Exhaust Manifold W/ Turbocharger (W/O Egr Cooler) -- Installation |

| 1. INSTALL EXHAUST MANIFOLD |

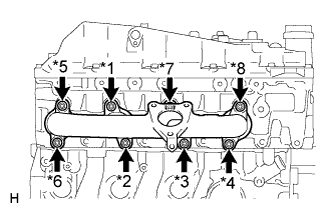

Install a new gasket, exhaust manifold and 8 plate washers to the cylinder head with 8 new nuts.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

- NOTICE:

- Tighten the nuts in the order shown in the illustration.

|

| 2. CLEAN TURBOCHARGER SUB-ASSEMBLY |

| 3. INSTALL TURBOCHARGER SUB-ASSEMBLY |

Temporarily install a new gasket and the turbocharger with 3 new nuts.

- HINT:

- When installing the turbo oil pipe, loosely install the 3 nuts so that the turbocharger and cylinder head can be aligned easily.

Temporarily install the turbo oil pipe and manifold stay.

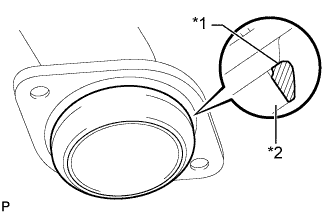

Text in Illustration *1 New Gasket *2 Claw *3 Narrow *4 Wide

Outside - - - HINT:

- Wash the oil pipe before installing it.

Temporarily install a new gasket and the turbo oil pipe with the 2 nuts, but only loosely install the nuts.

- NOTICE:

- The notch (wide part) of the gasket must face the engine.

Temporarily install a new gasket and the turbo oil pipe with the 2 bolts (labeled: A), but only loosely install the bolts.

- NOTICE:

- The claws of the gasket must face the turbo oil pipe.

Temporarily install a new gasket and the turbo oil pipe with the union bolt (labeled: B), but only loosely install the union bolt.

Temporarily install the manifold stay with the 2 bolts.

- HINT:

- The manifold stay's indented area must face the turbocharger.

Tighten the bolts and nuts.

Tighten the 3 nuts of the turbocharger.

- Torque:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

Tighten the 2 nuts of the turbo oil pipe.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Tighten the 2 bolts of the turbo oil pipe.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

Tighten the union bolt.

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

Tighten the 2 bolts of the manifold stay.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

| 4. INSTALL TURBINE OUTLET ELBOW |

Temporarily install a new gasket and the turbine outlet elbow (with turbocharger stay) to the turbocharger with the 4 new nuts.

Temporarily install the turbocharger stay with the 4 bolts.

Tighten the 4 nuts of the turbocharger.

- Torque:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

Tighten the 4 bolts of the turbocharger stay.

- Torque:

- 38 N*m{387 kgf*cm, 28 ft.*lbf}

| 5. INSTALL NO. 2 AIR CLEANER PIPE SUB-ASSEMBLY |

Connect the No. 2 air cleaner pipe with the 2 air hoses and install the bolt.

- Torque:

- 20 N*m{204 kgf*cm, 15 ft.*lbf}

Tighten the 2 clamps.

Connect the vacuum hose to the gas filter.

Connect the manifold absolute pressure sensor connector.

| 6. INSTALL VENTILATION HOSE HEAT INSULATOR |

Install the ventilation hose heat insulator with the 2 bolts.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

| 7. INSTALL AIR CLEANER ASSEMBLY |

Connect the No. 1 air cleaner hose.

Install the cleaner with the 2 bolts.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

Tighten the hose clamp.

w/ Mass Air Flow Meter:

Connect the connector to the mass air flow meter.

w/o Mass Air Flow Meter:

Attach the clamp and connect the intake air temperature sensor connector.

| 8. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY (w/ No. 1 Engine Cover) |

Attach the 4 claws to the pins of the cover bracket and install the No. 1 engine cover.

| 9. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Using a vernier caliper, measure the free length of the compression spring.

- Minimum length:

- 40 mm (1.57 in.)

|

Install the front exhaust pipe to the exhaust pipe support.

Install a new gasket to the turbine outlet elbow.

Text in Illustration *1 Gasket *2 Turbine Outlet Elbow - NOTICE:

- Be careful with the installation direction of the gasket.

- Do not reuse the gasket.

- To ensure a proper seal, do not use the front exhaust pipe to force the gasket onto the turbine outlet elbow.

- HINT:

- Using a plastic-faced hammer, uniformly strike the gasket so that the gasket and turbine outlet elbow are properly fit.

|

Install the front exhaust pipe and 2 compression springs with the 2 bolts. Alternately tighten the bolts in several passes.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

| 10. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (HILUX_TGN26 RM000004QR3008X.html).

| 11. INSPECT FOR OIL LEAK |

Start the engine. Make sure that there are no oil leaks from the areas that were worked on.

| 12. INSPECT FOR EXHAUST LEAK |

| 13. INSTALL FRONT FENDER APRON SEAL UPPER |

Install the front fender apron seal upper with the 5 clips.

| 14. INSTALL FRONT FENDER SEAL |

Install the front fender seal with the 5 clips.

| 15. INSTALL FRONT WHEEL RH |

| 16. INSTALL NO. 2 ENGINE UNDER COVER |

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 17. INSTALL NO. 1 ENGINE UNDER COVER |

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}