CHECK COMMUNICATION BETWEEN GTS AND ECM

CHECK TERMINAL VOLTAGE (POWER SOURCE OF ECM)

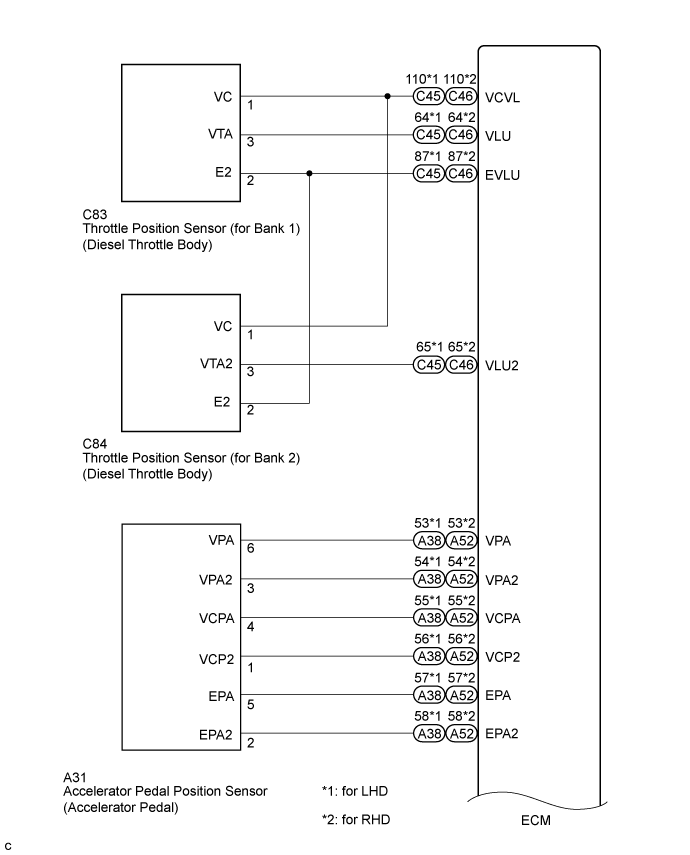

CHECK CONNECTION BETWEEN GTS AND ECM (THROTTLE POSITION SENSOR (for Bank 1))

CHECK CONNECTION BETWEEN GTS AND ECM (THROTTLE POSITION SENSOR (for Bank 2))

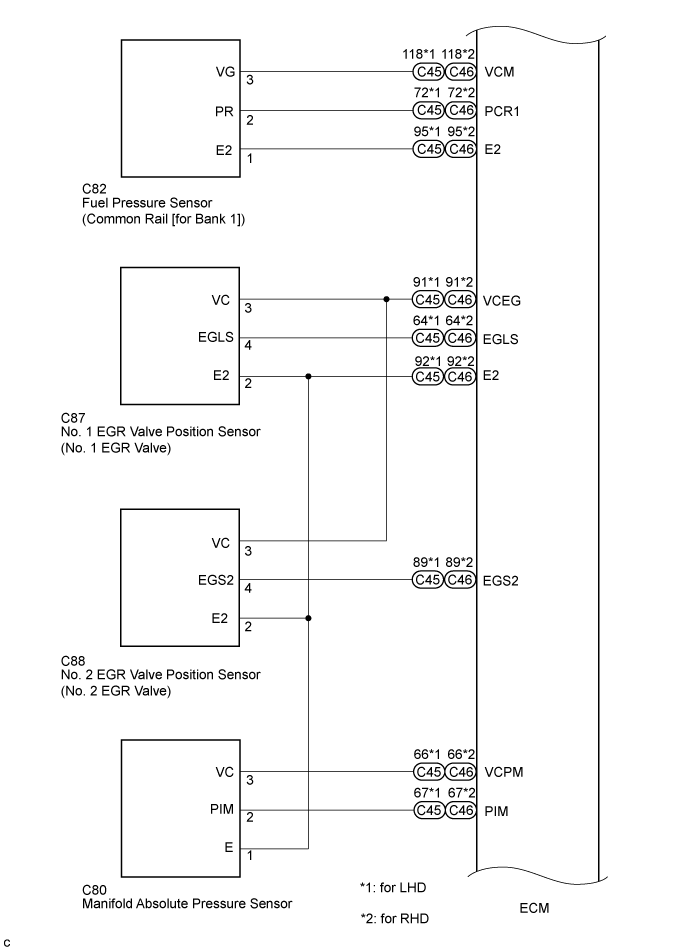

CHECK CONNECTION BETWEEN GTS AND ECM (NO. 1 EGR VALVE POSITION SENSOR)

CHECK CONNECTION BETWEEN GTS AND ECM (NO. 2 EGR VALVE POSITION SENSOR)

CHECK CONNECTION BETWEEN GTS AND ECM (ACCELERATOR PEDAL POSITION SENSOR)

CHECK CONNECTION BETWEEN GTS AND ECM (MANIFOLD ABSOLUTE PRESSURE SENSOR)

CHECK CONNECTION BETWEEN GTS AND ECM (FUEL PRESSURE SENSOR)

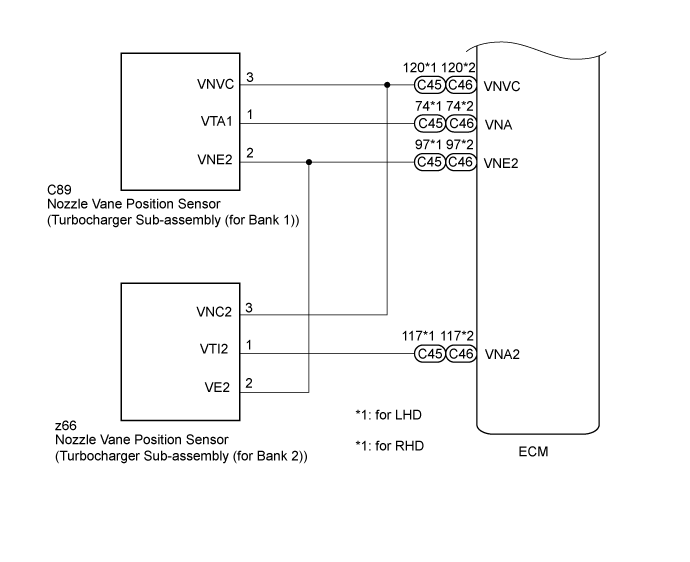

CHECK CONNECTION BETWEEN GTS AND ECM (NOZZLE VANE POSITION SENSOR (for Bank 1))

CHECK CONNECTION BETWEEN GTS AND ECM (NOZZLE VANE POSITION SENSOR (for Bank 2))

ECD SYSTEM (w/o DPF) - VC Output Circuit |

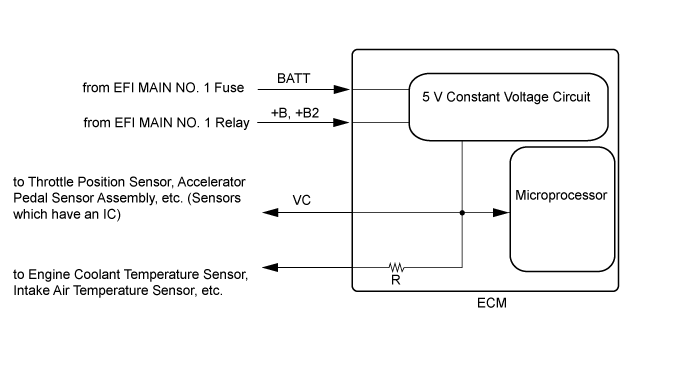

DESCRIPTION

The ECM constantly generates 5 V of power from the battery voltage supplied to the +B (BATT) terminal to operate the microprocessor. The ECM also provides this power to the sensors through the VC output circuit.

When the VC circuit is short-circuited, the microprocessor in the ECM and sensors that are supplied with power through the VC circuit are inactivated because the power is not supplied from the VC circuit. Under this condition, the system does not start up and the MIL does not illuminate even if the system malfunctions.

- HINT:

- Under normal conditions, the MIL is illuminated for several seconds when the ignition switch is first turned to ON. The MIL goes off when the engine is started.

WIRING DIAGRAM

- For the circuit diagram of the ECM power source circuit (Click here)

- VC Power Source Circuit

INSPECTION PROCEDURE

- NOTICE:

- After replacing the ECM, the new ECM needs registration (Click here) and initialization (Click here).

| 1.CHECK COMMUNICATION BETWEEN GTS AND ECM |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and GTS on.

Check the communication between the GTS and ECM.

Result Result Proceed to Communication is not possible A Communication is possible B

|

| ||||

| A | |

| 2.CHECK TERMINAL VOLTAGE (POWER SOURCE OF ECM) |

Turn the ignition switch to ON.

|

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection Condition Specified Condition 1 (EFI No. 2 fuse) - Body ground Ignition switch ON 11 to 14 V

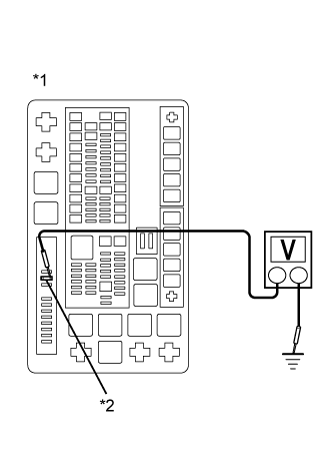

Text Illustration *1 Engine Room Relay Block *2 EFI No. 2 Fuse - HINT:

- If the result is not as specified, since current is not flowing to the +B and +B2 terminals of the ECM, the system may not be started.

|

| ||||

| OK | |

| 3.CHECK CONNECTION BETWEEN GTS AND ECM (THROTTLE POSITION SENSOR (for Bank 1)) |

Disconnect the throttle position sensor (for Bank 1) connector.

Turn the ignition switch to ON.

Check the MIL.

Result Result Proceed to Communication is possible A Communication is not possible B

Reconnect the throttle position sensor (for Bank 1) connector.

|

| ||||

| B | |

| 4.CHECK CONNECTION BETWEEN GTS AND ECM (THROTTLE POSITION SENSOR (for Bank 2)) |

Disconnect the throttle position sensor (for Bank 2) connector.

Turn the ignition switch to ON.

Check the MIL.

Result Result Proceed to Communication is possible A Communication is not possible B

Reconnect the throttle position sensor (for Bank 2) connector.

|

| ||||

| B | |

| 5.CHECK CONNECTION BETWEEN GTS AND ECM (NO. 1 EGR VALVE POSITION SENSOR) |

Disconnect the No. 1 EGR valve connector.

Turn the ignition switch to ON.

Check the MIL.

Result Result Proceed to Communication is possible A Communication is not possible B

Reconnect the No. 1 EGR valve connector.

|

| ||||

| B | |

| 6.CHECK CONNECTION BETWEEN GTS AND ECM (NO. 2 EGR VALVE POSITION SENSOR) |

Disconnect the No. 2 EGR valve connector.

Turn the ignition switch to ON.

Check the MIL.

Result Result Proceed to Communication is possible A Communication is not possible B

Reconnect the No. 2 EGR valve connector.

|

| ||||

| B | |

| 7.CHECK CONNECTION BETWEEN GTS AND ECM (ACCELERATOR PEDAL POSITION SENSOR) |

Disconnect the accelerator pedal position sensor connector.

Turn the ignition switch to ON.

Check the MIL.

Result Result Proceed to Communication is possible A Communication is not possible B

Reconnect the accelerator pedal position sensor connector.

|

| ||||

| B | |

| 8.CHECK CONNECTION BETWEEN GTS AND ECM (MANIFOLD ABSOLUTE PRESSURE SENSOR) |

Disconnect the manifold absolute pressure sensor connector.

Turn the ignition switch to ON.

Check the MIL.

Result Result Proceed to Communication is possible A Communication is not possible B

Reconnect the manifold absolute pressure sensor connector.

|

| ||||

| B | |

| 9.CHECK CONNECTION BETWEEN GTS AND ECM (FUEL PRESSURE SENSOR) |

Disconnect the fuel pressure sensor connector.

Turn the ignition switch to ON.

Check the MIL.

Result Result Proceed to Communication is possible A Communication is not possible B

Reconnect the fuel pressure sensor connector.

|

| ||||

| B | |

| 10.CHECK CONNECTION BETWEEN GTS AND ECM (NOZZLE VANE POSITION SENSOR (for Bank 1)) |

Disconnect the nozzle vane position sensor (for Bank 1) connector.

Turn the ignition switch to ON.

Check the MIL.

Result Result Proceed to Communication is possible A Communication is not possible B

Reconnect the nozzle vane position sensor (for Bank 1) connector.

|

| ||||

| B | |

| 11.CHECK CONNECTION BETWEEN GTS AND ECM (NOZZLE VANE POSITION SENSOR (for Bank 2)) |

Disconnect the nozzle vane position sensor (for Bank 2) connector.

Turn the ignition switch to ON.

Check the MIL.

Result Result Proceed to Communication is possible A Communication is not possible B

Reconnect the nozzle vane position sensor (for Bank 2) connector.

|

| ||||

| B | |

| 12.CHECK HARNESS AND CONNECTOR |

Disconnect the throttle position sensor (for Bank 1) connector.

Disconnect the throttle position sensor (for Bank 2) connector.

Disconnect the No. 1 EGR valve connector.

Disconnect the No. 2 EGR valve connector.

Disconnect the accelerator pedal position sensor connector.

Disconnect the manifold absolute pressure sensor connector.

Disconnect the fuel pressure sensor connector.

Disconnect the nozzle vane position sensor (for Bank 1) connector.

Disconnect the nozzle vane position sensor (for Bank 2) connector.

Disconnect the ECM connectors.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Short):

for LHD Tester Connection Condition Specified Condition C45-91 (VC) - Body ground Always 10 kΩ or higher C45-110 (VCVL) - Body ground Always 10 kΩ or higher C45-118 (VCM) - Body ground Always 10 kΩ or higher C45-120 (VNVC) - Body ground Always 10 kΩ or higher C45-66 (VCPM) - Body ground Always 10 kΩ or higher A38-55 (VCPA) - Body ground Always 10 kΩ or higher A38-56 (VCP2) - Body ground Always 10 kΩ or higher for RHD Tester Connection Condition Specified Condition C46-91 (VC) - Body ground Always 10 kΩ or higher C46-110 (VCVL) - Body ground Always 10 kΩ or higher C46-118 (VCM) - Body ground Always 10 kΩ or higher C46-120 (VNVC) - Body ground Always 10 kΩ or higher C46-66 (VCPM) - Body ground Always 10 kΩ or higher A52-55 (VCPA) - Body ground Always 10 kΩ or higher A52-56 (VCP2) - Body ground Always 10 kΩ or higher

Reconnect the throttle position sensor (for Bank 1) connector.

Reconnect the throttle position sensor (for Bank 2) connector.

Reconnect the No. 1 EGR valve connector.

Reconnect the No. 2 EGR valve connector.

Reconnect the accelerator pedal position sensor connector.

Reconnect the manifold absolute pressure sensor connector.

Reconnect the fuel pressure sensor connector.

Reconnect the nozzle vane position sensor (for Bank 1) connector.

Reconnect the nozzle vane position sensor (for Bank 2) connector.

Reconnect the ECM connectors.

|

| ||||

| OK | ||

| ||