DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING GTS (DIESEL THROTTLE TARGET ANGLE)

CHECK HARNESS AND CONNECTOR (THROTTLE CONTROL MOTOR POWER SOURCE)

CHECK HARNESS AND CONNECTOR (GROUND CIRCUIT)

CHECK HARNESS AND CONNECTOR (THROTTLE CONTROL MOTOR - ECM)

REMOVE DEPOSIT (DIESEL THROTTLE BODY ASSEMBLY)

PERFORM ACTIVE TEST USING GTS (DIESEL THROTTLE TARGET ANGLE)

REPLACE DIESEL THROTTLE BODY ASSEMBLY

CHECK WHETHER DTC OUTPUT RECURS

REPLACE ECM

REPAIR OR REPLACE HARNESS OR CONNECTOR (THROTTLE CONTROL MOTOR - INTEGRATION RELAY)

REPAIR OR REPLACE HARNESS OR CONNECTOR

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P0488 Exhaust Gas Recirculation Throttle Position Control Range / Performance |

DTC P213B Exhaust Gas Recirculation Throttle Position Control (Range / Performance) |

DESCRIPTION

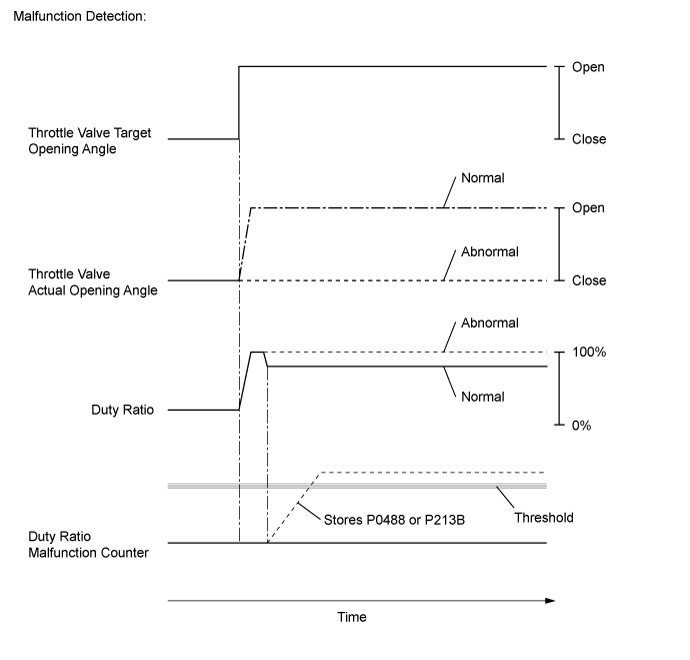

The ECM opens and closes the throttle valve using a rotary solenoid type actuator. Due to the opening and closing of the valve, the exhaust gas recirculation volume can be properly controlled. Also, engine vibration and noise will be reduced by closing the valve when the engine is stopped.P0488 (Bank 1), P213B (Bank 2)DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

Perform the following repeatedly for 1 minute: gradually raise the engine speed to 3000 rpm from idling over approximately 10 seconds, and then release the accelerator pedal to return to an idling state.

| Target and actual opening angle of the throttle valve differs for approximately 20 seconds.

(1 trip detection logic)

| - Throttle valve stuck

- Throttle valve does not move smoothly

- Open or short in throttle control motor circuit

- ECM

|

The throttle motor activation duty exceeds the threshold for 0.5 seconds a certain number of times (40 seconds or more).

(1 trip detection logic)

|

Related Data ListDTC No.

| Data List

|

P0488

| - Throttle Motor Duty

- Actual Throttle Position

|

P213B

| - Throttle Motor Duty #2

- Actual Throttle Position #2

|

ReferenceCondition

| Throttle Valve Position

|

Moment when accelerator pedal is depressed further or released at 3000 rpm

| Throttle valve opening angle varies smoothly

|

MONITOR DESCRIPTION

The ECM opens and closes the throttle valve by adjusting the current flowing to the rotary solenoid with a duty ratio. If the throttle valve does not move smoothly or is stuck, the duty ratio used during valve movement control increases or decreases greatly. The ECM will determine that the throttle valve is malfunctioning and illuminate the MIL.

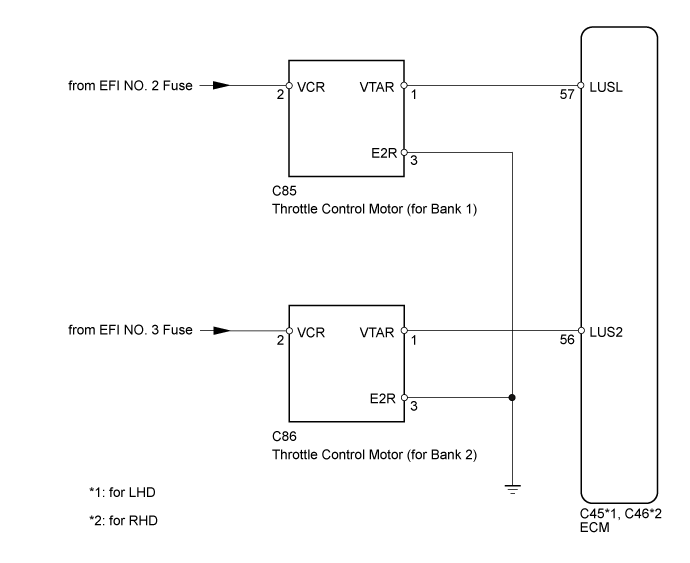

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses of circuits related to this system before performing the following inspection procedure.

- After replacing the ECM, the new ECM needs registration (Click here) and initialization (Click here).

- After replacing the fuel supply pump assembly, the ECM needs initialization (Click here).

- After replacing an injector assembly, the ECM needs registration (Click here).

- HINT:

- Although the DTC titles say "exhaust gas recirculation throttle position control range / performance", these DTCs relate to the throttle valve

- Read freeze frame data using the GTS. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.PERFORM ACTIVE TEST USING GTS (DIESEL THROTTLE TARGET ANGLE) |

Connect the GTS to the DLC3.

Turn the engine switch on (IG) and turn the GTS on.

Enter the following menus: Engine and ECT / Active Test / Diesel Throttle Target Angle or Diesel Throttle Target Angle #2.

While continuously changing the Active Test value to 0, 30, 60, 90, 60, 30 and 0%, check that "Actual Throttle Position" or "Actual Throttle Position #2" smoothly changes to the set opening amount.

- OK:

- Value smoothly changes to set opening amount.

| 2.CHECK HARNESS AND CONNECTOR (THROTTLE CONTROL MOTOR POWER SOURCE) |

Disconnect the throttle control motor connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

C85-2 (VCR) - Body ground

| Engine switch on (IG)

| 11 to 14 V

|

C86-2 (VCR) - Body ground

| Engine switch on (IG)

| 11 to 14 V

|

Text in Illustration*A

| for Bank 1

|

*B

| for Bank 2

|

*a

| Front view of wire harness connector

(to Throttle Control Motor)

|

Reconnect the throttle control motor connector.

| 3.CHECK HARNESS AND CONNECTOR (GROUND CIRCUIT) |

Disconnect the throttle control motor connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C85-3 (E2R) - Body ground

| Always

| Below 1 Ω

|

C86-3 (E2R) - Body ground

| Always

| Below 1 Ω

|

Reconnect the throttle control motor connector.

| 4.CHECK HARNESS AND CONNECTOR (THROTTLE CONTROL MOTOR - ECM) |

Disconnect the throttle control motor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHDTester Connection

| Condition

| Specified Condition

|

C85-1 (VTAR) - C45-57 (LUSL)

| Always

| Below 1 Ω

|

C86-1 (VTAR) - C45-56 (LUS2)

| Always

| Below 1 Ω

|

C85-1 (VTAR) or C45-57 (LUSL) - Body ground

| Always

| 10 kΩ or higher

|

C86-1 (VTAR) or C45-56 (LUS2) - Body ground

| Always

| 10 kΩ or higher

|

- Standard Resistance:

for RHDTester Connection

| Condition

| Specified Condition

|

C85-1 (VTAR) - C46-57 (LUSL)

| Always

| Below 1 Ω

|

C86-1 (VTAR) - C46-56 (LUS2)

| Always

| Below 1 Ω

|

C85-1 (VTAR) or C46-57 (LUSL) - Body ground

| Always

| 10 kΩ or higher

|

C86-1 (VTAR) or C46-56 (LUS2) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the throttle control motor connector.

Reconnect the ECM connector.

| 5.REMOVE DEPOSIT (DIESEL THROTTLE BODY ASSEMBLY) |

Visually check for deposits in the diesel throttle body assembly. If there are deposits, clean the diesel throttle body assembly.

| 6.PERFORM ACTIVE TEST USING GTS (DIESEL THROTTLE TARGET ANGLE) |

Connect the GTS to the DLC3.

Turn the engine switch on (IG) and turn the GTS on.

Enter the following menus: Engine and ECT / Active Test / Diesel Throttle Target Angle or Diesel Throttle Target Angle #2.

While continuously changing the Active Test value to 0, 30, 60, 90, 60, 30 and 0%, check that "Actual Throttle Position" or "Actual Throttle Position #2" smoothly changes to the set opening amount.

- OK:

- Value smoothly changes to set opening amount.

| 7.REPLACE DIESEL THROTTLE BODY ASSEMBLY |

When DTC P0488 is output:- Replace the diesel throttle body assembly (for bank 1) (Click here).

When DTC P213B is output:- Replace the diesel throttle body assembly (for bank 2) (Click here).

| 8.CHECK WHETHER DTC OUTPUT RECURS |

Clear the DTCs (Click here).

Turn the engine switch off and wait for 30 seconds.

Connect the GTS to the DLC3.

Turn the engine switch on (IG) and turn the GTS on.

Start the engine.

Over a period of 10 seconds or more, slowly raise the engine speed to 3000 rpm and lower it.

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

Read the DTCs.

ResultResult

| Proceed to

|

P0488 or P213B is output

| A

|

No DTC is output

| B

|

Replace the ECM (Click here).

| 10.REPAIR OR REPLACE HARNESS OR CONNECTOR (THROTTLE CONTROL MOTOR - INTEGRATION RELAY) |

Repair or replace the harness or connector.

| 11.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Repair or replace the harness or connector.

| 12.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the GTS to the DLC3.

Clear the DTCs (Click here).

Turn the engine switch off and wait for 30 seconds.

Start the engine.

Over a period of 10 seconds or more, slowly raise the engine speed to 3000 rpm, and then lower it.

Confirm that the DTC is not output again.

- HINT:

- Perform the following procedure using the GTS to determine whether or not the DTC judgment has been carried out.

Enter the following menus: Engine and ECT / Utility / All Readiness.

Input DTC P0488 and P213B.

Check that STATUS is NORMAL. If STATUS is INCOMPLETE or N/A, over a period of 10 seconds or more, slowly raise the engine speed to 3000 rpm again, and then idle the engine for 5 minutes.