Manual Transaxle Unit Reassembly

INSTALL SHIFT FORK SHAFT BEARING

INSTALL OUTPUT SHAFT COVER

INSTALL NO. 2 OUTPUT SHAFT FRONT BEARING

INSTALL OUTPUT SHAFT COVER

INSTALL OUTPUT SHAFT FRONT BEARING

INSTALL BEARING LOCK PLATE BOLT

INSTALL TRANSAXLE CASE OIL SEAL

INSTALL INPUT SHAFT FRONT BEARING

INSTALL BEARING LOCK PLATE BOLT

INSTALL INPUT SHAFT REAR BEARING SHAFT SNAP RING

INSTALL SHIFT AND SELECT LEVER SHAFT NEEDLE ROLLER BEARING

INSTALL SHIFT FORK SHAFT BEARING

INSTALL FRONT DIFFERENTIAL CASE FRONT TAPERED ROLLER BEARING

INSTALL FRONT DIFFERENTIAL CASE REAR SHIM

INSTALL FRONT DIFFERENTIAL CASE REAR TAPERED ROLLER BEARING

ADJUST DIFFERENTIAL SIDE BEARING PRELOAD

INSTALL OUTPUT SHAFT NO. 2 REAR BEARING OUTER RACE

ADJUST NO. 2 OUTPUT SHAFT REAR BEARING PRELOAD

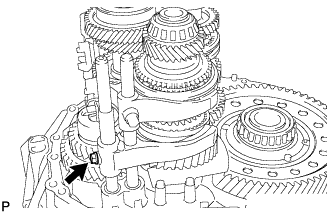

INSTALL TRANSMISSION MAGNET

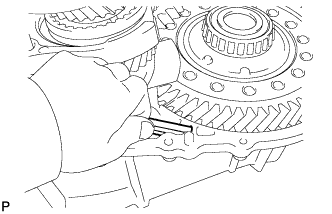

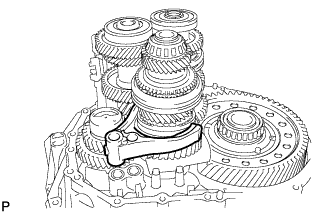

INSTALL FRONT DIFFERENTIAL CASE ASSEMBLY

INSTALL TRANSMISSION OIL SEPARATOR

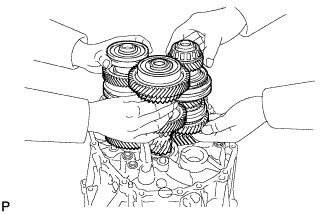

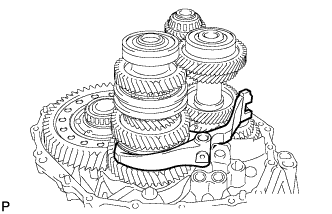

INSTALL INPUT SHAFT, NO. 1 OUTPUT SHAFT AND NO. 2 OUTPUT SHAFT

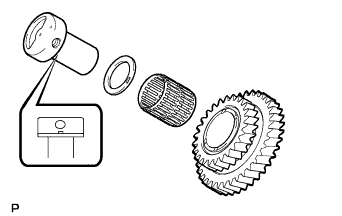

INSTALL REVERSE IDLER GEAR

INSTALL REVERSE SHIFT FORK

INSTALL NO. 3 GEAR SHIFT FORK

INSTALL 5TH AND 6TH SHIFT FORK SHAFT

INSTALL REVERSE SHIFT FORK SHAFT

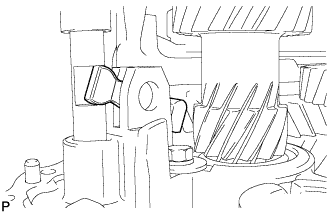

INSTALL SHIFT ARM

INSTALL NO.1 GEAR SHIFT FORK

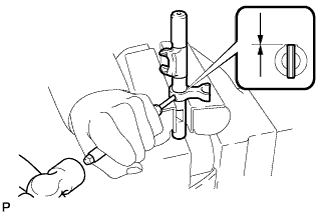

INSTALL NO. 5 GEAR SHIFT FORK SHAFT

INSTALL NO. 2 GEAR SHIFT FORK

INSTALL 3RD AND 4TH SHIFT FORK SHAFT

INSTALL 1ST AND 2ND SHIFT FORK SHAFT

INSTALL TRANSMISSION OIL SEPARATOR

INSTALL NO. 1 OIL RECEIVER PIPE

INSTALL MANUAL TRANSMISSION CASE

INSTALL REVERSE IDLER GEAR SHAFT BOLT

INSTALL SHIFT DETENT BALL

INSTALL MANUAL TRANSMISSION CASE PLUG

INSTALL O-RING

INSTALL SHIFT AND SELECT PIN

INSTALL MANUAL TRANSMISSION FILLER PLUG

INSTALL DRAIN PLUG

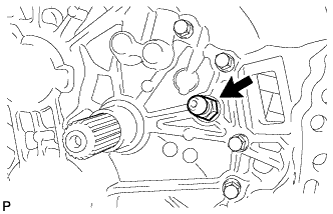

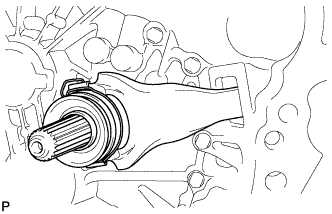

INSTALL TRANSMISSION CASE OIL SEAL

INSTALL TRANSAXLE CASE OIL SEAL

INSTALL CONTROL SHAFT COVER

INSTALL SHIFT GATE PIN

INSTALL NO. 2 LOCK BALL ASSEMBLY

INSTALL NO. 1 LOCK BALL ASSEMBLY

INSTALL BACK-UP LIGHT SWITCH ASSEMBLY

INSTALL SELECTING BELL CRANK ASSEMBLY

INSTALL FLOOR SHIFT CONTROL LEVER HOUSING SUPPORT BRACKET

INSTALL CLUTCH RELEASE FORK BOOT

INSTALL RELEASE FORK SUPPORT

INSTALL CLUTCH RELEASE BEARING ASSEMBLY

INSTALL CLUTCH RELEASE FORK SUB-ASSEMBLY

Manual Transaxle Unit -- Reassembly |

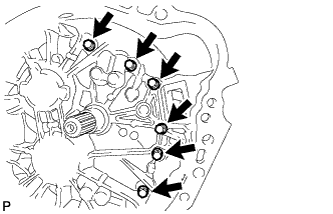

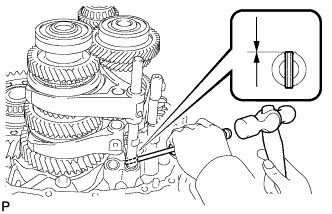

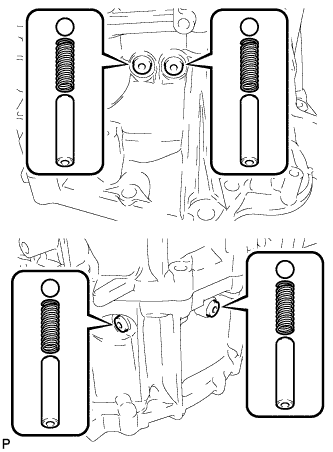

| 1. INSTALL SHIFT FORK SHAFT BEARING |

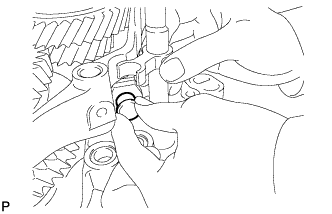

Using SST and a press, press in the 4 bearings.

- Специальный инструмент (SST):

- 09820-00031

- Standard clearance:

- 0 to 0.5 mm (0.000 to 0.020 in.)

| 2. INSTALL OUTPUT SHAFT COVER |

Install the output shaft cover, as shown in the illustration.

| 3. INSTALL NO. 2 OUTPUT SHAFT FRONT BEARING |

Using SST and hammer, tap in the bearing.

- Специальный инструмент (SST):

- 09950-70010(09951-07100,09951-00710)

| 4. INSTALL OUTPUT SHAFT COVER |

Install the output shaft cover, as shown in the illustration.

| 5. INSTALL OUTPUT SHAFT FRONT BEARING |

Coat a new bearing with gear oil.

Using SST and a press, press in the bearing.

- Специальный инструмент (SST):

- 09223-15020

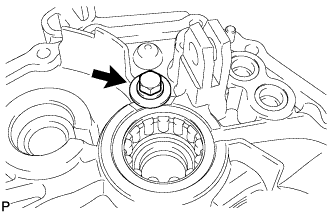

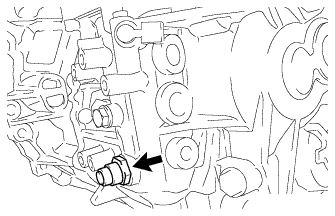

| 6. INSTALL BEARING LOCK PLATE BOLT |

Install the bearing lock plate bolt.

- Момент затяжки:

- 11 Н*м{115 кгс*см, 8 фунт-сила-футов}

| 7. INSTALL TRANSAXLE CASE OIL SEAL |

Using SST and a hammer, tap in a new oil seal to the front transaxle case.

- Специальный инструмент (SST):

- 09950-60010(09951-00580)

- Standard depth:

- 4.4 to 5.0 mm (0.173 to 0.197 in.)

Coat the lip of the oil seal with MP grease.

| 8. INSTALL INPUT SHAFT FRONT BEARING |

Coat a new bearing with gear oil.

Using SST and a press, press in the bearing.

- Специальный инструмент (SST):

- 09223-00010

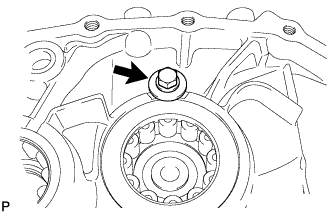

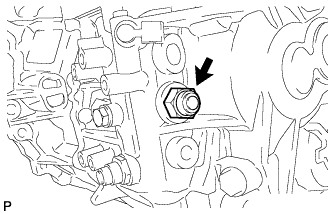

| 9. INSTALL BEARING LOCK PLATE BOLT |

Install the lock plate bolt.

- Момент затяжки:

- 11 Н*м{115 кгс*см, 8 фунт-сила-футов}

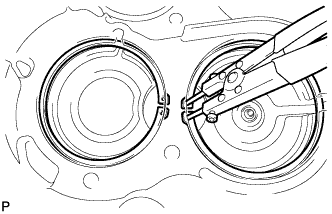

| 10. INSTALL INPUT SHAFT REAR BEARING SHAFT SNAP RING |

Using snap ring pliers, install the 2 snap rings.

| 11. INSTALL SHIFT AND SELECT LEVER SHAFT NEEDLE ROLLER BEARING |

Using SST and a press, press in a new needle roller bearing.

- Специальный инструмент (SST):

- 09285-76010

- Standard clearance:

- 177.8 to 178.7 mm (7.000 to 7.035 in.)

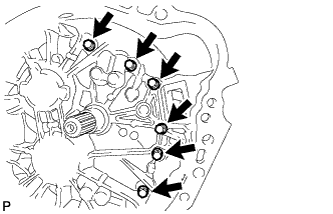

| 12. INSTALL SHIFT FORK SHAFT BEARING |

Using SST and a press, press in 4 new bearings.

- Специальный инструмент (SST):

- 09307-12010

09820-00031

- Standard clearance:

- A:

- 168.2 to 169.3 mm (6.622 to 6.665 in.)

- B:

- 162.2 to 163.3 mm (6.386 to 6.429 in.)

| 13. INSTALL FRONT DIFFERENTIAL CASE FRONT TAPERED ROLLER BEARING |

Using SST and a hammer, tap in the tapered roller bearing.

- Специальный инструмент (SST):

- 09950-70010(09951-00910,09951-07150)

| 14. INSTALL FRONT DIFFERENTIAL CASE REAR SHIM |

Install the shim into the transmission case.

| 15. INSTALL FRONT DIFFERENTIAL CASE REAR TAPERED ROLLER BEARING |

Using SST and a hammer, install the tapered roller bearing.

- Специальный инструмент (SST):

- 09950-60010(09951-00910)

09950-70010(09951-07100)

| 16. ADJUST DIFFERENTIAL SIDE BEARING PRELOAD |

Install the differential case to the front transaxle case.

Install the transmission case to the transaxle case with the 12 bolts.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

Install the 6 bolts of the transaxle case side.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

Turn the differential case in both directions to smooth its movement.

Using SST and a torque wrench, measure the starting preload.

- Специальный инструмент (SST):

- 09564-32011

- Standard new bearing preload:

- 0.96 to 2.38 N*m (9.8 to 24.3 kgf*cm, 8.5 to 21.07 in.*lbf)

Select a new shim.

- Standard shim thickness:

Mark

| Thickness

| Mark

| Thickness

| Mark

| Thickness

|

0

| 1.99 to 2.01 mm (0.0783 to 0.0791 in.)

| 6

| 2.29 to 2.31 mm (0.0902 to 0.0909 in.)

| C

| 2.59 to 2.61 mm (0.1020 to 0.1028 in.)

|

1

| 2.04 to 2.06 mm (0.0803 to 0.0811 in.)

| 7

| 2.34 to 2.36 mm (0.0921 to 0.0929 in.)

| D

| 2.64 to 2.66 mm (0.1039 to 0.1047 in.)

|

2

| 2.09 to 2.11 mm (0.0823 to 0.0831 in.)

| 8

| 2.39 to 2.41 mm (0.0941 to 0.0949 in.)

| E

| 2.69 to 2.71 mm (0.1059 to 0.1067 in.)

|

3

| 2.14 to 2.16 mm (0.0843 to 0.0850 in.)

| 9

| 2.44 to 2.46 mm (0.0961 to 0.0969 in.)

| F

| 2.74 to 2.76 mm (0.1079 to 0.1087 in.)

|

4

| 2.19 to 2.21 mm (0.0862 to 0.0870 in.)

| A

| 2.49 to 2.51 mm (0.0981 to 0.0988 in.)

| G

| 2.79 to 2.81 mm (0.1098 to 0.1106 in.)

|

5

| 2.24 to 2.26 mm (0.0882 to 0.0890 in.)

| B

| 2.54 to 2.56 mm (0.1000 to 0.1008 in.)

| H

| 2.84 to 2.86 mm (0.1118 to 0.1126 in.)

|

Remove the transmission case from the front transaxle case.

Remove the 18 bolts and transmission case.

| 17. INSTALL OUTPUT SHAFT NO. 2 REAR BEARING OUTER RACE |

Install the shim onto the transmission case.

- УКАЗАНИЕ:

- When reusing the output shaft rear tapered roller bearing, first install a shim of the same thickness as the original. When installing a new output shaft front bearing, first select and install a shim which is thinner than the original.

Using SST and a press, press in the bearing outer race.

- Специальный инструмент (SST):

- 09950-60010(09951-00650)

09950-70010(09951-07200)

| 18. ADJUST NO. 2 OUTPUT SHAFT REAR BEARING PRELOAD |

Install the No. 2 output shaft and differential case onto the front transaxle case.

Install the transmission case to the front transaxle case with the 12 bolts.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

Install the 6 bolts of the transaxle case side.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

|

Measure the No. 2 output shaft rear bearing preload. Subtract the value of the differential side bearing preload from the measured No. 2 output shaft rear bearing preload. Select a shim that will set the preload within the specified range below and install the shim.

- Standard new bearing preload:

- 4.4 to 6.2 N*m (45 to 63 kgf*cm, 39 to 55 in.*lbf)

- Standard shim thickness:

Mark

| Thickness

| Mark

| Thickness

| Mark

| Thickness

|

A

| 1.79 to 1.81 mm (0.0705 to 0.0713 in.)

| G

| 2.09 to 2.11 mm (0.0823 to 0.0831 in.)

| N

| 2.39 to 2.41 mm (0.0941 to 0.0949 in.)

|

B

| 1.84 to 1.86 mm (0.0724 to 0.0732 in.)

| H

| 2.14 to 2.16 mm (0.0843 to 0.0850 in.)

| P

| 2.44 to 2.46 mm (0.0961 to 0.0969 in.)

|

C

| 1.89 to 1.91 mm (0.0744 to 0.0752 in.)

| J

| 2.19 to 2.21 mm (0.0862 to 0.0870 in.)

| Q

| 2.49 to 2.51 mm (0.0980 to 0.0988 in.)

|

D

| 1.94 to 1.96 mm (0.0764 to 0.0772 in.)

| K

| 2.24 to 2.26 mm (0.0882 to 0.0890 in.)

| R

| 2.54 to 2.56 mm (0.1000 to 0.1008 in.)

|

E

| 1.99 to 2.01 mm (0.0783 to 0.0791 in.)

| L

| 2.29 to 2.31 mm (0.0902 to 0.0909 in.)

| S

| 2.59 to 2.61 mm (0.1020 to 0.1028 in.)

|

F

| 2.04 to 2.06 mm (0.0803 to 0.0811 in.)

| M

| 2.34 to 2.36 mm (0.0921 to 0.0929 in.)

| T

| 2.64 to 2.66 mm (0.1039 to 0.1047 in.)

|

Remove the transmission case.

Remove the 18 bolts and transmission case.

Remove the output shaft assembly from the front transaxle case.

Remove the differential case from the front transaxle case.

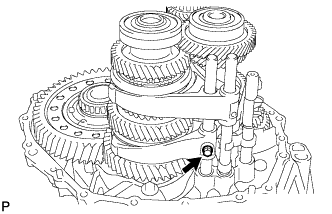

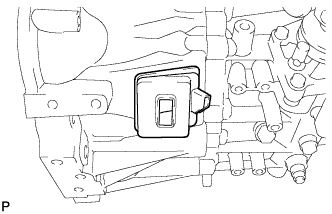

| 19. INSTALL TRANSMISSION MAGNET |

Clean and install the transmission magnet onto the front transaxle case.

| 20. INSTALL FRONT DIFFERENTIAL CASE ASSEMBLY |

Coat the differential case tapered roller bearing with gear oil, and install it onto the front transaxle case.

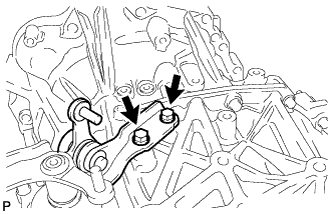

| 21. INSTALL TRANSMISSION OIL SEPARATOR |

Install the oil separator onto the front transaxle case with the 2 bolts.

- Момент затяжки:

- 8.5 Н*м{87 кгс*см, 75 фунт-сила-дюймов}

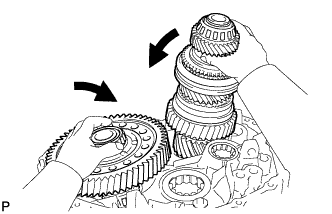

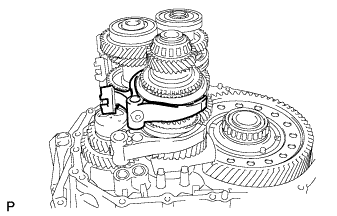

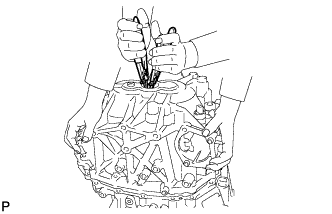

| 22. INSTALL INPUT SHAFT, NO. 1 OUTPUT SHAFT AND NO. 2 OUTPUT SHAFT |

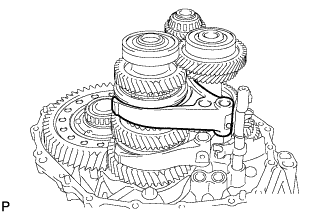

Install the 3 shafts at the same time.

| 23. INSTALL REVERSE IDLER GEAR |

Coat the reverse idler gear, needle roller bearing and reverse idler thrust washer with MP grease, and install them to the reverse idler gear shaft.

- УКАЗАНИЕ:

- Make sure that the protruding part on the reverse idler thrust washer is fitted into the groove of the reverse idler shaft.

Install the reverse idler gear shaft by sliding and lifting it.

Align the mark of the reverse idler gear shaft with the hole of the bolt.

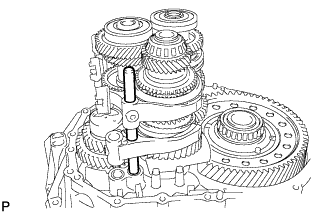

| 24. INSTALL REVERSE SHIFT FORK |

Install the reverse shift fork onto the No. 4 hub sleeve.

| 25. INSTALL NO. 3 GEAR SHIFT FORK |

Install the No. 3 gear shift fork onto the No. 3 hub sleeve.

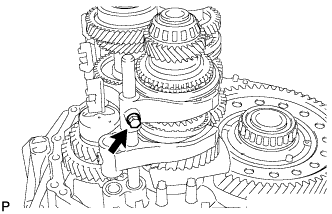

| 26. INSTALL 5TH AND 6TH SHIFT FORK SHAFT |

Install the 5th and 6th shift fork shaft onto the front transaxle case.

Install the bolt into the No. 3 gear shift fork.

- Момент затяжки:

- 20 Н*м{204 кгс*см, 14 фунт-сила-футов}

| 27. INSTALL REVERSE SHIFT FORK SHAFT |

Install the reverse shift fork shaft into the front transaxle case.

Install the bolt into the No. 4 gear shift fork.

- Момент затяжки:

- 20 Н*м{204 кгс*см, 14 фунт-сила-футов}

Install the shaft arm into the front transaxle case.

| 29. INSTALL NO.1 GEAR SHIFT FORK |

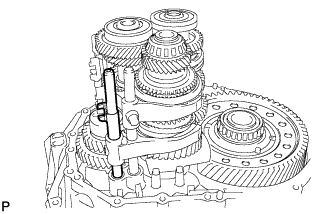

Install the No. 1 gear shift fork onto the No. 1 hub sleeve.

| 30. INSTALL NO. 5 GEAR SHIFT FORK SHAFT |

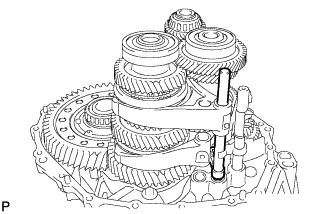

Install the No. 3 gear shift head to the No. 5 gear shift fork shaft.

Using a pin punch and hammer, tap the slotted pin into the No. 3 gear shift head.

- Standard depth:

- -0.5 to 0.5 mm (-0.0197 to 0.0197 in.)

Install the No. 5 gear shift fork shaft into the front transaxle case.

Assemble the shift arm and No. 5 gear shift fork shaft.

Install the shift arm pin into the shift arm.

Using a brass bar and hammer, tap a new E-ring onto the shift arm pin.

| 31. INSTALL NO. 2 GEAR SHIFT FORK |

Install the No. 2 gear shift fork onto the No. 2 hub sleeve.

| 32. INSTALL 3RD AND 4TH SHIFT FORK SHAFT |

Install the No. 3 gear shift head to the 3rd and 4th shift fork shaft.

Install the 3rd and 4th shift fork shaft to the transmission case.

Using a pin punch and hammer, tap a new slotted spring pin into the No. 2 gear shift fork.

- Standard depth:

- -0.5 to 0.5 mm (-0.0197 to 0.0197 in.)

Using a pin punch and hammer, tap the slotted spring pin into the No. 3 gear shift head.

- Standard depth:

- -0.5 to 0.5 mm (-0.0197 to 0.0197 in.)

| 33. INSTALL 1ST AND 2ND SHIFT FORK SHAFT |

Install the 1st and 2nd shift fork shaft into the front transaxle case.

Install the bolt onto the No. 1 gear shift fork.

- Момент затяжки:

- 20 Н*м{204 кгс*см, 14 фунт-сила-футов}

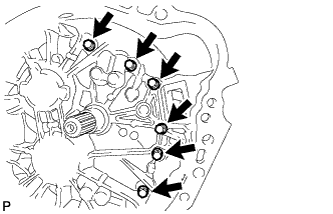

| 34. INSTALL TRANSMISSION OIL SEPARATOR |

Install the oil separator onto the transmission case with the 2 bolts.

- Момент затяжки:

- 8.5 Н*м{87 кгс*см, 75 фунт-сила-дюймов}

| 35. INSTALL NO. 1 OIL RECEIVER PIPE |

Install the oil receiver pipe onto the transmission case.

- ПРИМЕЧАНИЕ:

- Do not damage the oil receiver pipe.

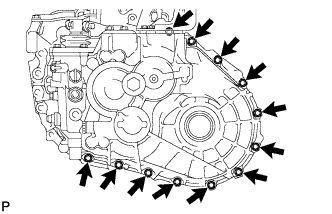

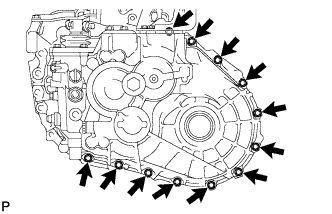

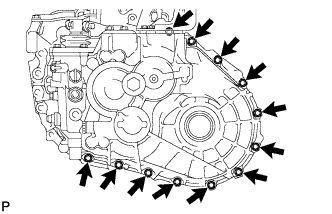

| 36. INSTALL MANUAL TRANSMISSION CASE |

Apply seal packing to the transmission case, as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or Equivalent

- ПРИМЕЧАНИЕ:

- Assemble parts within 10 minutes of application. Otherwise, the packing (Toyota Genuine Seal Packing) material must be removed and reapplied.

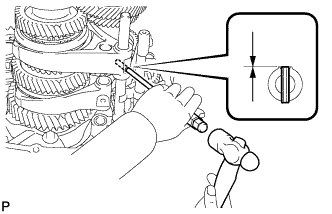

Use 2 snap ring pliers to keep the snap ring stretched and install the transmission case.

Install a bolt to the No. 1 output shaft and lift the No. 1 output shaft from the service hole. Make sure that the snap rings are positioned correctly in the bearing grooves by checking that the distances between the centers of the snap ring holes are as shown in the illustration.

Install the transmission case to the front transaxle case with the 12 bolts.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

Install the transmission case to the front transaxle case with the 6 bolts.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

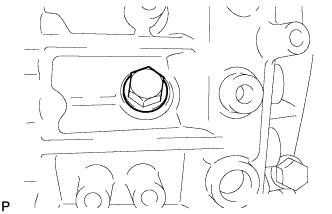

| 37. INSTALL REVERSE IDLER GEAR SHAFT BOLT |

Coat the shaft bolt with adhesive, and install it and a new gasket.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

- Момент затяжки:

- 80 Н*м{816 кгс*см, 59 фунт-сила-футов}

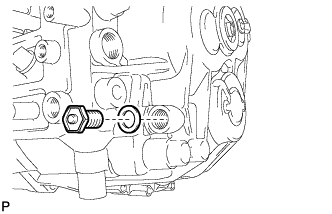

| 38. INSTALL SHIFT DETENT BALL |

Coat the plugs with adhesive.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

Using a 6 mm hexagon wrench, install the 4 balls, 4 spring seats and 4 plugs.

- Момент затяжки:

- 22 Н*м{228 кгс*см, 17 фунт-сила-футов}

| 39. INSTALL MANUAL TRANSMISSION CASE PLUG |

Apply seal packing black to the transmission case, as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing, Three Bond 1207B or Equivalent

Coat the transmission case plug with adhesive.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

Install the transmission case plug into the transmission case.

- Момент затяжки:

- 55 Н*м{561 кгс*см, 41 фунт-сила-футов} for case plug *1

- 22 Н*м{228 кгс*см, 17 фунт-сила-футов}for case plug *2

Coat the O-ring with the grease, and install it into the shift and select pin.

| 41. INSTALL SHIFT AND SELECT PIN |

Install the spring.

While pressing the shift and select pin (*1) in as much as possible, push in the shift and select pin (*2).

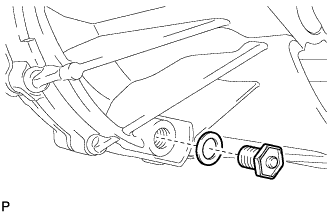

| 42. INSTALL MANUAL TRANSMISSION FILLER PLUG |

Install a new gasket and the filler plug.

- Момент затяжки:

- 39 Н*м{400 кгс*см, 29 фунт-сила-футов}

Install a new gasket and the drain plug.

- Момент затяжки:

- 39 Н*м{400 кгс*см, 29 фунт-сила-футов}

| 44. INSTALL TRANSMISSION CASE OIL SEAL |

Coat the lip of a new oil seal with MP grease.

Using SST and a hammer, tap in the seal.

- Standard depth:

- -0.5 to 0.5 mm (-0.012 to 0.012 in.)

- ПРИМЕЧАНИЕ:

- Do not damage the lip of the oil seal.

| 45. INSTALL TRANSAXLE CASE OIL SEAL |

Coat the lip of a new oil seal with MP grease.

Using SST and a hammer, install the oil seal.

- Standard depth:

- -0.5 to 0.5 mm (-0.012 to 0.012 in.)

- ПРИМЕЧАНИЕ:

- Do not damage the lip of the oil seal.

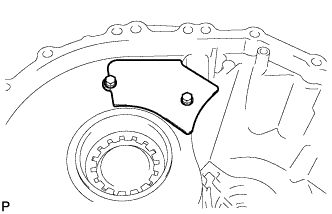

| 46. INSTALL CONTROL SHAFT COVER |

Align the 4 shift fork shafts as shown in the illustration.

Apply seal packing black to the transmission case, as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing, Three Bond 1207B or Equivalent

Coat the 4 bolts with adhesive.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

Install the shift and select lever shaft onto the transmission case with the 4 bolts.

- Момент затяжки:

- 19 Н*м{190 кгс*см, 14 фунт-сила-футов}

| 47. INSTALL SHIFT GATE PIN |

Coat the shift gate pin with sealant.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344, or equivalent

Install the shift gate pin onto the manual transmission case.

- Момент затяжки:

- 30 Н*м{306 кгс*см, 22 фунт-сила-футов}

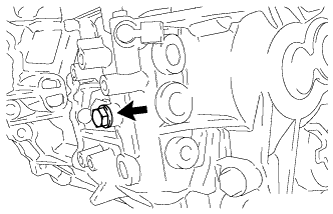

| 48. INSTALL NO. 2 LOCK BALL ASSEMBLY |

Coat the lock ball with sealant.

- Adhesive:

- Toyota Genuine Adhesive 1344, THREE BOND 1344 or equivalent

Install the lock ball onto the transmission case.

- Момент затяжки:

- 29 Н*м{299 кгс*см, 22 фунт-сила-футов}

| 49. INSTALL NO. 1 LOCK BALL ASSEMBLY |

Coat the lock ball with sealant.

- Adhesive:

- Toyota Genuine Adhesive 1344, THREE BOND 1344 or Equivalent

Install the lock ball onto the transmission case.

- Момент затяжки:

- 39 Н*м{400 кгс*см, 29 фунт-сила-футов}

| 50. INSTALL BACK-UP LIGHT SWITCH ASSEMBLY |

Install the back-up light switch onto the transmission case.

- Специальный инструмент (SST):

- 09816-30010

- Момент затяжки:

- 40 Н*м{410 кгс*см, 30 фунт-сила-футов}

| 51. INSTALL SELECTING BELL CRANK ASSEMBLY |

Coat the 2 bolts with sealant, and install the selecting bell crank to the transmission case with the bolts.

- Sealant:

- Toyota genuine adhesive 1344, THREE BOND 1344, LOCTITE 242 or equivalent

- Момент затяжки:

- 20 Н*м{204 кгс*см, 15 фунт-сила-футов}

| 52. INSTALL FLOOR SHIFT CONTROL LEVER HOUSING SUPPORT BRACKET |

Install the floor shift control lever housing support bracket onto the transaxle case with the 3 bolts.

- Момент затяжки:

- 17 Н*м{173 кгс*см, 13 фунт-сила-футов}

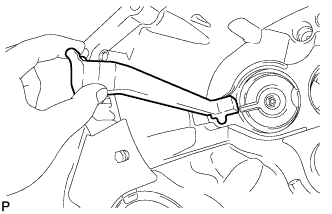

| 53. INSTALL CLUTCH RELEASE FORK BOOT |

Install the clutch release fork boot onto the transmission case.

| 54. INSTALL RELEASE FORK SUPPORT |

Using a deep socket wrench, install the release fork support to the front transaxle case.

- Момент затяжки:

- 37 Н*м{375 кгс*см, 27 фунт-сила-футов}

| 55. INSTALL CLUTCH RELEASE BEARING ASSEMBLY |

Apply release hub grease to the following areas

- The contact surface of the release fork and release bearing.

- The contact surface of the release fork and push rod.

- The pivot points of the release fork.

- Release hub grease:

- Part No. 08887-01806, RELEASE HUB GREASE or equivalent

Apply clutch sealant grease to the spline coupling part.

- Clutch spline grease:

- Part No. 08887-01706, CLUTCH SPLINE GREASE or equivalent

| 56. INSTALL CLUTCH RELEASE FORK SUB-ASSEMBLY |

Install the bearing to the release fork, and then install them to the transaxle.