Engine Assembly -- Installation |

| 1. INSTALL NO. 2 FRONT ENGINE MOUNTING BRACKET LH |

Install the No. 2 front engine mounting bracket LH with the bolt.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf}

| 2. INSTALL FRONT ENGINE MOUNTING INSULATOR RH |

Install the mounting insulator with the nut.

- Torque:

- 72 N*m{734 kgf*cm, 53 ft.*lbf}

| 3. INSTALL FRONT ENGINE MOUNTING INSULATOR LH |

Install the mounting insulator with the nut.

- Torque:

- 72 N*m{734 kgf*cm, 53 ft.*lbf}

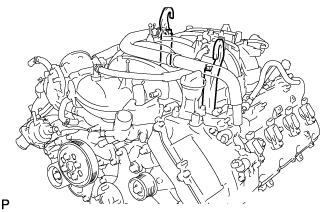

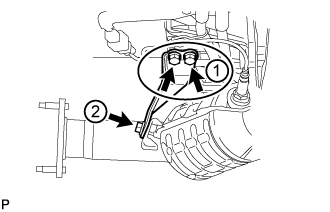

| 4. REMOVE ENGINE STAND |

Install 2 engine hangers with 2 bolts as shown in the illustration.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

- HINT:

Engine hanger 12281-38150 Bolt 90119-14120

|

Attach an engine sling device and hang the engine with a chain block.

Remove the bolts and engine assembly from the engine stand.

- NOTICE:

- With the exception of installing the engine assembly to an engine stand or removing the engine assembly from an engine stand, do not perform any work on the engine while it is suspended, as doing so is dangerous.

- Pay attention to the angle of the sling device as the engine assembly or engine hangers may be damaged or deformed if the angle is incorrect.

| 5. INSTALL ENGINE ASSEMBLY |

Slowly lower the engine assembly into the engine compartment.

- NOTICE:

- Make sure that the engine is clear of all wiring and hoses.

Attach the engine mounting insulators to the vehicle.

Install the 4 engine mounting insulator bolts.

- Torque:

- 79 N*m{806 kgf*cm, 58 ft.*lbf}

Remove the 2 bolts and 2 engine hangers.

| 6. INSTALL WATER PIPE AND HOSE SUB-ASSEMBLY |

Connect the hose and install the water pipe and hose with the 2 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

| 7. CONNECT OIL COOLER PIPE ASSEMBLY |

Connect the oil cooler pipe with the 2 bolts.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

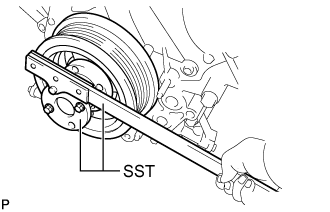

| 8. INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY |

Using SST, hold the crankshaft.

- SST

- 09213-70011

09330-00021

|

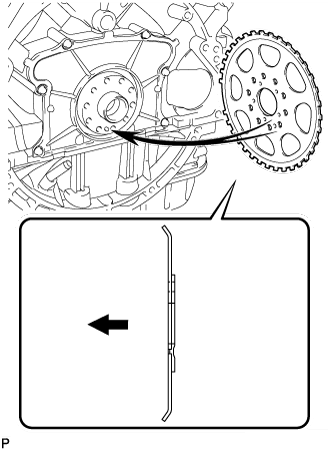

Install the crankshaft angle sensor rotor.

Text in Illustration

Engine Side - HINT:

- Align the pin hole of the crankshaft angle sensor rotor with the pin of the crankshaft.

- As the crankshaft angle sensor rotor is not reversible, be sure to install it so that it is facing in the direction shown in the illustration.

|

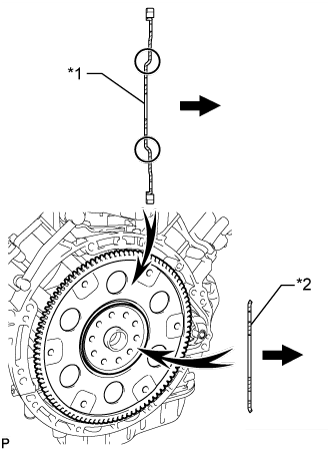

Install the drive plate and rear drive plate spacer onto the crankshaft.

Text in Illustration *1 Drive Plate *2 Rear Drive Plate Spacer

Automatic Transmission Side - HINT:

- As the rear drive plate spacer and the drive plate are not reversible, be sure to install them so that they are facing in the direction shown in the illustration.

|

Install the drive plate and ring gear and bolts.

- HINT:

- The bolts are tightened in 2 progressive steps.

Clean the bolts and bolt holes.

Apply adhesive to 2 or 3 threads at the end of each of the 10 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Text in Illustration *1 Adhesive Step 1:

Install and uniformly tighten 10 new bolts in the sequence shown in the illustration.- Torque:

- 30 N*m{301 kgf*cm, 22 ft.*lbf}

- NOTICE:

- Do not reuse the drive plate installation bolts.

- Do not strike or damage the drive plate installation bolts. Be sure to handle them carefully.

Mark the upside of each drive plate installation bolt with paint.

Step 2:

Tighten the cylinder head bolts another 90°.Check that the painted marks are now at a 90° angle to the upside.

- NOTICE:

- Do not start the engine for at least an hour after installing the drive plate.

| 9. INSTALL REAR NO. 1 ENGINE MOUNTING INSULATOR |

- HINT:

- Only perform this procedure when replacement of the engine mounting insulator is necessary.

Install the rear engine mounting insulator to the transmission with the 4 bolts.

- Torque:

- 59 N*m{602 kgf*cm, 44 ft.*lbf}

Install the front engine mounting insulator RH with the 2 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

| 10. INSTALL AUTOMATIC TRANSMISSION ASSEMBLY |

| 11. INSTALL STARTER ASSEMBLY |

Install the flywheel housing side cover.

Install the starter with the 2 bolts.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

Install the starter wire with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Connect the starter connector.

| 12. INSTALL STARTER COVER |

Install the starter cover with the 3 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

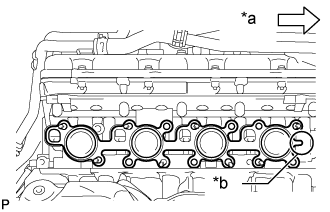

| 13. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH |

Install a new gasket to the cylinder head.

Text in Illustration *a Front *b Tab - HINT:

- Install the exhaust manifold gasket with the gasket tab facing toward the front of the engine.

|

Temporarily install the exhaust manifold sub-assembly RH with the 8 new nuts.

Uniformly tighten the 8 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Attach the wire harness clamp to the bracket and connect the connector.

| 14. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with the 3 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 15. INSTALL NO. 1 MANIFOLD STAY |

Temporarily install the No. 1 manifold stay with the 3 bolts.

Tighten the 3 bolts in the order shown in the illustration.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

|

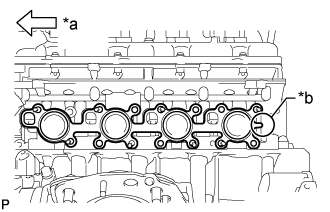

| 16. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH |

Install a new gasket to the cylinder head.

Text in Illustration *a Front *b Tab - HINT:

- Install the exhaust manifold gasket with the gasket tab facing toward the rear of the engine.

|

Temporarily install the exhaust manifold sub-assembly LH with the 8 new nuts.

Uniformly tighten the 8 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Attach the wire harness clamp to the bracket and connect the connector.

| 17. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with the 3 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 18. INSTALL NO. 2 MANIFOLD STAY |

Temporarily install the No. 2 manifold stay with the 3 bolts.

Tighten the 3 bolts in the order shown in the illustration.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

|

| 19. INSTALL PROPELLER SHAFT HEAT INSULATOR |

Install the heat insulator with the 2 bolts.

- Torque:

- 16 N*m{160 kgf*cm, 12 ft.*lbf}

| 20. INSTALL REAR PROPELLER SHAFT ASSEMBLY |

| 21. INSTALL FRONT PROPELLER SHAFT ASSEMBLY |

| 22. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE |

Apply a light coat of engine oil to a new O-ring.

Install the O-ring to the guide.

Install the dipstick guide with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the dipstick.

Connect the wire harness clamp.

| 23. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Install a new gasket and the front exhaust pipe to the exhaust manifold RH with 2 new nuts.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

Install the wire harness clamp bracket of the oxygen sensor to the transmission with the bolt.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

Connect the heated oxygen sensor connector.

| 24. INSTALL FRONT NO. 2 EXHAUST PIPE ASSEMBLY |

Install a new gasket and the front No. 2 exhaust pipe to the exhaust manifold LH with 2 new nuts.

- Torque:

- 54 N*m{551 kgf*cm, 40 ft.*lbf}

Install the wire harness clamp bracket of the oxygen sensor to the transmission with the bolt.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

Connect the heated oxygen sensor connector.

| 25. INSTALL CENTER EXHAUST PIPE ASSEMBLY |

Install 2 new gaskets to the front exhaust pipe and front No. 2 exhaust pipe.

Install the center exhaust pipe to the 3 exhaust pipe supports, and then install the 4 bolts.

- Torque:

- 48 N*m{489 kgf*cm, 35 ft.*lbf}

| 26. INSTALL TAILPIPE ASSEMBLY |

Install the tailpipe to the 2 exhaust pipe supports.

Install a new gasket to the center exhaust pipe.

Connect the tailpipe to the center exhaust pipe.

Attach a new clamp to the tailpipe and center exhaust pipe. Then install the bolt to the clamp.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf}

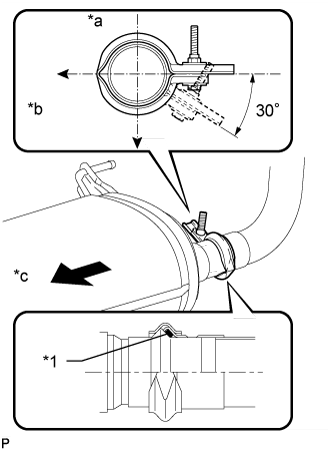

Text in Illustration *1 Gasket *a Top *b LH Side *c Front - HINT:

- Install the clamp within the angle range shown in the illustration.

|

| 27. INSTALL GENERATOR ASSEMBLY |

Install the stud bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the generator assembly with the 3 bolts and nut.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

Connect the harness bracket to the generator assembly with the bolt.

- Torque:

- 31 N*m{316 kgf*cm, 23 ft.*lbf}

Connect the generator wire with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Close the terminal cap.

Connect the generator connector.

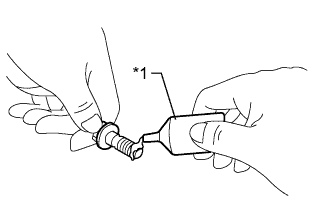

| 28. CONNECT VANE PUMP ASSEMBLY |

|

- HINT:

- Before performing the following procedures, move the spacer until the vane pump can be installed.

| *1 | Spacer |

Connect the vane pump to the timing chain cover with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 29. CONNECT COOLER COMPRESSOR ASSEMBLY |

Install the cooler compressor with the stud bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

Install the 3 bolts and nut.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

- NOTICE:

- Tighten the bolts and nut in the order shown in the illustration to install the cooler compressor.

| 30. CONNECT WIRE HARNESS AND HOSE |

w/ Winch:

Attach the wire harness clamp and connect the ground wire to the wire harness clamp bracket with the nut.- Torque:

- 19 N*m{195 kgf*cm, 14 ft.*lbf}

Connect the 2 connectors and 2 clamps.

Connect the 2 connectors and 2 clips to the engine room junction block.

Install the engine wire to the engine room junction block with the nut. Then connect the 2 clips.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the ground wire to the body with the bolt.

- Torque:

- 8.4 N*m{86 kgf*cm, 74 in.*lbf}

Connect the clamp.

Connect the cable to the positive (+) battery terminal.

Install the wire to the positive (+) battery cable with the nut.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

Install the ground wire with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Connect the clip and 5 connectors to the connector holder block.

Install the heater hose.

Connect the ECM connector and clamp.

- HINT:

- Refer to the following procedures to connect the ECM connector (Click here).

Connect the purge line hose.

| 31. CONNECT FUEL MAIN AND RETURN HOSE |

Connect the fuel main and return hoses (Click here).

Install the fuel pipe clamp.

| 32. INSTALL RADIATOR ASSEMBLY |

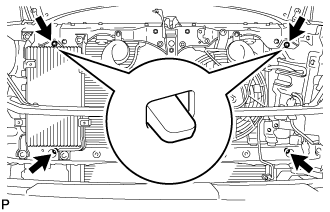

Set the radiator bracket hooks to the radiator support holes.

|

Install the radiator with the 4 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

Connect the 2 oil cooler hoses.

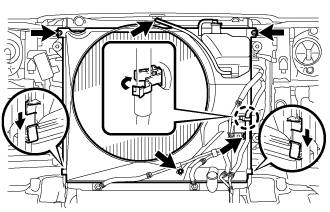

| 33. INSTALL FAN SHROUD |

Install the fan pulley.

Place the shroud together with the coupling fan between the radiator and engine.

- NOTICE:

- Be careful not to damage the radiator core.

Temporarily install the fluid coupling fan to the fluid coupling bracket with the 4 nuts. Tighten the nuts as much as possible by hand.

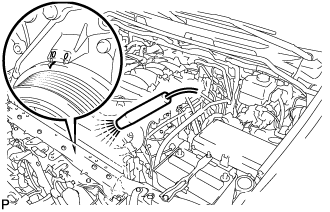

Attach the claws of the shroud to the radiator as shown in the illustration.

|

Install the shroud with the 2 bolts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Connect the oil cooler tube to the fan shroud with the 2 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Pass the hose through the flexible hose clamp and close the clamp as shown in the illustration.

Connect the reservoir hose to the upper radiator tank.

Install the fan and generator V belt (Click here).

Tighten the 4 nuts of the fluid coupling fan.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 34. INSTALL NO. 2 RADIATOR HOSE |

| 35. INSTALL NO. 1 RADIATOR HOSE |

| 36. INSTALL AIR CLEANER ASSEMBLY |

Install the air cleaner with the 3 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

| 37. INSTALL AIR CLEANER HOSE ASSEMBLY |

Install the air cleaner hose so that the protrusion of the air cleaner cap aligns with the groove of the hose as shown in the illustration.

Text in Illustration *1 Groove *2 Protrusion

|

Tighten the 2 clamps.

- Torque:

- 2.5 N*m{25 kgf*cm, 22 in.*lbf}

Connect the vacuum hose.

Connect the No. 2 ventilation hose.

| 38. ADD ENGINE OIL |

Add fresh oil and install the oil filler cap.

- Standard Oil Grade:

Oil Grade Oil Viscosity (SAE) API grade SL "Energy-Conserving", SM "Energy-Conserving", SN "Resource-Conserving" or ILSAC multigrade engine oil 5W-30

10W-30API grade SL, SM or SN multigrade engine oil 15W-40

20W-50

- Standard Oil Capacity:

Item Specified Condition Drain and refill without oil filter change 7.1 liters (7.5 US qts, 6.2 Imp. qts) Drain and refill with oil filter change 7.5 liters (7.9 US qts, 6.6 Imp. qts) Dry fill 9.3 liters (9.8 US qts, 8.2 Imp. qts)

| 39. ADD ENGINE COOLANT |

Add engine coolant.

- Standard Capacity:

Item Specified Condition with rear heater 16.2 liters (17.1 US qts, 14.3 Imp. qts) without rear heater 13.4 liters (14.2 US qts, 11.8 Imp. qts)

- NOTICE:

- Do not substitute plain water for engine coolant.

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

Slowly pour coolant into the radiator reservoir until it reaches the F line.

Install the reservoir cap.

Press the No. 1 and No. 2 radiator hoses several times by hand, and then check the coolant level. If the coolant level is low, add coolant.

Install the radiator cap.

Start the engine and warm it up until the thermostat opens.

- HINT:

- The thermostat opening timing can be confirmed by pressing the radiator inlet hose by hand, and checking when the engine coolant starts to flow inside the hose.

Maintain the engine speed at 2000 to 2500 rpm.

- NOTICE:

- Make sure that the radiator reservoir still has some coolant in it.

- Pay attention to the needle of the water temperature meter. Make sure that the needle does not show an abnormally high temperature.

- If there is not enough coolant, the engine may burn out or overheat.

- Immediately after starting the engine, if the radiator reservoir does not have any coolant, perform the following: 1) stop the engine, 2) wait until the coolant has cooled down, and 3) add coolant until the coolant is filled to the F line.

- Run the engine at 2000 rpm until the coolant level has stabilized.

Press the No. 1 and No. 2 radiator hoses several times by hand to bleed air.

- CAUTION:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the fan.

Stop the engine, and wait until the engine coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Check that the coolant level is between the F and L lines.

If the coolant level is below the L line, repeat all of the procedures above.

If the coolant level is above the F line, drain coolant so that the coolant level is between the F and L lines.

| 40. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (Click here).

| 41. INSPECT FOR OIL LEAK |

Start the engine. Make sure that there are no oil leaks from the area that was worked on.

| 42. INSPECT FOR COOLANT LEAK |

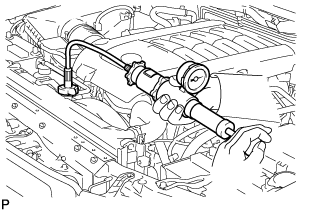

|

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Fill the radiator with coolant and attach a radiator cap tester.

Warm up the engine.

Using the radiator cap tester, increase the pressure inside the radiator to 123 kPa (1.3 kgf/cm2, 18 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks. If no external leaks are found, check the heater core, cylinder block and head.

| 43. INSPECT FOR EXHAUST GAS LEAK |

| 44. INSPECT FOR FUEL LEAK |

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG) and intelligent tester main switch on.

- NOTICE:

- Do not start the engine.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

Check that there are no fuel leaks after doing maintenance anywhere on the fuel system.

- HINT:

- If DTC P1603 is output, clear the DTC (Click here).

| 45. INSPECT SHIFT LEVER POSITION |

When moving the shift lever from P to R with the ignition switch ON and the brake pedal depressed, make sure that it moves smoothly and correctly into position.

Check that the shift lever does not stop when moving the shift lever from R to P, and check that the shift lever does not stick when moving the shift lever from D to S.

Start the engine and make sure that the vehicle moves forward after moving the shift lever from N to D and moves rearward after moving the shift lever to R.

If the operation cannot be performed as specified, inspect the park/neutral position switch assembly and check the shift lever assembly installation condition.

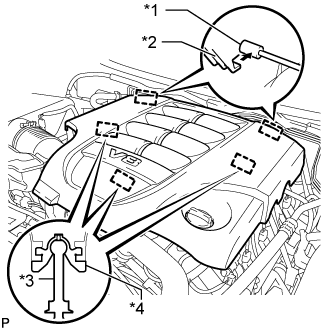

| 46. INSTALL V-BANK COVER SUB-ASSEMBLY |

Attach the 2 V-bank cover hooks to the bracket. Then align the 3 V-bank cover grommets with the 3 pins, and press down on the V-bank cover to attach the pins.

Text in Illustration *1 Bracket *2 Hook *3 Pin *4 Grommet

|

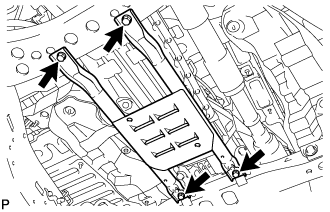

| 47. INSTALL OIL PAN PROTECTOR ASSEMBLY |

Install the oil pan protector with the 4 bolts.

- Torque:

- 50 N*m{510 kgf*cm, 37 ft.*lbf}

|

| 48. INSTALL NO. 2 ENGINE UNDER COVER |

Install the No. 2 engine under cover with the 2 bolts.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 49. INSTALL NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY |

Install the No. 1 engine under cover with the 10 bolts.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 50. INSTALL FRONT FENDER APRON SEAL REAR RH |

Install the fender apron seal with the 4 clips.

| 51. INSTALL FRONT FENDER APRON SEAL FRONT RH |

Install the fender apron seal with the 3 clips.

| 52. INSTALL FRONT FENDER APRON SEAL REAR LH |

Install the fender apron seal with the 4 clips.

| 53. INSTALL FRONT FENDER APRON SEAL LH |

Install the fender apron seal with the 3 clips.

| 54. INSTALL COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY |

| 55. INSTALL HOOD SUB-ASSEMBLY |

Install the hood with the 4 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Connect the 2 hood supports with the 2 hood support bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

- CAUTION:

- Install the hood support while supporting the hood by hand.

- NOTICE:

- Check that the hood support is engaged in the ball joint and that it cannot be pulled out.

| 56. ADJUST HOOD SUB-ASSEMBLY |

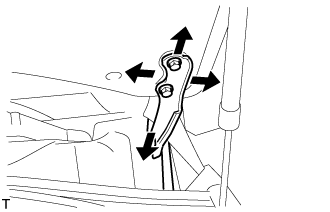

Adjust the hood position.

Loosen the 4 hinge bolts of the hood.

Move the hood and adjust the clearance between the hood and front fender.

Tighten the hinge bolts of the hood after the adjustment.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

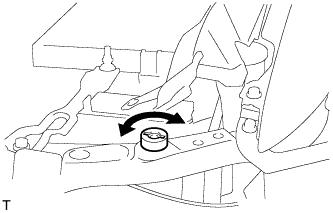

Adjust the cushion rubber so that the height of the hood and fender are aligned.

- HINT:

- Raise or lower the hood front end by turning the cushion rubber.

|

Adjust the hood lock.

Remove the upper radiator support seal (Click here).

Remove the lower No. 1 radiator mounting bracket (Click here).

Loosen the 2 bolts and hood lock nut.

Adjust the hood lock position so that the striker can enter it smoothly.

Tighten the bolts and nut after the adjustment.

- Torque:

- 5.5 N*m{56 kgf*cm, 49 in.*lbf}

Install the lower No. 1 radiator mounting bracket (Click here).

Install the upper radiator support seal (Click here).

| 57. INSTALL RADIATOR SIDE DEFLECTOR LH |

Install the radiator side deflector LH with the 4 clips.

| 58. INSTALL TRANSMISSION OIL COOLER AIR DUCT |

| 59. INSTALL FRONT BUMPER COVER |

- for Standard (Click here)

- w/ Winch (Click here)

| 60. INSPECT IGNITION TIMING |

Warm up and stop the engine.

Allow the engine to warm up to a normal operating temperature.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

Start the engine and idle it.

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Primary / IGN Advance.

- HINT:

- Refer to the intelligent tester operator's manual for further details.

- Standard ignition timing:

- 8 to 12° BTDC @ idling (transmission in neutral and A/C switch off)

Disconnect the intelligent tester from the DLC3.

When not using the intelligent tester:

Connect the tester probe of a timing light to the wire of the ignition coil connector for the No. 1 cylinder.

- NOTICE:

- Use a timing light that detects primary signals.

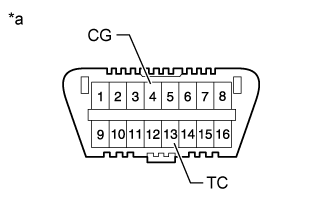

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

Text in Illustration *a Front view of DLC3 - NOTICE:

- Confirm the terminal numbers before connecting them. Connecting the wrong terminals can damage the engine.

- Switch off all accessories and the A/C before connecting the terminals.

Using the timing light, check the ignition timing.

- Standard ignition timing:

- 8 to 12° BTDC @ idling (transmission in neutral and A/C switch off)

Remove SST from the DLC3.

Check the ignition timing.

- Standard ignition timing:

- 7 to 24° BTDC @ idling (transmission in neutral and A/C switch off)

Disconnect the timing light from the engine.

| 61. INSPECT ENGINE IDLE SPEED |

Warm up and stop the engine.

Allow the engine to warm up to a normal operating temperature.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

- NOTICE:

- Switch off all accessories and the A/C before connecting the intelligent tester.

Race the engine at 2500 rpm for approximately 90 seconds.

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Primary / Engine Speed.

- Standard idle speed:

- 650 to 750 rpm (transmission in neutral and A/C switch off)

- HINT:

- Refer to the intelligent tester operator's manual for further details.

Disconnect the intelligent tester from the DLC3.

When not using the intelligent tester:

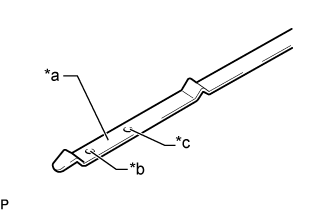

Using SST, connect the tachometer probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

Text in Illustration *a Front view of DLC3 - NOTICE:

- Confirm the terminal number before connecting the probe. Connecting the probe to the wrong terminal can damage the engine.

- Switch off all accessories and the A/C before connecting the probe.

Race the engine at 2500 rpm for approximately 90 seconds.

Check the idle speed.

- Standard idle speed:

- 650 to 750 rpm (transmission in neutral and A/C switch off)

Disconnect the tachometer probe from the DLC3.

|

| 62. INSPECT CO/HC |

- HINT:

- This check is used only to determine whether or not the idle CO/HC complies with regulations.

Start the engine.

Keep the engine speed at 2500 rpm for approximately 180 seconds.

Insert the CO/HC meter testing probe at least 40 cm (1.31 ft.) into the tailpipe during idling.

Immediately check CO/HC concentration at idle and/or 2500 rpm.

- HINT:

- When performing the 2 mode (2500 rpm and idle) test, follow the measurement order prescribed by the applicable local regulations.

If the CO/HC concentration does not comply with the regulations, troubleshoot in the order given below.

Check the A/F sensor (Click here) and heated oxygen sensor (Click here) operation.

See the table below for possible causes, and then inspect and correct the applicable causes if necessary.

CO HC Symptom Cause Normal High Rough idle - Faulty ignitions:

- Incorrect timing

- Plugs (contaminated, shorted or gaps are defective)

- Incorrect valve clearance

- Leaky intake and exhaust valves

- Leaky cylinder

Low High Rough idle

(Fluctuating HC reading)- Vacuum leaks:

- PCV hose

- Intake manifold

- Throttle body

- Lean mixture causing misfire

High High Rough idle

(Black smoke from exhaust)- Restricted air filter

- Faulty SFI system:

- Faulty pressure regulator

- Defective engine coolant temperature sensor

- Faulty ECM

- Faulty injectors

- Faulty throttle position sensor

- Faulty mass air flow meter

- Faulty ignitions:

| 63. INSPECT ENGINE OIL LEVEL |

Warm up the engine. Then stop the engine and wait for 5 minutes.

Check that the engine oil level is between the dipstick low level mark and full level mark.

If the level is low, check for leakage and add oil up to the full level mark.Text in Illustration *a Measuring Surface *b Low Level Mark *c Full Level Mark - NOTICE:

- Do not fill engine oil above the full level mark.

- HINT:

- A certain amount of engine oil will be consumed while driving. In the following situations, oil consumption may increase, and engine oil may need to be refilled in between oil maintenance intervals.

- When the engine is new, for example directly after purchasing the vehicle or after replacing the engine.

- If low quality oil or oil of an inappropriate viscosity is used.

- When driving at high engine speed or with a heavy load, (when towing, or), when driving while accelerating or decelerating frequently.

- When leaving the idling for a long time, or when driving frequently through heavy traffic.

- When judging the amount of oil consumption, keep in mind that the oil may have become diluted, making it difficult to judge the true level accurately.

|

| 64. INSPECT ENGINE COOLANT LEVEL |

Check that the engine coolant level is between the L and F lines when the engine is cold.

If the engine coolant is below the L line, check for leaks and add "TOYOTA Super Long Life Coolant" or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite and non-borate coolant with long-life hybrid organic acid technology to the F line.- NOTICE:

- Do not substitute plain water for engine coolant.