DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0400, P1248)

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (CONTROL THE EGR STEP POSITION)

READ VALUE USING INTELLIGENT TESTER (EGR VALVE LEARNING VALUE)

CHECK FOR DEPOSIT (EGR PASSAGE)

CHECK FOR EXHAUST GAS LEAKS

INSPECT EGR VALVE ASSEMBLY (POWER SOURCE)

CHECK HARNESS AND CONNECTOR (EGR VALVE ASSEMBLY - ECM)

REPLACE EGR VALVE ASSEMBLY (No. 1 or No. 2)

CHECK WHETHER DTC OUTPUT RECURS

REMOVE FOREIGN OBJECT AND CLEAN EGR VALVE (No. 1 or No. 2)

REPAIR OR REPLACE MALFUNCTIONING PARTS, COMPONENT AND AREA

REPAIR EXHAUST GAS LEAKAGE POINT

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - EGR VALVE CONNECTOR)

REPAIR OR REPLACE HARNESS OR CONNECTOR

REPLACE ECM

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P0400 Exhaust Gas Recirculation Flow |

DTC P1248 Exhaust Gas Recirculation Flow Bank 2 |

DESCRIPTION

The EGR system recirculates exhaust gases. The recirculated gas mingles with the intake air so that the EGR system can slow combustion speed and keep the combustion temperature down. This helps reduce NOx emissions.In order to increase EGR circulation efficiency, the ECM adjusts the lift amount of the EGR valve and the throttle valve angle.P0400 (No. 1 EGR valve malfunction)DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

After warming up engine and idling for 60 seconds, maintain engine speed at 2500 rpm for 40 seconds, drive vehicle and perform engine break deceleration by fully closing accelerator when engine speed is 2000 rpm or more

| The target and actual positions of the No. 1 EGR valve assembly are different for 30 seconds or more (1 trip detection logic).

| - EGR valve stuck

- EGR valve does not move smoothly

- Open or short in EGR valve circuit

- EGR valve deposit

- EGR valve passage

- ECM

|

P1248 (No. 2 EGR valve malfunction)DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

After warming up engine and idling for 60 seconds, maintain engine speed at 2500 rpm for 40 seconds, drive vehicle and perform engine break deceleration by fully closing accelerator when engine speed is 2000 rpm or more

| The target and actual positions of the No. 1 EGR valve assembly are different for 30 seconds or more (1 trip detection logic).

| - EGR valve stuck

- EGR valve does not move smoothly

- Open or short in EGR valve circuit

- EGR valve deposit

- EGR valve passage

- ECM

|

P0400 (Flow malfunction)DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

Decelerate from a speed of 50 km/h (80 mph) or more (release accelerator pedal for approximately 5 seconds)

| Mass air flow rate is not changed when turning on the electric EGR control valve while decelerating (2 trip detection logic).

| - EGR valve stuck

- EGR valve does not move smoothly

- Open or short in EGR valve circuit

- EGR valve deposit

- EGR valve passage

- ECM

|

Related Data ListDTC No.

| Data List

|

P0400

(No. 1 EGR valve malfunction)

| - MAF

- MAP

- Actual EGR Valve Pos.

- Actual EGR Valve Pos. #2

- Target EGR Valve Pos.

- Target EGR Valve Pos. #2

- EGR Close Lrn. Val.

- EGR Close Lrn. Val. #2

- EGR Close Learn Val.

- EGR Close Lrn. Val. #2

- EGR Close Lrn. Status

- EGR Close Lrn. Status #2

- EGR Lift Sensor Volt %

- EGR Lift Sensor Volt % #2

- EGR Motor Duty #1

- EGR Motor Duty #2

|

P1248

(No. 2 EGR valve malfunction)

|

P0400

(Flow malfunction)

|

- HINT:

- If DTC P0400 and/or P1238 is stored, the following symptoms may appear:

- Stuck closed malfunction

- Intake booming noise

- Slight combustion noise

- Stuck open malfunction

- Black smoke

- Lack of power

- Vibration at engine stop

- Hesitation

MONITOR DESCRIPTION

- When the target and actual positions of the EGR valve are different, the ECM interprets this as a malfunction of the EGR valve and illuminates the MIL (1 trip detection logic).

- If the electric EGR control valve is forcibly operated but the intake air amount does not vary, the ECM determines that the electric EGR control valve is malfunctioning. The ECM then illuminates the MIL (2 trip detection logic).

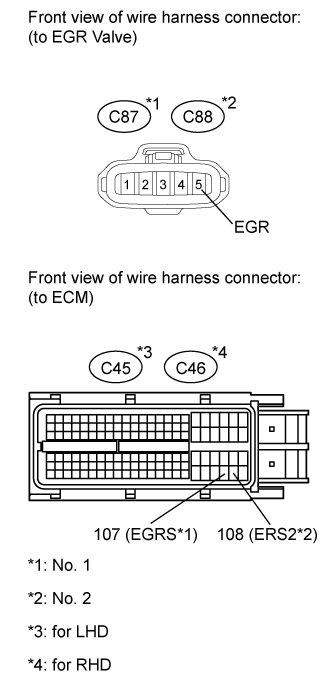

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- After replacing the ECM, the new ECM needs registration (Click here) and initialization (Click here).

- HINT:

- The Data List item Actual EGR Valve Pos. changes to follow Target EGR Position. When the ignition switch is ON (engine stopped), the EGR valve is fully closed (Actual EGR Valve Pos. = 0), and when idling, the EGR valve is open partway (neither fully closed nor fully open).

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0400, P1248) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Enter the following menus: Powertrain / Engine / DTC.

Read the DTCs.

ResultResult

| Proceed to

|

P0400 and/or P1248 are output

| A

|

P0400, P1248 and other DTCs are output

| B

|

- HINT:

- If codes other than P0400 and P1248 are output, perform troubleshooting for those DTCs first.

| 2.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (CONTROL THE EGR STEP POSITION) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Enter the following menus: Powertrain / Engine / Active Test / Control the EGR Step Position or Control the EGR Step Position #2 / Data List / Actual EGR Valve Pos. or Actual EGR Valve Pos. #2.

When changing the Active Test value from 0 to 100%, check that Actual EGR Valve Pos. or Actual EGR Valve Pos. #2 smoothly changes to the set opening angle.

- OK:

- Value smoothly changes to within +/-10% of set opening angle.

- HINT:

- EGR valve closed: Actual EGR Valve Pos. is 0%

- EGR valve open: Actual EGR Valve Pos. is 94.9%

| 3.READ VALUE USING INTELLIGENT TESTER (EGR VALVE LEARNING VALUE) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch from ON to off, and wait 5 seconds. Then turn the ignition switch to ON and the tester on.

Enter the following menus: Powertrain / Engine / Data List / EGR Close Learn Val. or EGR Close Lrn. Val. #2, and EGR Lift Sensor Volt % or EGR Lift Sensor Volt % #2.

Check the value.

- OK:

Tester Display

| Standard value

|

EGR Close Learn Val.

| 3.5 to 4.5 V

|

EGR Close Lrn. Val. #2

| 3.5 to 4.5 V

|

EGR Lift Sensor Volt %

| 70 to 90%

|

EGR Lift Sensor Volt % #2

| 70 to 90%

|

- HINT:

- When EGR Close Lrn. Status is OFF (learning is incomplete) or EGR Close Lrn. Value is 3.5 V (lower limit), there is foreign matter stuck in the valve.

- The median value of EGR Close Lrn. Value is 4.0 V.

| 4.CHECK FOR DEPOSIT (EGR PASSAGE) |

Check for any deposits.

- OK:

- No deposits.

| 5.CHECK FOR EXHAUST GAS LEAKS |

Check for exhaust gas leaks.

- OK:

- No leaks.

| 6.INSPECT EGR VALVE ASSEMBLY (POWER SOURCE) |

Disconnect the EGR valve connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

No. 1Tester Connection

| Switch Condition

| Specified Condition

|

C87-1 (+B) - Body ground

| Ignition switch ON

| 11 to 14 V

|

No. 2Tester Connection

| Switch Condition

| Specified Condition

|

C88-1 (+B) - Body ground

| Ignition switch ON

| 11 to 14 V

|

| 7.CHECK HARNESS AND CONNECTOR (EGR VALVE ASSEMBLY - ECM) |

Disconnect the EGR valve connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

No. 1 (LHD)Tester Connection

| Condition

| Specified Condition

|

C87-5 (EGR) - C45-107 (EGRS)

| Always

| Below 1 Ω

|

No. 2 (LHD)Tester Connection

| Condition

| Specified Condition

|

C88-5 (EGR) - C45-108 (ERS2)

| Always

| Below 1 Ω

|

No. 1 (RHD)Tester Connection

| Condition

| Specified Condition

|

C87-5 (EGR) - C46-107 (EGRS)

| Always

| Below 1 Ω

|

No. 2 (RHD)Tester Connection

| Condition

| Specified Condition

|

C88-5 (EGR) - C46-108 (ERS2)

| Always

| Below 1 Ω

|

- Standard Resistance (Check for Short):

No. 1 (LHD)Tester Connection

| Condition

| Specified Condition

|

C87-5 (EGR) or C45-107 (EGRS) - Body ground

| Always

| 10 kΩ or higher

|

No. 2 (LHD)Tester Connection

| Condition

| Specified Condition

|

C88-5 (EGR) or C45-108 (ERS2) - Body ground

| Always

| 10 kΩ or higher

|

No. 1 (RHD)Tester Connection

| Condition

| Specified Condition

|

C87-5 (EGR) or C46-107 (EGRS) - Body ground

| Always

| 10 kΩ or higher

|

No. 2 (RHD)Tester Connection

| Condition

| Specified Condition

|

C88-5 (EGR) or C46-108 (ERS2) - Body ground

| Always

| 10 kΩ or higher

|

| 8.REPLACE EGR VALVE ASSEMBLY (No. 1 or No. 2) |

Replace the EGR valve assembly (No. 1 or No. 2) (Click here).

| 9.CHECK WHETHER DTC OUTPUT RECURS |

Clear the DTCs (Click here).

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Start the engine and warm it up.

Switch the ECM from normal mode to check mode using the tester (Click here).

After warming up the engine and idling for 60 seconds, maintain the engine speed at 2500 rpm for 40 seconds, decelerate from a speed of 50 km/h (80 mph) or more (release accelerator pedal for approximately 5 seconds).

Confirm that the DTC is not output again.

- HINT:

- Perform the following procedure using the tester to determine whether or not the DTC judgment has been carried out.

Enter the following menus: Powertrain / Engine / Utility / All Readiness.

Input DTC P0400 and/or P1248.

Check that STATUS is NORMAL. If STATUS is INCOMPLETE or UNKNOWN, after warming up the engine and idling for 60 seconds, maintain the engine speed at 2500 rpm for 40 seconds, decelerate from a speed of 50 km/h (80 mph) or more (release accelerator pedal for approximately 5 seconds).

ResultResult

| Proceed to

|

NORMAL

| A

|

ABNORMAL

| B

|

| 10.REMOVE FOREIGN OBJECT AND CLEAN EGR VALVE (No. 1 or No. 2) |

| 11.REPAIR OR REPLACE MALFUNCTIONING PARTS, COMPONENT AND AREA |

| 12.REPAIR EXHAUST GAS LEAKAGE POINT |

| 13.REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - EGR VALVE CONNECTOR) |

| 14.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Replace the ECM (Click here).

| 16.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the intelligent tester to the DLC3.

Clear the DTCs (Click here).

Turn the ignition switch off.

Start the engine.

After warming up the engine and idling for 60 seconds, maintain the engine speed at 2500 rpm for 40 seconds, decelerate from a speed of 50 km/h (80 mph) or more (release accelerator pedal for approximately 5 seconds).

Confirm that the DTC is not output again.

- HINT:

- Perform the following procedure using the tester to determine whether or not the DTC judgment has been carried out.

Enter the following menus: Powertrain / Engine / Utility / All Readiness.

Input DTC P0400 and/or P1248.

Check that STATUS is NORMAL. If STATUS is INCOMPLETE or UNKNOWN, after warming up the engine and idling for 60 seconds, maintain the engine speed at 2500 rpm for 40 seconds, decelerate from a speed of 50 km/h (80 mph) or more (release accelerator pedal for approximately 5 seconds).