DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK IF VEHICLE IS EQUIPPED WITH ENTRY AND START SYSTEM

READ VALUE USING GTS (STARTER SIGNAL)

INSPECT STARTER RELAY (ST)

CHECK HARNESS AND CONNECTOR (ST RELAY - CLUTCH START SWITCH)

CHECK HARNESS AND CONNECTOR (POWER SOURCE)

INSPECT STARTER

INSPECT CLUTCH START SWITCH ASSEMBLY

CHECK HARNESS AND CONNECTOR (CLUTCH START SWITCH - ECM)

INSPECT IGNITION SWITCH ASSEMBLY

CHECK HARNESS AND CONNECTOR (CLUTCH START SWITCH - IGNITION SWITCH)

INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY

CHECK HARNESS AND CONNECTOR (PARK/NEUTRAL POSITION SWITCH, CLUTCH START SWITCH - ECM)

SFI SYSTEM - Starter Signal Circuit |

DESCRIPTION

While the engine is being cranked, current flows from terminal ST2 of the ignition switch assembly*1 or terminal STAR of the certification ECU (smart key ECU assembly)*2 to the park/neutral position switch*3 or clutch start switch*4 and to terminal STA of the ECM (STA signal).- *1: w/o Entry and Start System

*2: w/ Entry and Start System

*3: for A/T

*4: for M/T

WIRING DIAGRAM

Refer to DTC P0617 (Click here).

INSPECTION PROCEDURE

| 1.CHECK IF VEHICLE IS EQUIPPED WITH ENTRY AND START SYSTEM |

ResultResult

| Proceed to

|

w/o Entry and Start System

| A

|

w/ Entry and Start System

| B

|

| 2.READ VALUE USING GTS (STARTER SIGNAL) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Starter Signal.

Read values.

Check the result when the ignition switch is turned to ON and when the engine is started.

- OK:

Condition

| Display (Starter Signal)

|

Ignition switch ON

| OFF

|

Engine is started

| ON

|

| 3.INSPECT STARTER RELAY (ST) |

Inspect the starter relay (ST) (Click here).

| | REPLACE STARTER RELAY (ST) |

|

|

| 4.CHECK HARNESS AND CONNECTOR (ST RELAY - CLUTCH START SWITCH) |

Disconnect the clutch start switch.

Remove the ST relay from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHDTester Connection

| Condition

| Specified Condition

|

ST relay (2) - A49-2

| Always

| Below 1 Ω

|

ST relay (2) or A49-2 - Body ground

| Always

| 10 kΩ or higher

|

for RHDTester Connection

| Condition

| Specified Condition

|

ST relay (2) - e1-2

| Always

| Below 1 Ω

|

ST relay (2) or e1-2 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 5.CHECK HARNESS AND CONNECTOR (POWER SOURCE) |

Remove the ST relay from the engine room relay block.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

ST relay (1) - ST relay (5)

| Always

| 11 to 14 V

|

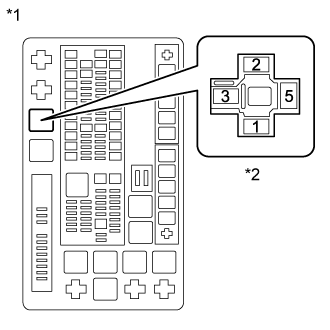

Text in Illustration*1

| Engine Room Relay Block Assembly

|

*2

| ST Relay

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (STARTER RELAY (ST) - BATTERY, BODY GROUND) |

|

|

Inspect the starter (Click here).

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 7.INSPECT CLUTCH START SWITCH ASSEMBLY |

Inspect the clutch start switch (for LHD) (Click here).

Inspect the clutch start switch (for RHD) (Click here).

ResultResult

| Proceed to

|

OK

| A

|

NG (for LHD)

| B

|

NG (for RHD)

| C

|

| 8.CHECK HARNESS AND CONNECTOR (CLUTCH START SWITCH - ECM) |

Disconnect the clutch start switch connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHDTester Connection

| Condition

| Specified Condition

|

A49-2 - A38-46 (STA)

| Always

| Below 1 Ω

|

A49-2 or A38-46 (STA) - Body ground

| Always

| 10 kΩ or higher

|

for RHDTester Connection

| Condition

| Specified Condition

|

e1-2 - A52-46 (STA)

| Always

| Below 1 Ω

|

e1-2 or A52-46 (STA) - Body ground

| Always

| 10 kΩ or higher

|

| 9.INSPECT IGNITION SWITCH ASSEMBLY |

Inspect the ignition switch assembly (Click here).

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 10.CHECK HARNESS AND CONNECTOR (CLUTCH START SWITCH - IGNITION SWITCH) |

Disconnect the clutch start switch connector.

Disconnect the ignition switch connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHDTester Connection

| Condition

| Specified Condition

|

A49-1 - E93-7 (ST2)

| Always

| Below 1 Ω

|

A49-1 or E93-7 (ST2) - Body ground

| Always

| 10 kΩ or higher

|

for RHDTester Connection

| Condition

| Specified Condition

|

e1-1 - E93-7 (ST2)

| Always

| Below 1 Ω

|

e1-1 or E93-7 (ST2) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (STARTER - STARTER RELAY (ST), BATTERY) |

|

|

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR (IGNITION SWITCH - BATTERY) |

|

| 11.INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

Inspect the park/neutral position switch assembly (Click here).

| | REPLACE PARK/NEUTRAL POSITION SWITCH ASSEMBLY (Click here) |

|

|

| 12.CHECK HARNESS AND CONNECTOR (PARK/NEUTRAL POSITION SWITCH, CLUTCH START SWITCH - ECM) |

Disconnect the park/neutral position switch connector.

Disconnect the clutch start switch connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for A/TTester Connection

| Condition

| Specified Condition

|

C24-5 (L) - A38-46 (STA)

| Always

| Below 1 Ω

|

C24-5 (L) or A38-46 (STA) - Body ground

| Always

| 10 kΩ or higher

|

for M/TTester Connection

| Condition

| Specified Condition

|

A49-2 - A38-46 (STA)

| Always

| Below 1 Ω

|

A49-2 or A38-46 (STA) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| OK |

|

|

|

| GO TO ENTRY AND START SYSTEM (ENGINE DOES NOT START) (Click here) |

|