Drivetrain. Hilux. Tgn26, 36 Kun25, 26, 35, 36 Ggn25

INSPECT 1ST GEAR THRUST CLEARANCE

INSPECT 2ND GEAR THRUST CLEARANCE

INSPECT 3RD GEAR THRUST CLEARANCE

INSPECT 1ST GEAR RADIAL CLEARANCE

INSPECT 2ND GEAR RADIAL CLEARANCE

INSPECT 3RD GEAR RADIAL CLEARANCE

INSPECT OUTPUT SHAFT

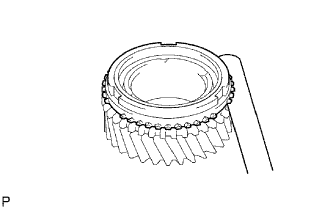

INSPECT 3RD GEAR

INSPECT 2ND GEAR

INSPECT 1ST GEAR

INSPECT 1ST GEAR THRUST WASHER

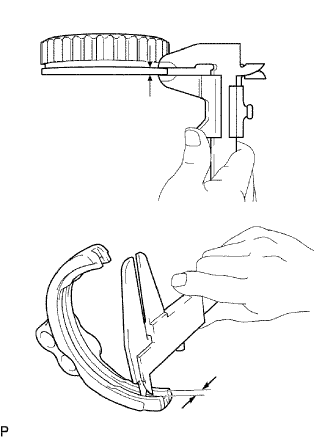

INSPECT NO. 1 SYNCHRONIZER RING SET (FOR 1ST GEAR)

INSPECT NO. 1 SYNCHRONIZER RING SET (FOR 2ND GEAR)

INSPECT NO. 2 SYNCHRONIZER RING (FOR 3RD GEAR)

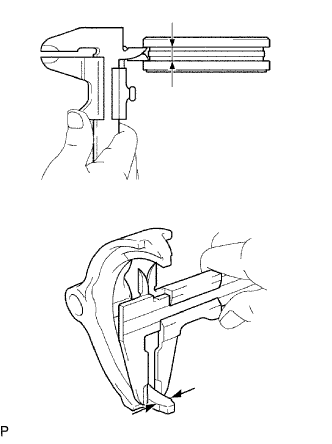

INSPECT REVERSE GEAR

INSPECT NO. 1 TRANSMISSION CLUTCH HUB

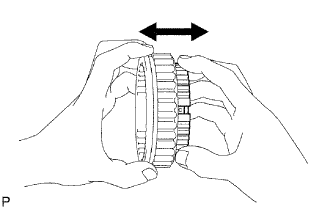

INSPECT NO. 2 TRANSMISSION HUB SLEEVE

INSPECT NO. 2 TRANSMISSION CLUTCH HUB

Output Shaft -- Inspection |

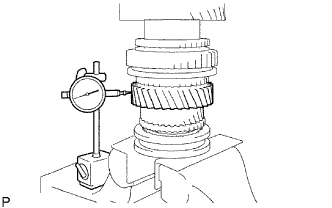

| 1. INSPECT 1ST GEAR THRUST CLEARANCE |

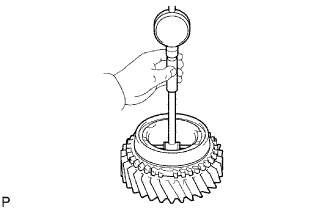

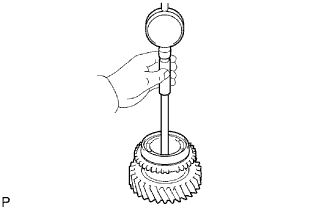

Using a dial indicator, measure the thrust clearance.

- Standard clearance:

- 0.20 to 0.45 mm (0.00789 to 0.0177 in.)

If the clearance is not as specified, replace the No. 1 synchronizer ring set.

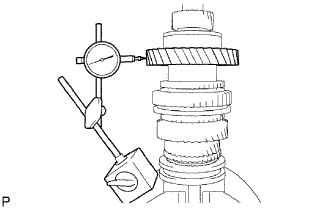

| 2. INSPECT 2ND GEAR THRUST CLEARANCE |

Using a dial indicator, measure the thrust clearance.

- Standard clearance:

- 0.10 to 0.25 mm (0.00394 to 0.00984 in.)

If the clearance is not as specified, replace the No. 1 synchronizer ring set.

| 3. INSPECT 3RD GEAR THRUST CLEARANCE |

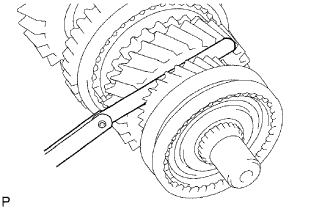

Using a feeler gauge, measure the thrust clearance.

- Standard clearance:

- 0.10 to 0.25 mm (0.00394 to 0.00984 in.)

If the clearance is not as specified, replace the No. 2 synchronizer ring set.

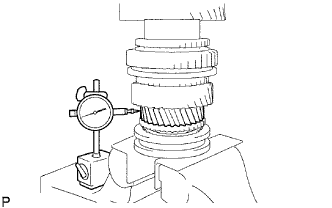

| 4. INSPECT 1ST GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.020 to 0.073 mm (0.00078 to 0.00287 in.)

If the clearance is not as specified, replace the 1st gear needle roller bearing with a new one.

| 5. INSPECT 2ND GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.015 to 0.068 mm (0.000598 to 0.00267 in.)

If the clearance is not as specified, replace the 2nd gear needle roller bearing with a new one.

| 6. INSPECT 3RD GEAR RADIAL CLEARANCE |

Using a dial indicator, measure the radial clearance.

- Standard clearance:

- 0.015 to 0.068 mm (0.00059 to 0.00267 in.)

If the clearance is not as specified, replace the 3rd gear needle roller bearing with a new one.

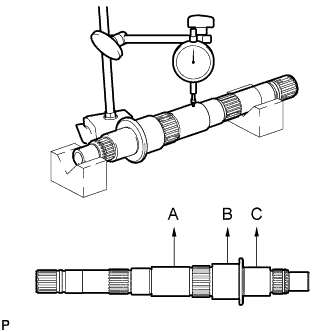

Using a dial indicator, measure the output shaft at point A, B and C shown in the illustration, and measure the runout of the output shaft.

- Maximum runout:

- 0.03 mm (0.00118 in.)

If the runout is more than the maximum, replace the output shaft with a new one.

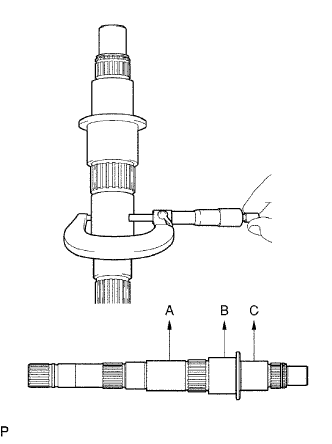

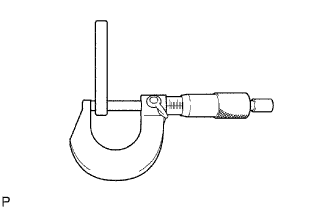

Using a micrometer, measure the journal diameter of the output shaft journal surface.

- Standard Outside Diameter:

Item

| Specified Condition

|

Journal A

| 38.979 to 38.995 mm (1.5346 to 1.5340 in.)

|

Journal B

| 46.984 to 47.000 mm (1.8498 to 1.8503 in.)

|

Journal C

| 37.984 to 38.000 mm (1.4955 to 1.4960 in.)

|

If the outside diameter is not as specified, replace the output shaft with a new one.

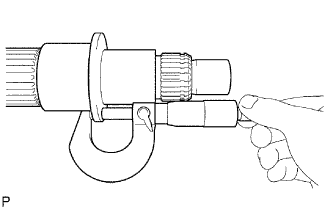

Using a micrometer, measure the thickness of the output shaft flange as shown in the illustration.

- Standard thickness:

- 4.8 to 5.2 mm (0.1890 to 0.2047 in.)

If the thickness is not as specified, replace the output shaft.

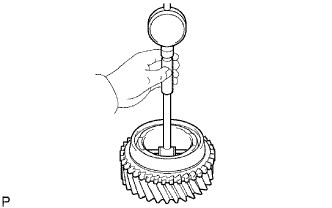

Using a cylinder gauge, measure the inside diameter of the 3rd gear.

- Standard inside diameter:

- 44.015 to 44.040 mm (1.7329 to 1.7338 in.)

- Maximum inside diameter:

- 44.040 mm (1.7338 in.)

If the inside diameter is more than the maximum, replace the 3rd gear with a new one.

Using a cylinder gauge, measure the inside diameter of the 2nd gear.

- Standard inside diameter:

- 53.015 to 53.040 mm (2.0872 to 2.0881 in.)

- Maximum inside diameter:

- 53.040 mm (2.0881 in.)

If the inside diameter is more than the maximum, replace the 2nd gear with a new one.

Using a cylinder gauge, measure the inside diameter of the 1st gear.

- Standard inside diameter:

- 46.015 to 46.040 mm (1.8117 to 1.8125 in.)

- Maximum inside diameter:

- 46.040 mm (1.8125 in.)

If the inside diameter is more than the maximum, replace the 1st gear with a new one.

| 11. INSPECT 1ST GEAR THRUST WASHER |

Using a micrometer, measure the thickness of the thrust washer.

- Standard thickness:

- 5.95 to 6.05 mm (0.235 to 0.238 in.)

- Minimum thickness:

- 5.95 mm (0.235 in.)

If the thickness is less than the minimum, replace the 1st gear thrust washer.

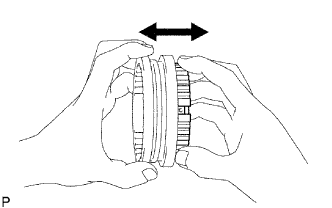

| 12. INSPECT NO. 1 SYNCHRONIZER RING SET (FOR 1ST GEAR) |

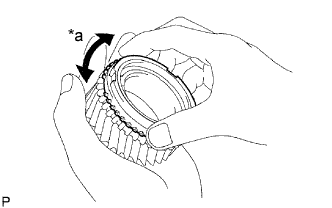

Apply gear oil to the cone of the 1st gear, and check that it does not turn in either direction while pushing the No. 1 synchronizer ring set.

Text in Illustration*a

| Locks

|

If it turns, replace the synchronizer ring.

Measure the clearance between the No. 1 synchronizer ring and 1st gear while pushing the No. 1 synchronizer ring against the cone of the 1st gear.

- Standard clearance:

- for TR Engine series:

- 0.75 to 1.65 mm (0.0296 to 0.0649 in.)

- for 1KD-FTV, 2KD-FTV:

- 0.65 to 1.75 mm (0.0256 to 0.0688 in.)

If the clearance is not as specified, replace the No. 1 synchronizer ring with a new one.

| 13. INSPECT NO. 1 SYNCHRONIZER RING SET (FOR 2ND GEAR) |

Apply gear oil to the cone of the 2nd gear, and check that it does not turn in both directions while pushing the No. 1 synchronizer ring set.

Text in Illustration*a

| Locks

|

If it can turn, replace the No. 1 synchronizer ring set.

Push the No. 1 synchronizer ring set against the cone of the 2nd gear. Measure the clearance between the No. 1 synchronizer ring set and 2nd gear.

- Standard clearance:

- 0.65 to 1.75 mm (0.0256 to 0.0688 in.)

If the clearance is not as specified, replace the No. 1 synchronizer ring with a new one.

| 14. INSPECT NO. 2 SYNCHRONIZER RING (FOR 3RD GEAR) |

Apply gear oil to the cone of the 3rd gear, and check that it does not turn in either direction while pushing the No. 2 synchronizer ring (for the 3rd gear).

Text in Illustration*a

| Locks

|

If it can turn, replace the No. 2 synchronizer ring.

Push the No. 2 synchronizer ring against the cone of the 3rd gear. Measure the clearance between the No. 2 synchronizer ring (for the 3rd gear) and 3rd gear.

- Standard clearance:

- 0.75 to 1.65 mm (0.0296 to 0.0649 in.)

If the clearance is not as specified, replace the No. 2 synchronizer ring with a new one.

Using a vernier caliper, measure the reverse gear groove and the thickness of the claw of the No. 1 shift fork to calculate the clearance.

- Standard clearance:

- 0.15 to 0.41 mm (0.00591 to 0.0161 in.)

If the clearance is not as specified, replace the reverse gear and No. 1 shift fork with new ones.

| 16. INSPECT NO. 1 TRANSMISSION CLUTCH HUB |

Check the sliding condition between the No. 1 clutch hub and the reverse gear.

Check the spline gear sleeve of the reverse gear for wear.

If there are any defects, replace the No. 1 clutch hub.

| 17. INSPECT NO. 2 TRANSMISSION HUB SLEEVE |

Using a vernier caliper, measure the No. 2 hub sleeve groove and the thickness of the claw of the No. 2 shift fork.

- Standard clearance:

- 0.15 to 0.35 mm (0.00591 to 0.0137 in.)

If the clearance is not as specified, replace the No. 2 hub sleeve and No. 2 shift fork with new ones.

| 18. INSPECT NO. 2 TRANSMISSION CLUTCH HUB |

Check the sliding condition between the No. 2 clutch hub and No. 2 hub sleeve.

Check the spline gear of the No. 2 hub sleeve for wear.