

REMOVE CRANKSHAFT

REMOVE CRANKSHAFT THRUST WASHER SET

REMOVE CRANKSHAFT BEARING

REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY

INSPECT INPUT SHAFT BEARING (for Manual Transmission)

REMOVE CYLINDER BLOCK STRAIGHT SCREW PLUG

Cylinder Block -- Disassembly |

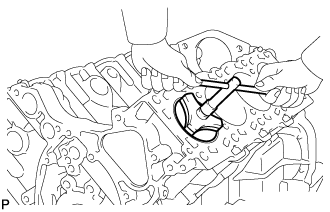

| 1. INSPECT CONNECTING ROD THRUST CLEARANCE |

Using a dial indicator, measure the thrust clearance while moving the connecting rod back and forth.

- Standard thrust clearance:

- 0.14 to 0.54 mm (0.00551 to 0.0213 in.)

- Maximum thrust clearance:

- 0.60 mm (0.0236 in.)

If the thrust clearance is more than the maximum, replace one or more connecting rods as necessary.

If necessary, replace the crankshaft.

| 2. REMOVE PISTON SUB-ASSEMBLY WITH CONNECTING ROD |

Using a ridge reamer, remove all the carbon from the top of the cylinder.

Uniformly loosen the connecting rod bolts, and remove the connecting rod cap with bearing.

Push out the piston and connecting rod with bearing through the top of the cylinder block.

- HINT:

- Arrange the piston and connecting rod assemblies in the correct order.

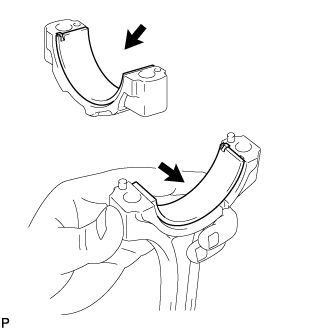

| 3. REMOVE CONNECTING ROD BEARING |

Remove the connecting rod and connecting rod cap bearings.

- HINT:

- Arrange the removed parts in the correct order.

| 4. REMOVE PISTON RING SET |

Using a piston ring expander, remove the No. 1 and No. 2 compression rings.

Using a piston ring expander, remove the oil ring.

Remove the oil ring expander by hand.

- HINT:

- Arrange the removed parts in the correct order.

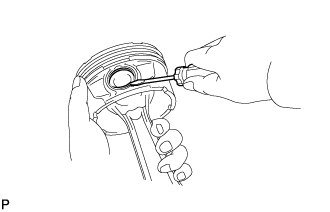

| 5. REMOVE PISTON WITH PIN SUB-ASSEMBLY |

Check the fitting condition between the piston and piston pin by trying to move the piston back and forth on the piston pin.

If any movement is felt, replace the piston and pin as a set.

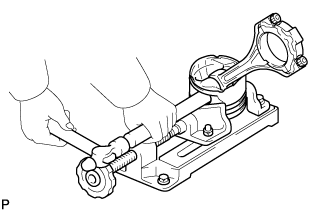

Using a screwdriver, pry out the 2 snap rings.

Gradually heat the piston to approximately 80°C (176°F).

Using a plastic-faced hammer and brass bar, lightly tap out the piston pin and remove the connecting rod.

- HINT:

- The piston and pin are a matched set.

- Arrange the piston and connecting rod assemblies in the correct order.

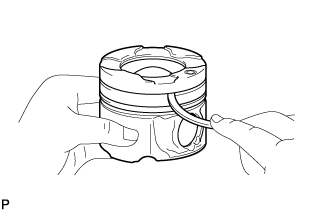

Using a gasket scraper, remove the carbon from the piston top.

Using a groove cleaning tool or broken ring, clean the piston ring grooves.

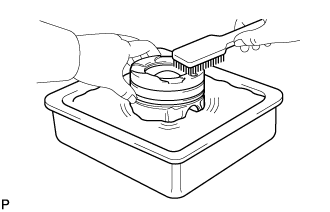

Using solvent and a brush, thoroughly clean the piston.

- NOTICE:

- Do not use a wire brush.

| 7. INSPECT CRANKSHAFT THRUST CLEARANCE |

Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with a screwdriver.

- Standard thrust clearance:

- 0.02 to 0.22 mm (0.000787 to 0.00866 in.)

- Maximum thrust clearance:

- 0.30 mm (0.0118 in.)

If the thrust clearance is more than the maximum, replace the thrust washers as a set.

- Standard thrust washer thickness:

- 2.44 to 2.49 mm (0.0961 to 0.0980 in.)

If necessary, replace the crankshaft.

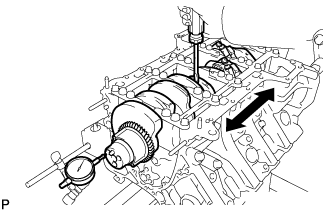

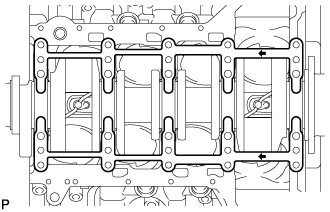

Using several steps, loosen and remove the 10 crankshaft bearing cap set bolts uniformly in the sequence shown in the illustration.

Using several steps, loosen and remove the 20 crankshaft bearing cap set bolts uniformly in the sequence shown in the illustration.

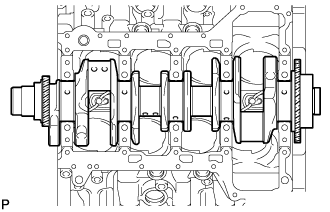

Remove the 2 cylinder block stiffening plates.

Using 2 crankshaft bearing cap set bolts, pull out the 5 bearing caps.

- NOTICE:

- Take care not to damage the contact surfaces of the crankshaft bearing cap and cylinder block.

- HINT:

- Keep the lower bearing and crankshaft bearing cap as a set.

- Arrange the crankshaft bearing caps in the correct order.

Remove the crankshaft.

| 9. REMOVE CRANKSHAFT THRUST WASHER SET |

| 10. REMOVE CRANKSHAFT BEARING |

- HINT:

- Keep the upper and lower crankshaft bearings and crankshaft bearing cap as a set.

- Arrange the crankshaft bearing caps and bearings in the correct order.

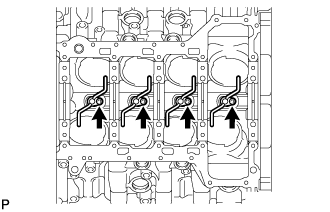

| 11. REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY |

Using a 5 mm hexagon wrench, remove the 4 bolts and 4 oil nozzles.

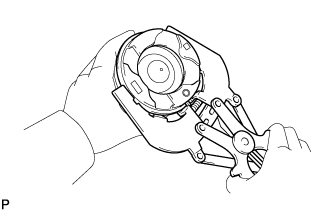

| 12. INSPECT INPUT SHAFT BEARING (for Manual Transmission) |

Turn the bearing by hand.

If the bearing is stuck or difficult to turn, replace the input shaft bearing. For removal procedures, refer to the following (Click here) and for installation procedures, refer to the following (Click here).

- HINT:

- The bearing is permanently lubricated and requires no cleaning or lubrication.

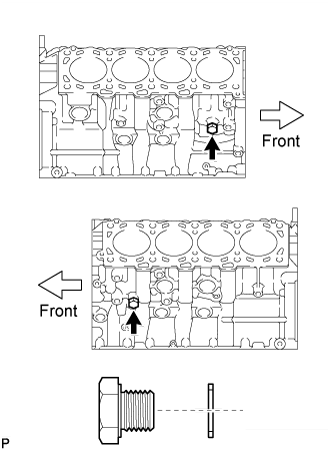

| 13. REMOVE CYLINDER BLOCK STRAIGHT SCREW PLUG |

Remove the 2 straight screw plugs and 2 gaskets.