Exhaust Pipe (W/ Dpf) -- Installation |

| 1. INSTALL CONVERTER PROTECTOR STAY |

Install the 2 No. 1 converter protector stays and 2 No. 2 converter protector stays to the front exhaust pipe.

| 2. INSTALL MONOLITHIC CONVERTER PROTECTOR |

Install the upper monolithic converter protector and lower monolithic converter protector with the 4 bolts and 4 nuts.

- Torque:

- 11 N*m{107 kgf*cm, 8 ft.*lbf}

| 3. INSTALL EXHAUST PIPE CLAMP SUB-ASSEMBLY |

Install the exhaust pipe clamp with the bolt, and a new nut.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

| 4. INSTALL NO. 3 EXHAUST GAS TEMPERATURE SENSOR |

- NOTICE:

- If the sensor is dropped, replace it with a new one.

Using a 14 mm union nut wrench, install the No. 3 exhaust gas temperature sensor.

- Torque:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

| 5. INSTALL WIRING HARNESS CLAMP BRACKET |

Install the wiring harness clamp bracket with the bolt.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 6. INSTALL NO. 2 EXHAUST GAS TEMPERATURE SENSOR |

- NOTICE:

- If the sensor is dropped, replace it with a new one.

Using a 14 mm union nut wrench, install the No. 2 exhaust gas temperature sensor.

- Torque:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

Attach the 5 clamps.

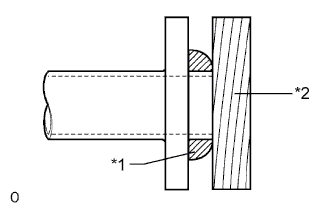

Text in Illustration *1 Wire Harness *2 Clamp - HINT:

- Make sure that the part of the wire harness is as shown in the illustration.

|

| 7. INSTALL EXHAUST GAS TEMPERATURE SENSOR |

- NOTICE:

- If the sensor is dropped, replace it with a new one.

Using a 14 mm union nut wrench, install the exhaust gas temperature sensor.

- Torque:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench (HILUX_TGN26 RM000004QR1006X.html).

- HINT:

- The sensor should be assembled within 20° of the prescribed position on either side.

Text in Illustration *a Top *b LH Side

| 8. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Using a vernier caliper, measure the free length of the compression spring.

- Minimum free length:

- 43 mm (1.69 in.)

- If the free length is less than the minimum, replace the compression spring.

|

Using a plastic-faced hammer and wooden block, tap on a new gasket until its surface is flush with the front exhaust pipe.

Text in Illustration *1 Gasket *2 Wooden Block - NOTICE:

- Be sure to install the gasket so that it faces the correct direction.

- Do not reuse the gasket.

- Do not damage the gasket.

- When connecting the exhaust pipe, do not push in the gasket with the exhaust pipe.

|

Install a new gasket and the front exhaust pipe to the No. 2 turbine outlet elbow with 3 new nuts.

- Torque:

- 54 N*m{554 kgf*cm, 40 ft.*lbf}

Connect the front exhaust pipe to the 2 exhaust pipe supports.

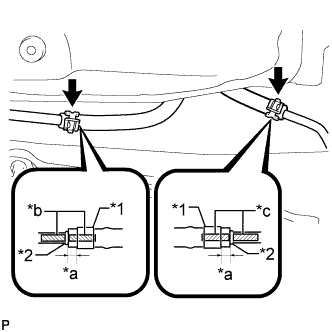

Connect the No. 6 exhaust pipe air hose and No. 7 exhaust pipe air hose to the front exhaust pipe with 2 new clips.

Text in Illustration *1 Clip *2 Stopper *a 4 to 10 mm (0.157 to 0.394 in.) *b Pink Paint *c Blue Paint

Paint Mark - NOTICE:

- Align the paint marks of the front exhaust pipe and exhaust pipe air hose and push on the exhaust pipe air hose until it contacts the stopper.

- Make sure the clip is 4 to 10 mm (0.157 to 0.394 in.) from the end of the exhaust pipe air hose when installing the clip.

- Make sure that there is no slack in the exhaust pipe air hose, and that it is not twisted or bent.

- Take care not to damage the inner or outer surface of the exhaust pipe air hose when installing it. If the exhaust pipe air hose is damaged, replace it with a new one.

|

Connect the No. 3 exhaust gas temperature sensor connector and attach the clamp.

Connect the No. 2 exhaust gas temperature sensor connector and attach the clamp.

Connect the exhaust gas temperature sensor connector and attach the clamp.

| 9. INSTALL AIR FUEL RATIO SENSOR |

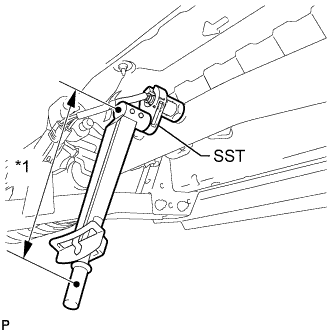

Using SST, install the air fuel ratio sensor to the front exhaust pipe.

- SST

- 09224-00010

- Torque:

- without SST:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

- with SST:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

Text in Illustration *1 Fulcrum Length - HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.8 in.). When using a torque wrench with a fulcrum length that is not 30 cm (11.8 in.), calculate the torque specification for the torque wrench and SST based on the "without SST" torque specification (HILUX_TGN26 RM000004QR1006X.html).

- Make sure SST and the wrench are connected in a straight line.

|

Connect the air fuel ratio sensor connector.

for 2WD:

Attach the clamp.

| 10. INSTALL NO. 2 EXHAUST PIPE SUPPORT BRACKET |

Install the No. 2 exhaust pipe support bracket with the 2 bolts.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

| 11. INSTALL NO. 3 FRAME CROSSMEMBER SUB-ASSEMBLY |

Install the No. 3 frame crossmember sub-assembly with the 4 bolts and 4 nuts.

- Torque:

- 50 N*m{510 kgf*cm, 37 ft.*lbf}

Connect the No. 3 frame crossmember sub-assembly to the No. 1 rear engine mounting insulator.

- Torque:

- 27 N*m{275 kgf*cm, 20 ft.*lbf}

| 12. INSTALL NO. 2 ENGINE UNDER COVER |

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 13. INSTALL CENTER EXHAUST PIPE ASSEMBLY |

Install the center exhaust pipe to the 3 exhaust pipe supports.

Install the center exhaust pipe and 2 compression springs with the 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

| 14. INSTALL TAILPIPE ASSEMBLY |

Install the tailpipe to the exhaust pipe support.

Install a new gasket and connect the tailpipe to the center exhaust pipe with the 2 bolts and 2 nuts. Alternately tighten the bolts in several passes.

- Torque:

- 48 N*m{489 kgf*cm, 35 ft.*lbf}

- NOTICE:

- Do not reuse the gasket.

| 15. INSPECT FOR EXHAUST GAS LEAK |

- If gas is leaking, tighten the areas necessary to stop the leak. Replace damaged parts as necessary.