INSPECT NO. 2 AND NO. 3 CAMSHAFT THRUST CLEARANCE (for Intake Camshaft)

INSPECT NO. 1 AND NO. 4 CAMSHAFT THRUST CLEARANCE (for Exhaust Camshaft)

Engine Unit -- Inspection |

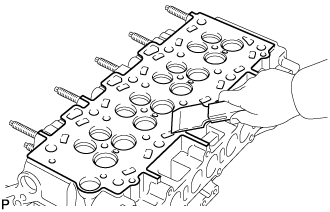

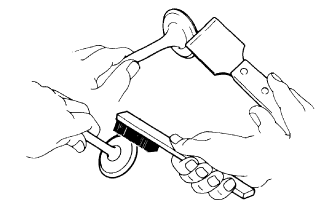

| 1. CLEAN CYLINDER HEAD SUB-ASSEMBLY |

Using a gasket scraper, remove all the gasket material from the cylinder block contact surface.

- NOTICE:

- Be careful not to scratch the cylinder block contact surface.

|

Using a wire brush, remove all the carbon from the combustion chambers.

- NOTICE:

- Be careful not to damage the combustion chambers and valve seats.

|

Using a valve guide bushing brush and solvent, clean all the valve guide bushes.

|

Using a soft brush and solvent, thoroughly clean the cylinder head.

|

| 2. INSPECT CYLINDER HEAD SUB-ASSEMBLY |

Using a precision straightedge and feeler gauge, measure the warpage of the contact surface between the cylinder head and cylinder block, and the cylinder head and manifolds.

- Standard Warpage:

Item Specified Condition Cylinder block side 0 to 0.05 mm (0 to 0.00197 in.) Intake manifold side 0 to 0.08 mm (0 to 0.00315 in.) Exhaust manifold side 0 to 0.08 mm (0 to 0.00315 in.)

- Maximum Warpage:

Item Specified Condition Cylinder block side 0.05 mm (0.00197 in.) Intake manifold side 0.08 mm (0.00315 in.) Exhaust manifold side 0.08 mm (0.00315 in.)

|

Using a dye penetrant, check the intake ports, exhaust ports and cylinder surface for cracks.

If there are cracks, replace the cylinder head sub-assembly.

|

| 3. INSPECT CYLINDER HEAD BOLT |

Using a vernier caliper, measure the outside thread diameter of the bolt.

- Standard diameter:

- 12.8 to 13.0 mm (0.504 to 0.512 in.)

- Minimum diameter:

- 12.5 mm (0.492 in.)

- HINT:

- If a visual check reveals no excessively thin areas, check the center of the bolt (see illustration) and find the area that has the smallest diameter.

|

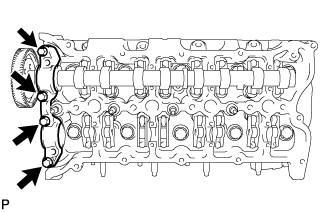

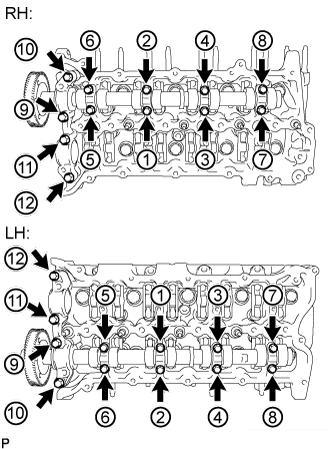

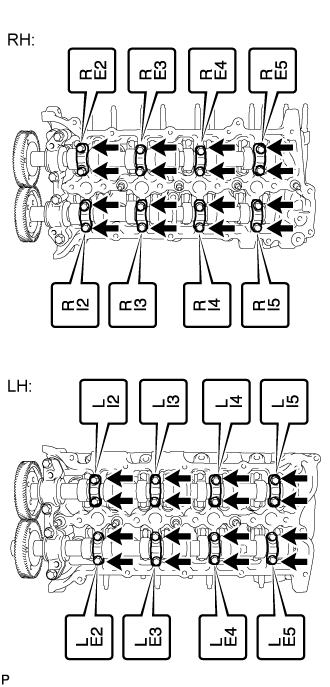

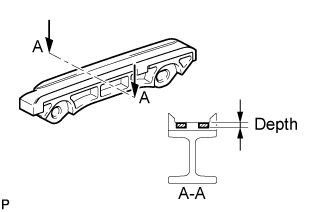

| 4. INSPECT NO. 2 AND NO. 3 CAMSHAFT THRUST CLEARANCE (for Intake Camshaft) |

Install the No. 2 and No. 5 camshaft bearing caps to the cylinder head.

Place the camshafts on the cylinder head.

Temporarily install the No. 1 and No. 4 camshaft bearing caps with the 4 bolts by hand.

- NOTICE:

- Do not turn the camshafts.

|

Install the No. 3 camshaft bearing caps.

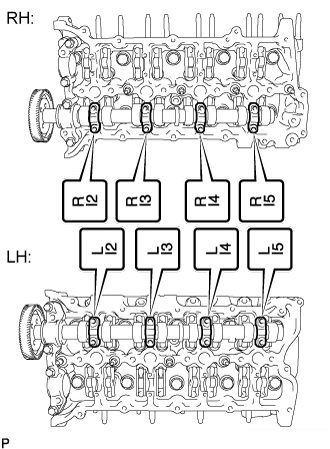

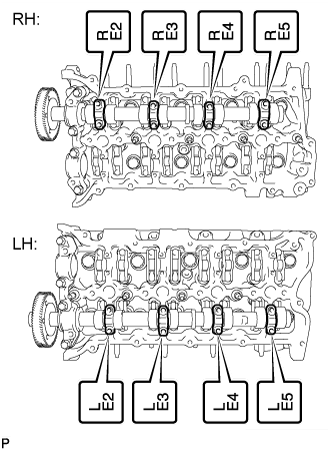

Confirm the marks and numbers on the camshaft bearing caps and place them in their proper position and direction.

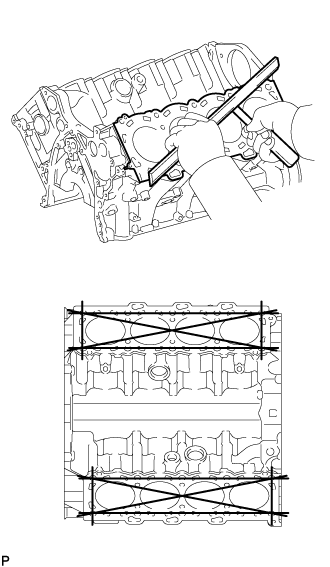

Temporarily install the 16 bolts.

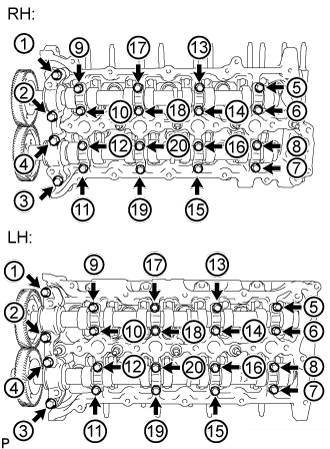

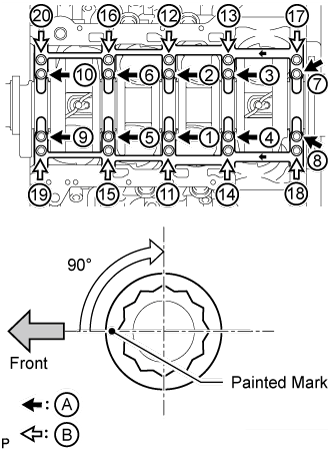

Uniformly tighten the 24 bolts in several steps in the order shown in the illustration.

- Torque:

- for 12 mm head bolt of No. 1 and No. 4 camshaft bearing cap:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- for 10 mm head bolt of No. 3 camshaft bearing cap:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

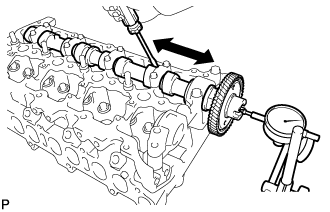

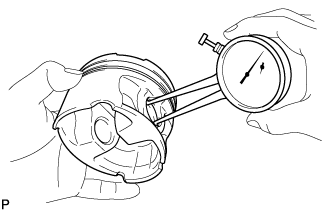

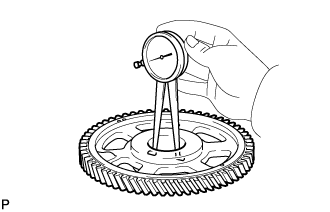

Using a dial indicator, measure the thrust clearance while moving the camshaft back and forth.

- Standard thrust clearance:

- 0.035 to 0.160 mm (0.00138 to 0.00630 in.)

- Maximum thrust clearance:

- 0.180 mm (0.00709 in.)

If necessary, replace the cylinder head sub-assembly.

|

| 5. INSPECT NO. 1 AND NO. 4 CAMSHAFT THRUST CLEARANCE (for Exhaust Camshaft) |

Install the No. 2 and No. 5 camshaft bearing caps to the cylinder head.

Place the camshafts on the cylinder head.

Temporarily install the No. 1 and No. 4 camshaft bearing caps with the 4 bolts by hand.

- NOTICE:

- Do not turn the camshafts.

|

Install the No. 3 camshaft bearing caps.

Confirm the marks and numbers on the camshaft bearing caps and place them in their proper position and direction.

Temporarily install the 16 bolts.

Uniformly tighten the 24 bolts in several steps in the order shown in the illustration.

- Torque:

- for 12 mm head bolt of No. 1 and No. 4 camshaft bearing cap:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- for 10 mm head bolt of No. 3 camshaft bearing cap:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

Using a dial indicator, measure the thrust clearance while moving the camshaft back and forth.

- Standard thrust clearance:

- 0.035 to 0.160 mm (0.00138 to 0.00630 in.)

- Maximum thrust clearance:

- 0.180 mm (0.00709 in.)

If necessary, replace the cylinder head sub-assembly.

|

| 6. INSPECT CAMSHAFT |

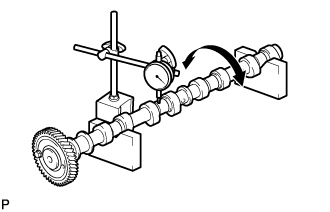

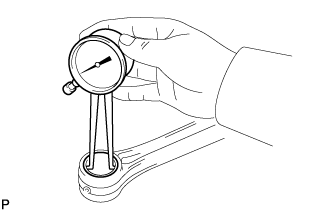

Inspect the camshaft for runout.

Place the camshaft on V-blocks.

Using a dial indicator, measure the runout at the center journal.

- Maximum runout:

- 0.03 mm (0.00118 in.)

|

Inspect the cam lobe height.

Using a micrometer, measure the cam lobe height.

- Standard Cam Lobe Height:

Item Specified Condition No. 2 and No. 3 camshaft

(intake)37.277 to 37.387 mm (1.468 to 1.472 in.) No. 1 and No. 4 camshaft

(exhaust)38.324 to 38.434 mm (1.509 to 1.513 in.)

- Minimum Cam Lobe Height:

Item Specified Condition No. 2 and No. 3 camshaft

(intake)37.277 mm (1.468 in.) No. 1 and No. 4 camshaft

(exhaust)38.324 mm (1.509 in.)

|

Inspect the camshaft journal diameter.

Using a micrometer, measure the journal diameter.

- Standard Journal Diameter:

Item Specified Condition No. 1 journal 29.969 to 29.985 mm (1.180 to 1.181 in.) Other journal 26.969 to 26.985 mm (1.0618 to 1.0624 in.)

|

| 7. INSPECT CAMSHAFT OIL CLEARANCE |

Clean the camshaft bearing caps and camshaft journals.

Place the camshafts on the cylinder head.

Lay a strip of Plastigage across each of the camshaft journals.

|

Temporarily install the camshaft bearing cap with the 4 bolts by hand.

- NOTICE:

- Do not turn the camshafts.

|

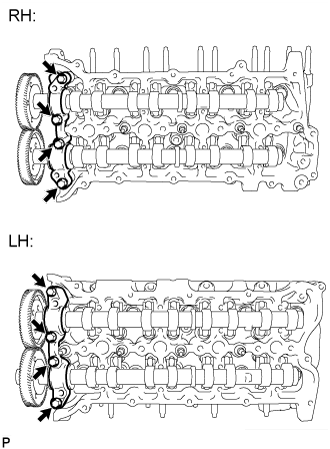

Install the No. 3 camshaft bearing caps with the 16 bolts.

Confirm the marks and numbers on the camshaft bearing caps and place them in their proper position and direction.

Temporarily install the 16 bolts.

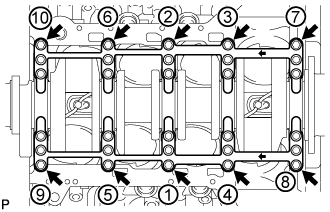

Uniformly tighten the 20 bolts in several steps in the order shown in the illustration.

- Torque:

- for 12 mm head bolt of No. 1 and No. 4 camshaft bearing cap:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- for 10 mm head bolt of No. 3 camshaft bearing cap:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

Uniformly loosen and remove the 20 bolts in the sequence shown in the illustration.

|

Measure the Plastigage at its widest point.

- Standard oil clearance:

- 0.025 to 0.062 mm (0.000984 to 0.00244 in.)

- Maximum oil clearance:

- 0.072 mm (0.00283 in.)

If necessary, replace the cylinder head sub-assembly.

|

Remove the Plastigage completely.

Remove the camshafts.

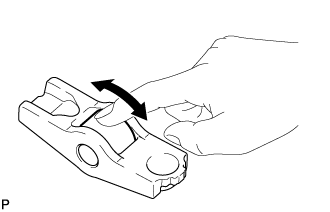

| 8. INSPECT VALVE ROCKER ARM SUB-ASSEMBLY |

Turn the roller by hand to check that it turns smoothly.

If the roller does not turn smoothly, replace the valve rocker arm.

|

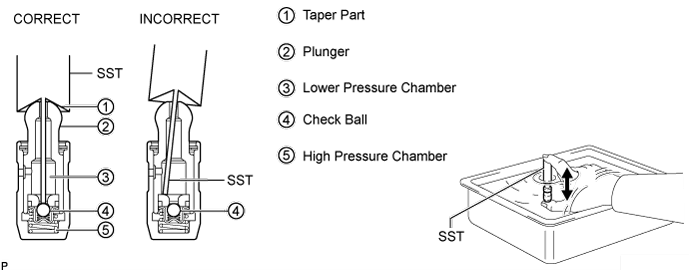

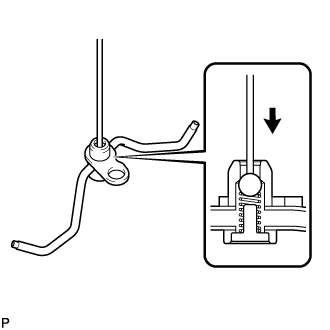

| 9. INSPECT VALVE LASH ADJUSTER ASSEMBLY |

- NOTICE:

- Keep the adjuster free from dirt and foreign objects.

- Use only clean engine oil.

Place the lash adjuster into a container full of new engine oil.

Insert SST tip into the lash adjuster plunger and use the tip to press down on the check ball inside the plunger.

- SST

- 09276-75010

Squeeze SST and the lash adjuster together to move the plunger up and down 5 to 6 times.

Check the movement of the plunger and bleed air.

- OK:

- Plunger moves up and down.

- NOTICE:

- When bleeding high-pressure air from the compression chamber, make sure that the tip of SST is actually pressing the check ball as shown in the illustration. If the check ball is not pressed, air will not bleed.

After bleeding the air, remove SST. Then try to quickly and firmly press the plunger with your fingers.

- OK:

- Plunger can be pressed 3 times.

| 10. INSPECT INNER COMPRESSION SPRING |

Inspect the inner compression spring deviation.

Using a steel square, measure the deviation of the inner compression spring.

- Maximum deviation:

- 1.5 mm (0.0591 in.)

Inspect the inner compression spring free length.

Using a vernier caliper, measure the free length of the inner compression spring.

- Standard free length:

- 45.9 mm (1.81 in.)

Inspect the inner compression spring tension.

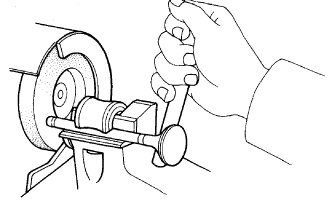

Using a spring tester, measure the tension of the inner compression spring at the specified installed length.

- Installed tension:

- 219 to 242 N (22 to 25 kgf, 49.2 to 54.4 lbf) at 31.0 mm (1.22 in.)

| 11. INSPECT VALVE GUIDE BUSH OIL CLEARANCE |

Using a caliper gauge, measure the inside diameter of the guide bush.

- Standard bush inside diameter:

- 6.01 to 6.03 mm (0.2366 to 0.2374 in.)

|

Subtract the valve stem diameter measurement from the guide bush inside diameter measurement.

- Standard Oil Clearance:

Item Specified Condition Intake 0.025 to 0.060 mm (0.000984 to 0.00236 in.) Exhaust 0.035 to 0.070 mm (0.00138 to 0.00276 in.)

- Maximum Oil Clearance:

Item Specified Condition Intake 0.120 mm (0.00472 in.) Exhaust 0.130 mm (0.00512 in.)

| 12. CLEAN VALVE |

Using a gasket scraper, chip off any carbon from the valve head.

- NOTICE:

- Be careful not to damage the valve face.

|

Using a wire brush, thoroughly clean the valve.

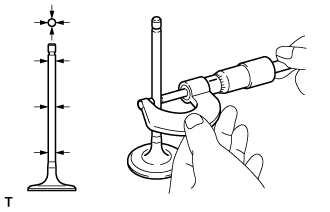

| 13. INSPECT VALVE |

Inspect the valve stem diameter.

Using a micrometer, measure the diameter of the valve stem.

- Standard Valve Stem Diameter:

Item Specified Condition Intake 5.970 to 5.985 mm (0.2350 to 0.2356 in.) Exhaust 5.960 to 5.975 mm (0.2346 to 0.2352 in.)

|

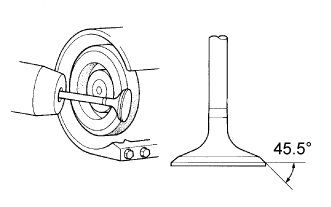

Inspect the valve face angle.

Grind the valve enough to remove pits and carbon.

Check that the valve is ground to the correct valve face angle.

- Standard valve face angle:

- 45.5°

|

Inspect the valve head margin thickness.

Using a vernier caliper, measure the valve head margin thickness.

- Standard margin thickness:

- 1.0 mm (0.0394 in.)

- Minimum margin thickness:

- 0.5 mm (0.0197 in.)

|

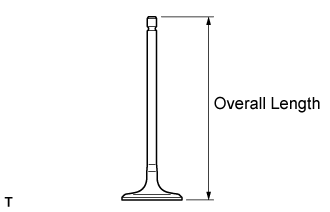

Inspect the valve overall length.

Using a vernier caliper, measure the overall length.

- Standard Overall Length:

Item Specified Condition Intake 104.4 mm (4.11 in.) Exhaust 104.1 mm (4.10 in.)

- Minimum Overall Length:

Item Specified Condition Intake 104.1 mm (4.10 in.) Exhaust 103.8 mm (4.09 in.)

|

Inspect the valve stem tip.

Check the surface of the valve stem tip for wear.

- NOTICE:

- Do not grind the valve so it becomes shorter than the minimum overall length.

|

| 14. CLEAN VALVE SEAT |

Using a 45° carbide cutter, resurface the valve seats.

- NOTICE:

- Be careful not to damage the combustion chambers and valve seats.

|

Clean the valve seats.

| 15. INSPECT INTAKE VALVE SEAT |

Apply a light coat of Prussian blue to the valve face.

|

Lightly press the valve face against the valve seat.

- NOTICE:

- Do not rotate the valve while pressing the valve.

Check the valve face and valve seat.

Check that the contact surfaces of the valve seat and valve face are in the middle area of their respective surfaces, with the width between 1.0 to 1.4 mm (0.0394 to 0.0551 in.).

If not, correct the valve seat.Check that the contact surfaces of the valve seat and valve face are even around the entire valve seat.

If not, correct the valve seat.

| 16. INSPECT EXHAUST VALVE SEAT |

Apply a light coat of Prussian blue to the valve face.

|

Lightly press the valve face against the valve seat.

- NOTICE:

- Do not rotate the valve while pressing the valve.

Check the valve face and valve seat.

Check that the contact surfaces of the valve seat and valve face are in the middle area of their respective surfaces, with the width between 1.0 to 1.4 mm (0.0394 to 0.0551 in.).

If not, correct the valve seat.Check that the contact surfaces of the valve seat and valve face are even around the entire valve seat.

If not, correct the valve seat.

| 17. VISUALLY CHECK CYLINDER BLOCK |

Visually check the cylinder for vertical scratches.

If necessary, replace the cylinder block.

|

| 18. INSPECT CYLINDER BLOCK FOR FLATNESS |

Using a precision straightedge and feeler gauge, measure the warpage of the contact surface between the cylinder head and cylinder head gaskets.

- Maximum warpage:

- 0.05 mm (0.00197 in.)

|

| 19. INSPECT CONNECTING ROD BOLT |

Using a vernier caliper, measure the tension portion diameter of the bolt.

- Standard diameter:

- 8.7 to 8.8 mm (0.343 to 0.346 in.)

- Minimum diameter:

- 8.5 mm (0.335 in.)

|

| 20. INSPECT CRANKSHAFT BEARING CAP BOLT |

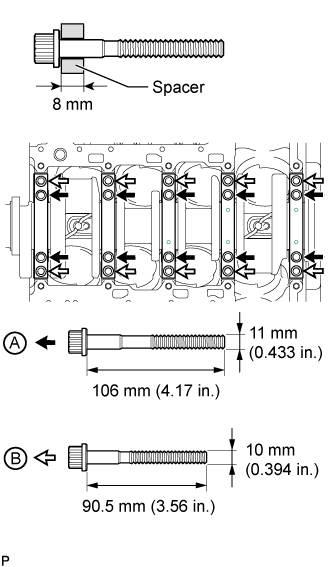

Using a vernier caliper, measure the outside thread diameter of bolt A and B.

Bolt Length Item Specified Condition Bolt A 106 mm (4.17 in.) Bolt B 90.5 mm (3.56 in.) - Measuring Area:

Item Specified Condition Bolt A 73 mm (2.87 in.) Bolt B 63 mm (2.48 in.)

- Standard diameter:

- for bolt A:

- 10.8 to 11.0 mm (0.425 to 0.433 in.)

- for bolt B:

- 9.8 to 10.0 mm (0.386 to 0.394 in.)

- Minimum diameter:

- for bolt A:

- 10.5 mm (0.413 in.)

- for bolt B:

- 9.5 mm (0.374 in.)

- HINT:

- If a visual check reveals no excessively thin areas, check the center of the bolt (see illustration) and find the area that has the lowest diameter.

|

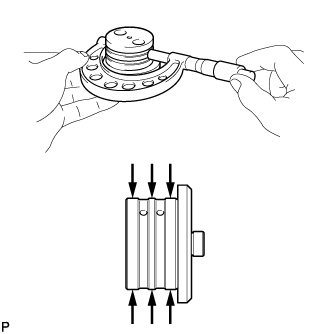

| 21. INSPECT PISTON WITH PIN SUB-ASSEMBLY |

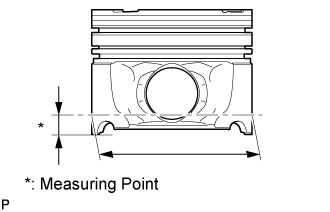

Using a micrometer, measure the piston diameter at a right angle to the piston pin center line, 12 mm (0.472 in.) from the piston skirt.

- Standard piston diameter:

- 85.932 to 85.966 mm (3.383 to 3.384 in.)

- Minimum piston diameter:

- 85.910 mm (3.382 in.)

|

| 22. INSPECT CYLINDER BORE |

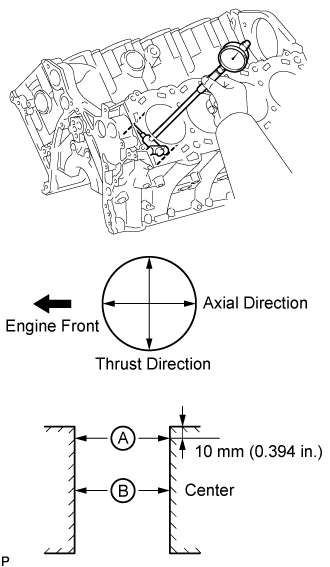

Using a cylinder gauge, measure the cylinder bore diameter at positions A and B in the thrust and axial directions.

- Standard diameter:

- 86.000 to 86.013 mm (3.3858 to 3.3863 in.)

- Maximum diameter:

- 86.03 mm (3.3870 in.)

|

| 23. INSPECT PISTON OIL CLEARANCE |

Subtract the piston diameter measurement from the cylinder bore diameter measurement.

- Standard oil clearance:

- 0.034 to 0.081 mm (0.00134 to 0.00319 in.)

- Maximum oil clearance:

- 0.091 mm (0.00358 in.)

| 24. INSPECT PISTON PIN OIL CLEARANCE |

Check each mark on the piston, piston pin and connecting rod.

Using a caliper gauge, measure the inside diameter of the piston pin hole.

- Standard Piston Pin Hole Inside Diameter:

Mark Specified Condition A 29.009 to 29.013 mm (1.1421 to 1.1422 in.) B 29.013 to 29.017 mm (1.1422 to 1.1424 in.) C 29.017 to 29.021 mm (1.1424 to 1.1426 in.)

|

Using a micrometer, measure the piston pin diameter.

- Standard Piston Pin Diameter:

Mark Paint Color Specified Condition A White 29.000 to 29.004 mm (1.1417 to 1.1419 in.) B Pink 29.004 to 29.008 mm (1.1419 to 1.1420 in.) C Blue 29.008 to 29.012 mm (1.1420 to 1.1422 in.)

|

Subtract the piston pin diameter measurement from the piston pin hole diameter measurement.

- Standard oil clearance:

- 0.005 to 0.013 mm (0.000197 to 0.000512 in.)

- Maximum oil clearance:

- 0.018 mm (0.000709 in.)

Using a caliper gauge, measure the inside diameter of the connecting rod bush.

- Standard Bush Inside Diameter:

Mark Specified Condition A 29.019 to 29.023 mm (1.1425 to 1.1426 in.) B 29.023 to 29.027 mm (1.1426 to 1.1428 in.) C 29.027 to 29.031 mm (1.1428 to 1.1430 in.)

|

Subtract the piston pin diameter measurement from the bush inside diameter measurement.

- Standard oil clearance:

- 0.015 to 0.023 mm (0.000591 to 0.000906 in.)

- Maximum oil clearance:

- 0.028 mm (0.00110 in.)

| 25. INSPECT RING GROOVE CLEARANCE |

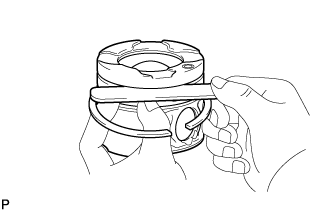

Using a feeler gauge, measure the clearance between a new piston ring and the wall of the ring groove.

- Standard Ring Groove Clearance:

Item Specified Condition No. 1 compression ring 0.11 to 0.15 mm (0.00433 to 0.00591 in.) No. 2 compression ring 0.08 to 0.12 mm (0.00315 to 0.00472 in.) Oil ring 0.03 to 0.07 mm (0.00118 to 0.00276 in.)

|

| 26. INSPECT PISTON RING END GAP |

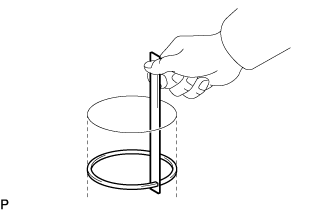

Insert the piston ring into the cylinder bore.

|

Using a piston, push the piston ring a little beyond the bottom of the ring travel, 60 mm (2.36 in.) from the top of the cylinder block.

Using a feeler gauge, measure the end gap.

- Standard End Gap:

Item Specified Condition No. 1 compression ring 0.20 to 0.30 mm (0.00787 to 0.0118 in.) No. 2 compression ring 0.47 to 0.62 mm (0.0185 to 0.0244 in.) Oil ring 0.10 to 0.40 mm (0.00394 to 0.0157 in.)

- Maximum End Gap:

Item Specified Condition No. 1 compression ring 0.40 mm (0.0157 in.) No. 2 compression ring 0.75 mm (0.0295 in.) Oil ring 0.50 mm (0.0197 in.)

|

| 27. INSPECT CONNECTING ROD SUB-ASSEMBLY |

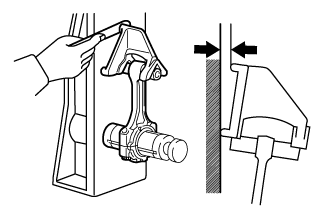

Using a rod aligner and feeler gauge, check the connecting rod alignment.

Check for bend.

- Maximum bend:

- 0.07 mm (0.00276 in.) per 100 mm (3.94 in.)

Check for twist.

- Maximum twist:

- 0.15 mm (0.00591 in.) per 100 mm (3.94 in.)

|

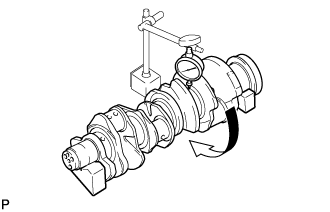

| 28. INSPECT CRANKSHAFT |

Using a dial indicator and V-blocks, measure the runout as shown in the illustration.

- Maximum circle runout:

- 0.04 mm (0.00157 in.)

|

Using a micrometer, measure the diameter of each main journal.

- Standard diameter:

- 74.982 to 75.000 mm (2.9520 to 2.9527 in.)

|

Check each main journal for taper and out-of-round as shown in the illustration.

- Maximum taper and out-of-round:

- 0.01 mm (0.000394 in.)

Using a micrometer, measure the diameter of each crank pin.

- Standard diameter:

- 54.982 to 55.000 mm (2.1646 to 2.1653 in.)

|

Check each crank pin for taper and out-of-round as shown in the illustration.

- Maximum taper and out-of-round:

- 0.01 mm (0.000394 in.)

| 29. INSPECT CRANKSHAFT THRUST CLEARANCE |

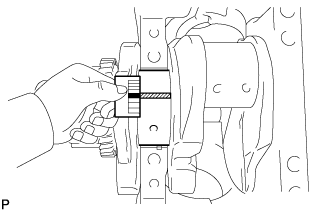

Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with a screwdriver.

- Standard thrust clearance:

- 0.02 to 0.22 mm (0.000787 to 0.00866 in.)

- Maximum thrust clearance:

- 0.30 mm (0.0118 in.)

- Standard thrust washer thickness:

- 2.44 to 2.49 mm (0.0961 to 0.0980 in.)

|

| 30. INSPECT CRANKSHAFT OIL CLEARANCE |

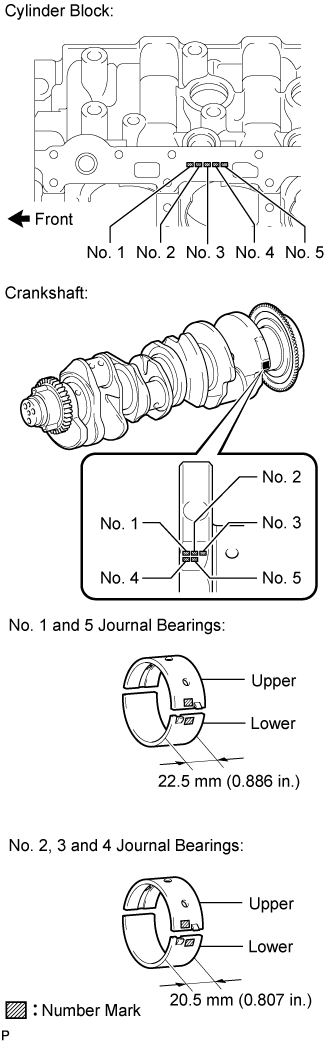

- HINT:

|

- Main bearings come in widths of 20.5 mm (0.807 in.) and 22.5 mm (0.886 in.).

| Item | Specified Condition |

| No. 1 and 5 journal bearings | 22.5 mm (0.886 in.) |

| No. 2, 3 and 4 journal bearings | 20.5 mm (0.807 in.) |

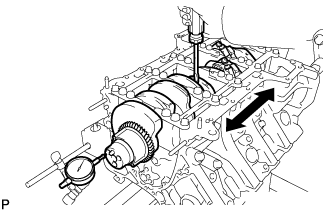

Clean each main journal and bearing.

Align the bearing claw with the claw groove of the cylinder block, and push in the 5 upper bearings.

- NOTICE:

- Do not apply engine oil to the bearings and the contact surfaces.

- Do not allow coolant to come into contact with the bearing inner surface. If any coolant comes into contact with the bearing inner surface, replace the bearing with a new one.

- Both sides of the oil groove in the cylinder block should be visible through the oil feed holes in the bearing. The amount visible on each side of the holes should be equal.

|

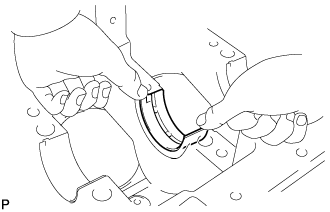

Align the bearing claw with the claw groove of the main bearing cap, and push in the 5 lower bearings.

- NOTICE:

- Do not apply engine oil to the bearings and the contact surfaces.

- Do not allow coolant to come into contact with the bearing inner surface.

If any coolant comes into contact with the bearing inner surface, replace the bearing with a new one.

- HINT:

- A number marked on each main bearing cap indicates the installation position.

|

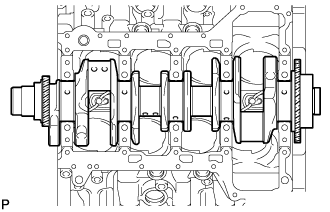

Place the crankshaft on the cylinder block.

|

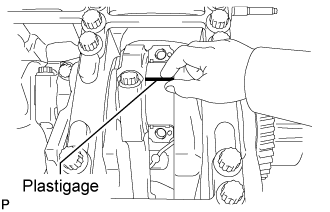

Lay a strip of Plastigage across each journal.

|

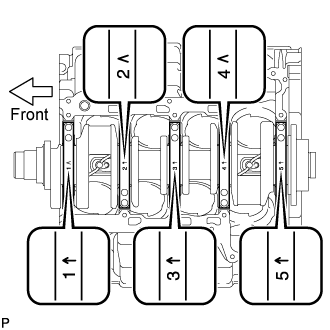

Examine the front marks and numbers and install the crankshaft bearing caps to the cylinder block.

- NOTICE:

- Do not turn the crankshaft.

|

Apply a light coat of engine oil to the threads of the crankshaft bearing cap bolts.

Temporarily install the crankshaft bearing cap bolts labeled A or the bolts labeled B.

- HINT:

- In place of cylinder block stiffening plates, install 8 mm (0.315 in.) thick spacers to the crankshaft bearing cap bolts.

|

Uniformly tighten the 2 crankshaft bearing cap bolts for each bearing cap in several passes to ensure a proper fit.

- NOTICE:

- Do not tap the bearing cap with a plastic-faced hammer.

Remove the crankshaft bearing cap bolts and spacers.

Set the 2 cylinder block stiffening plates on the cylinder block.

- HINT:

- Make sure the arrows on the stiffening plates face the engine front.

|

Step 1:

- HINT:

- The crankshaft bearing cap bolts are tightened in 3 progressive steps.

- If any crankshaft bearing cap bolt is broken or deformed, replace it.

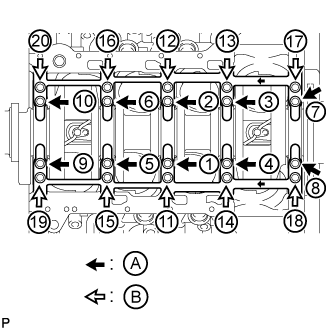

Apply a light coat of engine oil to the threads and under the heads of the 20 crankshaft bearing cap bolts.

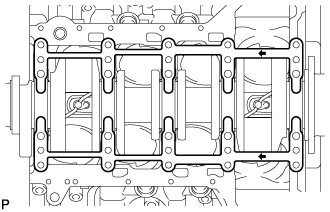

Install the 20 crankshaft bearing cap bolts. Using several steps, tighten the bolts uniformly in the sequence shown in the illustration.

- Torque:

- for bolt A:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

- for bolt B:

- 60 N*m{612 kgf*cm, 44 ft.*lbf}

|

Step 2:

Mark the front side of the crankshaft bearing cap bolts A and B with paint.

Tighten the crankshaft bearing cap bolts A and B 90° in the sequence shown in the illustration.

|

Step 3:

Tighten the crankshaft bearing cap bolts A another 90° in the sequence shown in the illustration.

Check that the painted marks of bolts A are now at a 180° angle to the front.

Check that the painted marks of bolts B are now at a 90° angle to the front.

- NOTICE:

- Do not turn the crankshaft.

|

Step 4:

Using several steps, install the 10 crankshaft bearing cap bolts uniformly in the sequence shown in the illustration.

- Torque:

- 56 N*m{571 kgf*cm, 41 ft.*lbf}

|

Remove the crankshaft bearing caps.

Step 1:

Using several steps, loosen and remove the 10 crankshaft bearing cap set bolts uniformly in the sequence shown in the illustration.Step 2:

Using several steps, loosen and remove the 20 crankshaft bearing cap set bolts uniformly in the sequence shown in the illustration.

Remove the 2 cylinder block stiffening plates.

|

Using 2 crankshaft bearing cap set bolts, pull out the 5 bearing caps.

- NOTICE:

- Take care not to damage the contact surface of the crankshaft bearing cap and cylinder block.

|

Measure the Plastigage at its widest point.

- Standard Oil Clearance:

Item Specified Condition No. 1 and 3 journals 0.020 to 0.038 mm (0.000787 to 0.00150 in.) No. 2, 4 and 5 journals 0.032 to 0.050 mm (0.00126 to 0.00197 in.)

- Maximum Clearance:

Item Specified Condition No. 1 and 3 journals 0.048 mm (0.00189 in.) No. 2, 4 and 5 journals 0.060 mm (0.00236 in.)

- Oil Clearance (Use for Over Size Bearing):

Item Specified Condition No. 1 and 3 journals 0.021 to 0.061 mm (0.000827 to 0.00240 in.) No. 2, 4 and 5 journals 0.033 to 0.073 mm (0.00130 to 0.00287 in.)

- HINT:

- Make sure to replace the upper and lower main bearings as one set.

|

Completely remove the Plastigage.

If replacing a bearing, replace it with one that has the same number. If the number of the bearing cannot be determined, select the correct bearing by adding together the numbers imprinted on the cylinder block and crankshaft, then refer to the appropriate bearing number. There are 7 sizes of standard bearings, marked "1", "2", "3", "4", "5", "6" and "7" accordingly.

EXAMPLE

Cylinder block main journal bore diameter "1" (A) + Crankshaft main journal diameter "2" (B) = Total number 3 (use bearing "3" (C))- No. 1 to No. 5 on Cylinder Block:

Cylinder Block (A) Crankshaft (B) Use Bearing (C) "1" "0" "1" "1" "2" "2" "3" "3" "4" "4" "5" "2" "0" "2" "1" "3" "2" "4" "3" "5" "4" "6" "3" "0" "3" "1" "4" "2" "5" "3" "6" "4" "7"

- Standard Cylinder Block Main Journal Bore Diameter (A):

Item Mark Specified Condition No. 1 and 3 journals "1" 79.000 to 79.006 mm (3.11023 to 3.11047 in.) "2" More than 79.006 to 79.012 mm (more than 3.11047 to 3.11070 in.) "3" More than 79.012 to 79.018 mm (more than 3.11070 to 3.11094 in.) No. 2, 4 and 5 journals "1" 79.000 to 79.006 mm (3.11023 to 3.11047 in.) "2" More than 79.006 to 79.012 mm (more than 3.11047 to 3.11070 in.) "3" More than 79.012 to 79.018 mm (more than 3.11070 to 3.11094 in.)

- Standard Crankshaft Main Journal Diameter (B):

Item Mark Specified Condition No. 1 and 3 journals "2" More than 74.994 to 75.000 mm (more than 2.95251 to 2.95275 in.) "3" More than 74.988 to 74.994 mm (more than 2.95228 to 2.95251 in.) "4" 74.982 to 74.988 mm (2.95204 to 2.95228 in.) No. 2, 4 and 5 journals "0" More than 74.994 to 75.000 mm (more than 2.95251 to 2.95275 in.) "1" More than 74.988 to 74.994 mm (more than 2.95288 to 2.95251 in.) "2" 74.982 to 74.988 mm (2.95204 to 2.95228 in.)

- Standard Crankshaft Bearing Center Wall Thickness (C):

Item Mark Specified Condition

(for Upper Bearing)Specified Condition

(for Lower Bearing)No. 1 and 5 journal bearings "1" More than 1.987 to 1.990 mm (more than 0.07823 to 0.07835 in.) More than 1.975 to 1.978 mm (more than 0.07776 to 0.07787 in.) "2" More than 1.990 to 1.993 mm (more than 0.07835 to 0.07846 in.) More than 1.978 to 1.981 mm (more than 0.07787 to 0.07799 in.) "3" More than 1.993 to 1.996 mm (more than 0.07846 to 0.07858 in.) More than 1.981 to 1.984 mm (more than 0.07799 to 0.07811 in.) "4" More than 1.996 to 1.999 mm (more than 0.07858 to 0.07870 in.) More than 1.984 to 1.987 mm (more than 0.07811 to 0.07823 in.) "5" More than 1.999 to 2.002 mm (more than 0.07870 to 0.07882 in.) More than 1.987 to 1.990 mm (more than 0.07823 to 0.07835 in.) "6" More than 2.002 to 2.005 mm (more than 0.07882 to 0.07894 in.) More than 1.990 to 1.993 mm (more than 0.07835 to 0.07846 in.) "7" More than 2.005 to 2.008 mm (more than 0.07894 to 0.07905 in.) More than 1.993 to 1.996 mm (more than 0.07846 to 0.07858 in.) No. 2, 3 and 4 journal bearings "1" More than 1.975 to 1.978 mm (more than 0.07776 to 0.07787 in.) More than 1.987 to 1.990 mm (more than 0.07823 to 0.07835 in.) "2" More than 1.978 to 1.981 mm (more than 0.07787 to 0.07799 in.) More than 1.990 to 1.993 mm (more than 0.07835 to 0.07846 in.) "3" More than 1.981 to 1.984 mm (more than 0.07799 to 0.07811 in.) More than 1.993 to 1.996 mm (more than 0.07846 to 0.07858 in.) "4" More than 1.984 to 1.987 mm (more than 0.07811 to 0.07823 in.) More than 1.996 to 1.999 mm (more than 0.07858 to 0.07870 in.) "5" More than 1.987 to 1.990 mm (more than 0.07823 to 0.07835 in.) More than 1.999 to 2.002 mm (more than 0.07870 to 0.07882 in.) "6" More than 1.990 to 1.993 mm (more than 0.07835 to 0.07846 in.) More than 2.002 to 2.005 mm (more than 0.07882 to 0.07894 in.) "7" More than 1.993 to 1.996 mm (more than 0.07846 to 0.07858 in.) More than 2.005 to 2.008 mm (more than 0.07894 to 0.07905 in.)

|

| 31. INSPECT CONNECTING ROD THRUST CLEARANCE |

Using a dial indicator, measure the thrust clearance while moving the connecting rod back and forth.

- Standard thrust clearance:

- 0.14 to 0.54 mm (0.00551 to 0.0213 in.)

- Maximum thrust clearance:

- 0.60 mm (0.0236 in.)

If necessary, replace the crankshaft.

|

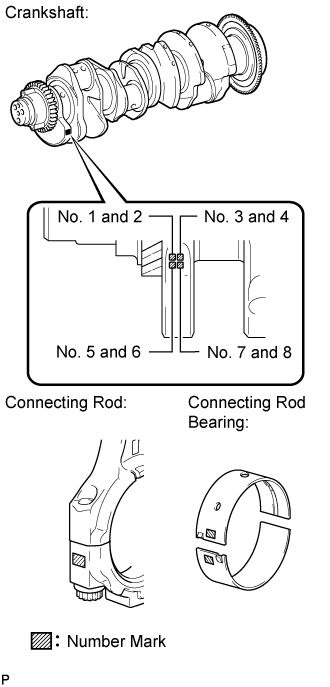

| 32. INSPECT CONNECTING ROD OIL CLEARANCE |

Install the crankshaft bearing (Click here).

Install the crankshaft (Click here).

Lay a strip of Plastigage across the crank pin.

|

Install the connecting rod cap so that its protrusion is facing the correct direction.

- NOTICE:

- Match the numbered connecting rod cap with the connecting rod.

|

Apply a light coat of engine oil to the threads of the connecting rod cap bolts.

Step 1:

- HINT:

- The connecting rod bearing cap bolts are tightened in 2 progressive steps.

- If any connecting rod bearing cap bolt is broken or deformed, replace it.

Install and alternately tighten the bolts of the connecting rod cap in several steps.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

|

Step 2:

Mark the front side of each connecting rod cap bolt with paint.

Tighten the bearing cap bolts in step 1 90°.

|

Remove the 2 bolts, connecting rod cap and lower bearing.

Measure the Plastigage at its widest point.

- Standard oil clearance:

- 0.024 to 0.042 mm (0.000945 to 0.00165 in.)

- Maximum oil clearance:

- 0.052 mm (0.00205 in.)

|

Completely remove the Plastigage.

If replacing a bearing, replace it with one that has the same number marked on the connecting rod. There are 5 sizes of standard bearings, marked "1 ", "2", "3", "4" and "5" accordingly.

Select the correct bearing by adding together the number marks imprinted on the connecting rod and crankshaft.

EXAMPLE

Connecting rod "1" (A) + Crank pin "2" (B) = Total number 3 (use bearing "3" (C))- Standard Connecting Rod Big End Inside Diameter (A):

Mark Specified Condition "1" 58.000 to 58.006 mm (2.28346 to 2.28370 in.) "2" More than 58.006 to 58.012 mm (more than 2.28370 to 2.28393 in.) "3" More than 58.012 to 58.018 mm (more than 2.28393 to 2.28417 in.)

- Standard Crankshaft Pin Diameter (B):

Mark Specified Condition "0" More than 54.994 to 55.000 mm (more than 2.16511 to 2.16535 in.) "1" More than 54.988 to 54.994 mm (more than 2.16488 to 2.16511 in.) "2" 54.982 to 54.988 mm (2.16464 to 2.16488 in.)

- Standard Bearing Center Wall Thickness (C):

Mark Specified Condition "1" More than 1.485 to 1.488 mm (more than 0.05846 to 0.05858 in.) "2" More than 1.488 to 1.491 mm (more than 0.05858 to 0.05870 in.) "3" More than 1.491 to 1.494 mm (more than 0.05870 to 0.05882 in.) "4" More than 1.494 to 1.497 mm (more than 0.05882 to 0.05894 in.) "5" More than 1.497 to 1.500 mm (more than 0.05894 to 0.05910 in.)

|

Remove the crankshaft (Click here).

Remove the crankshaft bearing.

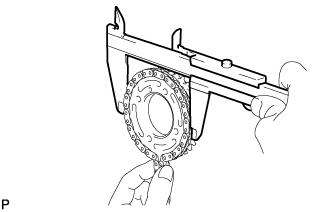

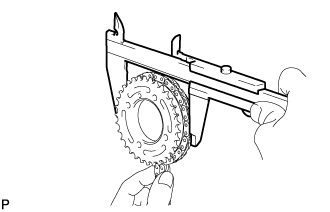

| 33. INSPECT NO. 1 CHAIN |

Using a spring scale, pull the No. 1 chain with a force of 147 N (15 kgf, 33.1 lbf) and measure the length of the No. 1 chain using a vernier caliper.

- Maximum chain elongation:

- 143.95 mm (5.67 in.)

- NOTICE:

- Perform the measurement at 3 random places.

|

| 34. INSPECT NO. 2 CHAIN |

Using a spring scale, pull the No. 2 chain with a force of 147 N (15 kgf, 33.1 lbf) and measure the length of the No. 2 chain using a vernier caliper.

- Maximum chain elongation:

- 143.95 mm (5.67 in.)

- NOTICE:

- Perform the measurement at 3 random places.

|

| 35. INSPECT FUEL SUPPLY PUMP SHAFT SPROCKET |

Wrap the No. 1 chain around the sprocket place for the No. 1 chain.

|

Using a vernier caliper, measure the sprocket with the chain.

- Minimum gear diameter (with chain):

- 101.55 mm (4.00 in.)

- HINT:

- The vernier caliper must contact the chain rollers for the measurement.

Wrap the No. 2 chain around the sprocket place for the No. 2 chain.

|

Using a vernier caliper, measure the sprocket with the No. 2 chain.

- Minimum gear diameter (with chain):

- 101.55 mm (4.00 in.)

- HINT:

- The vernier caliper must contact the chain rollers for the measurement.

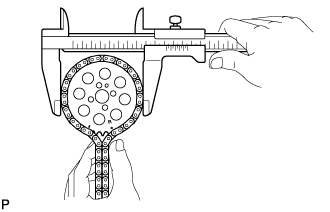

| 36. INSPECT NO. 1 CAMSHAFT TIMING SPROCKET |

Wrap the No. 1 chain around the sprocket.

|

Using a vernier caliper, measure the No. 1 camshaft timing sprocket diameter with the No. 1 chain.

- Minimum gear diameter (with chain):

- 134.90 mm (5.31 in.)

- HINT:

- The vernier caliper must contact the chain rollers for the measurement.

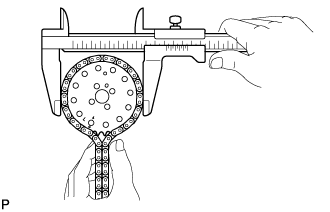

| 37. INSPECT NO. 2 CAMSHAFT TIMING SPROCKET |

Wrap the No. 2 chain around the sprocket.

|

Using a vernier caliper, measure the No. 2 camshaft timing sprocket diameter with the No. 2 chain.

- Minimum gear diameter (with chain):

- 134.90 mm (5.31 in.)

- HINT:

- The vernier caliper must contact the chain rollers for the measurement.

| 38. INSPECT NO. 1 IDLE GEAR SHAFT OIL CLEARANCE |

Using a micrometer, measure the No. 1 idle gear shaft diameter.

- Standard idle gear shaft diameter:

- 44.947 to 44.975 mm (1.770 to 1.771 in.)

|

Using a caliper gauge, measure the inside diameter of the idle gear.

- Standard idle gear inside diameter:

- 45.000 to 45.025 mm (1.772 to 1.773 in.)

|

Subtract the No. 1 idle gear shaft diameter measurement from the idle gear inside diameter measurement.

- Standard oil clearance:

- 0.025 to 0.078 mm (0.000984 to 0.00307 in.)

- Maximum oil clearance:

- 0.078 mm (0.00307 in.)

| 39. INSPECT NO. 1 CHAIN TENSIONER ASSEMBLY |

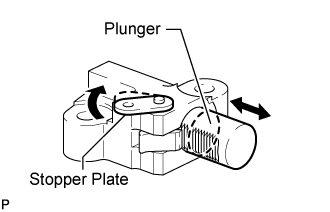

Move the stopper plate clockwise to release the lock. Push the plunger and check that it moves smoothly.

If necessary, replace the No. 1 chain tensioner assembly.

|

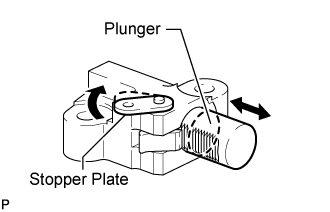

| 40. INSPECT NO. 2 CHAIN TENSIONER ASSEMBLY |

Move the stopper plate clockwise to release the lock. Push the plunger and check that it moves smoothly.

If necessary, replace the No. 2 chain tensioner assembly.

|

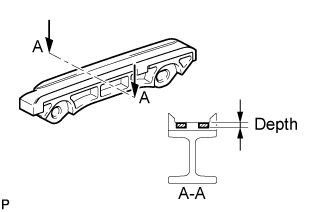

| 41. INSPECT NO. 1 CHAIN TENSIONER SLIPPER |

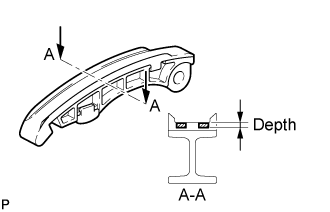

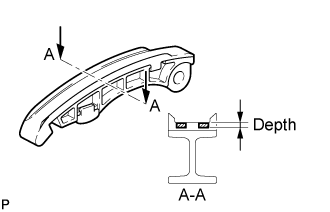

Measure the worn depth of the No. 1 chain tensioner slipper.

- Maximum depth:

- 1.0 mm (0.0394 in.)

|

| 42. INSPECT NO. 2 CHAIN TENSIONER SLIPPER |

Measure the worn depth of the No. 2 chain tensioner slipper.

- Maximum depth:

- 1.0 mm (0.0394 in.)

|

| 43. INSPECT NO. 1 CHAIN VIBRATION DAMPER |

Measure the worn depth of the No. 1 chain vibration damper.

- Maximum depth:

- 1.0 mm (0.0394 in.)

|

| 44. INSPECT NO. 2 CHAIN VIBRATION DAMPER |

Measure the worn depth of the No. 2 chain vibration damper.

- Maximum depth:

- 1.0 mm (0.0394 in.)

|

| 45. INSPECT NO. 1 OIL NOZZLE SUB-ASSEMBLY |

Push the check valve with a pin to check if it is stuck.

If stuck, replace the No. 1 oil nozzle sub-assembly.

|

Push the check valve with a pin to check if it moves smoothly.

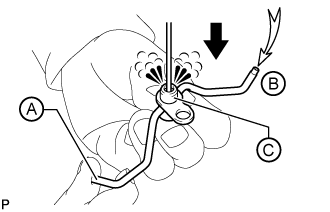

While covering A, apply air into B. Check that air does not leak through C. Perform the check again while covering B and applying air into A.

If air leaks, clean or replace the No. 1 oil nozzle sub-assembly.

|

Push the check valve while covering A, and apply air into B. Check that air passes through C. Perform the check again while covering B, pushing the check valve and applying air into A.

If air does not pass through C, clean or replace the No. 1 oil nozzle sub-assembly.

|

| 46. INSPECT NO. 1 INTAKE MANIFOLD FOR FLATNESS |

Using a precision straightedge and feeler gauge, measure the warpage of the contact surface between the No. 1 and No. 3 intake manifold, and the No. 1 intake manifold and cylinder head.

- Maximum Warpage:

Item Specified Condition No. 3 intake manifold 0.10 mm (0.00394 in.) Cylinder head 0.10 mm (0.00394 in.)

|

| 47. INSPECT NO. 2 INTAKE MANIFOLD FOR FLATNESS |

Using a precision straightedge and feeler gauge, measure the warpage of the contact surface between the No. 2 and No. 3 intake manifold, and the No. 2 intake manifold and cylinder head.

- Maximum Warpage:

Item Specified Condition No. 3 intake manifold 0.10 mm (0.00394 in.) Cylinder head 0.10 mm (0.00394 in.)

|

| 48. INSPECT NO. 3 INTAKE MANIFOLD FOR FLATNESS |

Using a precision straightedge and feeler gauge, measure the warpage of the contact surface between the No. 3 and No. 1 intake manifold, the No. 3 and No. 2 intake manifold, and the No. 3 intake manifold and intake pipe.

- Maximum Warpage:

Item Specified Condition Intake pipe 0.10 mm (0.00394 in.) No. 2 and No. 3 intake manifold 0.15 mm (0.00591 in.)

|

| 49. INSPECT EXHAUST MANIFOLD FOR FLATNESS |

Using a precision straightedge and feeler gauge, measure the warpage of the contact surface between the exhaust manifold and cylinder head.

- Maximum warpage:

- 0.80 mm (0.0315 in.)

|