Camshaft -- Removal |

| 1. PRECAUTION |

- NOTICE:

- After turning the ignition switch off, waiting time may be required before disconnecting the cable from the battery terminal. Therefore, make sure to read the disconnecting the cable from the battery terminal notice before proceeding with work (HILUX_TGN26 RM000004QR1006X.html).

| 2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (HILUX_TGN26 RM000004QR300CX.html).

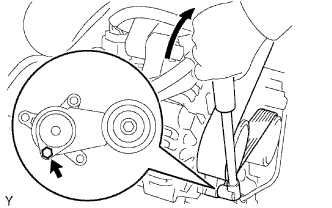

| 3. REMOVE FAN AND GENERATOR V BELT |

Use the hexagon-shaped part indicated by the arrow in the illustration to move the tensioner pulley downward and decrease the tension in the fan and generator V belt. Then remove the fan and generator V belt.

- NOTICE:

- When removing the fan and generator V belt, do not use the idle pulley's bolt.

- HINT:

- After removing the fan and generator V belt, move the tensioner upward as far as possible.

|

| 4. REMOVE INTAKE AIR CONNECTOR |

Disconnect the No. 2 ventilation hose.

Disconnect the vacuum hose.

Loosen the 2 hose clamps and remove the 2 bolts and disconnect the intake air connector.

| 5. REMOVE IGNITION COIL ASSEMBLY |

|

Disconnect the 4 ignition coil connectors.

Remove the 4 bolts and pull out the 4 ignition coils.

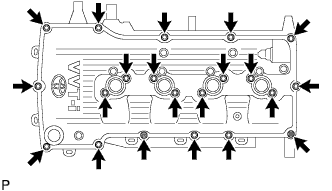

| 6. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY |

Remove the 19 bolts, 2 nuts, cylinder head cover and 2 gaskets.

|

| 7. REMOVE TIMING CHAIN GUIDE |

Remove the 2 bolts, chain guide and O-ring.

Text in Illustration *1 O-Ring

|

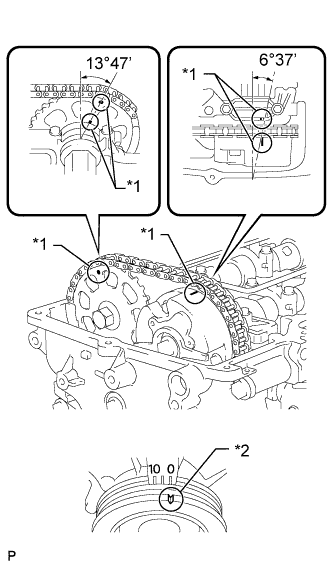

| 8. REMOVE CAMSHAFT TIMING SPROCKET |

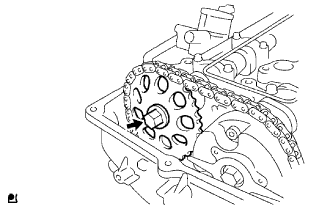

Turn the crankshaft pulley, and align its groove with the "0" timing mark of the timing chain cover.

|

Check that the timing marks of the camshaft timing gear and sprocket are aligned with the timing marks of the No. 1 bearing cap as shown in the illustration.

Text in Illustration *1 Timing Mark *2 Groove - HINT:

- If the timing marks do not align, rotate the crankshaft clockwise again and align the timing marks.

Place paint marks on the timing chain, camshaft timing gear and sprocket.

Text in Illustration *1 Paint Mark *2 Timing Mark

|

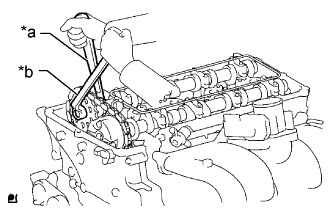

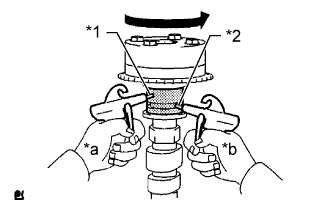

Hold the camshaft with a wrench and loosen the sprocket bolt.

Text in Illustration *a Hold *b Loosen - NOTICE:

- Be careful not to damage the oil delivery pipe.

|

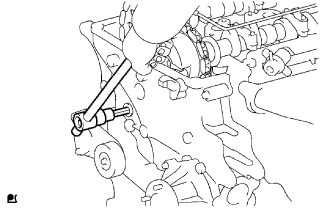

Using a 10 mm socket hexagon wrench, remove the timing chain cover plug.

|

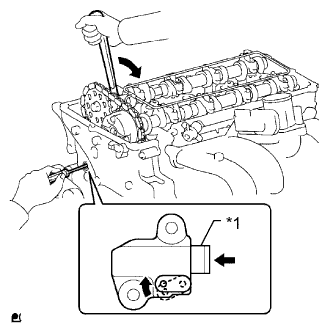

Using a screwdriver, access the tensioner stopper plate through the chain tensioner service hole. Move the stopper plate upward to release the lock. Then hold the plate in that position as shown in the illustration.

Text in Illustration *1 Stopper Plate - HINT:

- If the lock of the stopper plate is difficult to release, slightly rotate the hexagonal part of the camshaft to the left and right.

|

With the lock of the stopper plate released, slightly rotate the camshaft clockwise and keep it in that position.

Text in Illustration *1 Plunger - NOTICE:

- Be careful not to damage the oil delivery pipe.

- HINT:

- Rotating the camshaft clockwise will cause pressure to be applied to the tensioner plunger.

|

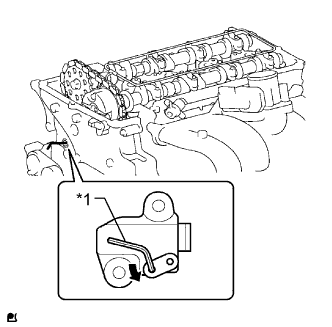

Remove the screwdriver from the chain tensioner service hole. Move the stopper plate to the position shown in the illustration. Then insert a hexagon wrench into the hole.

Text in Illustration *1 Hexagon Wrench - HINT:

- If the wrench cannot fit into the hole, slightly rotate the camshaft counterclockwise, and then clockwise. Then insert the wrench.

- To prevent the wrench from falling out, use tape to fix the wrench in place.

|

Remove the camshaft timing sprocket from the No. 2 camshaft.

|

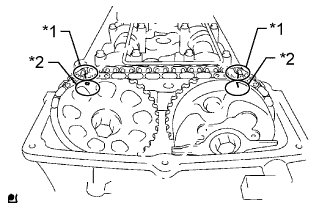

| 9. REMOVE CAMSHAFT |

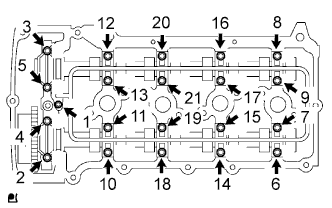

Uniformly loosen the 21 bearing cap bolts in several passes in the sequence shown in the illustration.

|

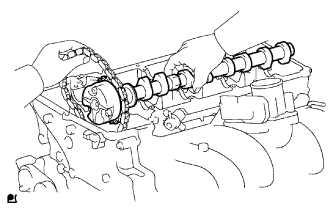

Remove the 9 bearing caps, oil delivery pipe, O-ring and No. 2 camshaft.

- NOTICE:

- Uniformly loosen the bolts while keeping the camshafts level.

- Do not pry the camshaft with a tool as an excessive amount of force may be applied to it.

Remove the No. 1 camshaft while holding the timing chain.

|

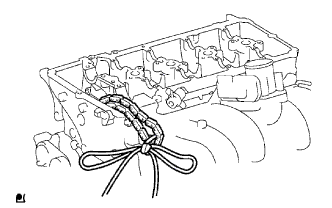

Secure the timing chain with a string as shown in the illustration.

- NOTICE:

- Be careful not to drop anything inside the timing chain cover.

|

| 10. REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

Remove the 16 valve rocker arms from the cylinder head.

- HINT:

- Arrange the removed parts in the correct order.

| 11. REMOVE VALVE LASH ADJUSTER ASSEMBLY |

Remove the 16 valve lash adjusters from the cylinder head.

- HINT:

- Arrange the removed parts in the correct order.

| 12. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY |

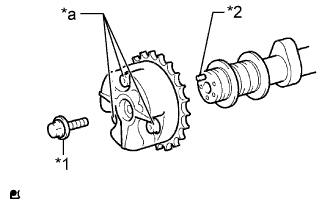

Remove the flange bolt of the camshaft timing gear.

Text in Illustration *1 Flange Bolt *2 Straight Pin *a Do Not Remove - NOTICE:

- Be sure not to remove the other 3 bolts.

|

| 13. INSPECT VALVE LASH ADJUSTER ASSEMBLY |

- NOTICE:

- Keep the lash adjuster free from dirt and foreign objects.

- Only use clean engine oil.

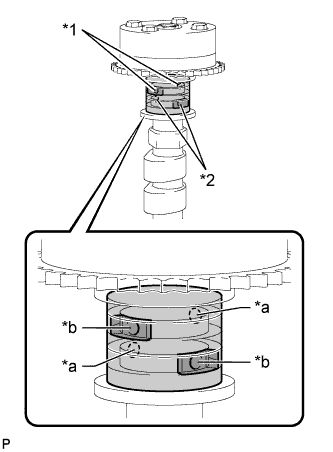

Place the lash adjuster into a container full of new engine oil.

Text in Illustration *1 Tapered Part *2 Plunger *3 Low Pressure Chamber *4 Check Ball *5 High Pressure Chamber *a CORRECT *b INCORRECT

|

Insert the tip of SST into the lash adjuster plunger and use the tip to press down on the check ball inside the plunger.

- SST

- 09276-75010

Squeeze SST and the lash adjuster together to move the plunger up and down 5 to 6 times.

Check the movement of the plunger and bleed air.

- OK:

- Plunger moves up and down.

- NOTICE:

- When bleeding high-pressure air from the compression chamber, make sure that the tip of SST is actually pressing the check ball as shown in the illustration. If the check ball is not pressed, air will not bleed.

After bleeding the air, remove SST. Then try to quickly and firmly press the plunger with your fingers.

- OK:

- Plunger can be pressed 3 times.

| 14. INSPECT CAMSHAFT TIMING GEAR ASSEMBLY |

Check the lock of the camshaft timing gear.

Mount the camshaft in a vise and confirm that the camshaft timing gear is locked.

Text in Illustration *1 Retard Side Path *2 Advance Side Path *a Open *b Close

Rubber Piece

Vinyl Tape - NOTICE:

- Do not damage the camshaft.

|

Release the lock pin.

Cover the 4 oil paths of the cam journal with vinyl tape as shown in the illustration.

- HINT:

- 2 advance side paths are provided in the groove of the camshaft. Plug one of the paths with a rubber piece.

Break through the tape over the advance side path, and then break through the tape over the retard side path on the opposite side from the hole over the advance side path as shown in the illustration.

Apply compressed air at approximately 200 kPa (2.0 kgf/cm2, 28 psi) to the two paths accessible through the holes in the tape.

Text in Illustration *1 Retard Side Path *2 Advance Side Path - CAUTION:

- Some oil splashing will occur. Cover the paths with a piece of cloth.

Check that the camshaft timing gear revolves in the advance direction when reducing the air pressure applied to the retard side path.

- OK:

- Gear rotates in the advance direction.

Text in Illustration *1 Retard Side Path *2 Advance Side Path *a Decompress *b Hold Pressure - HINT:

- This operation releases the lock pin which holds the timing gear in the most retarded position.

When the camshaft timing gear reaches the most advanced position, release the air pressure from the retard side path and advance side path in that order.

- NOTICE:

- Do not release the air pressure from the advance side path first. The gear may abruptly shift in the retard direction and break the lock pin.

Check for smooth rotation.

Rotate the camshaft timing gear within its movable range several times, but do not turn it to the most retarded position. Check that the gear rotates smoothly.

- CAUTION:

- Do not use air pressure to perform the smooth operation check.

Check the lock in the most retarded position.

Confirm that the camshaft timing gear becomes locked at the most retarded position.