Camshaft -- Installation |

| 1. INSTALL CAMSHAFT BEARING CAP LH |

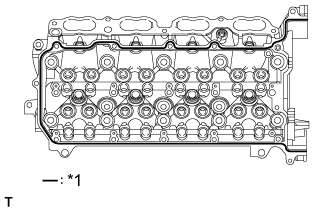

Apply a light coat of engine oil to the camshaft journals, camshaft housing and camshaft bearing caps.

Install the No. 3 and No. 4 camshafts to the camshaft housing.

Confirm the marks and numbers on the camshaft bearing caps and place them in their proper positions and directions.

|

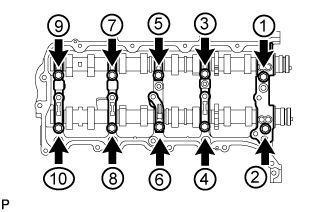

Temporarily install the 10 bolts in the order shown in the illustration.

|

| 2. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY LH |

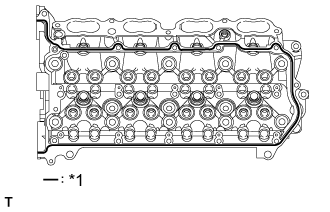

Check the valve rocker arms as shown in the illustration.

Text in Illustration *1 Valve Rocker Arm *2 Valve Stem Cap *3 Valve Lash Adjuster

|

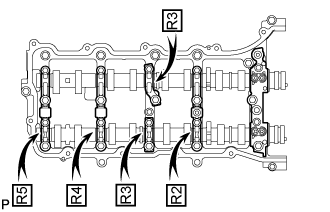

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.5 to 4.0 mm (0.138 to 0.157 in.)

Text in Illustration *1 Seal Packing - NOTICE:

- Remove any oil from the contact surface.

- Install the camshaft housing within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

|

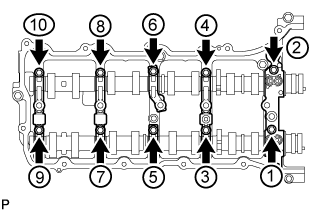

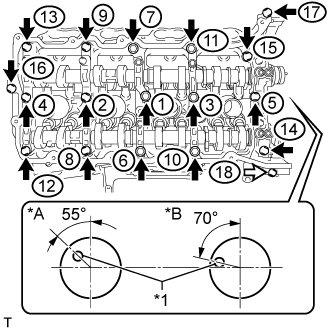

Install the camshaft housing, and then install the 18 bolts in the order shown in the illustration.

- Torque:

- for bolt A:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

- except bolt A:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

Text in Illustration *A for Intake Side *B for Exhaust Side *1 Knock Pin

Bolt

Bolt A - NOTICE:

- Do not start the engine for at least 2 hours after the installation.

- Make sure that the knock pins of the camshafts are positioned as shown in the illustration before installing the camshaft housing.

|

Tighten the 10 bolts in the order shown in the illustration.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

- NOTICE:

- Thoroughly wipe clean any seal packing.

|

| 3. INSTALL CAMSHAFT BEARING CAP RH |

Apply a light coat of engine oil to the camshaft journals, camshaft housing and camshaft bearing caps.

Install the No. 1 and No. 2 camshafts to the camshaft housing.

Confirm the marks and numbers on the camshaft bearing caps and place them in their proper positions and directions.

|

Temporarily install the 10 bolts in the order shown in the illustration.

|

| 4. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY RH |

Check the valve rocker arms as shown in the illustration.

Text in Illustration *1 Valve Rocker Arm *2 Valve Stem Cap *3 Valve Lash Adjuster

|

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.5 to 4.0 mm (0.138 to 0.157 in.)

Text in Illustration *1 Seal Packing - NOTICE:

- Remove any oil from the contact surface.

- Install the camshaft housing within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

|

Install the camshaft housing, and then install the 18 bolts in the order shown in the illustration.

- Torque:

- for bolt A:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

- except bolt A:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

Text in Illustration *A for Exhaust Side *B for Intake Side *1 Knock Pin

Bolt

Bolt A - NOTICE:

- Do not start the engine for at least 2 hours after the installation.

- Make sure that the knock pins of the camshafts are positioned as shown in the illustration before installing the camshaft housing.

|

Tighten the 10 bolts in the order shown in the illustration.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

- NOTICE:

- Thoroughly wipe clean any seal packing.

|

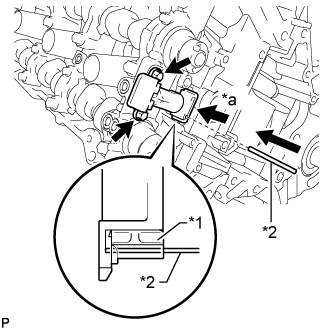

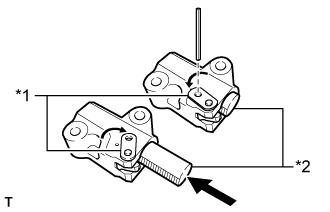

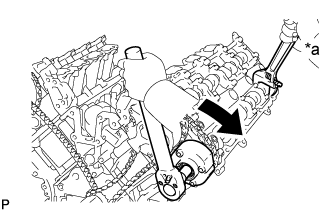

| 5. INSTALL NO. 2 CHAIN TENSIONER ASSEMBLY |

Install the No. 2 chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Text in Illustration *1 Plunger *2 Pin *a Push

|

While raising up the No. 2 chain tensioner, insert a pin with a diameter of 1.0 mm (0.0394 in.) into the hole to fix the tensioner in place.

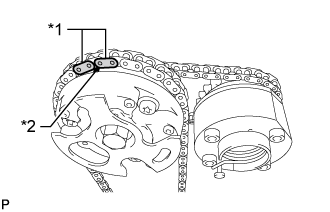

| 6. INSTALL NO. 1 CHAIN SUB-ASSEMBLY RH |

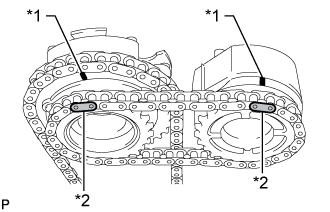

Align the No. 1 chain's mark plates (orange) with the camshaft timing gear's timing mark and attach the chain to the gear as shown in the illustration.

Text in Illustration *1 Mark Plate (Orange) *2 Timing Mark

|

Align the No. 1 chain's mark plate (orange) with the crankshaft timing gear's timing mark and attach the chain to the gear as shown in the illustration.

Text in Illustration *1 Timing Mark *2 Mark Plate (Orange)

|

Align the No. 2 chain's mark plates (yellow) with the timing marks (1-dot marks) of the camshaft timing gear and camshaft timing exhaust gear, and attach the No. 2 chain to the gears as shown in the illustration.

Text in Illustration *1 Timing Mark *2 Mark Plate (Yellow) - HINT:

- The crankshaft timing gear and camshaft exhaust gear are installed with the No. 1 and No. 2 chains connected to the gears.

|

Install the crankshaft timing sprocket RH to the crankshaft.

Align the knock pin of the No. 1 camshaft with the pin hole of the camshaft timing gear and install the camshaft timing gear.

Using the hexagonal portion of the No. 2 camshaft, align the knock pin of the No. 2 camshaft with the pin hole of the camshaft timing exhaust gear and install the camshaft timing exhaust gear.

Remove the pin from the No. 2 chain tensioner.

| 7. INSTALL NO. 1 CHAIN VIBRATION DAMPER RH |

Install the No. 1 chain vibration damper RH with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 8. INSTALL CHAIN TENSIONER SLIPPER RH |

- HINT:

- If the No. 1 chain tensioner slipper cannot be installed due to the tension of the chain, use the hexagonal portion of the camshaft to loosen the chain, and then install the chain tensioner slipper RH.

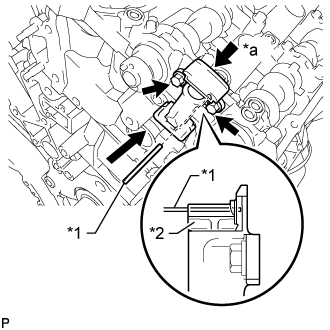

| 9. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY RH |

Move the stopper plate upward to release the lock and push the plunger deep into the No. 1 chain tensioner.

Text in Illustration *1 Stopper Plate *2 Plunger

|

Move the stopper plate downward to set the lock and insert a hexagon wrench into the hole of the stopper plate.

Install the No. 1 chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Remove the hexagon wrench from the No. 1 chain tensioner.

| 10. INSTALL NO. 3 CHAIN TENSIONER ASSEMBLY |

Install the No. 3 chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Text in Illustration *1 Pin *2 Plunger *a Push

|

While pushing down the No. 3 chain tensioner, insert a pin with a diameter of 1.0 mm (0.0394 in.) into the hole to fix the tensioner in place.

| 11. INSTALL NO. 1 CHAIN SUB-ASSEMBLY LH |

Align the No. 1 chain's mark plates (orange) with the camshaft timing gear's timing mark and attach the chain to the gear as shown in the illustration.

Text in Illustration *1 Mark Plate (Orange) *2 Timing Mark

|

Align the No. 1 chain's mark plate (orange) with the crankshaft timing gear's timing mark and attach the chain to the gear as shown in the illustration.

Text in Illustration *1 Timing Mark *2 Mark Plate (Orange)

|

Align the No. 2 chain's mark plates (yellow) with the timing marks (1-dot marks) of the camshaft timing gear and camshaft timing exhaust gear, and attach the No. 2 chain to the gears as shown in the illustration.

Text in Illustration *1 Timing Mark *2 Mark Plate (Yellow) - HINT:

- The crankshaft timing gear and camshaft exhaust gear are installed with the No. 1 and No. 2 chains connected to the gears.

|

Install the crankshaft timing sprocket LH to the crankshaft.

Align the knock pin of the No. 3 camshaft with the pin hole of the camshaft timing gear and install the camshaft timing gear.

Using the hexagonal portion of the No. 4 camshaft, align the knock pin of the No. 4 camshaft with the pin hole of the camshaft timing exhaust gear and install the camshaft timing exhaust gear.

- NOTICE:

- Because the gears' timing mark positions may shift due to looseness of the No. 1 chain, use the hexagonal portion of the camshaft to hold the No. 3 camshaft in place until the No. 1 chain tensioner is installed.

Remove the pin from the No. 3 chain tensioner.

| 12. INSTALL CHAIN TENSIONER SLIPPER LH |

- HINT:

- If the chain tensioner slipper cannot be installed due to the tension of the chain, use the hexagonal portion of the camshaft to loosen the chain and install the chain tensioner slipper LH.

| 13. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY LH |

Move the stopper plate upward to release the lock and push the plunger deep into the No. 1 chain tensioner.

Text in Illustration *1 Stopper Plate *2 Plunger

|

Move the stopper plate downward to set the lock and insert a hexagon wrench into the hole of the stopper plate.

Install a new gasket and the No. 1 chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 14. INSTALL NO. 1 CHAIN VIBRATION DAMPER LH |

Install the No. 1 chain vibration damper with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Remove the hexagon wrench from the No. 1 chain tensioner.

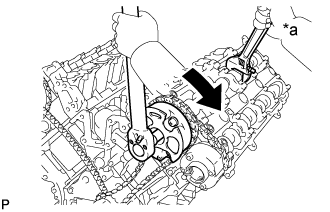

| 15. TIGHTEN CAMSHAFT TIMING GEAR ASSEMBLY |

for Bank 1:

Using a wrench to hold the hexagonal portion of the No. 3 camshaft, install the camshaft timing gear bolt.

- Torque:

- 100 N*m{1020 kgf*cm, 74 ft.*lbf}

Text in Illustration *a Hold

Turn Using a wrench to hold the hexagonal portion of the No. 4 camshaft, install the camshaft timing exhaust gear bolt.

- Torque:

- 100 N*m{1020 kgf*cm, 74 ft.*lbf}

Text in Illustration *a Hold

Turn

for Bank 2:

Using a wrench to hold the hexagonal portion of the No. 1 camshaft, install the camshaft timing gear bolt.

- Torque:

- 100 N*m{1020 kgf*cm, 74 ft.*lbf}

Text in Illustration *a Hold

Turn Using a wrench to hold the hexagonal portion of the No. 2 camshaft, install the camshaft timing exhaust gear bolt.

- Torque:

- 100 N*m{1020 kgf*cm, 74 ft.*lbf}

Text in Illustration *a Hold

Turn

| 16. CHECK NO. 1 CYLINDER TO TDC/COMPRESSION |

Temporarily install the pulley set bolt.

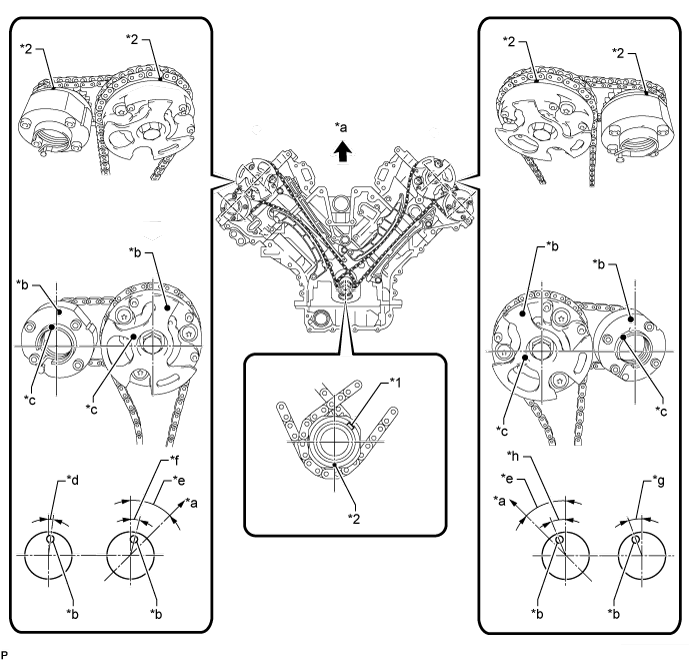

Rotate the crankshaft clockwise and check that the timing marks on the crankshaft timing gear and camshaft timing gears are as shown in the illustration.

Remove the crankshaft pulley set bolt.

Text in Illustration *1 Crankshaft Timing Gear Key *2 Timing Mark *a Toward Ceiling *b Timing Mark Position *c Knock Pin Position *d Approximately 2° *e Approximately 45° *f Approximately 16° *g Approximately 18° *h Approximately 32°

| 17. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY |

| 18. INSPECT IGNITION TIMING |

- NOTICE:

- Turn all electrical systems off.

- Perform the inspection when the cooling fan motor is turned off.

Warm up the engine.

When using the GTS:

Connect the GTS to the DLC3.

Enter the following menus: Powertrain / Engine and ECT / Data List / All Data / IGN Advance.

- Standard ignition timing:

- 7 to 24° BTDC @ idle (transmission in neutral and A/C switch off)

- HINT:

- Refer to the GTS operator's manual for further details.

Check that the ignition timing advances immediately when the engine speed is increased.

Disconnect the GTS from the DLC3.

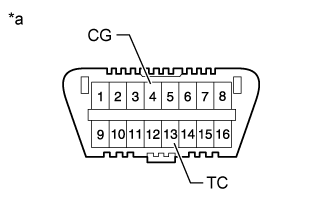

When not using the GTS:

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

Text in Illustration *a Front view of DLC3 - NOTICE:

- Be sure not to improperly connect the terminals. This may damage the engine.

Connect the tester probe of a timing light to the wire of the ignition coil connector for the No. 1 cylinder.

- NOTICE:

- Use a timing light that detects primary signals.

Inspect the ignition timing during idling.

- Standard ignition timing:

- 8 to 12° BTDC @ idle (transmission in neutral and A/C switch off)

Remove SST from the DLC3.

Inspect the ignition timing during idling.

- Standard ignition timing:

- 7 to 24° BTDC @ idle (transmission in neutral and A/C switch off)

Disconnect the timing light from the engine.

| 19. INSPECT ENGINE IDLE SPEED |

- NOTICE:

- Turn all the electrical systems off.

- Perform the inspection when the cooling fan motor is turned off.

Warm up the engine.

When using the GTS:

Connect the GTS to the DLC3.

Enter the following menus: Powertrain / Engine and ECT / Data List / All Data / Engine Speed.

- Standard idle speed:

- 650 to 750 rpm (transmission in neutral and A/C switch off)

- HINT:

- Refer to the GTS operator's manual for further details.

Disconnect the GTS from the DLC3.

When not using the GTS:

Connect SST to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

Text in Illustration *a Front view of DLC3 - NOTICE:

- Be sure not to improperly connect SST. This may damage the engine.

Race the engine at 2500 rpm for approximately 90 seconds.

Inspect the engine idle speed.

- Standard idle speed:

- 650 to 750 rpm (transmission in neutral and A/C switch off)