Ecd System -- System Description |

| ENGINE CONTROL SYSTEM |

| COMMON RAIL SYSTEM DESCRIPTION |

Common rail system:

The common rail system uses high-pressure fuel for improved fuel economy. This system also provides robust engine power, while suppressing engine vibration and noise.

This system stores fuel in the common rail, which has been pressurized and supplied by the supply pump. By storing fuel at high-pressure, the common rail system can provide fuel at stable fuel injection pressures, regardless of engine speed or engine load.

The ECM, using the EDU, provides an electric current to the piezo actuator in each injector to regulate the fuel injection timing and volume. The ECM also monitors the internal fuel pressure of the common rail using the fuel pressure sensor. The ECM causes the supply pump to supply the fuel necessary to obtain the target fuel pressure.

In addition, this system uses the 2-Way Valve (TWV) inside each injector to open and close the fuel passages. Therefore, both fuel injection time and fuel injection volume can be precisely regulated by the ECM.

The common rail system allows a two stage fuel injection process. In order to soften combustion shock, this system performs "pilot-injection" prior to the main fuel injection. This helps to reduce engine" vibration and noise.

Common rail system components:

Component Description Common rail Stores high-pressure fuel produced by supply pump Supply pump Operated by crankshaft

Supplies high-pressure fuel to common railInjector Injects fuel to combustion chamber based on signals from ECM Fuel pressure sensor Monitors internal fuel pressure of common rail and sends signals to ECM Pressure limiter Opens pressure limiter valve to reduce internal pressure in common rail when common rail pressure exceeds specified level Suction control valve Based on signals from ECM, adjusts fuel volume supplied to common rail and regulates internal fuel pressure Diagnostic trouble codes (DTCs) table for the common rail system

- УКАЗАНИЕ:

- This table indicates typical DTC combinations for each malfunction occurrence.

Trouble Area Malfunction DTC No. Injector Open or short in injector circuit P0200/97, P0088/78* Injector Stuck open P0088/78 Fuel pressure sensor Open or short in fuel pressure sensor circuit or pressure sensor output fixed P0087/49, P0190/49, P0192/49, P0193/49 Pressure limiter Stuck open P0093/78 Pressure limiter Stuck closed P0088/78* Suction control valve Open or short in suction control valve circuit P0627/78, P1229/78, P0088/78* Suction control valve Stuck open P1229/78, P0088/78* EDU Faulty EDU P0093/78*, P0200/97* Common rail system (Fuel system) Fuel leaks in high-pressure areas P0093/78 - УКАЗАНИЕ:

- *: There may be no DTC output depending on the condition of the malfunction.

| INJECTION CONTROL SYSTEM DESCRIPTION |

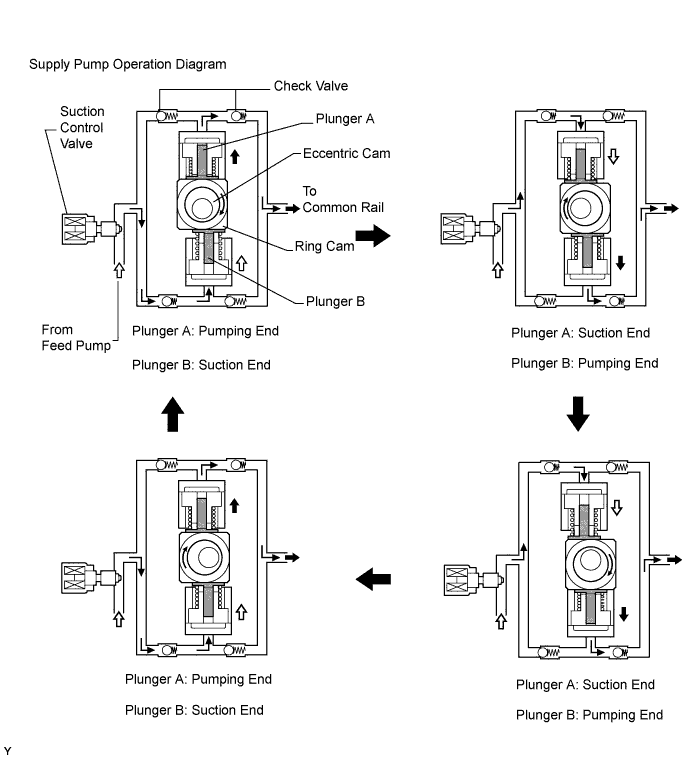

The feed pump is used to pump fuel from the fuel tank to the supply pump.

| SUPPLY PUMP OPERATION SYSTEM DESCRIPTION |

| SUCTION CONTROL VALVE OPERATION SYSTEM DESCRIPTION |

- УКАЗАНИЕ:

- The ECM controls the suction control valve operation to regulate the fuel volume that is produced by the supply pump for the common rail. This control is performed to regulate the internal fuel pressure of the common rail to the targeted injection pressure.

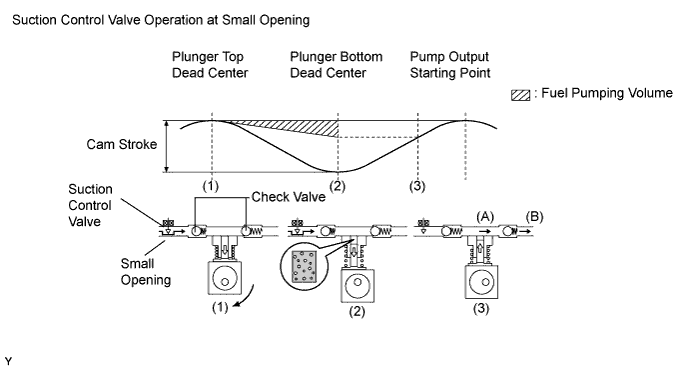

Small opening of the suction control valve:

(1) When the opening of the suction control valve is small, the volume of supplied fuel is small.

(2) The suction volume becomes small due to the narrow path despite the plunger stroke being full. The difference between the geometrical volume and suction volume creates a vacuum.

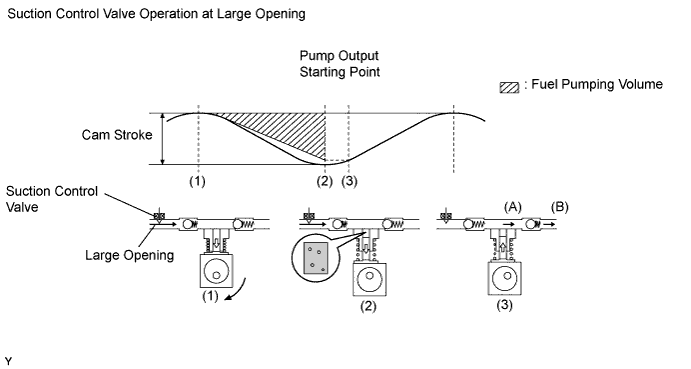

(3) Pump output will start when the fuel pressure at (A) becomes higher than the common rail pressure (B).Large opening of the suction control valve:

(1) When the opening of the suction control valve is large, the volume of supplied fuel is increased.

(2) If the plunger stroke is full, the suction volume becomes large because of the wide path.

(3) Pump output will start when the fuel pressure at (A) becomes higher than the common rail pressure (B).