Cylinder Head -- Inspection |

| 1. INSPECT CYLINDER HEAD SUB-ASSEMBLY |

|

Using a precision straightedge and feeler gauge, measure the warpage of the surfaces where the cylinder head contacts the cylinder block and manifold.

- Standard Warpage:

Item Specified Condition Cylinder head lower side 0.05 mm (0.00197 in.) Intake side 0.08 mm (0.00315 in.) Exhaust side 0.05 mm (0.00197 in.)

- Maximum warpage:

- 0.10 mm (0.00394 in.)

If the warpage is more than the maximum, replace the cylinder head.Text in Illustration *A Cylinder Head Lower Side *B Intake Side *C Exhaust Side

Using a dye penetrant, check the intake ports, exhaust ports and cylinder surface for cracks.

If cracked, replace the cylinder head.

| 2. INSPECT INTAKE VALVE |

Using a micrometer, measure the diameter of the valve stem.

- Standard valve stem diameter:

- 5.470 to 5.485 mm (0.215 to 0.216 in.)

Using a vernier caliper, measure the valve head margin thickness.

- Standard margin thickness:

- 1.25 mm (0.0492 in.)

- Minimum margin thickness:

- 0.50 mm (0.0197 in.)

If the margin thickness is less than the minimum, replace the intake valve.Text in Illustration *1 Margin Thickness

|

Using a vernier caliper, measure the valve overall length.

- Standard overall length:

- 105.85 mm (4.17 in.)

- Minimum overall length:

- 105.35 mm (4.15 in.)

| 3. INSPECT EXHAUST VALVE |

Using a micrometer, measure the diameter of the valve stem.

- Standard valve stem diameter:

- 5.465 to 5.480 mm (0.215 to 0.216 in.)

Using a vernier caliper, measure the valve head margin thickness.

- Standard margin thickness:

- 1.4 mm (0.0551 in.)

- Minimum margin thickness:

- 0.50 mm (0.0197 in.)

If the margin thickness is less than the minimum, replace the exhaust valve.Text in Illustration *1 Margin Thickness

|

Using a vernier caliper, measure the valve overall length.

- Standard overall length:

- 110.40 mm (4.35 in.)

- Minimum overall length:

- 109.90 mm (4.33 in.)

| 4. INSPECT INTAKE VALVE SEAT |

Apply a light coat of Prussian blue to the valve face.

Lightly press the valve face against the valve seat.

- HINT:

- Do not rotate the valve while pressing the valve.

Check the valve face and valve seat.

Text in Illustration *1 Width Check that the contact surfaces of the valve seat and valve face are in the middle area of their respective surfaces, with the width between 1.1 and 1.5 mm (0.0433 and 0.0591 in.).

If not, correct the valve seat.Check that the contact surfaces of the valve seat and valve face are even around the entire valve seat.

If not, correct the valve seat.

|

| 5. INSPECT EXHAUST VALVE SEAT |

Apply a light coat of Prussian blue to the valve face.

Lightly press the valve face against the valve seat.

- HINT:

- Do not rotate the valve while pressing the valve.

Check the valve face and valve seat.

Text in Illustration *1 Width Check that the contact surfaces of the valve seat and valve face are in the middle area of their respective surfaces, with the width between 1.1 and 1.5 mm (0.0433 and 0.0591 in.).

If not, correct the valve seat.Check that the contact surfaces of the valve seat and valve face are even around the entire valve seat.

If not, correct the valve seat.

|

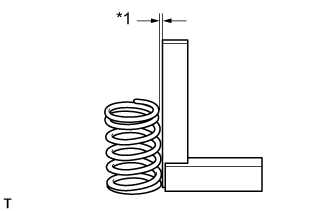

| 6. INSPECT COMPRESSION SPRING |

Using a vernier caliper, measure the free length of the inner compression spring.

- Standard free length:

- 51.59 mm (2.03 in.)

|

Using a steel square, measure the deviation of the inner compression spring.

- Maximum deviation:

- 1.0 mm (0.0394 in.)

- Maximum angle (reference):

- 2°

If the deviation is more than the maximum, replace the spring.Text in Illustration *1 Deviation

|

| 7. INSPECT VALVE GUIDE BUSH OIL CLEARANCE |

|

Using a caliper gauge, measure the inside diameter of the guide bush.

- Standard bush inside diameter:

- 5.51 to 5.53 mm (0.217 to 0.218 in.)

Subtract the valve stem diameter measurement from the guide bush inside diameter measurement.

- Standard Oil Clearance:

Item Specified Condition Intake 0.025 to 0.060 mm (0.000984 to 0.00236 in.) Exhaust 0.030 to 0.065 mm (0.00118 to 0.00256 in.)

- Maximum Oil Clearance:

Item Specified Condition Intake 0.08 mm (0.00315 in.) Exhaust 0.10 mm (0.00394 in.)

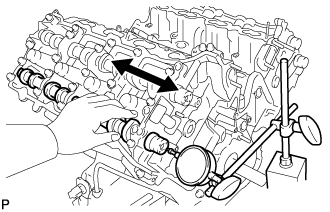

| 8. INSPECT CAMSHAFT THRUST CLEARANCE |

Inspect the bank 1 camshafts.

Install the bank 1 camshafts.

Using a dial indicator, measure the thrust clearance while moving the camshaft back and forth.

- Standard thrust clearance:

- 0.08 to 0.135 mm (0.00315 to 0.00531 in.)

- Maximum thrust clearance:

- 0.15 mm (0.00591 in.)

Inspect the bank 2 camshafts.

Install the bank 2 camshafts.

Using a dial indicator, measure the thrust clearance while moving the camshaft back and forth.

- Standard thrust clearance:

- 0.08 to 0.135 mm (0.00315 to 0.00531 in.)

- Maximum thrust clearance:

- 0.15 mm (0.00591 in.)